Professional Documents

Culture Documents

BMFP Aep MSB CN 0041 Rev 1

Uploaded by

Dinidu PriyankaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BMFP Aep MSB CN 0041 Rev 1

Uploaded by

Dinidu PriyankaraCopyright:

Available Formats

Page No: Page 1 of 18 Material Submittal for Coating

Date & Revision: 09 March 2022, Rev. 1 Scheme of Slip Critical Bolted BMFP-AEP-MSB-CN- 004

Splice Connection Areas of

Prepared By: Access Engineering PLC Steel Structure

ACCESS ENGINEERING PLC

DESIGN AND CONSTRUCTION OF A

FLYOVER CONNECTING BALADAKSHA

MAWATHA AND CHITTAMPALAM A

GARDINER MAWATHA OVER RAILWAY

TRACK AND BEIRA LAKE IN SLAVE ISLAND

MATERIAL SUBMITTAL FOR COATING

SCHEME OF SLIP CRITICAL BOLTED

SPLICE CONNECTION AREA OF STEEL

STRUCTURE

CONTRACT PACKAGE NO. RDA/MFAP/GOSL/SI/FO/02

EMPLOYER:

ROAD DEVELOPMENT

AUTHORITY MINISTRY OF

HIGHWAYS

Version History

Revision Date Status Changes Overview

0 01/10/2021 Issued for approval Initial Issue

1 26/02/2022 Issued for approval Complete coating scheme

Classification: Restricted

1. DESCRIPTION

This document is intended to provide complete coating scheme for all faying surfaces, splice plates, fill

plates and bolts. Scheme will be complete in two stages one is in workshop and the second one is after the

installation. BMFP-AEP-MSB-CN-004-Rev 0 has been submitted for the workshop painting work in above

mentioned areas. In this revision further coating is described and relevant product data sheets also attached

for more technical details of the products.

2. GENERICS OF PROPOSED SYSTEM

Workshop coating

Two-component, moisture-curing zinc (ethyl) silicate primer (Certificate for ASTM A-490 class 'B' for slip

coefficient)

After installation coatings

Two component Zinc Phosphate Epoxy Coating followed by two component high build Aliphatic Acrylic

Polyurethane finish compliance with ISO 12944-C5-2018

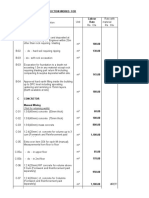

3. SYSTEM SPECIFICATION DETAILS

COATINGS AT FAYING SURFACES FOR SLIP CRITICAL CONNECTIONS

In addition to the coatings mentioned in the below table, stripe coating shall be applied in nut and bolts and

slip critical areas before application of each main layer.

At Workshop After Installation

Component Paint Coating Paint Minimum Coating

thickness(microns) thickness(microns)

Faying surfaces Sigma Zinc 158 75 microns Sigmafast 278 100

Sigmafast 278 100

Sigmadur 550 60

Splice plates Sigma Zinc 158 75 microns Sigmafast 278 100

Sigmafast 278 100

Sigmadur 550 60

Fill plates Sigma Zinc 158 75 microns Sigmafast 278 100

Sigmafast 278 100

Nut and Bolts Sigmaprime 200 60

(HDG)

Sigmafast 278 100

Sigmafast 278 100

Sigmadur 550 60

Connection Gaps HEMPEL EPOXI

FILLER 35250 or

equivalent

ANENX A

PRODUCT TECHNICAL DATE SHEETS

1. SIGMA ZINC 158

2. SIGMAPRIME 200

3. SIGMAFAST 278

4. SIGMADU 550

PRODUCT DATA SHEET January 17, 2021 (Revision of April 18, 2018)

SIGMAZINC™ 158

DESCRIPTION

Two-component, moisture-curing zinc (ethyl) silicate primer

PRINCIPAL CHARACTERISTICS

• Certificate for ASTM A-490 class 'B' for slip coefficient

• Complies with the compositional requirements of SSPC-Paint 20, Level 2

• Anticorrosive primer for structural steel

• Suitable as a system primer in various paint systems based on unsaponifiable binders

• Galvanic action eliminates sub-film corrosion

• Can withstand substrate temperatures from –90°C (–130°F) up to 400°C (750°F), under normal atmospheric exposure

conditions

• When suitably topcoated provides excellent corrosion protection for steel substrates up to 540°C (1000°F)

• Good low-temperature curing

• Good impact and abrasion resistance

• Must not be exposed to alkaline (more than pH 9) or acidic (less than pH 5.5) liquids

COLOR AND GLOSS LEVEL

• Gray, greenish gray

• Flat

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density 2.3 kg/l (19.2 lb/US gal)

Volume solids 65 ± 2%

VOC (Supplied) Directive 1999/13/EC, SED: max. 219.0 g/kg

max. 507.0 g/l (approx. 4.2 lb/US gal)

Recommended dry film thickness 75 - 100 µm (3.0 - 4.0 mils) depending on system

Theoretical spreading rate 8.7 m²/l for 75 µm (348 ft²/US gal for 3.0 mils)

Dry to touch 30 minutes

Overcoating Interval Minimum: 12 hours

Maximum: Unlimited

Full cure after 12 hours

Shelf life Binder: at least 9 months when stored cool and dry

Pigment: at least 24 months when stored pigment moisture free

Notes:

- See ADDITIONAL DATA – Spreading rate and film thickness

- See ADDITIONAL DATA – Overcoating intervals

- See ADDITIONAL DATA – Curing time

Ref. 7558 Page 1/6

PRODUCT DATA SHEET January 17, 2021 (Revision of April 18, 2018)

SIGMAZINC™ 158

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Immersion exposure

• Steel; blast cleaned to ISO-Sa2½, blasting profile 40 – 70 µm (1.6 – 2.8 mils)

• Steel with approved zinc silicate shop primer; sweep blasted to SPSS-Ss, welds, rusty and damaged areas blast cleaned

to ISO-Sa2½

Atmospheric exposure conditions

• Steel; blast cleaned to ISO-Sa2½, blasting profile 40 – 70 µm (1.6 – 2.8 mils)

• Steel with approved zinc silicate shop primer; pretreated to to SPSS-Pt3

Substrate temperature and application conditions

• Substrate temperature during application and curing down to -5°C (23°F) is acceptable; provided the substrate is free

from ice and dry

• Substrate temperature during application up to 50°C (122°F) is acceptable

• Substrate temperature during application and curing should be at least 3°C (5°F) above dew point

• Relative humidity during curing should be above 50%

INSTRUCTIONS FOR USE

Mixing ratio by volume: binder to zinc powder 81:19

• Many of PPG's zinc silicates are supplied as two-pack materials consisting of a container with pigmented binder and a

drum containing a bag of zinc powder.

• To ensure proper mixing of both components, the instructions given below must be followed

• To avoid lumps in the paint do not add the binder to the zinc powder

• [1] Take the bag with zinc powder out of the drum

• [2] Shake the binder in the jerrycan a few times to reach a certain degree of homogenization

• [3] Pour about 2/3 of the binder into the empty drum

• [4] With the jerrycan now reduced in weight and containing more free space, shake it vigorously to obtain a homogeneous

mix with no deposits left on the bottom, and add this to the drum

• [5] Add the zinc powder gradually to the pigmented binder in the drum and, at the same time, continuously stir the

mixture by using a mechanical mixer (keep the speed low)

• [6] Stir the zinc dust powder thoroughly through the binder (high speed) and keep stirring until a homogeneous mixture is

obtained

• [7] Strain mixture through a 30 – 60 mesh screen

• [8] Agitate continuously during application (low speed). The use of a dedicated pump with a constant agitation for a zinc

silicate coating is recommended

Note: At application temperature above 30°C (86°F) addition of max 10% by volume of THINNER 90-53 may be necessary

Induction time

None

Ref. 7558 Page 2/6

PRODUCT DATA SHEET January 17, 2021 (Revision of April 18, 2018)

SIGMAZINC™ 158

Pot life

12 hours at 20°C (68°F)

Note: See ADDITIONAL DATA – Pot life

Air spray

Recommended thinner

THINNER 90-53

Volume of thinner

0 - 10%, depending on required thickness and application conditions

Nozzle orifice

2.0 mm (approx. 0.079 in)

Nozzle pressure

0.3 MPa (approx. 3 Bar; 44 p.s.i.)

Note: A dedicated pump for a zinc silicate coating with constant agitation must be used

Airless spray

Recommended thinner

THINNER 90-53

Volume of thinner

0 - 10%, depending on required thickness and application conditions

Nozzle orifice

Approx. 0.48 – 0.64 mm (0.019 – 0.025 in)

Nozzle pressure

9.0 - 12.0 MPa (approx. 90 - 120 bar; 1306 - 1741 p.s.i.)

Note: A dedicated pump for a zinc silicate coating with constant agitation must be used

Ref. 7558 Page 3/6

PRODUCT DATA SHEET January 17, 2021 (Revision of April 18, 2018)

SIGMAZINC™ 158

Brush/roller

• Only for touch-up and spot repair

• Roller application is not recommended

Recommended thinner

THINNER 90-53

Volume of thinner

5 – 15%

Note: Apply a visible wet coat with a max. dft of 25 µm (1.0 mils)|same for subsequent coats in order to obtain the required dft

Cleaning solvent

THINNER 90-53

Upgrading

• This is only valid for spray application

• If the DFT is below specification and an extra coat of SIGMAZINC 158 has to be applied, SIGMAZINC 158 should be

thinned down with 25 – 50% THINNER 90-53, in order to obtain a visible wet coat that remains wet for some time

ADDITIONAL DATA

Spreading rate and film thickness

DFT Theoretical spreading rate

75 µm (3.0 mils) 8.7 m²/l (348 ft²/US gal)

100 µm (4.0 mils) 6.5 m²/l (261 ft²/US gal)

Notes:

- Maximum DFT when brushing: 35 µm (1.4 mils)

- Above 150 µm (6.0 mils) mudcracking can occur

- Average DFT 75 µm (3.0 mils) with a minimum of 60 µm (2.4 mils) on smooth non-pitted blast cleaned steel

- Average DFT 100 µm (4.0 mils) with a minimum of 75 µm (3.0 mils) on rough or pitted, blast cleaned steel

Ref. 7558 Page 4/6

PRODUCT DATA SHEET January 17, 2021 (Revision of April 18, 2018)

SIGMAZINC™ 158

Overcoating interval for DFT up to 100 µm (4.0 mils) and 50% relative humidity

Overcoating with... Interval -5°C (23°F) 0°C (32°F) 10°C (50°F) 20°C (68°F) 30°C (86°F) 40°C (104°F)

recommended topcoats Minimum 24 hours 24 hours 18 hours 12 hours 6 hours 4 hours

Maximum Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited

Notes:

- For recoating with itself to take required dft, recommend to apply within 2 days before full cure. No minimum recoating interval

limitation for itself.

- To confirm cure to topcoat, conduct a MEK rub test per ASTM D4752. A rating of 4 or higher is sufficient for topcoating

- For measuring of the curing, the MEK rub test according to ASTM 4752 is a suitable method: after 50 double rubs with a cloth soaked

in MEK (or alternatively THINNER 90-53) no dissolving of the coating should be observed

- Curing/recoating time will be shortened by the increase of humidity, please contact regional technical service team for details

- A mist coat / full coating application technique is required when topcoating to prevent application bubbling. Ensure dry spray is

removed from the surface

- SIGMAZINC 158 is a moisture curing zinc silicate, this means that it cures after sufficient exposure to moisture from the atmosphere

during and after application; it is recommended that relative humidity and temperature are measured during the curing time

- When curing conditions are unfavorable or when reduced overcoat times are desired, curing can be accelerated 4 hours after

application by: [1] Wetting or soaking with water, keeping the surface wet for the next 2 hours, followed by drying; [2] Wetting or soaking

with a 0.5% ammonia solution, followed by drying

- Maximum interval is only unlimited when the surface is free from any contamination

Curing time for DFT up to 100 µm (4.0 mils) and 50% relative humidity

Substrate temperature Dry to handle Full cure

-5°C (23°F) 2 hours 24 hours

0°C (32°F) 2 hours 24 hours

10°C (50°F) 1 hour 18 hours

20°C (68°F) 30 minutes 12 hours

30°C (86°F) 30 minutes 6 hours

40°C (104°F) 30 minutes 4 hours

Notes:

- SIGMAZINC 158 is a moisture curing zinc silicate, this means that it only cures after sufficient take up of water, (from the atmosphere)

during and after application

- It is recommended that relative humidity and temperature are measured during the curing time

- Relative humidity during curing recommended to be above 50%

- Adequate ventilation must be maintained during application and curing (please refer to INFORMATION SHEETS 1433 and 1434)

Pot life (at application viscosity)

Mixed product temperature Pot life

0°C (32°F) 24 hours

10°C (50°F) 16 hours

20°C (68°F) 12 hours

30°C (86°F) 6 hours

Ref. 7558 Page 5/6

PRODUCT DATA SHEET January 17, 2021 (Revision of April 18, 2018)

SIGMAZINC™ 158

SAFETY PRECAUTIONS

• For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

• This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact

between the wet paint and exposed skin or eyes

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

REFERENCES

• CONVERSION TABLES INFORMATION SHEET 1410

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

• SAFETY INDICATIONS INFORMATION SHEET 1430

• SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD – INFORMATION SHEET 1431

TOXIC HAZARD

• SAFE WORKING IN CONFINED SPACES INFORMATION SHEET 1433

• DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

• CLEANING OF STEEL AND REMOVAL OF RUST INFORMATION SHEET 1490

• SPECIFICATION FOR MINERAL ABRASIVES INFORMATION SHEET 1491

• RELATIVE HUMIDITY – SUBSTRATE TEMPERATURE – AIR TEMPERATURE INFORMATION SHEET 1650

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the

rightful claim of any third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER

STATUTE OR ARISING OTHERWISE IN LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE,

ARE DISCLAIMED BY PPG. Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the

applicable shelf life of the product, or one year from the date of the delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar

Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon

laboratory tests that PPG believes to be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or

suggestions relating to the use of the PPG product, whether in technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own

particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and

application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or the contents of this information (unless there are written agreements

stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This sheet supersedes all previous versions and it is the

Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

The PPG logo, and all other PPG marks are property of the PPG group of companies. All other third-party marks are property of their respective owners.

Ref. 7558 Page 6/6

PRODUCT DATA SHEET February 18, 2022 (Revision of February 7, 2022)

SIGMAFAST™ 278

DESCRIPTION

Two-component, high solids, zinc phosphate epoxy primer and buildcoat

PRINCIPAL CHARACTERISTICS

• Epoxy primer or buildcoat in protective coating systems

• Excellent corrosion resistance in atmospheric exposure

• Cures at temperatures down to -5°C (23°F)

• Speed curing in steel fabrication

• Easy application by airless spray

• Wide application range

• ACQPA 27752-certified

COLOR AND GLOSS LEVEL

• Redbrown, gray and a selected range of (MIO) colors

• Semi-gloss

Notes:

- Epoxy coatings will chalk and fade upon exposure to sunlight, elevated temperatures, or chemical exposure. Discoloration and normal

chalking do not impact performance. Light colors will darken over time. Some batch-to-batch variation in color is to be expected. Color

matches are approximate.

- The addition of a UV stable topcoat should be considered when using epoxy coatings in cosmetic areas

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density 1.5 kg/l (12.5 lb/US gal)

Volume solids 80 ± 2%

VOC (Supplied) Directive 2010/75/EU, SED: max. 153.0 g/kg

UK PG 6/23(92) Appendix 3: max. 230.0 g/l (approx. 1.9 lb/US gal)

EPA Method 24: 220.0 g/ltr (1.8 lb/USgal)

Recommended dry film thickness 75 - 250 µm (3.0 - 10.0 mils)

Theoretical spreading rate 6.4 m²/l for 125 µm (257 ft²/US gal for 5.0 mils)

Dry to touch 1 hour

Overcoating Interval Minimum: 2 hours

Maximum: Extended

Full cure after 4 days

Ref. 6829 Page 1/6

PRODUCT DATA SHEET February 18, 2022 (Revision of February 7, 2022)

SIGMAFAST™ 278

Data for mixed product

Shelf life Base: at least 24 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA – Spreading rate and film thickness

- See ADDITIONAL DATA – Overcoating intervals

- See ADDITIONAL DATA – Curing time

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

• Apply this product to the specified thickness as soon as possible after the surface is prepared

Substrate conditions

• Steel; blast cleaned to ISO-Sa2½ or minimum SSPC SP-6, blasting profile 40 – 70 µm (1.6 – 2.8 mils) or power tool

cleaned to minimum ISO-St3 / SSPC SP3

Primed steel or previous coat

• Previous suitable coat must be dry and free from any contamination

• Surface of previous coat should be sufficiently roughened if necessary

• When applied to zinc silicate, a mist coat and full coat technique is required

Galvanized steel

• The surface must be properly prepared, dry, clean and free of any contamination

• The surface should be sufficiently roughened by sweep blasting to achieve a uniform matt appearance

• Sweep blast in accordance with the SSPC SP-16 guidelines

Stainless steel

• The surface must be properly prepared, dry, clean and free of any contamination

• The surface should be sufficiently roughened by sweep blasting with inert non-metallic abrasives

• Sweep blast in accordance with the SSPC SP-16 guidelines

Thermal Sprayed Metallization (TSM)

• Surface must be dry and free from any contamination

• The mist coat / full coat technique is required. See mist coat thinning recommendation in the Instructions For Use part

below

Ref. 6829 Page 2/6

PRODUCT DATA SHEET February 18, 2022 (Revision of February 7, 2022)

SIGMAFAST™ 278

Substrate temperature and application conditions

• Substrate temperature during application and curing should be at least 3°C (5°F) above dew point

• Substrate temperature during application and curing down to -5°C (23°F) is acceptable; provided the substrate is free

from ice and dry

INSTRUCTIONS FOR USE

Mixing ratio by volume: base to hardener 75:25 (3:1)

• The temperature of the paint should preferably be above 15°C (59°F), otherwise extra thinner may be required to obtain

application viscosity

• Adding too much thinner results in reduced sag resistance and slower cure

• Thinner should be added after mixing the components

Induction time

None

Pot life

1 hour at 20°C (68°F)

Air spray

Recommended thinner

THINNER 91-92

Volume of thinner

0 - 10%, depending on required thickness and application conditions

Nozzle orifice

1.7 – 2.0 mm (approx. 0.070 – 0.079 in)

Nozzle pressure

0.3 - 0.4 MPa (approx. 3 - 4 bar; 44 - 58 p.s.i.)

Ref. 6829 Page 3/6

PRODUCT DATA SHEET February 18, 2022 (Revision of February 7, 2022)

SIGMAFAST™ 278

Airless spray

Recommended thinner

THINNER 91-92

Volume of thinner

0 - 10%, 30 - 40% when mist coat applied

Nozzle orifice

Approx. 0.46 – 0.53 mm (0.018 – 0.021 in)

Nozzle pressure

20.0 - 25.0 MPa (approx. 200 - 250 bar; 2901 - 3626 p.s.i.)

Brush/roller

Recommended thinner

THINNER 91-92

Volume of thinner

0 – 5%

Notes:

- Application by roller will leave roller marking and is suitable for minimum DFT requirements only

- A roller suitable for epoxy application must be used

- Application by brush may show brush marking, due to the thixatropic nature of the paint and is most suitable to small areas, tight angle

areas or for stripe coating or touch-up

Cleaning solvent

THINNER 90-53

ADDITIONAL DATA

Spreading rate and film thickness

DFT Theoretical spreading rate

75 µm (3.0 mils) 10.7 m²/l (428 ft²/US gal)

125 µm (5.0 mils) 6.4 m²/l (257 ft²/US gal)

250 µm (10.0 mils) 3.2 m²/l (128 ft²/US gal)

Ref. 6829 Page 4/6

PRODUCT DATA SHEET February 18, 2022 (Revision of February 7, 2022)

SIGMAFAST™ 278

Overcoating interval for DFT up to 125 µm (5.0 mils)

Overcoating with... Interval -5°C (23°F) 0°C (32°F) 10°C (50°F) 20°C (68°F) 30°C (86°F)

various epoxy coatings, Minimum 24 hours 14 hours 4 hours 2 hours 1 hour

polyurethane coatings, Maximum Extended Extended Extended Extended Extended

and PSX

Notes:

- Actual maximum overcoating times will be influenced by local conditions

- A detergent wash with PREP 88 or equivalent is recommended prior to application of topcoats after 30 days of exposure if chalking or

contamination is present

- To ensure optimal adhesion of the next coat, the surface must be dry and free from all contaminations (oil, grease, chalking, etc...)

which would require cleaning and/or abrading

Curing time for DFT up to 125 µm (5.0 mils)

Substrate temperature Dry to touch Dry to handle Full cure

-5°C (23°F) 16 hours 38 hours N/A

0°C (32°F) 11 hours 24 hours 21 days

10°C (50°F) 4 hours 8 hours 8 days

20°C (68°F) 2 hours 4 hours 4 days

30°C (86°F) 1 hour 2 hours 3 days

Note: Adequate ventilation must be maintained during application and curing

Pot life (at application viscosity)

Mixed product temperature Pot life

0°C (32°F) 10 hours

10°C (50°F) 3 hours

20°C (68°F) 1 hour

30°C (86°F) 30 minutes

SAFETY PRECAUTIONS

• See Safety Data Sheet and product label for complete safety and precaution requirements

• This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact

between the wet paint and exposed skin or eyes

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

Ref. 6829 Page 5/6

PRODUCT DATA SHEET February 18, 2022 (Revision of February 7, 2022)

SIGMAFAST™ 278

REFERENCES

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the

rightful claim of any third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER

STATUTE OR ARISING OTHERWISE IN LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE,

ARE DISCLAIMED BY PPG. Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the

applicable shelf life of the product, or one year from the date of the delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar

Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon

laboratory tests that PPG believes to be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or

suggestions relating to the use of the PPG product, whether in technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own

particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and

application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or the contents of this information (unless there are written agreements

stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This sheet supersedes all previous versions and it is the

Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

The PPG logo, and all other PPG marks are property of the PPG group of companies. All other third-party marks are property of their respective owners.

Ref. 6829 Page 6/6

PRODUCT DATA SHEET February 25, 2021 (Revision of January 17, 2021)

SIGMAPRIME® 200 SERIES

DESCRIPTION

Universal epoxy anticorrosive primer, based upon pure epoxy technology

PRINCIPAL CHARACTERISTICS

• Universal epoxy primer system suitable for ballast tanks, deck, topside, superstructure, hull, cargo oil tanks and cargo

holds

• Excellent anticorrosive properties and water resistance

• Surface tolerant primer

• Good chemical resistance

• Good abrasion resistance for dedicated areas of application

• Excellent adhesion to steel, shop primer, galvanized steel and non-ferrous metals

• Excellent recoatability

• Suitable for application and curing in a wide range of climatic conditions

• Suitable for bulk supply and twin feed application

• Suitable on wet blast cleaned substrates (damp or dry)

COLOR AND GLOSS LEVEL

• Alu light, alu yellow, gray, yellow/green, redbrown

• Eggshell

Note: Alu Light and Alu Yellow are available with SIGMAPRIME 200K version

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density SIGMAPRIME 200: 1.3 kg/l (10.8 lb/US gal)

SIGMAPRIME 200 K: 1.4 kg/l (11.7 lb/US gal)

Volume solids SIGMAPRIME 200: 57 ± 2%

SIGMAPRIME 200 K: 60 ± 2%

VOC (Supplied) Directive 1999/13/EC, SED: max. 326 g/kg (SIGMAPRIME 200)

max. 430.0 g/l (approx. 3.6 lb/gal) (SIGMAPRIME 200)

Directive 1999/13/EC, SED: max. 287 g/kg (SIGMAPRIME 200 K)

max. 392.0 g/l (approx. 3.3 lb/gal) (SIGMAPRIME 200 K)

Recommended dry film thickness See spreading rate tables

Theoretical spreading rate SIGMAPRIME 200: 3.8 m²/l for 150 µm (152 ft²/US gal for 6.0 mils)

SIGMAPRIME 200 K: 6.0 m²/l for 100 µm (241 ft²/US gal for 4.0 mils)

Dry to touch 1.5 hours

Overcoating Interval See overcoating tables

Full cure after 7 days

Ref. 7416 Page 1/7

PRODUCT DATA SHEET February 25, 2021 (Revision of January 17, 2021)

SIGMAPRIME® 200 SERIES

Data for mixed product

Shelf life Base: at least 24 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA – Spreading rate and film thickness

- See ADDITIONAL DATA – Overcoating intervals

- See ADDITIONAL DATA – Curing time

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Immersion exposure

• Steel or steel with not approved zinc silicate shop primer; blast cleaned (dry or wet) to ISO-Sa2½, blasting profile 30 - 75

µm (1.2 – 3.0 mils)

• Steel with approved zinc silicate shop primer; weld seams and areas of damaged shop primer or breakdown should be

blast cleaned to ISO-Sa2½, blasting profile 30 - 75 µm (1.2 – 3.0 mils) or power tool cleaned to SPSS-Pt3

• Coated steel; hydrojetted to VIS WJ2L (blasting profile 30 – 75 µm (1.2 – 3.0 mils))

• Primed steel or previous coat must be dry and free from any contamination

IMO-MSC.215(82) Requirements for Water Ballast Tanks and IMO-MSC.288(87) for Cargo tanks of Crude Oil Tankers

(specified areas only)

• Steel; ISO 8501-3:2006 grade P2, with all edges treated to a rounded radius of minimum 2 mm (0.079 in) or subject to

three pass grinding or at least equivalent process before painting

• Steel or steel with not approved zinc silicate shop primer; blast cleaned to ISO-Sa2½, blasting profile 30 - 75 µm (1.2 – 3.0

mils)

• Steel with approved zinc silicate shop primer; weld seams and areas of shop primer damage or break down should be

blast cleaned to Iso-Sa 2½ blasting profile 30 – 75 µm (1.2 – 3.0 mils): [1] For shop primer with IMO type approval; no

additional requirements; [2] For shop primer without IMO type approval; blast cleaned to ISO-Sa2 removing at least 70%

of intact shop primer, blasting profile 30 – 75 µm (1.2 – 3.0 mils)

• Dust quantity on the surface to be coated must not exceed rating "1" for dust size class "3", "4" or "5" (ISO 8502-3-2017).

Lower dust size classes (“1” and/or “2”) to be removed if visible without magnification.

• Primed steel or previous coat must be dry and free from any contamination

Atmospheric exposure conditions

• Steel; blast cleaned to ISO-Sa2½, blasting profile 30 - 75 µm (1.2 – 3.0 mils) or according to ISO-St3

• Shop primed steel; pretreated to SPSS-Pt3

• Galvanized steel must be free from grease, salts and any contamination

• Galvanized steel must be cleaned by solvent or roughened by sandpaper

• Coated steel; hydrojetted to VIS WJ2L (blasting profile 30 – 75 µm (1.2 – 3.0 mils))

• Primed steel or previous coat must be dry and free from any contamination

Ref. 7416 Page 2/7

PRODUCT DATA SHEET February 25, 2021 (Revision of January 17, 2021)

SIGMAPRIME® 200 SERIES

Substrate temperature and application conditions

• Substrate temperature during application and curing should be above 5°C (41°F)

• Substrate temperature during application and curing should be at least 3°C (5°F) above dew point

• Relative humidity during application and curing should not exceed 85%

INSTRUCTIONS FOR USE

Mixing ratio by volume: base to hardener 80:20 (4:1)

• The temperature of the mixed base and hardener should preferably be above 15°C (59°F), otherwise extra thinner may be

required to obtain application viscosity

• Adding too much thinner results in reduced sag resistance and slower cure

• Thinner should be added after mixing the components

Induction time

None

Pot life

7 hours at 20°C (68°F)

Note: See ADDITIONAL DATA – Pot life

Air spray

Recommended thinner

THINNER 91-92

Volume of thinner

0 - 15%, depending on required thickness and application conditions

Nozzle orifice

1.5 – 2.0 mm (approx. 0.060 – 0.079 in)

Nozzle pressure

0.3 - 0.4 MPa (approx. 3 - 4 bar; 44 - 58 p.s.i.)

Ref. 7416 Page 3/7

PRODUCT DATA SHEET February 25, 2021 (Revision of January 17, 2021)

SIGMAPRIME® 200 SERIES

Airless spray

Recommended thinner

THINNER 91-92

Volume of thinner

0 - 15%, depending on required thickness and application conditions

Nozzle orifice

Approx. 0.53 – 0.74 mm (0.021 – 0.029 in)

Nozzle pressure

15.0 MPa (approx. 150 bar; 2176 p.s.i.)

Brush/roller

Recommended thinner

No extra thinner is necessary

Volume of thinner

Up to 5% THINNER 91-92 can be added if desired

Cleaning solvent

THINNER 90-53

ADDITIONAL DATA

Spreading rate and film thickness – SIGMAPRIME 200

DFT Theoretical spreading rate

75 µm (3.0 mils) 7.6 m²/l (305 ft²/US gal)

125 µm (5.0 mils) 4.6 m²/l (183 ft²/US gal)

160 µm (6.3 mils) 3.6 m²/l (145 ft²/US gal)

200 µm (8.0 mils) 2.9 m²/l (114 ft²/US gal)

Note: Max. dft: Dry Film Thickness of 2000 µm (80.0 mils) may occur occasionally (minor areas) where multiple overlapping is

unavoidable (i.e. around scallops, corners, erection joint lines etc.). PPG must be consulted in case of DFT readings fall outside

this recommendation.

Ref. 7416 Page 4/7

PRODUCT DATA SHEET February 25, 2021 (Revision of January 17, 2021)

SIGMAPRIME® 200 SERIES

Spreading rate and film thickness – SIGMAPRIME 200 K

DFT Theoretical spreading rate

100 µm (4.0 mils) 6.0 m²/l (241 ft²/US gal)

125 µm (5.0 mils) 4.8 m²/l (193 ft²/US gal)

160 µm (6.3 mils) 3.8 m²/l (153 ft²/US gal)

200 µm (8.0 mils) 3.0 m²/l (120 ft²/US gal)

Note: Max. dft: Dry Film Thickness of 2000 µm (80.0 mils) may occur occasionally (minor areas) where multiple overlapping is

unavoidable (i.e. around scallops, corners, erection joint lines etc.). PPG must be consulted in case of DFT readings fall outside

this recommendation.

Overcoating interval for DFT up to 160 µm (6.3 mils)

Overcoating with... Interval 5°C (41°F) 10°C (50°F) 20°C (68°F) 30°C (86°F) 40°C (104°F)

various two-pack epoxy Minimum 13 hours 6 hours 2.5 hours 1.5 hours 1 hour

coatings Maximum exposed to 3 months 3 months 3 months 3 months 3 months

direct sunshine

Maximum NOT exposed to 6 months 6 months 6 months 6 months 6 months

direct sunshine

Note: Surface should be dry and free from any contamination

Curing time for DFT up to 160 µm (6.3 mils)

Substrate temperature Dry to touch Dry to handle Full cure

5°C (41°F) 5 hours 14 hours 21 days

10°C (50°F) 3 hours 8 hours 14 days

20°C (68°F) 1.5 hours 4 hours 7 days

30°C (86°F) 45 minutes 2.5 hours 5 days

40°C (104°F) 30 minutes 1.5 hours 4 days

Note: Adequate ventilation must be maintained during application and curing (please refer to INFORMATION SHEETS 1433 and

1434)

Pot life (at application viscosity)

Mixed product temperature Pot life

15°C (59°F) 10 hours

20°C (68°F) 7 hours

30°C (86°F) 4 hours

Ref. 7416 Page 5/7

PRODUCT DATA SHEET February 25, 2021 (Revision of January 17, 2021)

SIGMAPRIME® 200 SERIES

SAFETY PRECAUTIONS

• For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

• This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact

between the wet paint and exposed skin or eyes

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

REFERENCES

• CONVERSION TABLES INFORMATION SHEET 1410

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

• SAFETY INDICATIONS INFORMATION SHEET 1430

• SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD – INFORMATION SHEET 1431

TOXIC HAZARD

• SAFE WORKING IN CONFINED SPACES INFORMATION SHEET 1433

• DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

• CLEANING OF STEEL AND REMOVAL OF RUST INFORMATION SHEET 1490

• SPECIFICATION FOR MINERAL ABRASIVES INFORMATION SHEET 1491

• RELATIVE HUMIDITY – SUBSTRATE TEMPERATURE – AIR TEMPERATURE INFORMATION SHEET 1650

• PPG PROTECTIVE & MARINE COATINGS' BALLAST TANK WORKING PROCEDURES

NEW-BUILDING

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the

rightful claim of any third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER

STATUTE OR ARISING OTHERWISE IN LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE,

ARE DISCLAIMED BY PPG. Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the

applicable shelf life of the product, or one year from the date of the delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar

Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon

laboratory tests that PPG believes to be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or

suggestions relating to the use of the PPG product, whether in technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own

particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and

application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or the contents of this information (unless there are written agreements

stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This sheet supersedes all previous versions and it is the

Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

Ref. 7416 Page 6/7

PRODUCT DATA SHEET February 25, 2021 (Revision of January 17, 2021)

SIGMAPRIME® 200 SERIES

Depending on specific country of application the following versions are available:

Article code Color Reference

202391 SIGMAPRIME 200: yellow/green 4009002200 (202390 base, 202389 hardener)

211291 SIGMAPRIME 200: grey 9515052200 (211282 base, 202389 hardener)

244820 SIGMAPRIME 200 K: grey 9515052150 (243529 base, 240992 hardener)

244832 SIGMAPRIME 200 K: redbrown 2008002150 (243540 base, 240992 hardener)

330749 SIGMAPRIME 200 K: alu light 9000002150 (330748 base, 240992 hardener)

330752 SIGMAPRIME 200 K: alu yellow 9300002150 (330751 base, 240992 hardener)

The PPG logo, and all other PPG marks are property of the PPG group of companies. All other third-party marks are property of their respective owners.

Ref. 7416 Page 7/7

PRODUCT DATA SHEET November 3, 2021 (Revision of November 3, 2021)

SIGMADUR™ 550

DESCRIPTION

Two-component, aliphatic acrylic polyurethane finish

PRINCIPAL CHARACTERISTICS

• Unlimited recoatable

• Excellent resistance to atmospheric exposure conditions

• Good color and gloss retention

• Cures at temperatures down to -5°C (23°F)

• Resistant to splash of mineral and vegetable oils, paraffins, aliphatic petroleum products and mild chemicals

• Can be recoated even after long atmospheric exposure

• Good application properties

COLOR AND GLOSS LEVEL

• White and various other colors (see also SIGMACARE shade card)

• Gloss

Note: Certain colors, especially red, orange, and yellow may require additional coats for adequate hiding, especially if applied

over primers with a significant color contrast

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density 1.3 kg/l (10.8 lb/US gal)

Volume solids 55 ± 2%

VOC (Supplied) Directive 1999/13/EC, SED: max. 334.0 g/kg

EUR Directive: 2004/42/IIA(i)(500) 459 g/l)

max. 430.0 g/l (approx. 3.6 lb/US gal)

Recommended dry film thickness 50 - 60 µm (2.0 - 2.4 mils) depending on system

Theoretical spreading rate 11.0 m²/l for 50 µm (441 ft²/US gal for 2.0 mils)

Dry to touch 1 hour

Overcoating Interval Maximum: 6 hours

Maximum: Unlimited

Full cure after 4 days

Shelf life Base: at least 36 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Ref. 7537 Page 1/5

PRODUCT DATA SHEET November 3, 2021 (Revision of November 3, 2021)

SIGMADUR™ 550

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Substrate conditions

• Previous coat (epoxy or polyurethane) must be dry and free from any contamination

• Previous coat: surface should be sufficiently roughened if necessary

Substrate temperature and application conditions

• Substrate temperature during application at -5°C (23°F) is acceptable; provided the substrate is free from ice and dry

• Substrate temperature during application and curing should be at least 3°C (5°F) above dew point

• Relative humidity during application and curing should not exceed 85%

• Should condensation on the surface occur during, or soon after application, this could result in color and gloss change

INSTRUCTIONS FOR USE

Mixing ratio by volume: base to hardener 88:12

• The temperature of the mixed base and hardener should be above 10°C (50°F), otherwise extra thinner may be required to

obtain application viscosity

• Thinner should be added after mixing the components

• Adding too much thinner results in reduced sag resistance

Induction time

None

Pot life

5 hours at 20°C (68°F)

Note: See ADDITIONAL DATA – Pot life

Air spray

Recommended thinner

THINNER 21-06

Volume of thinner

3 - 5%, depending on required thickness and application conditions

Nozzle orifice

1.0 - 1.5 mm (approx. 0.040 - 0.060 in)

Nozzle pressure

0.3 - 0.4 MPa (approx. 3 - 4 bar; 44 - 58 p.s.i.)

Ref. 7537 Page 2/5

PRODUCT DATA SHEET November 3, 2021 (Revision of November 3, 2021)

SIGMADUR™ 550

Airless spray

Recommended thinner

THINNER 21-06

Volume of thinner

3 - 5%, depending on required thickness and application conditions

Nozzle orifice

Approx. 0.43 – 0.48 mm (0.017 – 0.019 in)

Nozzle pressure

20.0 MPa (approx. 200 bar; 2901 p.s.i.)

Brush/roller

Recommended thinner

THINNER 21-06

Volume of thinner

0 – 5%

Cleaning solvent

THINNER 90-53

ADDITIONAL DATA

Spreading rate and film thickness

DFT Theoretical spreading rate

50 µm (2.0 mils) 11.0 m²/l (441 ft²/US gal)

60 µm (2.4 mils) 9.2 m²/l (368 ft²/US gal)

Overcoating interval for DFT up to 50 µm (2.0 mils)

Overcoating with... Interval -5°C (23°F) 0°C (32°F) 10°C (50°F) 20°C (68°F) 30°C (86°F) 40°C (104°F)

itself Minimum 24 hours 16 hours 8 hours 6 hours 5 hours 3 hours

Maximum Unlimited Unlimited Unlimited Unlimited Unlimited Unlimited

Note: Surface should be dry and free from any contamination

Ref. 7537 Page 3/5

PRODUCT DATA SHEET November 3, 2021 (Revision of November 3, 2021)

SIGMADUR™ 550

Curing time for DFT up to 60 µm (2.4 mils)

Substrate temperature Dry to handle Full cure

-5°C (23°F) 24 hours 15 days

0°C (32°F) 16 hours 11 days

10°C (50°F) 8 hours 6 days

20°C (68°F) 6 hours 4 days

30°C (86°F) 5 hours 3 days

40°C (104°F) 3 hours 48 hours

Notes:

- Adequate ventilation must be maintained during application and curing

- Premature exposure to early condensation and rain may cause color and gloss change

Pot life (at application viscosity)

Mixed product temperature Pot life

10°C (50°F) 7 hours

20°C (68°F) 5 hours

30°C (86°F) 3 hours

40°C (104°F) 2 hours

SAFETY PRECAUTIONS

• This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact

between the wet paint and exposed skin or eyes

• Contains a toxic polyisocyanate curing agent

• Avoid at all times inhalation of aerosol spray mist

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

REFERENCES

• CONVERSION TABLES INFORMATION SHEET 1410

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

• SAFETY INDICATIONS INFORMATION SHEET 1430

• SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD – INFORMATION SHEET 1431

TOXIC HAZARD

• SAFE WORKING IN CONFINED SPACES INFORMATION SHEET 1433

• DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

• RELATIVE HUMIDITY – SUBSTRATE TEMPERATURE – AIR TEMPERATURE INFORMATION SHEET 1650

Ref. 7537 Page 4/5

PRODUCT DATA SHEET November 3, 2021 (Revision of November 3, 2021)

SIGMADUR™ 550

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the

rightful claim of any third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER

STATUTE OR ARISING OTHERWISE IN LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE,

ARE DISCLAIMED BY PPG. Any claim under this warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the

applicable shelf life of the product, or one year from the date of the delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar

Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon

laboratory tests that PPG believes to be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or

suggestions relating to the use of the PPG product, whether in technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The

product and related information is designed for users having the requisite knowledge and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own

particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and

application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such use or the contents of this information (unless there are written agreements

stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This sheet supersedes all previous versions and it is the

Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at www.ppgpmc.com. The English text of

this sheet shall prevail over any translation thereof.

The PPG logo, and all other PPG marks are property of the PPG group of companies. All other third-party marks are property of their respective owners.

Ref. 7537 Page 5/5

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chevron Standard For PaintingDocument157 pagesChevron Standard For Paintingvuong100% (3)

- Koc P 003Document38 pagesKoc P 003Hari KrishnanNo ratings yet

- Interior Painting Scope of WorkDocument8 pagesInterior Painting Scope of WorkTalal ItaniNo ratings yet

- Reckli Concrete FinishDocument16 pagesReckli Concrete Finishanthonyquinn500No ratings yet

- Japan - EPICON ZINC RICH PRIMER B-2Document3 pagesJapan - EPICON ZINC RICH PRIMER B-2Bhayu Senoaji Dwi PrimasanjoyoNo ratings yet

- Fosroc Nitoflor TF5000: Constructive SolutionsDocument4 pagesFosroc Nitoflor TF5000: Constructive SolutionsVincent JavateNo ratings yet

- Sikaflex Concrete Fix: One-Component and Polyurethane-Based Elastomeric Sealant For Cracks, Gaps and JointsDocument2 pagesSikaflex Concrete Fix: One-Component and Polyurethane-Based Elastomeric Sealant For Cracks, Gaps and JointsNazee 122333No ratings yet

- Civil Rate Analysis 0 72-73 Kathmandu To Be UpdatedDocument697 pagesCivil Rate Analysis 0 72-73 Kathmandu To Be UpdatedAnonymous 3fQZqsGIu79% (62)

- Application Guide - Jotun Solvalitt AluDocument9 pagesApplication Guide - Jotun Solvalitt AluPolem IskandarNo ratings yet

- Deglazing FormDocument1 pageDeglazing FormPham LamNo ratings yet

- Technical Data Epoxy Primer EP-R-30Document2 pagesTechnical Data Epoxy Primer EP-R-30Sheikh Shoaib100% (1)

- Mastertop 1273 As: Description PackagingDocument3 pagesMastertop 1273 As: Description PackagingShaik J MohamedNo ratings yet

- Universal 1-Component Polyurethane Joint Sealant: DescriptionDocument2 pagesUniversal 1-Component Polyurethane Joint Sealant: DescriptionAkram ShaikhNo ratings yet

- Loctite 401™: Technical Data SheetDocument4 pagesLoctite 401™: Technical Data SheetAngga PramudyaNo ratings yet

- The KELATE® MR6 Product Information SheetDocument6 pagesThe KELATE® MR6 Product Information SheetTransporte GouveiaNo ratings yet

- Guideline For Planning and Executing WaterproofingDocument40 pagesGuideline For Planning and Executing WaterproofingBogdan MuresanNo ratings yet

- Arc 988 - en PDFDocument2 pagesArc 988 - en PDFthod3rNo ratings yet

- Dulux Firepro Epoxy Intumescent Application GuideDocument10 pagesDulux Firepro Epoxy Intumescent Application GuideAlpha DekoNo ratings yet

- NLG Drag Brace - CMM PN Tp500-E050Document159 pagesNLG Drag Brace - CMM PN Tp500-E050Anderson RamalhoNo ratings yet

- Sika Top Armatec - 110 EpoCemDocument4 pagesSika Top Armatec - 110 EpoCemTiago LopesNo ratings yet

- PAYGB Quotation Sample 2019Document53 pagesPAYGB Quotation Sample 2019Jamiu LateefNo ratings yet

- Speed Infra Rate Analysis For BudgetDocument37 pagesSpeed Infra Rate Analysis For Budgetmadhusudan GNo ratings yet

- Hi Pon 20 07 Epoxy Zinc Phosphate 70 Ver 13.0 PDFDocument4 pagesHi Pon 20 07 Epoxy Zinc Phosphate 70 Ver 13.0 PDFPushpendraNo ratings yet

- Features and Benefits: Technical Data SheetDocument6 pagesFeatures and Benefits: Technical Data SheetTaufiq SatrioNo ratings yet

- Package II Part I.3 Civil BOQ For Security BuildingDocument20 pagesPackage II Part I.3 Civil BOQ For Security Buildingdox4useNo ratings yet

- Anabond 666t Max Gasket SealantDocument3 pagesAnabond 666t Max Gasket SealantDinesh SaravanaNo ratings yet

- Moisture Cured Urethane CoatingsDocument11 pagesMoisture Cured Urethane Coatingszavisa2No ratings yet

- Nitoseal PU40: One Part, PU Based Building & Expansion Joint SealantDocument4 pagesNitoseal PU40: One Part, PU Based Building & Expansion Joint SealantMaruf MuhammadNo ratings yet

- Rate 2012 CecbDocument254 pagesRate 2012 CecbChathuranga PriyasamanNo ratings yet

- Fairtop Fast Floor - Cementitious Self Levelling Flooring SystemsDocument8 pagesFairtop Fast Floor - Cementitious Self Levelling Flooring SystemsfairmatechemicalNo ratings yet