Professional Documents

Culture Documents

COSH Training Manual

Uploaded by

Ading SamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

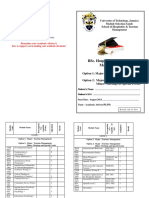

COSH Training Manual

Uploaded by

Ading SamCopyright:

Available Formats

Department of Labor and Employment

Occupational Safety and Health Center

Accredited Safety Training Organization

Accreditation No. 1030-101818-094

CONSTRUCTION

OCCUPATIONAL

SAFETY & HEALTH

(COSH)

TRAINING MANUAL

Name:

Company:

Dates:

Venue:

“The more you sweat in training, the less you bleed in battle”

Unit 14 & 15 Pilar Arcade Brgy. Panilao

Pilar, Bataan, Philippines

www.avietcs.com

Tel# 0995 980 2496 0921 929 0719

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

TABLE OF CONTENTS

Introduction: COSH Framework …………………..………………………………………...….. 3

Module 1: Importance of Safety and Health………………………………..……………….…. 6

Module 2: Unsafe act & Unsafe Condition (Basic causes of workplace

accidents)………………………………..………………………………………....10

Module 3: Construction Site/Premises ……………………………………………………..…...16

Module 4: Excavation Safety ………………………………………………………………….…35

Module 5: Tools and Equipment Safety ….………….....…………………………...……….…43

Module 6: Construction Machinery (Mobile Equipment)………………,,,,,,,,,,,,,,,…………....46

Module 7: Construction Machinery (Crane Safety)….……………------------.……………….. 54

Module 8: Fall Protection ……………………………………………………………………….. 59

Module 9: Temporary Structures (Scaffolding & Ladder/ Erection &

Dismantling)………..………………………………………..……………………..65

Module 10: Environmental Safety ……………………………………………………………….73

Module 11: CoViD-19 Prevention Measures …………...…………………….……………….101

Module 12: Occupational Health …………………………………………….…………….……112

Module 13: Personal Protective Equipment …………………………….……………………..129

Module 14: Demolition Safety …………………………………………………………………..138

Module 15: Routine Site Safety Inspection ..…….……………………………….……………142

Module 16: Job Hazard Analysis..…….………………………………………..…………….…147

Module 17: Accident Investigation & Reporting ..…….…………………….…………………152

Module 18: Role of Safety Officers ………………………….……………………….………...161

Module 19: Tool Box Meeting………………………………………………………………...…163

Module 20: Emergency Preparedness ………………………………………………….….….166

Module 21: Employees’ Compensation Program ………………………………………....….171

Module 22: OSH Legislations and Programming ……………...…………….…….…….……181

ANNEX A - Department Order No. 198-18 or The Implementing Rules and Regulations of

Republic Act No. 11058

ANNEX B - COVID-19 Prevention and Control in the Workplace

ANNEX C – Department Order Bo. 13-98 or The Guidelines Governing OSH in the

Construction Industry

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

2 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

INTRODUCTION: COSH Framework

COURSE DESCRIPTION:

The Construction Occupational Safety and Health (COSH) Training for Safety Officers is one

of the mandatory 40-hour training courses required for safety officers working in the

construction industry under Rule1030 of the Occupational Safety and Health Standards

(OSHS), Sections 14 and 16 of the DOLE Department Order No. 198 series 2008, and the

DOLE Department Order No. 13 series 1998: Guidelines Governing Safety and Health in the

Construction Industry.

• Course Overview, Requirements and Objectives

o To learn the basic principles of Occupational Safety and Health (OSH)

o To reinforce participants’ positive behavior towards Occupational Safety and Health

(OSH)

o To increase awareness of the participants on the implementation of Occupational

Safety and Health (OSH) program

o To familiarize with the Occupational Safety and Health Standards as promulgated by

the Department of Labor and Employment (DOLE)

o To know the requirements for the appointment of a Safety Officer and for OSHC-

DOLE accreditation as OSH Practitioner/Consultant

o Individually, the participants shall develop a safety and health action plan or program

designed to prevent accidents and occupational diseases in accordance with the

provisions of the Occupational Safety and Health Standards

(OSHS)

Introduction of Speakers and Participants

o Day 1

o Day 2

o Day 3

o Day 4

o Day 5

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

3 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• House rules - for Webinars

1. Every participant must join the webinar and check their internet connection 30minutes prior

to start of the webinar and must inform the ATCS technical team in advance

2. Only the enrolled participants shall be on the webinar platform

3. During breaks everyone is ask to stand up relax and stretch, have a snacks or coffee

4. Everyone will have the privilege of ask question during the webinar. He/she must send his

question via chat so that the flow of training will not be much affected

5. Quizzes, exams and practical Q@A must be dealt with outmost truthfulness/ cheating is not

advisable

6. Participants shall wear proper attire during the seminar

7. All videos of the participants must be working at all times

8. If there is an emergency or need to go out, the participants must inform the group by

chatting "going out for a moment or gofm" and it must not last 10mnts

9. Must use their true names in the zoom platform

10. Assignments/homework shall be done accordingly to avoid the delay of distribution of the

certificates

• House rules - for Classroom Type of Training

1. Be on time at the beginning of the day and every breaks.

2. Come prepared with workbook and completed homework if any

3. Be kind, polite, and courteous to others.

4. Be respectful to classmates, speakers, and property.

5. Engage with the discussion and group activities.

6. Obey Housekeeping Rules

7. If need to go for personal comfort – no need to ask permission.

8. Obey all House rules.

• Diagnostic Examination/Pre-Test

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

4 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Course Outline / Learning Road Map:

Nominal

Schedule Module No. Module Title

Duration (Hrs)

1 Importance of Safety and Health 1 Hr.

Unsafe act & Unsafe Condition (Basic causes

2 1.5 Hrs.

Day 1 of workplace accidents)

3 Construction Site/Premises 1.75 Hrs.

4 Excavation Safety 1 Hr.

5 Tools and Equipment Safety 1 Hr.

6 Construction Machinery (Mobile Equipment) 1.75 Hrs.

7 Construction Machinery (Crane Safety) 1.75 Hrs.

8 Fall Protection 1 Hr.

Day 2

9 Temporary Structures (Scaffolding & Ladder) 1.25 Hrs.

Temporary Structures (Erection &

2.50 Hrs

Dismantling))

10 Environmental Safety 1.75 Hrs.

11 CoViD-19 Prevention Measures 1.5 Hrs.

12 Occupational Health 1.75 Hrs.

Day 3 13 Personal Protective Equipment 1.75 Hrs.

14 Demolition Safety 1 Hr.

15 Routine Site Safety Inspection 1 Hr.

Construction Site Visit and Presentation of

4 Hrs,

Inspection Results

16 Job Hazard Analysis 1 Hr.

Day 4 17 Accident Investigation & Reporting 1 Hr.

18 Role of Safety Officers 1 Hr.

19 OSH Communication (Tool Box Meeting) 2 Hr.

20 Emergency Preparedness 1 Hr.

Day 5

21 Employees Compensation 1 Hr.

22 OSH Legislation and Programming 1.50 Hrs.

Re-entry Plan and Training Evaluation

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

5 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Module 1 – Importance of Safety and Health

• Module Objectives

Upon completion of the module, participants will be able to:

1. Explain the current Philippine OSH situation

2. Describe the OSH situation in their own workplaces

W hatat is Occupational Safety and Health (OSH)?

OSH also commonly referred to as health and safety, occupational health and safety (OHS),

occupational health, or occupational safety, is a multidisciplinary field concerned with the

safety, health, and welfare of people at work.

OSH is generally defined as the science of the anticipation, recognition, evaluation and

control of hazards arising in or from the workplace that could impair the health and well-

being of workers, taking into account the possible impact on the surrounding communities and

the general environment.

OSH Situationer (Global and Local)

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

6 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Latest data from the Philippine Statistical Authority’s survey (PSA) reveal that there has been

an increase on occupational injuries between the years 2003 to 2015 from 23,000

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

7 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

occupational injuries to an approximate of 51,000, and 55,000 occupational diseases to

around 128,000. However, there is a possibility of under-reporting of both occupational

injuries and diseases due to weakness in the notification system of workplace accidents and

data/report on workers’ exposure to hazard.

- Bureau of Labor and Employment Statistics 2003/2004, 2007/2008, 2009/2010, 2011 /2012 BLES

Integrated Survey, Philippine Statistics Authority, 2013/2014,2015/2016 Integrated Survey on Labor and

Employment

According to the Philippine Statistics Authority, the total cases of occupational diseases in

workplaces reached over 125,000 in 2015. Back pain is the most common type of occupational

disease, making up 32.8% of the reported cases. This is followed by essential hypertension

(11.5%) and neck and shoulder pain (11.4%).

Meanwhile, the most at risk industry for workers was found to be in administrative and support

service activities (34.3%) and manufacturing industry (31.1%), jointly comprising almost two

thirds of the total cases of occupational diseases in 2015.

- Faizza Tanggol | Communications Officer WHO Philippines | 23 August 2018 | The Occupational

Safety and Health Standards Act will protect the health of workers in the Philippines

The Philippine Government estimates that 2.2 million Filipino workers in medium and

large enterprises enjoy effective occupational safety and health (OSH) protection and

services. In other words, 17 of 18 persons in the nation’s workforce of 38.8 million do

not benefit from acceptable working conditions. Studies substantiate that OSH conditions

in micro-firms and the informal sector pose risks and hazards.

- Ma Lourdes Macapanpan | Programme Assistant in Employment Policy and Job Creation ILO

Country Office for the Philippines (CO-Manila) |

https://www.ilo.org/manila/areasofwork/safety-and-health-at-work/lang-- en/index.htm

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

8 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

COSTS OF ACCIDENTS AND ILLNESSES:

Human Costs

The effect of accident to a worker entails a lot of losses in terms of:

Ø Disability- (temporary or permanent) Pain and suffering

Ø Loss of income; loss of earning capacity

Ø Change in social life

Ø Death

Economic Costs

The economic cost of incidents and illnesses are far greater than most people realize

Direct Costs:

Ø Medical Costs

Ø Insurance premium

Ø Employee compensation

Ø Regulatory penalties

Indirect Costs:

Ø Investigation of the incident

Ø Cleaning up of incident site

Ø Disruption in production

Ø Repair/ replacement of damaged materials/ equipment

Ø Training of new/ replacement employees

Ø Poor employee morale leading to low production

Ø Environmental litigation

Ø Ecological remediation

Ø Marketing efforts to project image

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

9 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Summary Key Points:

• Every workplace has different hazards, risk, and level of exposures. Tailor fit your OSH

response.

• Safety officers play a key role in the overall management of programs in their

companies.

• Accidents and injuries result to losses of lives, limbs, time and property. Most

accidents at work could have been prevented. Immediate causes of accidents are

unsafe and unhealthy acts and conditions.

• Conduct workplace risk assessment through hazards identification, evaluation and

control.

Module 2 – Unsafe act & Unsafe Condition (Basic causes of workplace accidents)

• Module Objectives

Upon completion of the module, participants will be able to:

1. Identify the two immediate causes of accidents

2. Explain the differences between the following OSH Concepts:

a. Unsafe Act VS Unsafe Condition

b. Accident VS Incident

c. Hazard VS Risk

3. Relate some examples of unsafe acts and condition to the construction industry

4. Practice identifying unsafe acts and unsafe condition in the workplace

General Concepts on OSH

Accident Causation Theories

Accidents occur every day and, one way or another, will impact virtually everyone. For the

record, an accident is technically anything that happens by chance or misfortune. This

definition provides two important points. First, accidents are unavoidable as a whole; the

chance of one occurring will virtually always be present. Second, the chance of an accident

occurring is a variable that can be changed. While it is impossible to prevent all accidents, it

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

10 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

is possible to decrease their rate of occurrence. Understanding the cause of a phenomenon

such as this is key to decreasing its occurrences, as often knowing the cause is the only

way to formulate effective prevention strategies.

Heinrich’s Domino Theory

As one could easily guess from the commonly used name for Heinrich’s theory, Heinrich

(1936) explained accidents using an analogy to dominos falling over one another and

creating a chain of events. While this theory is not the most advanced or complex theory,

it is especially noteworthy as one of the first scientific theories used to explain accidents.

It is often still referenced today, seven decades later.

When dominos fall over, each tips the next enough to push it over and continue the

process until all the connected dominos have fallen. However, if just a single domino is

removed, the entire process ceases. Heinrich explains accident causation in the same

way:

As you can see from the figure, Heinrich identified five stages of accident causation. The first

stage, the social environment and ancestry, encompasses anything that may lead to

producing undesirable traits in people. More precisely,

this includes the nature and nurture aspects of

someone’s background. Genetics, poor

parenting/socializing, and an unhealthy subculture are all

examples of characteristics o f nature and nurture that

can negatively influence individuals and lead to the next

stage of accident causation. It is worth noting that

Heinrich’s inclusion of genetics and ancestry is very

much a product of the time it was written. A modernized

version of this theory would likely use the term “inherited

behavior,” similar to how alcoholism and temperaments can be inherited.

The second stage, faults of a person, refers to personal characteristics that are

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

11 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

conducive to accidents. For example, having a bad temper may lead to spontaneous

outbursts and disregard for safety. Similarly, general recklessness can also be one of the

manifestations o f poor character. Ignorance, such as not knowing safety regulations or

standard operating procedures, is also an example of this stage.

The third stage, an unsafe act or condition, is often the beginning of a specific incident.

Unlike the first two stages, which affect the probability of accidents occurring, this stage is

closer to the accident in terms of temporal proximity. This can include a specific act that is

unsafe, such as starting a machine without proper warning, or failing to perform appropriate

preventative actions, such as using guardrails or other safety measures. In essence, this

stage entails acts (or failures to act) that occasionally cause accidents.

The next stage, logically, is the accident itself. This, in and of itself, needs little explanation.

It is, simply, when something occurs that is undesirable and not intended. The final stage,

injury, is the unfortunate outcome of some accidents. Whether an injury occurs during

an accident is often a matter of chance and not always the outcome. This relationship

highlights the relationships between stages in terms of causality. An accident occurring

is not a sufficient cause for an injury, but it is a necessary one. Similarly, the undesirable

characteristics in stage two do not always occur in poor environments, but could not occur

without such environments.

Given this necessary causality, the most important policy implication is to remove one of the

dominos (though try for more than one just to be safe); produce a healthy subculture through

positive accident prevention training and seminars, attempt to weed out people with

undesirable characteristics (or otherwise address said traits), and, if all else fails, have a

procedure in place for dealing with accidents to minimize injury and loss.

This “Loss - Causation model ” which has been made by Mr. Frank E. Bird, Jr. of the

International Loss Control Institute (ILCI) i n the USA was based on an earlier model

developed by Heinrich. This model can be considered a "negative" model since the

outcome of failures in the various phases is loss. As such the model can be used to

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

12 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

understand the various causes leading to accidents and as a framework for

accident/incident investigation.

Definition of terms:

Safety – Freedom from accident. The control of hazards to attain an acceptable level of risk.

Incident- An event that may or may not result to loss.

Accident- Unplanned, undesired event, not necessarily injurious or damaging, that disrupts

the completion of an activity.

Hazard- Is any potential or existing condition in the workplace that, by itself or by interacting

with other variables, can result in death, injuries, property damage, and other losses.

Risk- Chance of physical or personal loss.

Another definition of accident is usually a result of contact of a body with a source of energy

above the threshold limit of the body or structure.

Causes of Accidents

➢ Unsafe acts. A violation of safe procedure

• act of omission

• act of commission

➢ Unsafe Conditions. Seen as a physical or chemical property in the material

Three Steps to Control Hazards and Accidents:

1. Identify- Involves knowledge and understanding of the several types of workplace

environmental stresses and the effect of these upon the health of the worker.

2. Evaluate- The decision- making process resulting in an opinion as to the degree of

health hazard that exists from chemical of physical agents from industrial exposure.

3. Correct- Engineering, Administrative Control and PPE.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

13 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Risk Assessment

“overall process of estimating the magnitude of risk and deciding whether or not the risk is

tolerable”

Tolerable Risk

“risk that has been reduced to a level that can be endured by the organization having regard to

its legal obligations and its own OH & S policy”

Residual Risk

Once we have done all we can to reduce the risk on a particular hazard, there will still be some

risk there (we can rarely get it down to no risk without eliminating the job all together). The

amount of risk that remains after we’ve put our controls in place is called the residual risk.

In simple terms, the risk from the hazard should be determined by estimating

Ø Severity of harm

Ø Likelihood of harm occurring

Risk can be classified as:

Low Risk – considered acceptable. No further actions are necessary as existing Health &

Safety arrangements is adequate

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

14 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Medium Risk – moderately acceptable level of risk. But risk reduction measures must be

developed and implemented

High Risk – unacceptable level of risk. Actions must be immediately implemented or the

risk mitigated or controlled

MANAGEMENT OF RISK

Based on the results of the risk assessment the organization must now decide if:

Ø No action required

Ø No additional controls required

Ø Efforts to be made to reduce the risks

Ø Work should not be started or continue until the risks have been reduced or urgent

action required

Summary Key Points:

• Safety Officers have the role of classifying their establishments through proper

identification of the different health hazards as part of the risk assessment process

• Unsafe c o n d i t i o n i s t h e d e v i a t i o n f r o m t h e s t a n d a r d physical /

chemical condition

• Unsafe act is the deviation from the standard practices

• Unsafe condition and acts are not only encountered in the construction industry but

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

15 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

also in everyday life

• Accident results to harm to a person while incident does not result to harm to a

person

• Hazard is anything the has the potential to cause harm, damage, health effect, or

environmental impact

• Risk is the chance or probability that a person will be harmed if exposed to a hazard

• Accidents are caused and accidents can be prevented

Module 3 – Construction Site/Premises

• Module Objectives

Upon completion of the module, participants will be able to:

1. Identify the things to consider in ensuring a safe and healthy construction site

premise

2. Relate some government regulations to the needed requirements in having a safe

and healthy construction site premise

3. Explain some OSH requirements in construction site premise

SEE ANNEX – Department Order No. 13 series 1998 or Guidelines

Governing Safety and Health in the Construction Industry

Coverage

• Good Housekeeping

• Safety Signage

• Fire Safety

• Means of Access and Egress

• Heavy Equipment

• Lifting Equipment

• Excavation

• Scaffolding

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

16 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Ladder

• Safety Inspection

HOUSEKEEPING

SIGNS OF POOR HOUSEKEEPING

1. cluttered and poorly arranged areas

2. untidy or dangerous storage of materials

3. presence of items no longer needed or in excess

4. dusty, dirty floors and work surfaces

5. tools and equipment left in work areas

6. no waste bins and containers

7. presence of spills and leaks

Disadvantages of Poor Housekeeping

• Low Morale

• Low Productivity

• Fire

Three Types of Hazards Resulting From Poor Housekeeping

1. Slip, trip, and fall hazards- One of the most common type of

hazards created by poor housekeeping are slip, trip, and fall hazards.

When objects, materials, tools, and equipment are not properly stored

workers are bound to trip over them. Slippery conditions are created

when water, moisture, oils, grease, etc. are left on the floor in work

areas. Fall hazards are created when employees have to stand on

make shift surfaces to reach items stored at higher levels. Falls also

occur when changes in elevation are not properly marked or

barricaded in work areas.

2. Strain and sprain hazards- Sprain and strain injuries can result from slip, trip, and fall

incidents. They also can occur when heavy items are not properly put away. When heavy or

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

17 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

awkward objects are placed on the floor and need to be picked up by a worker it creates a risk

for injury. Too often items have to be moved when there is poor housekeeping in a work area

just for the sake of getting them out of the way. Because of unnecessary lifting, sprains and

strains can occur.

3. Laceration hazards- Whether you are working in

a construction or a manufacturing setting, there are

plenty of sharp objects that can cut your hand or

body. When items are not properly stored this

creates a huge risk for laceration injuries. Sharp

tools, jagged metal, sharp edged material, etc. can

all easily cut through a glove or clothing and injure

a worker

WHAT IS GOOD HOUSEKEEPING?

Good housekeeping means there is a clean and orderly place for everything and

everything is in place.

The 5S of Good Housekeeping

Seri (Sort/eliminate)

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

18 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Seaton (Systematize/organize)

Seiko (Sweep/clean/polish)

Seekers (Sanitize/standardize)

Shinseki (Self-discipline/ training

Controls

• Clean work area

• Provide waste bins

• Keep floors, aisles and stairs free from obstructions

• Properly stack & store materials, tools and equipment

Rule 1060 - Premises of Establishment

1. Building premises shall have adequate fire, emergency or danger sign and safety

instructions of standard colors and sizes visible at all times

2. Other visible signs that may be needed to direct the driver of motorized vehicle

such as STOP, YIELD, and DO NOT ENTER, properly positioned within the

compound of the establishment shall be used to increase safety especially during the night

3. Handicapped employees should be restricted only to designated workplaces.

As far as practicable and feasible they should be provided with facilities for safe and

convenient movement in the establishment

4. Good housekeeping shall be maintained at all times through cleanliness of

building, yards, machines, equipment, regular waste disposal, and orderly

arrangement of processes, operations, storage and filing of materials

5. Personal Facilities: Adequate comfort rooms and lavatories separate for male and

female workers, adequate dressing rooms for female workers and locker rooms for male

workers shall be provided

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

19 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

SAFETY SIGNAGES

A Safety Sign provides information about health and safety at work by means of a

signboard, a safety color and a safety message to a specific object, activity or situation.

D.O. 13 Section 9

Construction Safety Signage

Construction Safety Signage must be provided to warn the workers and the public of

hazards existing in the workplace. Signage shall be posted in prominent positions at

strategic locations and, as far as practicable, be in the language understandable to most

of the workers employed.

Section 9.1 The signage should include but are not limited to:

a) Mandatory requirement on the usage of personal protective equipment prior to entry to the

project site.

b) Areas where there are potential risks of falling objects.

c) Areas where there are potential risks of falling.

d) Areas where explosives and flammable substances are used and stored.

e) Areas where there are tripping or slipping hazards.

f) Approaches to working areas where danger from toxic or irritant airborne

contaminants/substances may exist which should indicate the name of the contaminant/

substance involve and the type of respiratory equipment to be worn.

g) All places where contact with or proximity to electrical/ facility equipment can cause danger.

h) All places where workers may come into contact with dangerous moving parts of

machineries or equipment.

I) Location of fire alarms and firefighting equipment.

j) Instruction on the usage of specific construction equipment.

k) Periodic updating of man-hours lost.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

20 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Safety Bulletin Board

Mandatory provision of safety and warning signs are

reiterated not only for the protection of workers, but also

the public in general. Signs should conform with the

standard requirements of the OSHS.

Where Signage’s are needed . . .

• Usage of PPE

• Falling/falling objects

• Explosives and flammable substances

• Tripping and Slipping Hazards

• Toxic or irritant airborne contaminants/ substances

• Proximity to electrical facilities/equipment

• Moving parts of machines

• Location of Fire Fighting Equipment

• Instructional signs/Update of man-hours lost

PPE and Safety Scoreboard

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

21 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

FIRE PROTECTION

Fire is the result of the chemical combination of a combustible

material (fuel) with oxygen in the presence of enough heat. If any

one of the three is missing, a fire will not start. The relationship is

called fire triangle. It is important that every worker, not only

supervisor, knows the main causes of fire, how fire spreads, how

to fight fire, and how to prevent fire.

Basic Chemistry of Fire

Fuel. Or combustible materials. This includes many substances

such as natural gas (methane), plastics, wood, natural and artificial

fibers, paper, coal and other living matter. Inorganic substances are

also combustible, substances like hydrogen, ammonium nitrate

magnesium, phosphorus, sodium and sulfur.

Flashpoint - is the lowest temperature at which its vapors ignite if

given an ignition source. Examples of flashpoints:

Auto ignition temperature - is the temperature that causes spontaneous ignition

Oxygen. Fire normally draws its fire through the air, which is a mixture of 21 percent oxygen

and 78 percent nitrogen. 16% of oxygen is needed to sustain fire.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

22 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Heat. Sufficient heat to raise the temperature of the fuel surface to a point where chemical union

of the fuel and oxygen occurs. The temperature at which the substance gives off these vapors

or gases in sufficient quantity to be ignited is called the “flash point” of the substance.

Chemical Reaction. Vapors of gases, which are distilled during burning process of a material,

are carried into the flame

Three methods of Heat Transfer

➢ Conduction. Is the transfer of thermal energy between neighboring molecules in a

substance due to a temperature gradient. It takes place in solids, such as metals, timber,

concrete and glass. Some solids, such as metals, are better conductor of heat than woods, for

example.

➢ Convection. Is one of the major modes of heat transfer and mass transfer. It takes

place in fluids and gases cause by the convection currents.

➢ Radiation. Is electromagnetic radiation emitted from a material which is due to the heat

of the material, the characteristics of which depend on its temperature. It is the process of heat

transmission through air and gases. If you are sitting close to a bonfire, he will feel the heat of

the fire, even though the surrounding is cold, this is an example of heat radiation.

Sources of Ignition

➢ Electrical equipment. Hot surfaces produced by defective electrical equipment are a

common source of ignition.

➢ Spontaneous Ignition. If some liquids are heated or sprayed to a very hot surface, it

may ignite spontaneously without a present ignition source.

➢ Spontaneous Combustion. Is a type of combustion which occurs without an external

ignition source. Combustion begins if a sufficiently strong oxidizer, such as oxygen, is present.

➢ Smoking. In many workplaces, employees smoking, or other persons smoking in a

certain area, can be a source of fire.

➢ Friction. Sparks can be created by friction, for instance where the moving part of a

machine comes to contact with a fixed part, or two moving surfaces rub each other or slide

together during machine operation.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

23 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

➢ Engines, Vehicle Emissions and Hot Surfaces. In vehicle maintenance, and parking

areas, diesel-petrol engine, vehicle emissions and hot surfaces like exhaust systems can be a

source of ignition.

➢ Open Flame Sources. Open flame in the workplace such as boilers, furnaces, portable

heating appliances, etc. can be also a source of ignition.

➢ Lighting. In limited cases, lighting can be a source of ignition.

Products of Combustion

➢ Fire Gases. Are the vaporized products of combustion.

➢ Flame. Is the visible luminous body of a burning gas, which becomes hotter and less

luminous when it is mixed with increased amounts of oxygen.

➢ Heat. Is the process of energy transfer from one body or system due to thermal contact.

➢ Smoke. The Visible product of incomplete combustion.

Phases of Burning

➢ Incipient Phase or Beginning Phase

➢ Flame Producing or Free-Burning Phase

➢ Smoldering phase

INCIPIENT PHASE – or beginning of fire

• oxygen is plentiful

• Temp has not built to high peak

• Breathing not difficult

• Direct water application

• Ventilation: not a problem

• Little steam production

FREE BURNING PHASE – fire begins to deplete the room’s oxygen supply and temperature

greatly increased.

• Fire has involved more fuels

• Oxygen supply is being depleted

• Heat accumulates at ceiling

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

24 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• SCBA is a must

• Ventilation: not a definite need

• Good steam production

SMOLDERING PHASE – after oxygen content of the air falls below 15%, the fire enters a

smoldering phase where flame may cease but dense smoke and heat completely fill the room.

• Oxygen supply is below 15%

• Temp is very high

• Normal breathing not possible

• Backdraft hazard

• Fire extinguishment: indirect method

• Ventilation is a must

Fire Spread Control

Ø Starvation or Fuel Removal. There are three ways to achieve starvation:

• Take the fuel away from the fire

• Take the fire away from the fuel

• Reduce the quantity or bulk of the fuel.

Ø Smothering or oxygen removal. Smothering can be achieved by:

• Allowing the fire to consume the oxygen while preventing the inward flow

of more oxygen. Oxygen levels can be reduced below the minimum (16%)

percentage needed for combustion by purging and rendering the atmosphere

inert in closed containers or processing systems.

Ø Cooling or heat source control. The most common means of fire. Water is the

most effective and cheapest medium for fighting a fire.

Ø Inhibition. Breaking the chemical chain reaction.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

25 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Classifications of Fire and Extinguishing Methods

Ø Class A or combustible materials such as solid materials, wood,

cloth, paper, and natural fibers. Water is used in cooling to reduce the temperature of

the burning material below i t s i g n i t i o n temperature. It i s t h e m o s t e f f e c t i v e

way o f extinguishing the Class A fire.

Ø Class B fires involve Flammable liquids, greases and gases.

Foam, vaporizing liquids, carbon dioxide and dry powder can be used on Class B

fires. There may be some restrictions on the type of foam which can be used because

some foam breaks down on contact with alcohols.

Ø Class C fires involve energized electrical equipment. This class of fire can

be controlled by the use of non-conducting extinguishing agents. The safest procedure is to

always de-energize high voltage circuits and treat as Class A or Class B fire depending on the

fuel.

Ø Class D fires involve combustible metals such as magnesium,

titanium, zirconium, sodium and potassium. Water and other common extinguishing agents are

ineffective on this kind of fire because of its extremely high temperature. There is no agent

available that will effectively control fires in all combustible metals. Special extinguishing

agents are available for control of fire in each of the metals and are marked specifically for that

metal.

are

Ø Class K fire or kitchen fire. Fires that involve cooking oils or fats

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

26 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

designated “Class K” under the US system, and “Class F” under the European/Australasian

systems. Though such fires are technically a subclass of the flammable liquid/gas class, the

special characteristics of these types of fires are considered important enough to recognize

separately.

Fire Extinguishers - Is an active fire protection device used to extinguish or control

small fires, often in emergency situations. This is the first line of defense.

The Parts of the Fire Extinguisher

Proper Use of Fire Extinguisher

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

27 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

SAFETY IN LIFTING OPERATIONS

Material Handling

Material handling, whether done manually or with mechanical equipment, can be a major source

of occupational injuries. It was estimated that 25% of all occupational injuries are from manual

handling of materials.

Common manual handling injuries workers suffer from includes:

1. strains and sprains,

2. fractures and bruises.

3. Back Injuries

4. Nip points accidents

5. Etc.

On the other hand, Mechanical handling injuries suffers may include:

1. Crushing of hands or feet

2. Roll over by wheels

3. Pin down by equipment

4. Struck by

5. Etc.

These are caused primarily by unsafe practices such as improper lifting, carrying heavy loads,

incorrect gripping, failing to observe proper foot or hand clearances and not using or wearing

proper equipment and/ or personal protective equipment and clothing.

Another cause of materials handling accidents can be caused by poor job design. Ergonomics is

sometimes described as “fitting the job to the person, rather than the person to the job.” The

ergonomic approach therefore looks at manual handling as a whole, taking into account a range

of relevant factors including the nature of the task, the loads, the working environment and

individual capability.

Many manual handling injuries are cumulative rather than being truly attributable to any single

handling incident.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

28 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Pictures of Equipment and Use

Basic Handling Principles

➢ Needless handling costs but cannot add value to the product

➢ Manual handling must be eliminated whenever possible and

mechanical means should be employed

➢ Handling should be correlated with operations, inspections, storage

and other handling that comes All handling systems should be integrated

➢ Handling equipment should be replaced wherever greater efficiency

can be so obtained.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

29 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

CLASSIFICATION OF MATERIALS

According to

1. PHYSICAL CHARACTERISTICS:

a) SOLIDS

• Bulk – crated large machineries and parts, crated materials, caustic blocks, soap blocks,

etc.

• Powder – flours, phosphates, sugar, cement.

• Granules & Gravel size – copra meal pellets, silicates.

• Odd size – copra.

b) LIQUIDS

• Light – solvents, oils, fuels.

• Viscous – molasses, asphalt, heavy oil, paints.

• Pastes – detergent paste, adhesives.

c) GASES

According to HAZARDOUS CHARACTERISTICS:

d) Flammables – easily set on fire & likely to burn rapidly.

e) Explosives

f) Toxic – poisonous.

g) Corrosive

h) Emits Hazardous Fumes or Gases

i) Fragile

MATERIALS HANDLING – is the preparation, placing, and positioning of materials to facilitate

their movement or storage.

• There is now substantial international acceptance of both the scale of the manual

handling problem and methods of prevention.

• Modern medical and scientific knowledge stresses the importance of an ergonomic

approach in removing or reducing the risk of manual handling injury.

• ERGONOMICS – is sometimes described as “fitting the job to the person, rather than

the person to the job”.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

30 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

The ergonomic approach therefore looks at manual handling as a whole, taking into account a

range of relevant factors including the nature of risk, the load, the working environment and

individual capability.

Many manual handling injuries are cumulative rather than being truly attributable to any single

handling incident. The result can be physical impairment or even permanent disability.

MATERIALS HANDLING (Categories)

◼ LIFTING

Distance is particularly important where lifting is an integral part of the job.

◼ TRANSPORTING

Considerable thought should be given to the planning and routing of traffic.

◼ STORING

Depends on cost and type of materials and free flow of materials

TYPES OF MATERIALS HANDLING

◼ MANUAL

• Individual Capacity

• 25 kg…female

• 50 kg…male

• Accessories

• 2 wheeled hand trucks

• 4 wheeled hand trucks

• Crowbars

• Shovel

◼ MECHANICAL

• Powered Hand Truck

• Crane

• Hoist

• Forklift

• Boom Truck

• Heavy - Duty Truck

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

31 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Tractors

• Railroad Cars

• Conveyors

• Pipelines

• Pallets

• Carton Clamps

• Wire Ropes

• Lifting Bars

SAFE OPERATING PRACTICES

1) Can the job be engineered to possibly eliminate manual handling?

2) Can the material be conveyed or moved mechanically?

3) In what way do the materials being handled cause injury?

4) Can employees be given handling aids to make their job easier and safer?

5) Will protective clothing or equipment, help prevent injuries?

MATERIALS HANDLING PROBLEMS

Common injuries are strains, sprains, fractures & bruises. These are primarily caused by unsafe

practices:

• improper lifting,

• carrying too heavy load,

• incorrect gripping,

• failing to observe proper foot or hand clearance, and

• failing to use or wear proper equipment &/or personal protective equipment & clothing.

Property damage & serious injury/fatality caused by mechanical equipment!

Hazards in Crane Operations

• Structural failure

• Overloading

• Instability

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

32 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Falling or slipping load

• Electrical Hazards

Safety Precautions in Crane Operation

• Do not carry or use crane beyond the rated load

• Never move load over people.

• Never allow personnel to ride on a load.

• Center the crane over the load before starting to hoist.

• Lift, move & lower loads smoothly.

• Do not leave suspended load unattended.

• Keep hook block more than 2m above the floor when not in use.

• Use tagline to stabilize and control loads.

• Respond to signals from designated signalman only.

• Maintain safe distance from electrical transmission lines.

Rigging

is the process where a load is prepared for lifting using a lifting machine. The main part of this

process is the tying up of the load with sling and/or other connecting devices so that the load

could be hooked onto a crane.

Sling Inspection

• Broken Wires

• Abrasion

• Crushed Strands

• Corrosion

• Kinks

Safety Inspection

is a systematic way of identifying potential workplace hazards before they cause a health and

safety problem?

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

33 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Purposes of Safety Inspection

• Eliminate Hazards

• Assess Effectiveness of OSH Program

• Display Visible Management Commitment to Safety

• Establish Accountability

• Identify Training Needs

• Fulfill Legal Obligations

Types of Inspection

• Continuous Inspection

a process conducted as part of their job responsibilities in noting and correcting potential

danger

• Periodic/Interval Inspection

a systematic process with specific intervals and widely regarded as “real” safety and health

inspection

• Intermittent/Emergency Inspection

an unscheduled inspection may be

After Inspection

• Writing of inspection report

• Correction of hazards

• Monitoring and evaluation

Corrective Actions

• Immediately correct everything possible.

• Report at once conditions beyond one’s authority and suggest solutions.

• Take intermediate action as needed.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

34 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Summary Key Points:

• Although work processes are high risk, but a construction site can be managed to

maintain a safe and healthy work environment

• Layout plan, perimeter fences, and security personnel are vital to keep the people

safe and to keep the property secured

• Welfare facilities are needed to promote the health and well-being of workers

• A good traffic management plan prevents accidents of people and the public near

any construction activities

• Good housekeeping eliminates accident and fire hazards

• Proper segregation of wastes in construction is needed to comply with RA 9003

• Emergency exits and portable fire extinguishers in a construction should comply with

OSH Standards Rule 1940

• Construction Safety signage in a construction should comply with DOLE DO 13

Section 9

• Electrical hazards should be identified and controlled in the construction site

Module 4 – Excavation Safety

• Module Objectives

Upon completion of the module, participants will be able to:

1. Highlight the hazards of working in an excavation

2. Explain how to protect employees from cave-ins / soil collapse

3. Identify the factors that pose a hazard to the employees working in excavations

4. State the role of a competent person at an excavation site

Excavation

• Is any man-made cut, cavity or

depression in an earth surface that is

formed by earth removal

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

35 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Trench

• is a narrow excavation where the depth is greater than its width, and the width

measured at the bottom is not greater than 15 ft.

Hazards of Excavation Works

• Soil Collapse

• Falls

• Vehicular Traffic

• Underground Utilities

• Working Surface

• Confined Space Conditions

Principal Causes of Soil Collapse

• Steep cutting angle

• Super imposed load

• Shock & Vibration

• Water Pressure

• Drying

Prevention of Soil Collapse

Type A – Most stable: clay

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

36 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Type B – Medium stability: silt and unstable rock (disturbed soil as type B)

Type C – Least stable: gravel, loamy sand, submerged soil, soil from which water is

freely seeping.

Prevention of Soil Collapse

§ Cut the slope at a safe angle (H:V)

• Type A - 3/4:1 or 53°

• Type B - 1:1 or 45°

• Type C - 1½ :1 or 34°

Prevention of Soil Collapse…

• Provision of shoring and timbering

•

Sheet Piles

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

37 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Plate Lining System Box Type

Shielding

Per Rule 1413 of the Occupational Safety and Health

Standards (OSHS):

The walls of every excavation over 1-meter-deep shall be

supported by adequate shoring…

Falls

• Minimum Berm

- not less than one third of the depth of the excavation

- may be reduced to not less than 1 meter provided that

materials are stable, shoring and barriers are present

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

38 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

(Per Rule 1413 of the OSHS)

• Barricades of at least 1-meter high should be provided.

• Signs should be posted to prevent the public from going

near the excavation.

Surface Crossing of Trenches

• Walkways or bridges must be provided

• Minimum clear width of 20 in.

• With standard rails

• Extended a minimum of 24 in. past the surface edge

Vehicular Traffic

• Provide workers with warning vests or other suitable

garments marked with reflectorized materials

• Designate a trained flag person along with signs and barricades

when necessary

• Use horn or give signals to ensure safety.

Underground Utilities

• Determine location of underground facilities and take necessary steps to prevent damage to

these facilities.

• In an open excavation, support, protect or remove underground

installation.

Working Surface

• Excavation shall be kept free of water at all times

• And in muddy area, workers should be

provided with boots to reduce the hazard of slipping.

Confined Space Conditions

Hazardous Atmosphere:

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

39 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Oxygen, O2: < 19.5% or > 23.5%

• Flammable gas concentration > 10% of Lower Flammability Limit (LFL)

• Hazardous toxic chemicals

Excavation in confined space

• Check the condition of the atmosphere before entry

• Do not work alone in a confined space

• Provide lifeline

• Provide ventilation or blower before entering

• Provide emergency rescue equipment such as breathing apparatus, safety harness and line

and basket stretcher

Working in Excavation

• Prior to opening

• Check excavation permit

• Identify all underground installations

• Remove trees, boulders, stumps, other surface encumbrances and hazards before

starting excavation

• During operations

• Wear appropriate PPE

• Give special attention to side slopes that are adversely affected by weather,

moisture content or vibration

• Safe working distance between workers

• Maintain guardrails, fences, or other barricades and warning lights

• During break time, workmen should never stand or take rest on high banks of soft

material

• Do not leave tools, materials, or debris in walkways, ramps, or near the edge of

excavations

• Do not use guardrails as resting place

Inspection

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

40 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Daily before start of each shift

• After heavy rain

• When fissures, tension cracks, undercutting, water seepage, bulging at the bottom

or other conditions occur

• When there is any indication of change or movement in adjacent structures or

spoil pile

Rule 1413 of the OSHS states that excavation shall be inspected at least once

everyday.

Additional Reference for Confined Space

An enclosed or partially enclosed space that:

• Is not designed or intended for human occupancy except for the purpose of

performing work

• Has restricted means of access and egress

• May become hazardous to any person entering to it

• Even if a space is not fully enclosed it can still be classified as confined.

- An open ditch / trench / excavation can be classified as a confined space.

• A space doesn’t even have to be small to be considered confined.

- e.g. cold storage, ships hold, etc.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

41 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

Hazards of Confined Space

Summary Key Points:

- An excavation may not be safe to enter without a proper support structure being

provided.

- Types of Excavation Works include open excavation, pit excavation, and trench

- Excavation works are high risk because excavation failures like a soil collapse

occur quickly, limiting the ability of workers to escape

- There are safety and health risks in excavation works that need to be controlled

- The causes of soil collapse are steep cutting angle, super-imposed load, shock and

vibration, water accumulation, drying, and lack of regular monitoring and inspection

- There are several methods to protect and excavation and prevent soil collapse

- The type of soil should be considered in choosing the appropriate excavation

protection

- Minimum Berm for excavated material is 1/3 of the depth of the excavation

- Tools, materials, and machineries should be kept at a safe distance away from the

edge of the excavation

- Excavation more than 2 m deep shall be barricaded to a height of 1 m

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

42 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

- Water increases the possibility of a cave in.

- Excavation should be considered as a confined space.

Module 5 – Tools and Equipment Safety

• Module Objectives

Upon completion of the module, participants will be able to:

1. Know what is a heavy equipment

2. Learn the legal basis of heavy equipment safety

3. Identify the hazards related to heavy equipment operations and the persons at risk

4. Identify some of the blind spots of heavy equipment

5. Explain the responsibilities of workers on foot and heavy equipment operators

Introduction:

• The Supervisor is primarily responsible for ensuring the safe use of tools.

• The use of hand and portable power tools must be accompanied with proper

orientation.

• The use of right tools for the job eliminates potential hazards thus ensuring quality

of work.

Hand tool accidents from:

• Human carelessness

• Not knowing the right tool for the job

• Ignorance of safety precautions

• Failure to maintain/keep the tools properly

• Not instructed for the correct usage

Basic tool check

• Are the tools right for the job?

• Are the tools in safe working condition?

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

43 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Are the tools being used properly?

• Are the tools kept in a safe place?

HAND TOOLS SAFETY TIPS

• Keep tools clean

• Check tools for good working condition ü Use the right size and type for the job

• Carry tools in tool box, bag or belt

• Do not use excessive force on the tool

• Wear appropriate PPE

MAIN TYPES OF PORTABLE POWER TOOLS

• Electric

• Pneumatic

• Cartridge/powder actuated

• Gasoline

• Hydraulic

INJURIES CAUSED BY:

• Electric shock

• Particles in the eyes

• Fires

• Falls

• Explosions

• Falling tools

Wheel Breaking

• choose, right wheel for the task.

• don’t bend or stress wheel.

• ensure disc is compatible with grinder.

• ensure disc is correctly fitted.

• wear correct PPE for the task

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

44 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

PNEUMATIC TOOLS DANGER

• Leaving airline where it may cause tripping hazard of be damaged by traffic

• Leaving tool with air supply switched on

• Disconnecting the hose from the tool using it to clean machine or clothing.

• Squeezing the trigger before reaching the work

CARTRIDGE TOOLS

• Used for fastening fixtures and materials to metal, pre-cast, pre-stressed concrete,

masonry, block, brick, stone and wood surfaces

DANGERS

• Free shots

• Ricochet

• Atmosphere causing explosion

• Projectiles fired through the work

SAFETY TIPS

• Do not use if your hands are wet or if standing on

wet surfaces

• Make sure that you know how to use the tool properly

• If tools are misused, it can result in injury or spoiled work

COMMON ERGONOMIC INJURIES

• Bursitis ¡ Osteo-arthritis

• Carpal Tunnel Syndrome ¡ Tendonitis

• Cellulitis ¡ Tenosynovitis

• Epicondylitis ¡ Tension Neck/Shoulder

• Ganglion ¡ Trigger finger

INJURIES CAUSED BY…

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

45 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Repeated overtime use of vibrating tool/equipment.

• Tools/tasks which require twisting hand or joint movement.

• Applying force in an awkward position.

• Applying excessive pressure on parts of the hands, back, wrists or joints.

• Working with the arms over-stretched or overhead.

• Working with a bent back

•

• REMINDER!

The injury/disease caused by poorly designed or unsuitable tools

and work stations often develop slowly over a period of months or

years.

However, a worker will usually have some signs and symptoms for a

long period of time indicating that something is wrong.

THE USE OF PERSONAL PROTECTIVE EQUIPMENT

Because power tools often come into close contact with the body, wearing the appropriate

personal protective equipment is necessary to prevent personal injury.

Summary Key Points:

• Hand Tools are non-powered and operated by bare hands

• Portable Power Tools are operated through additional power source

• Types of Power Tools are Electric, Powered Abrasive Wheel Tool, Pneumatic, Hydraulic,

Liquid Fuel

Module 6 – Construction Machinery (Mobile Equipment)

• Module Objectives

Upon completion of the module, participants will be able to:

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

46 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

1. Learn the types of heavy equipment

2. Identify the hazards related to its operations

3. Know the factors that cause accidents

4. Learn the basic safety based from OSH Standards and DO 13

Introduction

• Many types of mobile construction heavy equipment are being used in a construction

site doing a wide variety of work. Most of these machines operate within close proximity

to persons on foot. With this, many people are exposed to hazards associated with this

equipment.

• In short, you have a congested construction site with personnel on foot, and mobile

machines working in the same area at the same time!

TOTAL EQUIPMENT SAFETY MANAGEMENT

1. Management Commitment

• Restrict entry onto site of non-essential personnel.

• Establish Controlled Entry Points to site.

• Coordinate Operations of Various Trades Working in the Same Areas.

• Provide Fundamental Site Rules and Training to all Persons at Risk.

• Adequate Lay-Down Areas Established.

2. Employee Involvement

• All must receive basic orientation.

• Attend operator’s Tool Box Meetings

• Must learn, follow, and obey established Safety rules.

• Realize that they must see, and be seen.

DO 13 Sec. 12

Safety & Health Information

12.6 Specialized instruction and training should be given to:

a. drivers/operators of lifting appliances, transport, earth- moving and materials-handling equipment

and machinery or any equipment of specialized or dangerous nature.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

47 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

b. Workers as signalers

3. Pre-Construction Job Hazard Analysis

• Identify Potential Known Hazards.

• Job Conditions: Haul Roads, Access Points.

• Lay down/Storage Areas.

4. HAZARD PREVENTION and CONTROLS

• Perimeter Fencing, Enclosures, signs.

• Spotters provided for in-the-blind, backing machines and/or equipment.

• Be Alert; Stay Clear; Hear Warnings.

• Temporary Barricades around Hazards.

5. Equipment maintenance

• Duly certified mechanics and operators shall conduct daily routine inspection

• Inspect before operation

• Check instrumentation

• Check safety devices; horns, lights

• Warm up and make trial run

• Keep machine clean

• Be aware of abnormalities

SAFE OPERATION GUIDELINES

1. AUTHORIZED OPERATOR

• Qualified with license

• Well trained

• Good physical condition

EQUIPMENT OPERATOR RESPONSIBILITIES

• Keep control of the Machine at all Times.

• Take Machine “Out of Service”, if it is unsafe to operate.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

48 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Familiarity with the operating characteristics of your machine.

• Be On the Look-Out for Other Trades Working in the Same Area.

• Frequently check for the Location of other Machines. Keep Lights and Backup Alarm

in Operating Condition.

• Allow NO ONE to Ride Outside the Cab for Any Reason!

• Always inform Appropriate Personnel of any Abnormal Conditions, Defects, or

Changes made in Machine and/or Job Procedure or Conditions.

• Report Unsafe Workers to Supervisor.

• Talk Safety with Those Who Work with You. Maintain “Constant Awareness”.

• Do Not Attempt Repairs or Maintenance that You Do Not Understand.

• Always Check the Mirror on the Blind Side, making Sure of Your Clearance.

(Backing on the Blind Side should be Avoided if at all Possible).

• Learn and Follow Safe Work Practices!

2. Personal Protection

3. Physical Condition

4. SAFETY RULES

• Check job site condition

• Soil condition

• Working near utilities

5. SALIENT POINTS

• HE Operators be tested and certified

• All Heavy Equipment tested and certified

6. Alertness

The Most Dangerous Movement is Backing!

• Know where your Blind Spots are.

• Look for people walking around you.

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

49 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• STOP! When Signaled; When waived at violently; Or if you are in doubt….

• Maintain a safe operating speed.

7. Avoiding Distraction

• Small Machines have small blind spots, where large machines have large blind spots,

both can cause serious injury or death!

• The taller and wider the machine, the bigger the blind spot area.

8. Appropriate Use

• Specific equipment operation

• Equipment capacity

• Equipment capability

• Equipment restriction

CONCERNED PERSONNEL

• Equipment Operator

• Workers on foot

• Spotters

• Management people and supervisors

• Other construction site personnel

HAZARDS PRESENT IN CONSTRUCTION HEAVY EQUIPMENT OPERATION

• Moving parts of the equipment

• Uneven terrain

• Energized electrical lines

• Fall

• Dust

• Overloaded equipment

• Noise

All rights reserved 2020 property of ATCS duplication in any form without written approval is strictly prohibited

50 | | P a g e Email Address jarosalve@gmail.com / www.avietcs.com / avie.avietcs.com

AVIE TRAINING AND CONSULTANCY SERVICES

Stall No 15. Panilao Arcade Pilar Bataan Philippines – 0995 980 2496 / 240 47 27

• Vibration

• Unsecured loads

• Improvised attachments

• Blind spot.

BLIND SPOTS – DUMP TRUCK

• Small heavy mobile equipment has small blind spots and heavy mobile equipment

have large blind spots, both can cause serious injury or death

• The taller and wider the machine, the bigger the blind spot area

• Operators, spotters and workers on foot need to be aware where the blind spots

are. Located

RESPONSIBILITIES OF WORKERS ON FOOT

• Wearing of high visibility vests (or equivalent) and other appropriate PPE’s.

• Keep a safe distance from heavy equipment

• Know the equipment’s blind spots. Never assume that the equipment operator sees

you

• Never ride on the steps or drawbars of any equipment.

• Watch out for swinging parts.

SPOTTER RESPONSIBILITIES

• Wearing of high visibility vests and other appropriate PPE’s.