Professional Documents

Culture Documents

Centro-Matic Flowmaster Rotary Driven Hydraulic Pump Models 85487 & 86258 Series B

Uploaded by

SIDI ahmedou yahyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centro-Matic Flowmaster Rotary Driven Hydraulic Pump Models 85487 & 86258 Series B

Uploaded by

SIDI ahmedou yahyaCopyright:

Available Formats

CENTRO-MATIC®

FlowMaster Rotary Driven Hydraulic Pump

Models 85487 & 86258

Series B

4.1A-68560-E00 Feb 2000 Form 402941 Section - C8 Page - 272D

CENTRO-MATIC® PUMP, MODELS 85487 & 86258

TABLE OF CONTENTS

Page

Safety...............................................................................................2

Specifications.................................................................................2

Description......................................................................................2 Do not exceed 3,000 PSIG (207 bar) maximum supply inlet

System Operation..........................................................................2 hydraulic pressure or 3500 PSIG (241 bar) maximum outlet

Installing the Pump......................................................................3 pressure. Exceeding the rated pressures may result in

Putting Pump into Operation.......................................................3 damage to system components and personal injury.

Maintenance & Repair...................................................................3

Dimensions....................................................................................6 DESCRIPTION

Repair Parts List............................................................................7

Troubleshooting...........................................................................8

General Description

SAFETY The Models 85487 and 86258 are pumping units designed

to operate a Centro-Matic® lubrication system. The units

Read and carefully observe these operating instructions include a vent valve to relieve the line pressure to recharge

before unpacking and operating the pump! The pump must the injectors. FlowMaster Rotary Driven Hydraulic Pump

be operated, maintained and repaired exclusively by includes pressure reducing valve, flow control valve and

persons familiar with the operating instructions. Local solenoid operated (24 VDC) On and Off valve.

safety regulations regarding installation, operation and

maintenance must be followed. The FlowMaster pump is fully automatic when used with

Model 85530 Controller and a pressure switch. The

Operate this pump only after safety instructions and this FlowMaster pump is double acting, dispensing lubricant on

service manual are fully understood. both the Up and Down strokes. This unit is designed to

be used with SL-1, SL-11, SL-32 and SL33 series injectors

or a combination of these.

Model 86258 includes follower plate and low level indicator.

Model 85487 has no follower plate and no low level

This symbol indicates a potentially hazardous situation indicator.

which, if not avoided, could result in death or serious injury.

Please refer to the 85481 operation manual, section C8, Appropriate Use

page 269 series for all other safety considerations. The pump on this unit is exclusively designed to pump

and dispense lubricants using hydraulic power only.

PRODUCT SPECIFICATIONS The maximum specification ratings should not be

exceeded.

Supply inlet hydraulic pressure, Any other use not in accordance with instructions will

maximum, PSIG (bar) - 3,000 (207) result in loss of claims for warranty and liability.

Operating working hydraulic

pressure, PSIG (bar) - 300 to 450 (21 to 31). SYSTEM OPERATION

Max. output pressure, PSIG (bar) - 3500 (241)

Hydraulic inlet flow, GPM (l/min) - Up to 7 (27)

Pump ratio with manifold - 9:1 at low inlet pressure

Operation with Model 85530 System Controller

(300 to 350 PSI [21 to 24 When Model 85530 times out, it will initiate a lube cycle.

bar]) and low inlet flow The solenoid is energized to deliver hydraulic pressure to

(below 2 gpm [7.5 lpm]) the pump and vent valve. Pump begins dispensing

Pump ratio approaches lubricant through injectors to the bearings.

11.0:1 ratio at higher

inlet pressure and flow. When all bearings have received lubricant, pressure rises

Ambient oper. temp. ºF (ºC) - -20 to +150 (-29 to +66) in the system to actuate the pressure switch. When

Operating voltage, VDC - 24 pressure switch actuates, the control is reset to de-energize

Hydraulic inlet port, In - SAE 4 the solenoid valve cutting off hydraulic oil pressure to the

Tank return port, In - SAE 6 pump and vent valve. Pump stops, pressure vents and

Maximum hydraulic pressure switch de-actuates. Control begins timing toward

fluid temp., ºF (ºC) - 200 (93) next lube event.

Weight, Lbs (Kg) -

- 86258 93 (41)

- 85487 83 (37)

Container capacity , Lbs (Kg) - 60 (27)

Page Number - 2 4.1A-68560-E00 Form 402941

CENTRO-MATIC® PUMP, MODEL 85487 & 86258

INSTALLING THE PUMP MAINTENANCE & REPAIR

Place the unit in the approximate location making sure that General Maintenance

electric and hydraulic power connections are accessible. Keep area around pump clean. Clean off filling port area

Mark center locations of the six holes at the bottom of the prior to filling reservoir. Clean area around filler after filling

reservoir. Then drill six 1/2 (13 mm) holes. The use of as lubricants will attract dirt.

7/16 (11 mm) bolts will offer some flexibility in securing the Keep lubricants clean and free of dirt and debris.

reservoir to the equipment. When replacing grease pails be especially careful to

prevent any foreign matter from entering the grease pail or

Lubricant outlet of pump should be connected to system with contaminating the grease, as it adheres to the pump.

suitable hose capable of 3,500 PSI (241 bar) working

pressure. Hydraulic inlet connection should be made with at In Case of System Malfunction

least 3/8 (9 mm) I. D. hose capable of at least 3,000 PSI (207

bar) operating pressure. Hydraulic return to tank connection

(See Trouble Shooting Chart Page 8)

line should be 3/4 (19 mm) I. D. hose or pipe. Use the Trouble Shooting Charts to determine where to

look if problems occur.

Please refer to the 85481 operation manual, section C8, page See the sections below for replacement and repair of

269 series for setting the pump pressure and flow control. specific areas of the check valve, vent valve or safety

unloader valve.

Each part is identified with a number keyed to the

Low Level Kit (Model 85490) matching part on the illustrated views.

Low Level Kit is recommended whenever higher viscosity

General recommendations of tools required are also

greases or lower temperatures are encountered and when

specified in each step.

an external indicator of lubricant level is desired. The kit is

Pay particular attention to the Warning statements to

composed of a follower with wiper and a level indicator gage

prevent personal injury and possible damage to pump

located on the cover of the reservoir. components.

PUTTING PUMP INTO OPERATION Outlet Check Service

(See Figures 1, 2, 7 & 8, Pages 5 & 6)

Filling Reservoir The pump will not build up sufficient lubricant pressure if the

To bulk fill the reservoir, remove the lower and upper pipe outlet check (47) is fouled. Foreign material may lodge

plugs from the side of the reservoir (see Figure 4). Attach beneath the Check Ball (25) or between check disc (21) and

the appropriatebulk-filling pump to the lower inlet (3/4 the seat of bushing assembly (22). Sealing surfaces of the

NPT). Fill reservoir until grease appears at the top 1/2 seat must form a perfect seal. Clean parts or replace if

NPT vent high level port.Remove the bulk-filling pump. pitted, worn or scored.

Replace both pipe plugs.

To use the reservoir with a five-gallon pail of lubricant 1. Turn off and disconnect the hydraulic and electric power

(Model 85487 only), first remove the six bolts that secure supply to the pump assembly.

the lid. Remove the entire assembly of lid, pump and vent 2. Standard tools required are a bench mounted vice, a set of

valve. Using pipe wrench or vice grips, remove the filler open end wrenches ranging from 7/16 (11 mm) to 1-1/2

nipple extension (35) (Figure 4) attached inside the (38 mm), a large 24 (600 mm) adjustable wrench and a

reservoir at the 3/4 NPT inlet nipple. Insert opened pail of smaller 10 (254 mm) adjustable wrench.

lubricant and reattach lid and pump assembly. 3. Remove bolts and lock washers (52 & 53).

4. Loosen adapter union (48). Set vent valve assembly to

Note: If five gallon pail lubrication is to be used (for Model the side.

85487 only), then the optional wing screws (38) should be 5. Remove entire outlet check assembly (47) by loosening

used in place of the hex bolt (39). adapter (46) from pump outlet.

6. Remove adapter (46) from outlet check assembly (47).

7. Remove outlet connector (26) from bushing (22).

8. Remove ball check seat (23) from outlet connector (26).

9. Inspect all check components (21, 22, 23, 25) for presence

When filling the reservoir, caution should be used as extreme of foreign material, scoring and or other damage, which

pressure can cause damage to the reservoir or serious may cause internal leakage. Replace components if

personal injury. damage is found.

Form 402941 4.1A-68560-E00 Page Number - 3

CENTRO-MATIC® PUMP, MODELS 85487 & 86258

10. If foreign material is present, clean components and 5. Now remove the entire follower assembly from the pump

reassemble. Be sure to always replace gaskets (20) & tube. After removing the follower assembly from the pump

(24) whenever vent valve is disassembled. Reverse the tube wipe off the excess grease which will allow clean

above procedure to reassemble. Torque check access to the eight bolts that must be removed.

assembly to 100 ft.-lbs. (13.5 N-M). 6. Loosen and remove the eight nuts (62) on top of the

follower.

Vent Valve Service (See Figures 3, 7 & 8 Pages 7. Remove the follower weight and the wiper (60).

5 & 6) Replace the wiper with a new one.

8. Reassemble in the reverse of the above procedure

1. Turn off and disconnect the hydraulic and electrical power

making sure that the long bolts are staggered with the

supply to the pump assembly.

small ones and that they extend below the follower per the

2. Standard tools required are a bench mounted vice, a set of

dimension shown.

open end wrenches ranging from 7/16 (11 mm) to 1-1/2

(38 mm), a large 24 (600 mm) adjustable wrench and a

smaller 10 (254 mm) adjustable wrench. Low Level Indicator (see Figure 4 & 5 Page 5)

3. Remove delivery hose (17). Loosen Adapter Union (48) If the indicator pin appears to drop prematurely or water is

and Vent Hose (14). noticeable on top of the follower then the indicator seal (1)

4. Remove bolts and lock washers (52 & 53). Remove vent may be damaged.

valve. 1. Remove the eight bolts (39) and lockwashers (40) which

6. Hold base of vent valve in vice to remove elbows (12 & 15). hold the cover on to the reservoir.

Turn vent valve in vice so that vice jaws are gripping flats 2. Inspect the reservoir gasket seal (41) for damage. If

machined on base of vent valve. damage is apparent then replace the gasket seal.

7. Remove hydraulic cylinder (27). Remove piston and 3. Remove the entire pump, vent valve and follower assembly

packing (28) from cylinder. If oil leakage was evident from the reservoir.

from side of hydraulic cylinder then replace packing. 4. Remove the retaining ring (56) from the indicator rod

8. Remove packing assembly (30). If grease leakage was assembly (3).

evident from side of hydraulic cylinder, then replace 5. Hold the indicator plug (4) with a wrench while removing

packing assembly. the indicator nut (2).

9. Inspect needle (29) and valve seat (31). If foreign matter is 6. Remove and replace the O-ring (1).

lodged and is keeping the needle from sealing in valve 7. Reassemble in the reverse of the above procedure.

seat, clean and inspect for damage. If seat appears Torque the indicator nut (2) to 20 ft.-lbs.

damaged by nicks, grooves or scouring it should be

replaced. Remove valve seat (31) from valve body (33) by Safety Unloader Valve

placing a ¾ open end wrench onto the flats and loosening (See Figure 1 Page 5)

the seat. The use of an adjustable wrench over the open Safety unloader valve (11) is not serviceable and should be

end wrench may be necessary due to the accessibility of replaced if malfunction is apparent. Upon reassembly,

the seat. tighten to 10 ft-lbs. (13.5 N-M).

10. Replace the valve seat (31) if damaged. Also be sure to

remove and replace the gasket (32) below the seat. The Safety Unloader (11) is set to open at 3,750 to 4,250 PSI

11. Reassembly is the reverse of the above procedure. lubricant pressure. If pressure Switch fails to operate and shut

Needle (29) and hydraulic cylinder (27) inside diameter off hydraulic supply to pump, the Safety Unloader will open at

should be coated with oil or grease to assist in approximately 4,000 PSI to relieve lubricant supply line pressure

assembly. (Safety Unloader is preset and cannot be adjusted.)

12. Upon reassembly tighten valve seat (31) into body (33)

using 25 ft-lbs. (39 N-M). Tighten hydraulic cylinder (27) Bare Pump Assembly (See Figure 4 Page 5)

onto valve body (33) using 100 ft-lbs. (135 N-M)

Please refer to the Operation Manual (C8, Page 269 series)

for the bare pump assembly (34).

Follower (see Figures 4, 5 & 6 Page 5)

If follower wiper appears to be damaged or does not wipe the

sides of the container effectively service may be necessary.

1. Disconnect hydraulic supply from pump.

2. Remove the eight bolts (39) and lock washers (40) which

attach the cover to the reservoir.

3. Lift the entire pump, vent valve, cover assembly and

follower out of the reservoir.

4. Unscrew the low level indicator (3) from the follower

plate (50).

Page Number - 4 4.1A-68560-E00 Form 402941

CENTRO-MATIC® PUMP, MODEL 85487 & 86258

12

Connect to Vent 22

13 Valve Port 20

10 21 23 26

24

25 1/4

NPTF

11

14

15 Connect

16 to Vent Pipe

19 16 18 17

Outlet Check Assembly (47)

Vent Assembly Figure 2

Figure 1

1/4 NPTF

34 38 (8 Reqd,

Not Shown

27

39 (8 Reqd)

28 40 (8 Reqd)

30

29

41

31

32 33

43 42

3/4 3/4 Vent

NPTF NPTF Port

Vent Valve (10)

Figure 3

44

Fill Port

3/4 NPT Male 35

Connect to Lube System

Figure 4

56

6

2

64

1

62 59

5 3 60 (8 Reqd) (8 Reqd)

4

61

(4 Reqd) 65

63

(4 Reqd)

Follower Assembly (50) (4 Reqd)

Low Level Figure 6©

Figure 5

© indicates change

Form 402941 4.1A-68560-E00 Page Number - 5

CENTRO-MATIC® PUMP, MODELS 85487 & 86258

45

47 46

49

48

17.132

(435 MM)

9.50

(242 mm)

Tank Port

SAE 6

Flow Control Valve

Solenoid Valve

Pressure Control

Valve

Figure 7

19.5

12 (495 mm)

Inlet Port

SAE 4

57 7

52

(6 Reqd)

53

54

(2 Reqd) 58

8 36 55

(4 Reqd) (4 Reqd) 30 15/16

9 51, 59 (786 mm)

(2 Reqd) (4 Reqd) 37

64

A A

50

15.12

(384mm)

Model 86258 Model 85487

Figure 8 Figure 9

© indicates change

Page Number - 6 4.1A-68560-E00 Form 402941

CENTRO-MATIC® PUMP, MODEL 85487 & 86258

SERVICE PARTS

Item Qty. Description Model Item Qty. Description Model

No. 84050 No. 84050

1 1 O-Ring *249532 33 1 Valve Body 239336

2 1 Indicator Nut 16352 34 1 Bare Pump Assembly 85481

3 1 Cable Assembly 249762 35 1 Extension Tube 249356

4 1 Indicator Plug 249357 36 4 Hex Nut 51026

5 1 Washer 48548 37 1 Vent pipe 67420

6 1 Indicator Bracket 361020 38 8 Wing Screws (not shown) 252727

7 1 Drum Cover 241085 39 8 Bolt 50015

8 4 Bolts 50016 40 8 Lock Washer 66220

9 2 Bracket 270723 41 1 Gasket *249355

10 1 Vent Valve Assembly 84980 42 1 Container Assembly 242765

11 1 Safety Unloader Assy *90942 43 1 Pipe Plug, Vent 67117

12 1 Elbow 20012 44 1 Pipe Plug, Fill 67224

13 1 Hydraulic Hose 241963 45 1 Vent Fitting 249354

14 1 Vent Hose 270726 46 1 Adapter 12213

15 1 Elbow 10160 47 1 Outlet Check Assembly 81938

16 2 Nipple 11197 48 1 Adapter Union 66645

17 1 Delivery Hose 236607 49 1 Reducer Nipple 14727

18 1 Adapter Union 66883 50 1 Follower Assembly 85489

19 1 Bushing 12018 51 4 Screw 50169

20 1 Gasket *31029 52 6 Lock Washer 66246

21 1 Pump Check Disc Assy +*80206 53 2 Bolt 50034

22 1 Outlet Check Bushing +*90204 54 1 Gasket *31010

23 1 Ball Check Seat *10313 55 1 Nut 12538

24 1 Gasket *31001 56 1 Retaining Ring *68888

25 1 Steel ball (3/8 Dia.) *66001 57 1 Elbow 249533

26 1 Outlet Connector +90860 58 1 Gasket 33152

27 1 Hydraulic Cylinder 241807 59 12 Lockwasher 66186

28 1 Piston +*244673 60 1 Wiper (Nitrile) *249331

29 1 Needle *14722 61 4 Carriage Bolt (Short) 249332

30 1 Viton Packing Assy +*239330 62 8 Nut 51304

31 1 Valve Seat *14723 63 4 Bolt (Long) 50084

32 1 Check Seat gasket *31047 64 1 O-Ring 270720

65 4 Spacer 249833

* Suggested service replacement component

+ Sold as an assembly. Individual parts not available.

* Suggested service replacement components

Form 402941 4.1A-68560-E00 Page Number - 7

CENTRO-MATIC® PUMP, MODELS 85487 & 86258

MODELS 85487 & 86258 TROUBLESHOOTING

CONDITION POSSIBLE CAUSE CORRECTIVE ACTION

Pump does not operate. No hydraulic power to pump. Turn on or connect hydraulic supply to

pump.

No pressure on gauge:

- Closed Supply line shut off valve. Open shut-off valve.

- No power to solenoid valve. Correct electrical fault.

- Faulty Solenoid. Replace solenoid.

- Pressure Reducing Valve is set too low. Reset Pressure Reducing Valve.

- Insufficient Hydraulic Fluid supply. Check hydraulic supply for proper

pressure and flow.

Pressure is shown on gauge on pump

manifold.

- Closed fluid outlet line. Check outlet line and clear

obstructions.

- Flow Control Valve is fully closed. Readjust flow control valve to 1 turn open.

- Pump is stalled due to grease Check vent valve in system.

backpressure.

Pump is seized or damaged. Dismantle the pump and repair

defective or seized component. See

pump service page.

Pump runs excessively. Pump tube malfunction. Refer to pump service page.

Outlet check damage or contamination. Repair check or remove contamination.

Vent valve damage or contamination. Repair vent valve or remove

contamination.

System component leaking. Repair leaks.

Vent valve not recieving proper pressure to Orifice fitting plugged.

keep it closed.

Injector bypassing. Repair injectors.

Pump speeds up or runs Low level of grease or reservoir Refill reservoir.

erratically. is empty.

Follower plate is stuck and separated Check follower plate and container

from grease. for damage.

Pump piston or checks are worn. Refer to pump service sheet.

Pump runs, but output is low. Insufficient hydraulic fluid supply. Check hydraulic supply and adjust

flow.

Inlet pressure too low. Increase pressure at pressure control

valve.

Faulty inlet or discharge check valve in pump. Replace faulty components. See pump

service page.

Lubricant leaking from safety Pressure of system set too high. Adjust pressure switch setting.

unloader valve. Safety unloader damaged or contaminated. Replace safety unloader.

Lubricant leaking from weep Vent valve lubricant seal damaged. Replace lubricant seal.

hole in vent valve.

Americas: Europe/Africa: Asia/Pacific:

One Lincoln Way Heinrich-Hertz-Str 2-8 25 Intl Business Park

St. Louis, MO 63120-1578 D-69183 Walldorf #01-65 German Centre © Copyright 1999

USA Germany Singapore 609916 Printed in USA

Phone +1.314.679.4200 Phone +49.6227.33.0 Phone +65.562.7960 Web site:

Fax +1.800.424.5359 Fax +49.6227.33.259 Fax +65.562.9967 www.lincolnindustrial.com

Page Number - 8 4.1A-68560-E00 Form 402941

You might also like

- FlowMaster Hydraulic PumpDocument8 pagesFlowMaster Hydraulic PumpRobert Karlo RodriguezNo ratings yet

- Centro-Matic Flowmaster Rotary Driven Hydraulic Pump Model 85219 With Grease Model 85220 Without Grease Series ADocument8 pagesCentro-Matic Flowmaster Rotary Driven Hydraulic Pump Model 85219 With Grease Model 85220 Without Grease Series ASIDI ahmedou yahyaNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- 2 PDFDocument9 pages2 PDFRicardo OjedaNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Conexiones Control de Lubricación Lincoln Model 84050 (Series "F")Document8 pagesConexiones Control de Lubricación Lincoln Model 84050 (Series "F")MERCH 06No ratings yet

- Centro-Matic: Model 84050 (Series F ) Model 85460 (Series A ) Air Operated PumpDocument8 pagesCentro-Matic: Model 84050 (Series F ) Model 85460 (Series A ) Air Operated PumpSIDI ahmedou yahyaNo ratings yet

- Bomba 85727Document16 pagesBomba 85727IthanLeonardoNo ratings yet

- FlowMaster Models85676&85678 C8 319Document20 pagesFlowMaster Models85676&85678 C8 319Juan Santiago RojasNo ratings yet

- Brands Vilter Manual VMC 400 SeriesDocument234 pagesBrands Vilter Manual VMC 400 SeriesJose Ricardo Prado SandovalNo ratings yet

- MD of 241 Vil Ter Compressor ManualDocument234 pagesMD of 241 Vil Ter Compressor Manualsergiopaul100% (1)

- 35391B RevaDocument234 pages35391B RevaFelipe FloresNo ratings yet

- A SeriesDocument10 pagesA SeriesagorbatenkoNo ratings yet

- Eng Rasad orDocument8 pagesEng Rasad orhernanaguirre7No ratings yet

- New Holland Skid Steer Service Manual Fo S NH l225Document6 pagesNew Holland Skid Steer Service Manual Fo S NH l225Rahim MehdiyevNo ratings yet

- H-Series Motor Graders: Slide/Text ReferenceDocument39 pagesH-Series Motor Graders: Slide/Text ReferenceVictorDjChiqueCastillo100% (1)

- U.S. Patent No. 6,102,676 U.S. Patent 6,102,676: Section Form 404383 JAN - 2012Document41 pagesU.S. Patent No. 6,102,676 U.S. Patent 6,102,676: Section Form 404383 JAN - 2012InsannulNo ratings yet

- 2 - Manut. Hydraulic M2Document64 pages2 - Manut. Hydraulic M2Ney HoraNo ratings yet

- Flow Divider Designs: HydraulikDocument40 pagesFlow Divider Designs: HydraulikHugo Muñoz ValdiviaNo ratings yet

- Pump 84962 B Section c8 Page 240b HydrauDocument8 pagesPump 84962 B Section c8 Page 240b Hydrauleaw81No ratings yet

- Lincoln FlowMaster Rotary Driven Pump Manual Parts Repairs Breakdown 270691Document41 pagesLincoln FlowMaster Rotary Driven Pump Manual Parts Repairs Breakdown 270691Pioneer PaperboyNo ratings yet

- ReliefDocument3 pagesReliefMohamed OmarNo ratings yet

- Osm-110 45000-200Document90 pagesOsm-110 45000-200Taller cncNo ratings yet

- Osm-099 55000-150Document80 pagesOsm-099 55000-150Taller cncNo ratings yet

- GX35 GX60 GS100 Operating InstructionsDocument18 pagesGX35 GX60 GS100 Operating InstructionsMiguel Jiménez FloresNo ratings yet

- Guide To The EJC 65 Hydraulic System: GeneralDocument50 pagesGuide To The EJC 65 Hydraulic System: GeneralSanti Al ElricNo ratings yet

- Descritivo de Manutenção - Guindaste Appleton Marine - SWL 30 TonsDocument9 pagesDescritivo de Manutenção - Guindaste Appleton Marine - SWL 30 TonsSérgio Meneses VieiraNo ratings yet

- ZT 2800 3100 3400 PDFDocument52 pagesZT 2800 3100 3400 PDFScott ZastrowNo ratings yet

- Scroll Compressor R22 Application GuidelinesDocument17 pagesScroll Compressor R22 Application GuidelinesMechanical PowerNo ratings yet

- Manual VilterDocument182 pagesManual VilterHernan GuerraNo ratings yet

- Hose Reel Pump Assembly: Assembly, Disassembly and Repair GuideDocument18 pagesHose Reel Pump Assembly: Assembly, Disassembly and Repair GuideВиталий КозловскийNo ratings yet

- Safety For Hydraulic System: Inter Plant Standard - Steel IndustryDocument22 pagesSafety For Hydraulic System: Inter Plant Standard - Steel IndustryWarrenNo ratings yet

- Hydraulic 03Document148 pagesHydraulic 03Алексей МироновNo ratings yet

- Db55 Transmission Service ManualDocument64 pagesDb55 Transmission Service Manualgustavo100% (1)

- DROPSADocument27 pagesDROPSAcguillermosmNo ratings yet

- Hydraulic System RequirementsDocument9 pagesHydraulic System RequirementsGuille GiraldoNo ratings yet

- 963 C Pressure TapsDocument105 pages963 C Pressure TapsBaron KasoziNo ratings yet

- MM Dresser FinalDocument236 pagesMM Dresser FinalPriyabrat Mohanty100% (1)

- Flowmaster Rotary Driven Electric Pump, 120/230 Vac Models: 85598 (400#) and 85599 (120#) Series "A"Document25 pagesFlowmaster Rotary Driven Electric Pump, 120/230 Vac Models: 85598 (400#) and 85599 (120#) Series "A"Rhyan FFNo ratings yet

- Flowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ADocument11 pagesFlowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ASIDI ahmedou yahyaNo ratings yet

- Pressure Reducing Valve (Pilot Oil) - Test and AdjustDocument3 pagesPressure Reducing Valve (Pilot Oil) - Test and AdjustgeniusnetxxxxNo ratings yet

- Flow Divider DesignsDocument38 pagesFlow Divider DesignssalesNo ratings yet

- Robinair Bombas de Vacío 15401 601Document32 pagesRobinair Bombas de Vacío 15401 601MarcWorld100% (1)

- Relief Valve (Line) - Test and Adjust: Shutdown SIS Previous ScreenDocument5 pagesRelief Valve (Line) - Test and Adjust: Shutdown SIS Previous Screenchanlin0% (1)

- 950H Valvula de LinhaDocument8 pages950H Valvula de LinhaAnderson OliveiraNo ratings yet

- FlowmwterDocument68 pagesFlowmwterjimmjimNo ratings yet

- Dokumen - Tips Operating and Maintenance Instructions Operating and Maintenance InstructionsDocument61 pagesDokumen - Tips Operating and Maintenance Instructions Operating and Maintenance InstructionsAri sofyan100% (1)

- Sect. 4 Tech Docum PC7 AutoLube - 1209 PDFDocument46 pagesSect. 4 Tech Docum PC7 AutoLube - 1209 PDFAlexis MikeNo ratings yet

- Instruction Manual AND Parts List For: SRM00032 Rev. 01 (13-0218) July 2013Document17 pagesInstruction Manual AND Parts List For: SRM00032 Rev. 01 (13-0218) July 2013royert80No ratings yet

- P28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayDocument8 pagesP28 and P128 Series Lube Oil Controls With Built-In Time Delay RelayFreddy de los SantosNo ratings yet

- Hydraulic Pump - Test and Adjust: Pantalla AnteriorDocument14 pagesHydraulic Pump - Test and Adjust: Pantalla Anterioriver_millan100% (1)

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorDocument18 pagesHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesNo ratings yet

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorDocument18 pagesHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesNo ratings yet

- Testing and Adjusting Hydraulic System: Shutdown SIS Previous ScreenDocument55 pagesTesting and Adjusting Hydraulic System: Shutdown SIS Previous Screenluis eduardo corzo enriquezNo ratings yet

- Linked PDFDocument150 pagesLinked PDFroparts cluj100% (2)

- Osm-093 57800-100Document86 pagesOsm-093 57800-100Taller cncNo ratings yet

- Oil Country - Llave Hidraulica 57853-100 (OSM-166 57853-100)Document75 pagesOil Country - Llave Hidraulica 57853-100 (OSM-166 57853-100)jhogs74100% (3)

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Hydraulic Start System DescriptionDocument5 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Hydraulic Start System DescriptionAndrea Cupello100% (1)

- Centro-Matic: Model 85535 Controller Series "C"©Document6 pagesCentro-Matic: Model 85535 Controller Series "C"©SIDI ahmedou yahyaNo ratings yet

- Air Operated Grease Pump 075Document4 pagesAir Operated Grease Pump 075SIDI ahmedou yahyaNo ratings yet

- Flowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ADocument11 pagesFlowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ASIDI ahmedou yahyaNo ratings yet

- Em 0307530001Document7 pagesEm 0307530001SIDI ahmedou yahya100% (1)

- Em 0307530001Document7 pagesEm 0307530001SIDI ahmedou yahya100% (1)

- Senr8425senr8425 SisDocument2 pagesSenr8425senr8425 SisSIDI ahmedou yahyaNo ratings yet

- Making The Supply Side Connection: Article 705: by Brian MehalicDocument3 pagesMaking The Supply Side Connection: Article 705: by Brian MehalicSIDI ahmedou yahyaNo ratings yet

- By Engr. Sami Alalwani For RawaqDocument19 pagesBy Engr. Sami Alalwani For RawaqSIDI ahmedou yahyaNo ratings yet

- International Electrotechnical Commission - World Voltage Frequency and Plug Type by LocationDocument20 pagesInternational Electrotechnical Commission - World Voltage Frequency and Plug Type by LocationSIDI ahmedou yahyaNo ratings yet

- 15-16 en Cours FR1040 FR104A FR1050 Handbook 15-16Document50 pages15-16 en Cours FR1040 FR104A FR1050 Handbook 15-16SIDI ahmedou yahyaNo ratings yet

- By Engr. Sami Alalwani For RawaqDocument20 pagesBy Engr. Sami Alalwani For RawaqSIDI ahmedou yahyaNo ratings yet

- 15-16 en Cours FR1040 FR104A FR1050 Handbook 15-16Document50 pages15-16 en Cours FR1040 FR104A FR1050 Handbook 15-16SIDI ahmedou yahyaNo ratings yet

- Article 705: Interconnected Electric Power Production SourcesDocument3 pagesArticle 705: Interconnected Electric Power Production SourcesSIDI ahmedou yahyaNo ratings yet

- By Engr. Sami Alalwani For RawaqDocument20 pagesBy Engr. Sami Alalwani For RawaqSIDI ahmedou yahyaNo ratings yet

- Utilization Voltages 1,000 VDC: in Nonresidential PV ApplicationsDocument13 pagesUtilization Voltages 1,000 VDC: in Nonresidential PV ApplicationsSIDI ahmedou yahyaNo ratings yet

- PV System SimplifiedDocument9 pagesPV System SimplifiedSIDI ahmedou yahyaNo ratings yet

- INTER ROW SHADING Problem Logan UtahDocument10 pagesINTER ROW SHADING Problem Logan UtahSIDI ahmedou yahyaNo ratings yet

- SP3.6 Array Voltage ConsiderationsDocument8 pagesSP3.6 Array Voltage ConsiderationsSIDI ahmedou yahyaNo ratings yet

- Solar Pro Issue 8.2 - Distribution and Substation TransformersDocument11 pagesSolar Pro Issue 8.2 - Distribution and Substation TransformersSIDI ahmedou yahyaNo ratings yet

- Making The Supply Side Connection: Article 705: by Brian MehalicDocument3 pagesMaking The Supply Side Connection: Article 705: by Brian MehalicSIDI ahmedou yahyaNo ratings yet

- Tracked: PV Array Systems & PerformanceDocument7 pagesTracked: PV Array Systems & PerformanceSIDI ahmedou yahyaNo ratings yet

- By Engr. Sami Alalwani For RawaqDocument19 pagesBy Engr. Sami Alalwani For RawaqSIDI ahmedou yahyaNo ratings yet

- International Electrotechnical Commission - World Voltage Frequency and Plug Type by LocationDocument20 pagesInternational Electrotechnical Commission - World Voltage Frequency and Plug Type by LocationSIDI ahmedou yahyaNo ratings yet

- Article 705: Interconnected Electric Power Production SourcesDocument3 pagesArticle 705: Interconnected Electric Power Production SourcesSIDI ahmedou yahyaNo ratings yet

- FL Sim HDocument387 pagesFL Sim HFadil TufekcicNo ratings yet

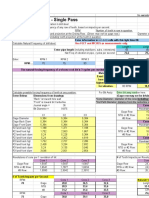

- Vibration Analysis - Single Pass: Use FEET and INCHES As Measurements OnlyDocument4 pagesVibration Analysis - Single Pass: Use FEET and INCHES As Measurements OnlySIDI ahmedou yahyaNo ratings yet

- Vibration Analysis - Single Pass: Use FEET and INCHES As Measurements OnlyDocument4 pagesVibration Analysis - Single Pass: Use FEET and INCHES As Measurements OnlySIDI ahmedou yahyaNo ratings yet

- Qualitrol Manual EnglezaDocument21 pagesQualitrol Manual EnglezaPriscilla SimsNo ratings yet

- ESAB LAX 320, LAX 380 Service ManualDocument44 pagesESAB LAX 320, LAX 380 Service ManualTommy MellemstrandNo ratings yet

- Diagrama Eletrico D5MXL-4JSDocument2 pagesDiagrama Eletrico D5MXL-4JSdosbrejoNo ratings yet

- LD5 Installation ManualDocument66 pagesLD5 Installation Manualarlindojl100% (1)

- Swimming PoolsDocument17 pagesSwimming PoolsspzemunNo ratings yet

- Windward IV 52 Ceiling Fan Owner's ManualDocument31 pagesWindward IV 52 Ceiling Fan Owner's ManualLisa RibbersNo ratings yet

- Prius ZVW5Document42 pagesPrius ZVW5Micah K100% (1)

- 1 - Installation Manual - OTS3-PigtailsDocument8 pages1 - Installation Manual - OTS3-PigtailsJavier LeónNo ratings yet

- Instalation Practice For Axle Counter On Indian RailwaysDocument36 pagesInstalation Practice For Axle Counter On Indian RailwaysVikas Srivastav100% (1)

- 522 2015 World Solar Challenge Event RegulationsDocument46 pages522 2015 World Solar Challenge Event RegulationsganamNo ratings yet

- Service ManualDocument163 pagesService Manualcmorley5057No ratings yet

- 1FT613-1FT616 Edition 03-2007Document136 pages1FT613-1FT616 Edition 03-2007Trevor SalazarNo ratings yet

- RCA222 Series Differential Pressure Transducer Remaining Filter Service Life IndicatorDocument2 pagesRCA222 Series Differential Pressure Transducer Remaining Filter Service Life IndicatorFaisal ImranNo ratings yet

- TF420 EnglishDocument46 pagesTF420 EnglishzackchenrogersNo ratings yet

- SPC Epsilon3 enDocument16 pagesSPC Epsilon3 enGiselle Sanchez100% (1)

- 4011a PDFDocument50 pages4011a PDFlungu mihaiNo ratings yet

- KG5071Document2 pagesKG5071Nikita SushkoNo ratings yet

- Panasonic KX-T7020 Reference GuideDocument16 pagesPanasonic KX-T7020 Reference Guidejveraf_No ratings yet

- Bs-300 Preventive Maintenance Manual v1-1.0 enDocument19 pagesBs-300 Preventive Maintenance Manual v1-1.0 ennery castro100% (1)

- Bissell Quick Steamer ManualDocument12 pagesBissell Quick Steamer ManualjewbatNo ratings yet

- Basic: Camera User GuideDocument26 pagesBasic: Camera User GuideReloikaNo ratings yet

- 4136 Agilent-Technologies MGA-85563 02Document6 pages4136 Agilent-Technologies MGA-85563 02RodolfoBucaloNo ratings yet

- P17 Tempra Pro Plugs, Mobile Sockets, Fixed Sockets, Surface Mounting Sockets and Appliance Inlets - IP 66/67 - 63 A - 125 ADocument8 pagesP17 Tempra Pro Plugs, Mobile Sockets, Fixed Sockets, Surface Mounting Sockets and Appliance Inlets - IP 66/67 - 63 A - 125 AAbdulaziz AlrawiNo ratings yet

- cc1390 Modulay LeafletDocument6 pagescc1390 Modulay LeafletShadi AbdelsalamNo ratings yet

- ESM-48100U5 V300R008C10 User ManualDocument70 pagesESM-48100U5 V300R008C10 User ManualHafzal HaniefNo ratings yet

- LCD TV: Service ManualDocument63 pagesLCD TV: Service ManualJonathan Da SilvaNo ratings yet

- PDFDocument68 pagesPDFneilNo ratings yet

- Catalogo General Sonatest PDFDocument105 pagesCatalogo General Sonatest PDFjimmy david espinoza mejiaNo ratings yet

- AN5006-20 Small-Sized Integrated Access Device Technical Manual (Version B)Document102 pagesAN5006-20 Small-Sized Integrated Access Device Technical Manual (Version B)Marcos AlexandreNo ratings yet

- MAX2982 Evaluation Kit Operation Manual V1.0Document33 pagesMAX2982 Evaluation Kit Operation Manual V1.0paulbodaNo ratings yet