Professional Documents

Culture Documents

Calculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up Properties

Uploaded by

Bagadi AvinashOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation of Diameter For Methanol-IPA System (Continuous) - Top Boil Up Properties

Uploaded by

Bagadi AvinashCopyright:

Available Formats

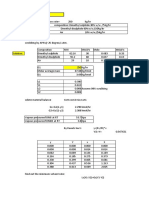

Client: M/s.Malladi Drugs,Chennai Design factor: 1.

2

Date: 15.03.12

Design of water + IPA Column Designed by : K.Santhosh

Feed (KL/day) 7.2 5868.7200 Kg/day Chd&Appd by : N.S.W

design factor feed 7042.4640

Calculation of diameter for Methanol-IPA system(Continuous)- Top Boil up properties

Feed B.P M.W Feed Feed Distillate Distillate Bottoms Bottoms Density l Viscosity

(°C) (kg/kg mol) (w/w%) (mol%) (w/w%) (mol%) (w/w%) (mol%) (gr/cc) (kcal/kg) cp

Water 100 18 15 37.072 0.5 1.6499 99.5 99.8497 0.98 540.0 0.600

IPA 82.22 60.09 85 62.928 99.5 98.3501 0.5000 0.1503 0.786 159.0 2

0.8151 160.91 1.993

Feed 282 6.3322 42.2548 Intercept = 0.12770 0.09100

kg/HR kgmole/hr 1267.64352 Rmin = -0.87 10

TIME parameter 30.000

Calculation of vapor . Column Dia calculation

0

Composition of the boilup w/w% 1.250 Max distillate rate 240.44 kg/hr

Water 0.5 1.200

IPA 99.5 1.472 Boilup rate 528.97 kg/hr

Refluxratio 1.2 (G=G' * A) 0.15 kg/sec

(L/G) 0.55 8.91 kgmol/hr

Aveg. temp of gas 82.31 °c Latent heat of vaporization 160.91 kcal/kg Structured packings (MELLAPAK 500Y)

Density of liquid 786.97 kg/m3 Heat load 85113.48 kcal/hr Ass. Dia. Of Col. 264 mm T 355.31 °K

Moles of distillate / 100 g distillate 1.6836 moles Area of the column 0.0747 m² Area of column 0.05466 m² P 1013.3 m bar

Operating pressure 760 m.m Hg Diameter of the column 308.38 mm L/G 0.55 M 59.396 kg/kgmol

Aveg M.W 59.396 kg/mol Condenser Density of gas 2.039 kg/m3 F factor 1.8834

Density of gas 2.039 kg/m3 Heat load 85113.48 kcal/hr Density of liquid 786.97 kg/m3 NTSM 4.1

X-axis 0.0278 Temp. at the top 82.31 °C Flow parameter 0.028 Height 0.00 m

Ordinate1 0.26 (pg:195 Treybal) CTW entering at 32 °C Cg,max 0.12 Pr.drop 5.0 mbar/m

1" Ceramic intallox saddles 98 CTW leaving at 37 °C Qty Evaporated 7213.19 kg Cg 0.096 Total pr.drop 0.00 mbar

Viscosity of liquid 1.993 cp LMTD 47.77 °C Correction factor, C 0.70 0.000 mm of Hg

0.001993 kg/m-sec U 500 kcal/hr-m²-°c Qty.remaining 1237.77 kg g 2.6881 kg/m2.s

Gas flow rate at flooding-G' 2.81 kg/m²-sec Main condenser area 3.5638 m² G 0.1469 kg/s

at 70% flooding 1.968 kg/m²-sec Vent condenser area 0.4928 m² Reboiler 528.9673 kg/hr

CTW Req. for Main condenser 17.0227 m3/hr Reboiler Load 85113.48 kcal/hr 8.9058 kgmol/hr

Pressure drop calculation CTW Req. for vent condenser 1.7023 m3/hr Temperature of the still at 760 m.m Hg at the end 99.9 °c T (hr) 0.0000 0.0000 0.0000 0.0000

Ordinate value 0.1274 CTW Req for sub cooler 1.5230 m3/hr Temperature of steam at 3 kg/cm2 -g 142.97 °c Distillation time 0.00 hrs

Pressure drop/m 6.746 mm Hg/m Total CTW Water Req 20.25 m3/hr l of steam at 3kg/cm²-g 508.16 kcal/kg

Total pressure drop 80.950 mm hg U 488.00 kcal/hr-m²-°c

Size of the reboiler is 4.051 m²

Steam Required is 167.493 kg/hr

(20% extra) 200.99 kg/hr

F 6.33

L 4.86

L' 11.19

L'/G 1.60

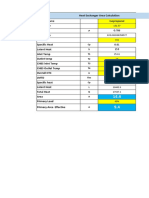

Calculation of diameter for Methanol-IPA system(Continuus)- Bottom boil up properties

Feed B.P M.W Bottoms Bottoms Density l Viscosity

(°C) (kg/kg mol) (w/w%) (mol%) (gr/cc) (kcal/kg) cp

Methanol 64.72 32 99.5 99.7331 0.98 540.0 0.600

IPA 82.22 60.09 0.5000 0.2669 0.786 159.0 2

0.9790 538.10 0.607 4

Calculation of vapor . Column Dia calculation

Composition of the boilup w/w% Max distillate rate kg/hr

Methanol 99.5 1122.62

IPA 0.5 Boilup rate 224.52 kg/hr

Refluxratio 1.60 (G=G' * A) 0.06 kg/sec

(L/G) 1.60 7.00 kgmol/hr

Aveg. temp of gas 64.81 °c Latent heat of vaporization 538.10 kcal/kg Structured packings (MELLAPAK 500Y)

Density of liquid 979.03 kg/m3 Heat load 120815.67 kcal/hr Ass. Dia. Of Col. 227 mm T 337.81 °K

Moles of distillate / 100 g distillate 3.1177 moles Area of the column 0.0387 m² Area of column 0.04058 m² P 1053.2987 m bar

Operating pressure 790 m.m Hg Diameter of the column 222.15 mm L/G 1.60 M 32.075 kg/kgmol

Aveg M.W 32.075 kg/mol Condenser Density of gas 1.204 kg/m3 F factor 1.4014

Density of gas 1.204 kg/m3 Heat load 120815.67 kcal/hr Density of liquid 979.03 kg/m3 NTSM 4.2

X-axis 0.0561 Temp. at the top 64.81 °C Flow parameter 0.056 Height 0.00 m

Ordinate1 0.21 (pg:195 Treybal) CTW entering at 32 °C Cg,max 0.08 Pr.drop 5.0 mbar/m

1" Ceramic intallox saddles 98 CTW leaving at 37 °C Cg 0.064 Total pr.drop 0.00 mbar

Viscosity of liquid 0.607 cp LMTD 30.24 °C Correction factor, C 0.70 0.000 mm of Hg

0.000607 kg/m-sec U 500 kcal/hr-m²-°c g 1.5369 kg/m2.s

Gas flow rate at flooding-G' 2.30 kg/m²-sec Main condenser area 7.9908 m² G 0.0624 kg/s

at 70% flooding 1.610 kg/m²-sec Vent condenser area 0.6990 m² Reboiler 224.5248 kg/hr

CTW Req. for Main condenser 24.1631 m3/hr Reboiler Load 120815.67 kcal/hr 7.0000 kgmol/hr

Pressure drop calculation CTW Req. for vent condenser 2.4163 m3/hr Temperature of the still at 760 m.m Hg at the end 64.8 °c T (hr) 0.0000 0.0000 0.0000 0.0000

Ordinate value 0.1029 CTW Req for sub cooler 1.5230 m3/hr Temperature of steam at 3 kg/cm2 -g 142.97 °c Distillation time 0.00 hrs

Pressure drop/m 6.746 mm Hg/m Total CTW Water Req 28.10 m3/hr l of steam at 3kg/cm²-g 508.16 kcal/kg

Total pressure drop 80.950 mm hg U 488.00 kcal/hr-m²-°c

Size of the reboiler is 3.167 m²

Steam Required is 237.751 kg/hr

(20% extra) 285.30 kg/hr

4..3 11000 3

3 12000 4.5

FEED TIME HEAT LOAD DIAMETER

MEOH-IPA 8KL/DAY 8 159123 420

ACETONE-WATER 4KL/DAY 20 178763 441

600 13 10000

710 20 6000

MAX. hold up in kettle

3 15

1 15

You might also like

- Emergency Scrubber DesignDocument36 pagesEmergency Scrubber DesignSurajit das0% (1)

- Heat Exchanger Area & Boilup Rate CalculationDocument19 pagesHeat Exchanger Area & Boilup Rate CalculationNitin KurupNo ratings yet

- Helical Super Heater DesignDocument13 pagesHelical Super Heater DesignG S DeshpandeNo ratings yet

- Final Ventury Working For Wet Alkaline ScrubberDocument11 pagesFinal Ventury Working For Wet Alkaline ScrubberNanasaheb JagtapNo ratings yet

- Sizing Column Distillation C-Factor MethodDocument20 pagesSizing Column Distillation C-Factor MethodCHANADASNo ratings yet

- Stacks: Ammonia Injection: A Route To CleanDocument8 pagesStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Pipe DimensionDocument7 pagesPipe DimensionLily NurdianaNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- Flares CalculationsDocument14 pagesFlares CalculationsAnonymous oVRvsdWzfBNo ratings yet

- Heatcalc: A Natural Gas Heat of Combustion CalculatorDocument7 pagesHeatcalc: A Natural Gas Heat of Combustion CalculatorMuzzamilNo ratings yet

- Design 2 ReboilerDocument5 pagesDesign 2 ReboilerAbdulrazzaqAL-MalikyNo ratings yet

- Boiler Efficiency Calculation MethodDocument2 pagesBoiler Efficiency Calculation MethodSomplak KudaNo ratings yet

- Boiler CalculationsDocument6 pagesBoiler CalculationsJesther Marlou C. OrongNo ratings yet

- Dps-3-1206-013-E1782-A4-2 (Final)Document449 pagesDps-3-1206-013-E1782-A4-2 (Final)Siva baalanNo ratings yet

- REACTOR DESIGN AND MATERIAL BALANCE FOR ACETONE REACTIONSDocument31 pagesREACTOR DESIGN AND MATERIAL BALANCE FOR ACETONE REACTIONSMortada OthmanNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocument2 pagesBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1100% (1)

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- Program For Calculation of Thermo Dynemic PropertiesDocument7 pagesProgram For Calculation of Thermo Dynemic PropertiesSuryakant RanderiNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- E3 Field Development Production Separator DesignDocument5 pagesE3 Field Development Production Separator DesignhaiderNo ratings yet

- Ammonia Wet Scrubber System (17-7-2018)Document12 pagesAmmonia Wet Scrubber System (17-7-2018)addin wokatuba100% (1)

- Ammonia Plant Simulation 25.08.2016Document81 pagesAmmonia Plant Simulation 25.08.2016Manish Gautam100% (1)

- Absorber and Regenerator Sizing Guide for Acid Gas Removal SystemsDocument1 pageAbsorber and Regenerator Sizing Guide for Acid Gas Removal SystemsAndres Crucetta100% (1)

- Heat Transfer Coeficient in ReactorDocument2 pagesHeat Transfer Coeficient in ReactorDavid LambertNo ratings yet

- Line Sizing Design Basis - General Specification PDFDocument11 pagesLine Sizing Design Basis - General Specification PDFSaiKumarNo ratings yet

- Proyek Mini LPG Plant Lapangan JataDocument6 pagesProyek Mini LPG Plant Lapangan JataDIANTORONo ratings yet

- Flare Stack Calculation Sheet by Erwin ADocument8 pagesFlare Stack Calculation Sheet by Erwin AaltruismNo ratings yet

- Centrif Pumps1 SpreadsheetDocument2 pagesCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Glycol Drum Sizing CheckDocument2 pagesGlycol Drum Sizing CheckmNo ratings yet

- Demister SizingDocument3 pagesDemister SizingD K SNo ratings yet

- Distillation Theoretical Stages CalculatorDocument687 pagesDistillation Theoretical Stages CalculatorgrabettyNo ratings yet

- Process Design of Solid-Liquid Separators (Project Standards and Specifications)Document10 pagesProcess Design of Solid-Liquid Separators (Project Standards and Specifications)nabilaNo ratings yet

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocument30 pagesJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- Peng Robinson MixturesDocument1 pagePeng Robinson MixturesdckristantoNo ratings yet

- Distillation Tower DesignDocument66 pagesDistillation Tower DesignHavocFireNo ratings yet

- Boiling Up Rate For Batch DistillationDocument4 pagesBoiling Up Rate For Batch DistillationKanhaiyalal PatilNo ratings yet

- Interpretation of natural draft burner clearance dataDocument1 pageInterpretation of natural draft burner clearance datamehul10941No ratings yet

- Thermal design of a 2-effect forward-feed evaporatorDocument4 pagesThermal design of a 2-effect forward-feed evaporatorAristya KurniawanNo ratings yet

- 6 Multicomponent Distillation Shortcut Method - CompleteDocument30 pages6 Multicomponent Distillation Shortcut Method - CompleteFadilla RahmiNo ratings yet

- Designing a Chlorine Sparger for Gas DispersionDocument18 pagesDesigning a Chlorine Sparger for Gas DispersionsrshahNo ratings yet

- Condenser Calculation - Shell and TubeDocument3 pagesCondenser Calculation - Shell and TubedeeptimisraNo ratings yet

- Heat Exchanger RatingDocument10 pagesHeat Exchanger RatingAnand BhiseNo ratings yet

- Radiation and Convection Heat TransferDocument5 pagesRadiation and Convection Heat TransfergsdaundhNo ratings yet

- Calculating flow and heat transfer in a cement plant cyclone preheaterDocument5 pagesCalculating flow and heat transfer in a cement plant cyclone preheaterhmaza shakeelNo ratings yet

- Process Side Mass and Heat BalancesDocument5 pagesProcess Side Mass and Heat BalancessahilchemNo ratings yet

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTNo ratings yet

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- Storage Tank Heat Loss Calculation Rev - 0Document23 pagesStorage Tank Heat Loss Calculation Rev - 0fsijestNo ratings yet

- Waste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobDocument30 pagesWaste Heat Recovery: AHEF.120.MD. Energy Efficiency Audit Guide For CHP and HobMoriyasuNguyen100% (1)

- Ammonia Design 2520of 2520equipmentsDocument32 pagesAmmonia Design 2520of 2520equipmentsapi-3714811100% (1)

- Standard Spreadsheet For Batch ColumnDocument14 pagesStandard Spreadsheet For Batch ColumnBagadi AvinashNo ratings yet

- A. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CDocument12 pagesA. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CPrad1979100% (1)

- Optimization of Distillation Column for Methanol and Water SeparationDocument131 pagesOptimization of Distillation Column for Methanol and Water SeparationFauzulNo ratings yet

- WOrd TADocument61 pagesWOrd TAFaizal AdityaNo ratings yet

- FlashDocument4 pagesFlashDrakzNo ratings yet

- He 1061Document12 pagesHe 1061vijay88666No ratings yet

- Gas Liquid Separator DesignDocument3 pagesGas Liquid Separator DesignSoheil MoradiNo ratings yet

- Flow Measuring Devices: Rotameters, Orifice Meters and Venturi MetersDocument18 pagesFlow Measuring Devices: Rotameters, Orifice Meters and Venturi MetersBagadi AvinashNo ratings yet

- Annexure 01Document1 pageAnnexure 01Bagadi AvinashNo ratings yet

- Piping Drawing - Rev-2-ModelDocument1 pagePiping Drawing - Rev-2-ModelBagadi AvinashNo ratings yet

- PDF 825490190291122Document1 pagePDF 825490190291122Bagadi AvinashNo ratings yet

- SummaryDocument1 pageSummaryBagadi AvinashNo ratings yet

- CYB03EC226625100Document1 pageCYB03EC226625100Bagadi AvinashNo ratings yet

- Inauguration 3Document1 pageInauguration 3Bagadi AvinashNo ratings yet

- Inprocess Webinario Revalidacionaliviopresion Descargaantorcha 210428Document25 pagesInprocess Webinario Revalidacionaliviopresion Descargaantorcha 210428Bagadi AvinashNo ratings yet

- DP Chocolates PVT LTD - Utility - 03.02.2022Document7 pagesDP Chocolates PVT LTD - Utility - 03.02.2022Bagadi AvinashNo ratings yet

- Overall Utility Summary - 29.10.19Document2 pagesOverall Utility Summary - 29.10.19Bagadi AvinashNo ratings yet

- Standard Spreadsheet For Continuous ColumnDocument12 pagesStandard Spreadsheet For Continuous ColumnBagadi AvinashNo ratings yet

- DP Chocolates PVT LTD - Process - 03.02.2022Document15 pagesDP Chocolates PVT LTD - Process - 03.02.2022Bagadi AvinashNo ratings yet

- Gowtham Resume-4Document2 pagesGowtham Resume-4Bagadi AvinashNo ratings yet

- PSV Scenario and CalculationDocument35 pagesPSV Scenario and Calculationminhphuongpham100% (9)

- Piping Boq Phase-2Document151 pagesPiping Boq Phase-2Bagadi AvinashNo ratings yet

- Press Release CBDT Extends Due Date For Filing of TDS Statement in Form 26Q For The Second Quarter of FY 2022 23Document1 pagePress Release CBDT Extends Due Date For Filing of TDS Statement in Form 26Q For The Second Quarter of FY 2022 23Bagadi AvinashNo ratings yet

- Standartd Sheet BoqDocument10 pagesStandartd Sheet BoqBagadi AvinashNo ratings yet

- Anfd - W2Document12 pagesAnfd - W2Bagadi AvinashNo ratings yet

- Onco SRP Layout Piperack Routing-ModelDocument1 pageOnco SRP Layout Piperack Routing-ModelBagadi AvinashNo ratings yet

- Standard Spreadsheet For Batch ColumnDocument14 pagesStandard Spreadsheet For Batch ColumnBagadi AvinashNo ratings yet

- Execution ScheduleDocument5 pagesExecution ScheduleBagadi AvinashNo ratings yet

- 09 Jun 1995 Male Obc-Ncl: Communication Address GATE Exam DetailsDocument1 page09 Jun 1995 Male Obc-Ncl: Communication Address GATE Exam DetailsBagadi AvinashNo ratings yet

- AutomationDocument208 pagesAutomationBagadi AvinashNo ratings yet

- Pre-Employment Medical ReportDocument9 pagesPre-Employment Medical ReportBagadi AvinashNo ratings yet

- SAI Life Sciences Pay SlipDocument2 pagesSAI Life Sciences Pay SlipBagadi AvinashNo ratings yet

- Air Filter Selection Chart: Filter Performance Ratings To Australian Standard AS1324.1Document3 pagesAir Filter Selection Chart: Filter Performance Ratings To Australian Standard AS1324.1Darius BooyensNo ratings yet

- Chain& Open Screw & SFD Feed ScrewDocument5 pagesChain& Open Screw & SFD Feed ScrewBagadi AvinashNo ratings yet

- Air Filter Selection Chart: Filter Performance Ratings To Australian Standard AS1324.1Document3 pagesAir Filter Selection Chart: Filter Performance Ratings To Australian Standard AS1324.1Darius BooyensNo ratings yet

- Meeting/Project Name: Date of Meeting: Project No. Meeting Facilitator: Document No. Venue Subject. 1. Meeting ObjectiveDocument2 pagesMeeting/Project Name: Date of Meeting: Project No. Meeting Facilitator: Document No. Venue Subject. 1. Meeting ObjectiveBagadi AvinashNo ratings yet

- Periodic Table MCQsDocument21 pagesPeriodic Table MCQsΙήήΘςέήτ βόγNo ratings yet

- Refrigerated Gas Plant: Gas Processing With Propane Refrigeration LoopDocument12 pagesRefrigerated Gas Plant: Gas Processing With Propane Refrigeration LoopTamer LordNo ratings yet

- Storage Tank Heat Loss Calcs - 28.09.2009Document10 pagesStorage Tank Heat Loss Calcs - 28.09.2009siva kumarNo ratings yet

- General Chemistry 2: Quarter 3 - Week 4Document20 pagesGeneral Chemistry 2: Quarter 3 - Week 4Anime KISSANIME100% (1)

- Review On Thin Film Coatings For Precision Glass MoldingDocument19 pagesReview On Thin Film Coatings For Precision Glass MoldingheheNo ratings yet

- The HydrosphereDocument14 pagesThe HydrosphereEstela Garcia AnayaNo ratings yet

- Kagan Revision CHM1Document9 pagesKagan Revision CHM1Majella FergusNo ratings yet

- Two-Component Phase Equilibrium ExperimentDocument7 pagesTwo-Component Phase Equilibrium ExperimentUtari Ika CahyaniNo ratings yet

- Transformation of Snow To IceDocument6 pagesTransformation of Snow To IceItinderjot SinghNo ratings yet

- Electron Configuration DLP CalatravaDocument13 pagesElectron Configuration DLP CalatravaGwendolyn CalatravaNo ratings yet

- O Level Chemistry Notes by Save My ExamsDocument1 pageO Level Chemistry Notes by Save My ExamsArvind Kumar0% (1)

- Tle Dry Run - Key AnswerDocument6 pagesTle Dry Run - Key AnswerIyhan S. SomosotNo ratings yet

- Activities About HydrosphereDocument4 pagesActivities About HydrosphereMaruja Ruiz100% (1)

- Semiconductor Basics: N Pérez SM Olaizola 2004Document33 pagesSemiconductor Basics: N Pérez SM Olaizola 2004swad1705No ratings yet

- Factors Influencing Venturi Scrubber PerformanceDocument27 pagesFactors Influencing Venturi Scrubber PerformanceDave Dumont100% (1)

- Machine Design Project On Ammonia Pressure VesselDocument31 pagesMachine Design Project On Ammonia Pressure VesselRobel FirewNo ratings yet

- Capillary Condensation of Nitrogen in MCM-48 and SBA-16: Kunimitsu Morishige, Noriko Tateishi, and Shingo FukumaDocument5 pagesCapillary Condensation of Nitrogen in MCM-48 and SBA-16: Kunimitsu Morishige, Noriko Tateishi, and Shingo FukumaFitra Isni RositaNo ratings yet

- MFHM I-Mid QB II Sem A y 2014-15Document3 pagesMFHM I-Mid QB II Sem A y 2014-15john_raju17No ratings yet

- Analyser Sample Handling System DesignDocument28 pagesAnalyser Sample Handling System Designmilton1987No ratings yet

- Latih Tubi Kimia Kumbe Matriculation Chemistry 2023Document7 pagesLatih Tubi Kimia Kumbe Matriculation Chemistry 2023Intan NoraisyahNo ratings yet

- Understanding the Particle Nature of MatterDocument52 pagesUnderstanding the Particle Nature of MatterJB SatesNo ratings yet

- Refrigeration CyclesDocument29 pagesRefrigeration CyclesJoulie Jonsi100% (1)

- Simulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationDocument9 pagesSimulation of Methanol Synthesis in Packed Bed Reactor Based On Gas From Biomass GasificationHaris Surya HidayatNo ratings yet

- Hs diagramHDstaaendeDocument5 pagesHs diagramHDstaaendevjakovljevicNo ratings yet

- Flow of FluidDocument28 pagesFlow of FluidJamal JalalaniNo ratings yet

- Part 4 Diffusivity Equation Line Source Radial Flow Radius Invest PDFDocument34 pagesPart 4 Diffusivity Equation Line Source Radial Flow Radius Invest PDFrasyal iyanNo ratings yet

- Centrifugal Extractor GuideDocument5 pagesCentrifugal Extractor GuideShivaniNo ratings yet

- Feed Water TankDocument8 pagesFeed Water Tankhansmru87No ratings yet

- Mini Project ReportDocument15 pagesMini Project ReportEhsan KhattakNo ratings yet

- United States Patent: (10) Patent No.: US 9,518,006 B2Document17 pagesUnited States Patent: (10) Patent No.: US 9,518,006 B2Kevin 070898No ratings yet