Professional Documents

Culture Documents

Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888

Uploaded by

design jyotihydrotech.com0 ratings0% found this document useful (0 votes)

13 views2 pagesKDT THREE PHASE MONOBLOC PUMPS

The document provides information on KDT three phase monobloc pumps from Kirloskar Brothers Limited, including technical specifications, features, materials of construction, applications, and other details. Key features highlighted are flatter efficiency curve, high head capability up to 98 meters, wide voltage tolerance from 350-440V, replaceable wearing parts, and dynamically balanced rotating parts. Applications include air conditioning, cooling towers, firefighting, and industrial pressure boosting.

Original Description:

hk,lhh

Original Title

KDT

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKDT THREE PHASE MONOBLOC PUMPS

The document provides information on KDT three phase monobloc pumps from Kirloskar Brothers Limited, including technical specifications, features, materials of construction, applications, and other details. Key features highlighted are flatter efficiency curve, high head capability up to 98 meters, wide voltage tolerance from 350-440V, replaceable wearing parts, and dynamically balanced rotating parts. Applications include air conditioning, cooling towers, firefighting, and industrial pressure boosting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888

Uploaded by

design jyotihydrotech.comKDT THREE PHASE MONOBLOC PUMPS

The document provides information on KDT three phase monobloc pumps from Kirloskar Brothers Limited, including technical specifications, features, materials of construction, applications, and other details. Key features highlighted are flatter efficiency curve, high head capability up to 98 meters, wide voltage tolerance from 350-440V, replaceable wearing parts, and dynamically balanced rotating parts. Applications include air conditioning, cooling towers, firefighting, and industrial pressure boosting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

KDT

THREE PHASE

MONOBLOC PUMPS

KIRLOSKAR BROTHERS LIMITED

A Kirloskar Group Company

Established 1888

KIRLOSKAR PUMPS

TECHNICAL SPECIFICATION FEATURES

Head Range : Upto 98 metres Flatter Efficiency Curve

Discharge Range : Upto 20 lps Minimum variations in efficiency during entire operating range increases the utility

of pumpset for variable conditions.

Power Ratings : 3.7 to 15 kW

(5 to 20 HP) High Head Applications

Voltage Range : 300 to 440 Volts (Three Phase) The pump has been designed to deliver large volumes of water for high head

applications, helping customers to achieve high turnaround time and productivity.

Insulation : B / F Class

Protection : IP 44 / IP 55 Wide Voltage Design

The motor is designed to withstand wide voltage fluctuations from 350 to 440 volts

and reduces motor burning in case of low voltage.

MATERIAL OF CONSTRUCTION Designed to Prevent Overloading

Impeller : Cast Iron / Bronze / Lesser chances of motor burning as the motor does not get overloaded even if the

Stainless Steel pump is operated at a head lower than recommended, thus ensuring substantial

cost savings due to low maintenance and breakdown.

Delivery Casing : Cast Iron

Motor Body : Cast Iron

Replaceable Wearing Parts

Pump Shaft : Carbon Steel / Stainless Steel All wearing parts within the pumps are easily accessible and replaceable which

Sealing : Gland Packed / Mechanical Seal facilitates ease of maintenance thereby extending the life of the pump.

Dynamically Balanced Rotating Parts

Minimum vibrations protect components from damages during the operations,

APPLICATIONS thus ensuring consistent performance as concentricity is maintained.

Ÿ Air conditioning and refrigeration systems

Ÿ Cooling towers CED – Cathodic Electro Deposition

Ÿ Clear water handling at high pressure in industries CED is the latest coating technology for corrosion resistance with uniform coating.

It provides 5 times more protection over conventional painting, resulting in longer

Ÿ Fire fighting systems life. All major CI parts of Kirloskar pumps coming in contact with the water are CED

Ÿ Industrial pressure boosting coated.

Automatic Air Release

Automatically releases air when the pump starts which ensures swifter and

smoother operations, thus eliminating the necessity of operating air release cock

and ensures swifter and smoother operations.

High Efficiency And Energy Saving Design

Innovative design manufactured at state-of-the-art plant, delivers optimum

efficiency at lower energy consumption resulting in significant cost savings.

KIRLOSKAR BROTHERS LIMITED Service Toll- Free No.

A Kirloskar Group Company

Established 1888 1800 103 4443

Registered Office & Global Headquarters : “Yamuna”, Survey No. 98 /(3 to7), Plot No. 3, Baner, Pune 411 045, State Maharashtra, India.

Tel.: +91 (20) 2721 4444 Fax: +91 (20) 67211060 Email: marketing@kbl.co.in Website: www.kirloskarpumps.com CIN No.: L29113PN1920PLC000670

You might also like

- 1Document2 pages1waseemybNo ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888ANJANEYA SHARMANo ratings yet

- Pumba Puzha LeafletDocument2 pagesPumba Puzha LeafletNishanth GaneshNo ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888Nishanth GaneshNo ratings yet

- JVS Openwell Submersible PumpsetDocument2 pagesJVS Openwell Submersible Pumpsetகோவி கோபால் ஆர்ட்ஸ்No ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888Debashis DasNo ratings yet

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Document2 pagesKirloskar Brothers Limited: A Kirloskar Group Company Established 1888walid kawsarNo ratings yet

- KV DVDocument2 pagesKV DVAbdullaKakkadKarumbilNo ratings yet

- KOS THREE PHASE OPEN-WELL PUMPSDocument2 pagesKOS THREE PHASE OPEN-WELL PUMPSkeeprocking9777No ratings yet

- Aqua-Knight-Leaflet FINAL CompressedDocument2 pagesAqua-Knight-Leaflet FINAL Compressedakash.fenadhnNo ratings yet

- Self Priming - MINI Range Pumps CMS CBR 140 AQUA V FLOWDocument2 pagesSelf Priming - MINI Range Pumps CMS CBR 140 AQUA V FLOWamitNo ratings yet

- Edx10 11Document8 pagesEdx10 11Fernando NapitupuluNo ratings yet

- Rotary Screw Air Compressors for IndustryDocument7 pagesRotary Screw Air Compressors for Industryrafaelmelo89No ratings yet

- Katalogovy List 762Document2 pagesKatalogovy List 762Tesla EcNo ratings yet

- Optimize Fuel Flow with Red Jacket STPsDocument6 pagesOptimize Fuel Flow with Red Jacket STPswarung1bensinNo ratings yet

- Big-Blue-Air-Pak-ed10-5 Oct08Document8 pagesBig-Blue-Air-Pak-ed10-5 Oct08Jhonny MorenoNo ratings yet

- Catalog - IEC LV Water-Cooled Motors - EN - 07-2023Document40 pagesCatalog - IEC LV Water-Cooled Motors - EN - 07-2023Mohamed MOUCHRIFNo ratings yet

- RIKT Isothermal Turbocompressors PDFDocument6 pagesRIKT Isothermal Turbocompressors PDFJaswindersingh BhatiaNo ratings yet

- Product CatalogDocument60 pagesProduct CatalogLEKH021No ratings yet

- High Productivity With ELECTRIC ARC FURNACES. Steelmaking PlantsDocument16 pagesHigh Productivity With ELECTRIC ARC FURNACES. Steelmaking PlantsflasnicugNo ratings yet

- Gas & Steam Turbine GeneratorsDocument2 pagesGas & Steam Turbine GeneratorsJuan Carlos Vivas GuioNo ratings yet

- Jalnayak Leaflet ORD - 10783 - v2 1Document2 pagesJalnayak Leaflet ORD - 10783 - v2 1Siddhant VohraNo ratings yet

- Miller Big Blue 600xDocument8 pagesMiller Big Blue 600xmathi vijayNo ratings yet

- 1510911700Document4 pages1510911700alex limachiNo ratings yet

- Catalog Motor KM6 50HzDocument8 pagesCatalog Motor KM6 50HzFahadNo ratings yet

- WCVS0905Document4 pagesWCVS0905Quynh NguyenNo ratings yet

- Doosan Steam TurbinesDocument24 pagesDoosan Steam TurbinesUhrin Imre0% (1)

- Big Blue 600 ProDocument8 pagesBig Blue 600 ProGabrielPacovilcaArhuataNo ratings yet

- Spares BrochureDocument6 pagesSpares BrochureRagul AnandNo ratings yet

- Transformer BrochureDocument6 pagesTransformer Brochuresunil patelNo ratings yet

- Compair Portables BrochureDocument14 pagesCompair Portables BrochureJoseNo ratings yet

- Three-phase Induction Motors: Empowering the FutureDocument180 pagesThree-phase Induction Motors: Empowering the Futurehardik033No ratings yet

- Grundfos Selection GuideDocument28 pagesGrundfos Selection Guideiman_pumpNo ratings yet

- COMPAIR Portable CompressorDocument14 pagesCOMPAIR Portable CompressorNova HeryNo ratings yet

- Carrier 38ckc E6pdDocument26 pagesCarrier 38ckc E6pdAlberto Popushoy0% (1)

- 2.1 EQ Series - Global CatalogueDocument8 pages2.1 EQ Series - Global CatalogueimkhanhnguyenNo ratings yet

- Pegasus: Medium Voltage AC Induction MotorsDocument6 pagesPegasus: Medium Voltage AC Induction MotorsSergio aldoNo ratings yet

- Water Cooled CompressorDocument13 pagesWater Cooled CompressorGeorge SobhyNo ratings yet

- KRSD CompressorDocument7 pagesKRSD CompressorMohit PanchalNo ratings yet

- USSXSMSK - SX SM SK Series - 07 2019 - 46 37080 PDFDocument8 pagesUSSXSMSK - SX SM SK Series - 07 2019 - 46 37080 PDFkagasaw023No ratings yet

- Development of High Speed Diesel EngineDocument7 pagesDevelopment of High Speed Diesel EngineJaikirat SinghNo ratings yet

- Especificaciones 315 CATDocument20 pagesEspecificaciones 315 CATgerman gualavisiNo ratings yet

- 287 287 Fb020-279 Flygt PC Pump BrochureDocument8 pages287 287 Fb020-279 Flygt PC Pump BrochureAndreas B Kresnawan100% (1)

- AVL Spectra-Emotordyno Web e 08.22-1Document2 pagesAVL Spectra-Emotordyno Web e 08.22-1FernandoNo ratings yet

- CD Tel - HT - High Temperature BrochureDocument8 pagesCD Tel - HT - High Temperature BrochureangelNo ratings yet

- Super Silent, Superior Life Technical DataDocument6 pagesSuper Silent, Superior Life Technical DataSteven E. EsquivelNo ratings yet

- UntitledDocument60 pagesUntitledAvinash SharmaNo ratings yet

- Mobil SHC PM SeriesDocument3 pagesMobil SHC PM SeriesVictor ZhicayNo ratings yet

- Fr60e PDFDocument11 pagesFr60e PDFAlexander Riscanevo100% (2)

- WEG Motors Low Voltage Product Lines Asian Market 275 Brochure English PDFDocument12 pagesWEG Motors Low Voltage Product Lines Asian Market 275 Brochure English PDFArnold StevenNo ratings yet

- Brosur Datasheet Yanmar - Sae - 19 Kva Sylent Type PDFDocument7 pagesBrosur Datasheet Yanmar - Sae - 19 Kva Sylent Type PDFPusat GensetNo ratings yet

- Long Retractable Sootblower: Superior Performance For A Moderate InvestmentDocument2 pagesLong Retractable Sootblower: Superior Performance For A Moderate InvestmentYanto TanujayaNo ratings yet

- GT O&M ManualDocument122 pagesGT O&M ManualAnand Varma100% (1)

- AGRE IndustrialPistons Leaflet en LRDocument20 pagesAGRE IndustrialPistons Leaflet en LRmogwai71No ratings yet

- Toshiba's Steam Turbines for Efficient and Environmentally Friendly Power GenerationDocument16 pagesToshiba's Steam Turbines for Efficient and Environmentally Friendly Power Generationilusee100% (1)

- 2014 Wind Turbine CatalogueDocument15 pages2014 Wind Turbine CatalogueSan AndersonNo ratings yet

- GSW275V-590V OpenDocument2 pagesGSW275V-590V OpenRafael Ribeiro LandmachineryNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Electro-Coagulation BrochureDocument8 pagesElectro-Coagulation Brochuredesign jyotihydrotech.comNo ratings yet

- SDS PLA V3.004-EnDocument5 pagesSDS PLA V3.004-Endesign jyotihydrotech.comNo ratings yet

- Guided Tours V3Document1 pageGuided Tours V3kbpatel123No ratings yet

- Geeetech A30M 3D Printer User Manual V1.10 : Shenzhen Getech Technology Co.,LtdDocument60 pagesGeeetech A30M 3D Printer User Manual V1.10 : Shenzhen Getech Technology Co.,Ltddesign jyotihydrotech.comNo ratings yet

- SDS PLA V3.004-EnDocument5 pagesSDS PLA V3.004-Endesign jyotihydrotech.comNo ratings yet

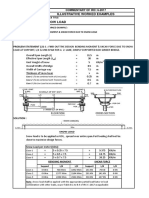

- Optimal Crane Hook Design for Maximum SafetyDocument6 pagesOptimal Crane Hook Design for Maximum Safetymukeshsonava076314No ratings yet

- TDS Brushbond IndiaDocument2 pagesTDS Brushbond IndiahemantrulzNo ratings yet

- Differential Scanning Calorimetry: For All RequirementsDocument14 pagesDifferential Scanning Calorimetry: For All RequirementsNdra PompomorinNo ratings yet

- GTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding CableDocument1 pageGTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding Cableshivam dwivedi100% (1)

- Diffusion CoefDocument1 pageDiffusion CoefCasey ChengNo ratings yet

- API 570 FormulasDocument2 pagesAPI 570 FormulasArif Mokhtar89% (9)

- The Phases of MatterDocument6 pagesThe Phases of MatterbettynogpoNo ratings yet

- Interior Design & Services: Ac Duct Layouts Prof. Krishna AnandDocument30 pagesInterior Design & Services: Ac Duct Layouts Prof. Krishna AnandKrishna AnandNo ratings yet

- Gasket HandbookDocument48 pagesGasket Handbookgladiatork00796% (24)

- CFD-Ch3: 1D Nozzle Flow AnalysisDocument3 pagesCFD-Ch3: 1D Nozzle Flow AnalysisMuhammad HakimNo ratings yet

- FinishesDocument75 pagesFinishesYna VictoriaNo ratings yet

- Liangchew CatalogueDocument48 pagesLiangchew CatalogueKyaw Naing AungNo ratings yet

- Emd00099en JWP26CDocument4 pagesEmd00099en JWP26CLupu Ane MarieNo ratings yet

- Cat 2 RCD QuestionsDocument2 pagesCat 2 RCD QuestionsNPhilemonNo ratings yet

- Painting ProcedureDocument20 pagesPainting ProcedureCRUSTEK ENGINEERSNo ratings yet

- Evonik-Ancamine 2726 EUDocument7 pagesEvonik-Ancamine 2726 EUkishanptlNo ratings yet

- Example 1-Special Moment FramesDocument16 pagesExample 1-Special Moment FramestoshicrystalNo ratings yet

- Part and Mold Design GuideDocument170 pagesPart and Mold Design GuideminhtintinNo ratings yet

- T2785 1U Glamo HousingDocument12 pagesT2785 1U Glamo HousingLiesa StoneNo ratings yet

- Performance of Centrifugal PumpsDocument52 pagesPerformance of Centrifugal Pumpsvisitabhinav100% (4)

- Anti-Corrosion en 110117 LowDocument12 pagesAnti-Corrosion en 110117 Lowinfo9316No ratings yet

- Aisi H13Document2 pagesAisi H13123vigenNo ratings yet

- Di Sabatino Fluidity Al Foundry Alloys PHD ThesisDocument161 pagesDi Sabatino Fluidity Al Foundry Alloys PHD Thesiscttcosta100% (1)

- Amendment No. 3 June 2018 TO Is 3597: 1998 Concrete Pipes - Methods of TestDocument5 pagesAmendment No. 3 June 2018 TO Is 3597: 1998 Concrete Pipes - Methods of TestPratik KharmateNo ratings yet

- Edutor Tank MixerDocument2 pagesEdutor Tank MixerLeandro BuosiNo ratings yet

- Material Selection For Oil Field Production Tubing and Casing PDFDocument3 pagesMaterial Selection For Oil Field Production Tubing and Casing PDFYousuf MemonNo ratings yet

- IRC Snow Load Design Calculations for Box Girder BridgeDocument1 pageIRC Snow Load Design Calculations for Box Girder Bridgejatin singlaNo ratings yet

- Multi Storey Building FramesDocument24 pagesMulti Storey Building Framespriyanka0% (2)

- Method To Determine Hot Permeability and Strength of Ceramic Shell MouldsDocument5 pagesMethod To Determine Hot Permeability and Strength of Ceramic Shell MouldsuzairmetallurgistNo ratings yet