Professional Documents

Culture Documents

Cnc4Pc: Manual

Uploaded by

Claudio AlmiciOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cnc4Pc: Manual

Uploaded by

Claudio AlmiciCopyright:

Available Formats

Manual

CNC4PC

C11G - MULTIFUNCTION CNC BOARD Rev. 5.4

Overview

This card has been designed to provide a flexible interface and functions to your computer

projects, by using the parallel port control software. This board comes as a response to many

customers that have been asking for a faster way to connect devices and reduce the

possibility of wiring errors.

Features

• Built-in Safety Charge Pump.

It has a built-in safety charge pump that can be enabled or disabled. It also comes with an

external enabling if you would also need an additional safety control device.

• Easy installation of an On/Off switch. You can control the card

externally.

An On/Off or an additional Safety Charge Pump can easily be installed to enable or disable

the card. CNC could be dangerous machines and, remember, safety comes first. Having the

power supplied externally gives you the ability to turn your system on or off. This card is

provided with an extra pin (EN) that allows you to control the card externally by enabling or

disabling outputs externally. The card must have +5vdc supplied in the EN pin to enable

outputs. You can hardwire the connection if you are not going to use this safety feature. That

way can choose which safety feature to implement, or a combination of both, or no safety

feature at all.

• Built-in Optoisolated Variable Speed Control.

It has an analog 0-10VDC output that will convert a step signal into an analog signal that can

be used to command a commercial VFD.

• Built-in 8 amp AC Solid State Relay.

It is very useful to use a solid state relay instead of a mechanical relay for starting motors or

other devices that might produce arcs at contact. This will increase the life of the motors and

relay. This relay is also optoisolated from the rest of the board and has a replaceable fuse.

• Built-in 8 amp Solid State Relay with NO and NC positions.

Mechanical relays are very flexible because they can be used for AC or DC and come with

NO and NC (Normally Open and Normally Closed) positions.

http://cnc4pc.com 1/5 Revision: 03/05/2020

• Buffered outputs.

All inputs and outputs are buffered through the use of high speed and high power buffers, with

the result that your devices receive all the power they need.

• Output pins 1,2,3,4,5,6,7,8,9,14,16,17.

• Input pins 10,11,12,13,15.

• Status LEDs on all inputs and output connections.

No more guessing. You can SEE all your signals. Save valuable time and brainpower for

cncing.

• Inputs and output pins with close by ground connections.

Easily connect your pin by using your close by ground connection. No need to be an

electronics expert to ground all your stuff.

• All TTL 5VDC signals.

Interface directly with parallel port interface products and other CNC4PC cards. 5VDC (TTL)

cards are very common among automation devices.

• Works directly with popular CNC hardware and software.

That goes for Geckdrive, DeskCNC or Rutex and parallel port control software such as

mach2, Linux EMC, TurboCNC, CNCPlayer, CNCZeus and other/ (Not all have been tested).

• Screw-On connections for all terminals.

You only have to screw-on the wires to make all your connections.

Installation

Requirements:

A power supply with 5vdc@ 1 amperes for operation. Cnc4pc offers an electronic switching

power supply that is ideal for this board.

Wiring:

Check the sample installation below.

1. Connect the board to power.

2. Provide +5 to enable pin next to the power connection. This pin must be connected to

+5 in order to enable outputs. If you are not going to use this feature, you can hardwire

it. If you are using an e-stop button with a NC connections, you can connect this line

into this terminal, and to terminal you have assigned for e-stop. This will disable the

outputs as soon as the button is pressed. Check this wiring information:

http://cnc4pc.com/Tech_Docs/E_STOP_N_EN_Wiring.pdf.

http://cnc4pc.com 2/5 Revision: 03/05/2020

3. If you are going to use the built-in safety charge pump, configure your software to

output the safety charge signal to pin 17 and place the jumper on position 2-3. If you

are not going to use this feature, place the jumper in position 1-2. If you hardwire the

EN pin and disable the safety charge pump your outputs will be enabled at al times.

Confirm at this time that the “Outputs LED” is lit. This indicates that the output signals

are getting through.

4. You can connect the parallel port cable and run your control software. You should be

able to see the status of each pin.

5. Confirm at this time that the “Outputs LED” is lit. This indicates that the output signals

are getting through.

6. For connecting the Solid State A/C Relay, keep in mind it can only be used for AC

currents. This is ideal for motors or other devices that might create an arc on startups.

These arcs will eventually damage an electromechanical relay and the motor. Use this

connection just as you would connect any other switch.

7. Use the electromechanical relay for when you need the NO (Normally Open) and NC

(Normally Closed) connections. Feed the input current to the center pin, connect to the

NO and NC accordingly.

8. For connecting the analog output, please refer to your speed controller’s or VFD’s

documentation. There is more specific information with the documentation of the C6 –

Variable Speed Control. The circuit that comes with this board is basically the same as

the circuit that comes with the C6. there is some useful information on wiring specific

controllers. http://www.cnc4pc.com/Variable_Speed_Control_Board.htm

9. Pin Assignment:

INPUT PINS:

PIN FUNCTION

10 E-STOP

11 X-HOMING

12 Y-HOMING

13 Z-HOMING

15 X,Y,Z,A LIMIT SWITCHES (CONNECTED IN SERIES USING THE NC

CONNECTION)

This is a suggestion, you can assign this pins freely.

OUTPUT PINS:

PIN FUNCTION

1 A/C SOLID STATE RELAY (PRE-WIRED)

2 X- STEP

3 X-DIR

4 Y-STEP

5 Y-DIR

6 Z-STEP

7 Z-DIR

8 4-STEP

9 4-DIR

14 0-10 VDC ANALOG OUTPUT (PRE-WIRED)

16 ELECTROMECHANICAL RELAY (PRE-WIRED)

17 SAFETY CHARGE PUMP (PRE-WIRED)

http://cnc4pc.com 3/5 Revision: 03/05/2020

Terminals for all pins are provided. You can still access the signal on these terminals

whether you are using the pre-wired function or not.

Configuring the Analog Output:

It is strongly recommend you read your control software’s manual. You need to configure

your control software to control the spindle as if it was any other angular axis. This card

requires a 25 KHz input signal to deliver 10VDC. So you need to configure the steps per

minute and velocity, to deliver a total of 1,500,000 (25,000 hz x 60 seconds) pulses when

going at max speed. I suggest setting using 1,000 for steps per unit and 1,500 for velocity.

For acceleration values adjust them to where you feel comfortable. Keep in mind the

acceleration of the motor must also be set in your VFD.

For configuring Machx follow these steps:

1. Go to Config / Ports&Pins / Motor Outputs. Enable the spindle and select the port and

pins you wired for step and direction.

2. Go to Config / Ports&Pins / Spindle Setup. In the motor control box, check Use Spindle

Motor Output and Step /Dir Motor. Under Pulley Ratios set the pulley ratios of your

machine.

3. Go to Config / Motor Tuning / Spindle. On Steps per unit put 1,000, for velocity put

1,500. For Acceleration, choose the acceleration that you feel comfortable with. Start

slow, increase acceleration as you test your system. Under Step Pulse length, use a

number from 1 to 5. This number is directly proportional to the final voltage you will get

in the analog output. Use this number and the fine tuning pot to adjust the voltage you

want to get at max speed.

Fine Tuning:

Make sure that when you reach the max speed in your software you get 10VDC out. This

voltage can vary depending on many things, including the electrical properties of parallel

port or breakout board you are using, the length of the step pulse your software is

delivering, and the normal hi or low status of your step pin. Play with the fine tuning pot in

the card, the normally hi or low status of your pin, and the pulse width

Performance:

OUTPUT:

Output Pins 2000 khz

Voltage 5 VDC

Max Current 24 mA

INPUT:

Max Speed on pins 10-13. 10Khz.

Max speed on pin 15 2000Khz.

Voltage 0 - 5 VDC

It can work with parallel ports with voltages from 3.3 and 5 volts.

This board consumes about (depending on the features used) 1.5 amperes.

http://cnc4pc.com 4/5 Revision: 03/05/2020

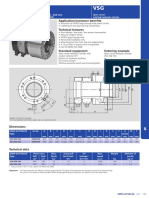

Dimensions:

Disclaimer:

Use caution. CNC machines are dangerous machines. DUNCAN USA, LLC nor Arturo

Duncan is liable for any accidents resulting from the improper use of these devices.

http://cnc4pc.com 5/5 Revision: 03/05/2020

You might also like

- LEARJET 45 AC Electrical SystemDocument4 pagesLEARJET 45 AC Electrical SystemRAFAEL MANZANILLANo ratings yet

- Installation of Sprinkler Piping System Checklist: Item No. Activity Yes No N/A RemarksDocument2 pagesInstallation of Sprinkler Piping System Checklist: Item No. Activity Yes No N/A Remarksshanawaz Shanu78% (9)

- Datacom 507 - Manual PDFDocument29 pagesDatacom 507 - Manual PDFvasilimertzani100% (1)

- GS, SY and VA Actuator Operating ManualDocument27 pagesGS, SY and VA Actuator Operating ManualJors SanzNo ratings yet

- PLDT Circuit Job Hazard AnalysisDocument2 pagesPLDT Circuit Job Hazard AnalysisDarwin AlvarezNo ratings yet

- Manual Pioneer Dehp645rDocument98 pagesManual Pioneer Dehp645raugustoNo ratings yet

- Driver Capy C11G Cnc4pcDocument19 pagesDriver Capy C11G Cnc4pccastellano_rNo ratings yet

- c11gs-r1 5 User ManualDocument21 pagesc11gs-r1 5 User Manualcastellano_rNo ratings yet

- C11G - R8 - 7 - User ManualDocument24 pagesC11G - R8 - 7 - User ManualRenato MeloNo ratings yet

- User'S Manual: JULY, 2015Document12 pagesUser'S Manual: JULY, 2015Mudassar RafiqNo ratings yet

- CNC4PC VSCB - MaunalDocument3 pagesCNC4PC VSCB - MaunalCarlos RamirezNo ratings yet

- Dkg-329 User ManualDocument43 pagesDkg-329 User ManualKỹ Sư TđhNo ratings yet

- Generator 307 USERDocument54 pagesGenerator 307 USERLiviu PopaNo ratings yet

- v570 57 t34 Vision Oplc Device ManualDocument20 pagesv570 57 t34 Vision Oplc Device Manualpoblemator12345No ratings yet

- Dkg-507 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocument54 pagesDkg-507 Automatic Mains Failure Unit: Canbus and Mpu VersionsFuqqi BhaiNo ratings yet

- C10R10 User Manual PDFDocument16 pagesC10R10 User Manual PDFGalanosNo ratings yet

- CNC Interface Board CM101 ManualDocument17 pagesCNC Interface Board CM101 ManualZorica SolunacNo ratings yet

- Dkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportDocument43 pagesDkg-329 Automatic Transfer Switch With Uninterrupted Transfer and Multiple Genset SupportLuis Fernando CuaspudNo ratings yet

- DKG-705 Automatic Mains Failure and Remote Start Unit User ManualDocument58 pagesDKG-705 Automatic Mains Failure and Remote Start Unit User ManualJefferson VieiraNo ratings yet

- A504 Manual Placa Controladora Usbcnc 4 EixosDocument11 pagesA504 Manual Placa Controladora Usbcnc 4 EixosAlexandre MarquesNo ratings yet

- DKG 517 J Manual de UsuarioDocument38 pagesDKG 517 J Manual de Usuarioenriquecourtadep100% (1)

- DataKom 507 - J - USERDocument42 pagesDataKom 507 - J - USERKhaleel KhanNo ratings yet

- IRT-660G Automatic Relay Test Set PDFDocument98 pagesIRT-660G Automatic Relay Test Set PDFRonicel Caryl de RamosNo ratings yet

- HY-TB3DV-M 3axis Driver PDFDocument10 pagesHY-TB3DV-M 3axis Driver PDFjoelgcrNo ratings yet

- DKG 705 User ManualDocument58 pagesDKG 705 User ManualMarioEnriqueAlcocerÁvila100% (1)

- 5 Series ControllerDocument9 pages5 Series ControllerSuresh RamachandranNo ratings yet

- User Guide for 5 axis TB6560 driver boardDocument14 pagesUser Guide for 5 axis TB6560 driver boardAli Asghar MuzzaffarNo ratings yet

- SimplexMotionHubManual 02bDocument14 pagesSimplexMotionHubManual 02benrique8herrera-10No ratings yet

- Dkg-307 Automatic Mains Failure and Remote Start UnitDocument29 pagesDkg-307 Automatic Mains Failure and Remote Start UnitSalmaan HaiderNo ratings yet

- Arduino DC Motor ControlDocument4 pagesArduino DC Motor ControlKathryn WorkmanNo ratings yet

- Fanuc: 5 Series ControllerDocument10 pagesFanuc: 5 Series ControllerHoangvinh DuongNo ratings yet

- AXBB E ManualDocument29 pagesAXBB E ManualKenny HebertNo ratings yet

- Arduino Hardware Guide: Stepper Motors, LCD Displays & MoreDocument10 pagesArduino Hardware Guide: Stepper Motors, LCD Displays & MoreRakesh ChaurasiaNo ratings yet

- Dkg-517-J Automatic Mains Failure UnitDocument38 pagesDkg-517-J Automatic Mains Failure Unitjose luis SerraNo ratings yet

- UPCX 530 controller firmwareDocument8 pagesUPCX 530 controller firmwareuongquocvuNo ratings yet

- Arduino Based DC Motor Speed Control Using PWMDocument5 pagesArduino Based DC Motor Speed Control Using PWMJinsha CNo ratings yet

- Dkg-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsDocument61 pagesDkg-309 Automatic Mains Failure Unit: Canbus and Mpu VersionsKhaleel KhanNo ratings yet

- NEC Format RemoteDocument15 pagesNEC Format RemoteMunish KaundalNo ratings yet

- DataKom 309J - USERDocument61 pagesDataKom 309J - USERKhaleel KhanNo ratings yet

- DataKom 207 - USERDocument28 pagesDataKom 207 - USERKhaleel KhanNo ratings yet

- Wild Thumper Controller InstructionsDocument5 pagesWild Thumper Controller InstructionsReza NaderiNo ratings yet

- Probo Step VXDocument3 pagesProbo Step VXIvan VillanevaNo ratings yet

- Vacon X5 DeviceNet Board Installation Manual DPD00Document30 pagesVacon X5 DeviceNet Board Installation Manual DPD00TanuTiganuNo ratings yet

- 509 - USER Datakom PDFDocument63 pages509 - USER Datakom PDFCarlos BarazarteNo ratings yet

- DataKom 537 - USERDocument39 pagesDataKom 537 - USERKhaleel KhanNo ratings yet

- CNC Instructables PDFDocument13 pagesCNC Instructables PDFNadim AhmedNo ratings yet

- Essentials of Motors and Motor Driver: Interfacing Proximity Sensor With MotorDocument28 pagesEssentials of Motors and Motor Driver: Interfacing Proximity Sensor With MotorAli KhormiNo ratings yet

- CNC USB Controller User ManualDocument153 pagesCNC USB Controller User ManualSathis KumarNo ratings yet

- CNC Usb ControllerDocument153 pagesCNC Usb ControllerValentin Banica0% (1)

- Railway FinalDocument56 pagesRailway FinalPnTiwariNo ratings yet

- 3 Axis TB6560 CNC Driver Board Users ManualDocument13 pages3 Axis TB6560 CNC Driver Board Users ManualJoão Luis Paiva JuniorNo ratings yet

- Rapier Switch: Quick Install GuideDocument12 pagesRapier Switch: Quick Install GuideEnzoNo ratings yet

- Dkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesDocument59 pagesDkg-509 Automatic Mains Failure Unit With J1939 Port: FeaturesAziz ArrahalNo ratings yet

- Kg-545 Automatic Mains Failure UnitDocument35 pagesKg-545 Automatic Mains Failure UnitJack GehlotNo ratings yet

- Datakom-Dkg 517Document39 pagesDatakom-Dkg 517Hernan100% (2)

- Accident Detection SystemDocument62 pagesAccident Detection SystemKarthik KingstarNo ratings yet

- 8Ch Relay PDFDocument8 pages8Ch Relay PDFFandi DwiNo ratings yet

- 309 UserDocument63 pages309 Userbatavia elektroNo ratings yet

- CNC Usb ControllerDocument153 pagesCNC Usb Controllerig16110% (1)

- DKG 545 EnglishDocument49 pagesDKG 545 EnglishrogerioNo ratings yet

- User Guide Rev 6: Safety & DisclaimersDocument6 pagesUser Guide Rev 6: Safety & DisclaimersGirinata WirawanNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Fuso Eixo ZDocument2 pagesFuso Eixo ZClaudio AlmiciNo ratings yet

- Lista de Spare Parts ODT DM 20Document1 pageLista de Spare Parts ODT DM 20Claudio AlmiciNo ratings yet

- SH 17068Document1 pageSH 17068Claudio AlmiciNo ratings yet

- Novo Documento 2020-09-23 14.29.18 - 4Document1 pageNovo Documento 2020-09-23 14.29.18 - 4Claudio AlmiciNo ratings yet

- Safety precautions documentDocument1 pageSafety precautions documentClaudio AlmiciNo ratings yet

- S40148e 3Document85 pagesS40148e 3Claudio AlmiciNo ratings yet

- S40148C 3Document81 pagesS40148C 3Claudio AlmiciNo ratings yet

- M.drive - dms08bf - Rev.05.eng - Final (Drive Barufaldi)Document23 pagesM.drive - dms08bf - Rev.05.eng - Final (Drive Barufaldi)Claudio Almici100% (2)

- Sinumerik Sinumerik 808D Commissioning ManualDocument136 pagesSinumerik Sinumerik 808D Commissioning ManualClaudio AlmiciNo ratings yet

- Safety Relay - EUCHNERDocument4 pagesSafety Relay - EUCHNERClaudio AlmiciNo ratings yet

- Band Saw Manual Velox LX330NC Color ControlDocument38 pagesBand Saw Manual Velox LX330NC Color ControlClaudio AlmiciNo ratings yet

- Up To 30 Bar EXTRA Large Through Hole Ø 165 - 204 MM Stroke Control Via Proximity SwitchDocument1 pageUp To 30 Bar EXTRA Large Through Hole Ø 165 - 204 MM Stroke Control Via Proximity SwitchClaudio AlmiciNo ratings yet

- Power DrillsDocument8 pagesPower DrillsdbNo ratings yet

- Trimble S8 - DATASHEETDocument4 pagesTrimble S8 - DATASHEETfatarnazam10No ratings yet

- 520l0541 PDFDocument36 pages520l0541 PDFdozer_kamilNo ratings yet

- Electro-Pneumatic Positioner with Keypad & Remote Infrared AutoCal CalibrationDocument2 pagesElectro-Pneumatic Positioner with Keypad & Remote Infrared AutoCal CalibrationisctomaslopezNo ratings yet

- CrsemihermeticcompressorDocument75 pagesCrsemihermeticcompressorworawan nuanpleanNo ratings yet

- NOJA-552-09 - Ground Mounted Kiosk Brochure - enDocument14 pagesNOJA-552-09 - Ground Mounted Kiosk Brochure - enRicardo Andres Benavides BenavidesNo ratings yet

- Firefly Price List 2015Document12 pagesFirefly Price List 2015Chi SantosNo ratings yet

- testo 540 pocket light meterDocument2 pagestesto 540 pocket light meterKike Velasquez BarrioNo ratings yet

- Kitchen Equipment Use and CareDocument25 pagesKitchen Equipment Use and CareDanny Ramos100% (1)

- Diagrama CatDocument2 pagesDiagrama Catastecnica100% (2)

- CR5884Document1 pageCR5884Howard BellabyNo ratings yet

- 1215Document2 pages1215Ghulam MujtabaNo ratings yet

- Preventive Maintenance Checklist for Medical Imaging EquipmentDocument24 pagesPreventive Maintenance Checklist for Medical Imaging EquipmentfortroniNo ratings yet

- Opf Pto 1 DDocument2 pagesOpf Pto 1 DDiego Cárdenas VelásquezNo ratings yet

- Proper Use of Hardware Tools for Computer RepairDocument10 pagesProper Use of Hardware Tools for Computer RepairEl G. Se ChengNo ratings yet

- DB - Pregen - Adult Mallard Mage - Animism 2Document1 pageDB - Pregen - Adult Mallard Mage - Animism 2MMKNo ratings yet

- Panel BOQDocument3 pagesPanel BOQBavakar ScribdNo ratings yet

- D223 - D224 - D225 - Exp Ricoh - SPDocument489 pagesD223 - D224 - D225 - Exp Ricoh - SPEduardo SánchezNo ratings yet

- Arc Sensor User Manual: MN026008ENDocument12 pagesArc Sensor User Manual: MN026008ENRoberto Patricio Llanquiman MuñosNo ratings yet

- Media Converter BasicsDocument9 pagesMedia Converter BasicsmitaNo ratings yet

- Bms DesignDocument22 pagesBms Designbilal almelegyNo ratings yet

- Tspir 1Document1 pageTspir 1ADRIAN AGRASO GONZALEZNo ratings yet

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- 1403E Under Over Stripper PDFDocument16 pages1403E Under Over Stripper PDFOvRrj AhmedNo ratings yet