Professional Documents

Culture Documents

Centro-Matic: Model 85535 Controller Series "C"©

Uploaded by

SIDI ahmedou yahyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centro-Matic: Model 85535 Controller Series "C"©

Uploaded by

SIDI ahmedou yahyaCopyright:

Available Formats

CENTRO-MATIC®

Model 85535 Controller

Series “C”©

© Indicates change

JAN - 06 Form 404005 Section - C8 Page - 278B

CENTRO-MATIC®

Table of Contents The memory feature will work as follows:

Safety........................................................................................2 Dipswitch set to “Memory Off” – Will result in a lube cycle each

Controller Operation...................................................................2 time power is turned on. Lube cycle will start at the beginning

Description................................................................................2 of the on time setting.

Field Connections.......................................................................3

Wiring Diagram...........................................................................3 Dipswitch set to “Memory On”

Contoller Components and Setting the Controller....................4 1. Power is turned off during the off time (time between lube

Repair Parts List........................................................................4 cycles). When turning power back on will cause the lube

Dimensions................................................................................5 cycle to continue from the point of interruption.

Troubleshooting....................................................................6 2. Power is turned off during the on time or pumping time.

Turning power back on will cause the lube cycle to start at

Safety the beginning of the on time setting.

Read and carefully observe these operating instructions before

unpacking and operating the controller! The Timer Mode

controller must be operated, maintained and repaired exclu- When the dipswitch is set to the timer mode, amount of time

sively by persons familiar with the operating that the pump is on will be determined by the setting of the

instructions. Local safety regulations regarding installation, dipswitch. Time will be either 30 seconds or 2 minutes.

operation and maintenance must be followed.

Operate this controller only after safety instructions and this

Controller Mode

When the dipswitch is set to the controller mode, a

service manual are fully understood.

pressure switch must be installed in the lube supply line. This

will provide pressure-monitoring capabilities. The

pressure switch will reset the controller when the set pres-

sure is detected. The controller will initiate an alarm when

the pump fails to develop sufficient pressure to actuate the

This symbol identifies

pressure switch within the dipswitch setting of 30 seconds or

the potential for a

2 minutes.

hazardous situation.

If this warning is not

followed, a serious Description

injury could occur.

General Description

Model 85535 controller is used to program the cycle

Controller Operation frequency of a lubrication pump. Lube cycles are

The time between lube events is determined by the setting of determined by the setting of internal switches. The cycles

the rotary switch, which selects the numeral setting, and the times are selected to meet system requirements. During the

dipswitch, which selects the units in either minutes or hours. “ON” time, the air to the pump solenoid will be

energized.

When used in the timer mode, the pump will remain on for the

amount of time that was selected by the dipswitch. Time will Appropriate Use

be either 30 seconds or 2 minutes (see Timer Mode). • Model 85535 is exclusively designed for use in a

Centralized Lubrication System.

When used in the controller mode, the amount of time that the • The maximum ratings given should not be exceeded.

pump is on is determined by the closing of a pressure switch in • Any other use not in accordance with the instructions will

the lube supply line (see Controller Mode). Failure of the pres- result in loss of claim for warranty and liability.

sure switch to close within the time setting of the dipswitch,

either 30 seconds or 2 minutes, will result in an alarm condi- Product Specification:

tion. The alarm LED will turn on and the alarm contact will Input Voltage: 21 VDC to 30 VDC

close. The controller will continue to initiate lube cycles while Current Consumption: 100 MA (less external load)

in alarm. Load Relay Contact: 2 amps inductive load at 30 VDC

Alarm Relay Contact: 2 amps inductive load at 30 VDC

When the low-level switch closes, the alarm LED will turn on Enclosure: NEMA 12

and the alarm contact will close. The controller will continue to Temperature Range: -40° F to 150° F (-40° C to 65° C)

initate lube cycles while in alarm. Alarm condition will remain Net Weight: 4 lbs.

until low-level switch opens. Off Time (adjustable): 30 seconds minimum

30 hours maximum

Pressing the manual lube button on the enclosure cover will On Time: 30 seconds minimum

always initiate a lube event. 2 minutes maximum

Lubrication System: Centro Matic

Page Number - 2 Form 404005

CENTRO-MATIC®

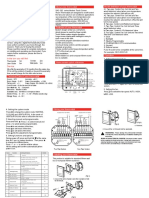

Field Connections

Terminal Strip 1 through 8 Terminal Strip 1 through 4

Terminal 1 Bat + Terminal 1 Low level switch

Terminal 2 Bat - Terminal 2 (closes to indicate an alarm)

Terminal 3 24 VDC source for Terminal 3 System pressure switch (closes to end lube

Terminal 4 external air to pump solenoid. Terminal 4 cycle). Only used in the Controller Mode.

Terminal 5 Dry alarm contact Terminal Strip AB

Terminal 6 (contact closes on fault) Terminal A Remote Normally Open

Terminal B Manual Lube Switch

Observe correct polarity for Terminals 1, 2, 3

and 4.

Illustration 1©

Wiring Diagram

1. Incoming Power: 24 VDC.

2. 24 VDC Air Solenoid Valve.

3. Optional Alarm wired by customer.

4. Keypad with indicator lights and manual lube push button.

5. Optional Low Level Switch wired by customer.

6. Pressure Switch wired by customer. Not needed if used in the timer mode.

© 7. Remote Manual Lube Switch.

© Indicates change

Form 404005 Page Number - 3

CENTRO-MATIC®

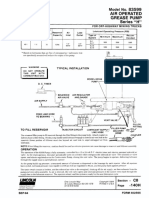

Controller Components and Setting the Off Time Switch - See Illustration 2

Using the Rotary Switch you can select .5, 1, 2, 4, 8, 15, 24 or

Controller 30. The units are either minutes or hours as determined by the

mode switch setting.

Mode Switch Identification - See Illustration 2

30 seconds or 2 minutes - Select the maximum amount

Enclosure Cover - See Illustration 2

of “On Time”.

Green LED - Indicates that power is applied to the

Timer or Controller - Select Timer Mode or

controller.

Controller Mode.

Green LED - Indicates that the pump is on.

Hours or Minutes - Select units for the “Off Time”

Red LED - Indicates an alarm condition.

used with the Rotary Switch.

Manual Lube - Pressing will initiate a lube cycle.

Memory Off or Memory On - Select memory feature.

Repair Parts List

Item Quan. Description Part Number

1 1 Timer Board 250599

2 1 Keypad Ass’y 249695

1 © 2

Illustration 2

© Indicates change

Page Number - 4 Form 404005

CENTRO-MATIC®

3 1/2” (89 mm)

5/16” (8 mm Dia. Mtg. Holes)

(4 places)

7 - 1/2”

(191 mm)

6 - 3/4”

© (171 mm)

2”

Conduit Hole

(51 mm) Conduit Plug

4 - 15/16”

(125 mm)

Dimensions

© Indicates change

Form 404005 Page Number - 5

CENTRO-MATIC®

Lube System without Alarm Monitoring

Condition Possible Cause Corrective Action

Controller does not operate. No electric power to controller. Turn on electric power to pump. “Power” L.E.D.

should light, “PUMP ON” L.E.D. should light when

“MANUAL LUBE” is pressed.

“PUMP ON” L.E.D. lights, but load Printed circuit board failure. Remove and replace.

connected to terminals 3 & 4 will

not energize.

Load connected to terminals 3 & 4 Printed circuit board failure or Remove and replace.

energized, but “PUMP ON” L.E.D. keypad failure.

does not light.

Bearing points are over lubricated. Timer/Controller memory mode Turn on memory mode of timer/controller.

is set to off.

Injector output adjustment setting Readjust to lower setting.

too high.

Bearing points are under Timer/Controller cycle time Set to longer cycle time or reevaluate lube

lubricated. setting too low. requirements.

Injector output adjustment setting Readjust to right setting.

too low.

Timer/Controller cycle timer Set to shorter cycle time or reevaluate lube

setting does not deliver lubricant requirements.

often enough.

System too large for pump output. Calculate system requirements per planning

manual.

Additional Troubleshooting when Alarm Monitoring is used

Some, but not all, of the injectors Timer/Controller is set to “Timer”. Set Timer/Controller to “Controller Mode.

are delivering lubricant. There is Pressure switch setting is too low. Adjust pressure setting to setting high enough for

no alarm condition. all injectors to cycle.

“Lube Alarm” L.E.D. turns and Bad electrical connection between Check all wiring between Pressure Switch and

stays on. Pressure Switch and Timer/ Timer/Controller.

Controller.

Pressure switch setting is too Adjust pressure switch to setting high enough for

high. all injectors to cycle.

Pressure Switch is defective. Repair or replace.

Printed circuit board is defective. Replace printed circuit board.

Low level switch wired incorrectly. Check low level switch wiring and correct if

necessary. Contact closure must be on low level

condition.

Low system air pressure. Increase air pressure.

Americas: Europe/Africa: Asia/Pacific:

One Lincoln Way Heinrich-Hertz-Str 2-8 51 Changi Business Park

Central 2

St. Louis, MO 63120-1578 D-69183 Walldorf

#09-06 The Signature © Copyright 2006

USA Germany Singapore 486066

Phone +1.314.679.4200 Phone +49.6227.33.0 Printed in USA

Phone +65.6588.0188 Web site: www.lincolnindustrial.com

Fax +1.800.424.5359 Fax +49.6227.33.259 Fax +65.6588.3438

Page Number - 6 Form 404005

You might also like

- Cummins - Transfer Switches and Control - ts1310 - PDFDocument4 pagesCummins - Transfer Switches and Control - ts1310 - PDFantonio pedro100% (1)

- Mushrooms, Electricity, and Neural Networks! - Herbal Visionz.Document22 pagesMushrooms, Electricity, and Neural Networks! - Herbal Visionz.nicungNo ratings yet

- LEF, DEF & LIB - Physical Design, STA & Synthesis, DFT, Automation & Flow Dev, Verification Services. Turnkey ProjectsDocument6 pagesLEF, DEF & LIB - Physical Design, STA & Synthesis, DFT, Automation & Flow Dev, Verification Services. Turnkey ProjectsHARISH DAMARLANo ratings yet

- Dixell XR60CDocument4 pagesDixell XR60CCarlos0% (1)

- HGM6110N 6120N 6110NC 6120NC 6110CAN 6120CAN En-1Document11 pagesHGM6110N 6120N 6110NC 6120NC 6110CAN 6120CAN En-1Marcos LunaNo ratings yet

- Goodman TSTATG1152-2 Owner's Manual enDocument23 pagesGoodman TSTATG1152-2 Owner's Manual enkrievkalnsgNo ratings yet

- Automatic Controls for Heating and Air Conditioning: Principles and ApplicationsFrom EverandAutomatic Controls for Heating and Air Conditioning: Principles and ApplicationsRating: 4 out of 5 stars4/5 (2)

- YM91ZU0009P1NAR0-sk160 sk190Document754 pagesYM91ZU0009P1NAR0-sk160 sk190hernando ramosNo ratings yet

- Alpha Lubricator Emergency OperationDocument2 pagesAlpha Lubricator Emergency OperationTimmyJuriNo ratings yet

- SP3.6 Array Voltage ConsiderationsDocument8 pagesSP3.6 Array Voltage ConsiderationsSIDI ahmedou yahyaNo ratings yet

- G2 Pulse Lubrication Controller Programming & Wiring GuideDocument4 pagesG2 Pulse Lubrication Controller Programming & Wiring GuideNova Kurniawan100% (1)

- Lincoln CentroMatic 85535 ControllerDocument6 pagesLincoln CentroMatic 85535 ControllerveereshNo ratings yet

- Gasoline GeneratorDocument1 pageGasoline GeneratormuhammadnainNo ratings yet

- JHD BNWAS JHD01-ManualDocument22 pagesJHD BNWAS JHD01-ManualVictorMejia100% (1)

- Tesla's Electric CarDocument5 pagesTesla's Electric CarRossen Petrov0% (1)

- Em 0307530001Document7 pagesEm 0307530001SIDI ahmedou yahya100% (1)

- Em 0307530001Document7 pagesEm 0307530001SIDI ahmedou yahya100% (1)

- User Manual: HGM6100K Series Genset ControllerDocument30 pagesUser Manual: HGM6100K Series Genset ControllerRODRIGO_RALONo ratings yet

- Waste Segregator ReportDocument33 pagesWaste Segregator ReportVinodNKumar25% (4)

- 1.CMOS VLSI DesignDocument2 pages1.CMOS VLSI DesignSYAMALA100% (1)

- Rt500 1 Service AdjustmentsDocument29 pagesRt500 1 Service AdjustmentsjulianmataNo ratings yet

- FL Sim HDocument387 pagesFL Sim HFadil TufekcicNo ratings yet

- Manual Transmisor FM Vimesa 1KW XPT1000Document128 pagesManual Transmisor FM Vimesa 1KW XPT1000Oscar Rendón50% (2)

- Plm2k-Vda M00219Document26 pagesPlm2k-Vda M00219Mohamed Tahar Boussaha50% (2)

- BARD S8201 169 InstructionsDocument2 pagesBARD S8201 169 InstructionsFotografias WONo ratings yet

- Tab 2 - Instruments OEMDocument111 pagesTab 2 - Instruments OEMJocelyn Ambar Gallardo ArismendiNo ratings yet

- 1ZSE 5492-155 en Rev 4Document12 pages1ZSE 5492-155 en Rev 4navsonaNo ratings yet

- Kriwan Ops 1 Oil Pressure SensorDocument1 pageKriwan Ops 1 Oil Pressure Sensoralasad4everNo ratings yet

- GO Switch, Seal Fail Relay PDFDocument2 pagesGO Switch, Seal Fail Relay PDFtotovasiNo ratings yet

- Aux BLR FD FanDocument6 pagesAux BLR FD Fankleber17100No ratings yet

- Manual LubDocument25 pagesManual LubMota Guine InformaçõesNo ratings yet

- Intelligent Pump Controller Installation & Operation ManualDocument29 pagesIntelligent Pump Controller Installation & Operation ManualYesid Luna100% (1)

- Microprocessor Controlled Load Panel Manual SectionDocument3 pagesMicroprocessor Controlled Load Panel Manual SectionBojan KitanovskiNo ratings yet

- XR80C - XR80D: Milk Tank ControllersDocument4 pagesXR80C - XR80D: Milk Tank ControllersJennifer Eszter SárközyNo ratings yet

- XW60LS GB Rel.1.0 27.10.06Document4 pagesXW60LS GB Rel.1.0 27.10.06Jennifer Eszter SárközyNo ratings yet

- Pump SeetingDocument11 pagesPump SeetingFaisal AlotaibiNo ratings yet

- dIXEL Installing and Operating Instructions Rel.2.0 - Cod. 1598002170, Manual XW60LDocument4 pagesdIXEL Installing and Operating Instructions Rel.2.0 - Cod. 1598002170, Manual XW60LAlexey IvanovNo ratings yet

- Water Level Limiter 932 (Instruction of Use)Document2 pagesWater Level Limiter 932 (Instruction of Use)Miraz RahmanNo ratings yet

- SI0283Document4 pagesSI0283Mosleh AbdelkaderNo ratings yet

- SuperTAPP SG RelayDocument10 pagesSuperTAPP SG RelayAtiqun NabiNo ratings yet

- Installation Instructions Operator: Save These Instructions For Future Use!Document8 pagesInstallation Instructions Operator: Save These Instructions For Future Use!jabarnesNo ratings yet

- 2 PDFDocument9 pages2 PDFRicardo OjedaNo ratings yet

- 16e09 101 Installation Operation Instructions en Us 4209196 PDFDocument16 pages16e09 101 Installation Operation Instructions en Us 4209196 PDFDaniel MontesNo ratings yet

- Fitting and Calibration Instruction For Maximum 3A OutputDocument10 pagesFitting and Calibration Instruction For Maximum 3A OutputengenheiroalencarNo ratings yet

- Gu3303 Controller ManualDocument44 pagesGu3303 Controller ManualFlavio SemineloNo ratings yet

- Features: LMR Electric Fire Pump ControllersDocument7 pagesFeatures: LMR Electric Fire Pump Controllerstransient matterNo ratings yet

- Electronic Lubrication Control Unit Model 85307, Single Line SystemDocument24 pagesElectronic Lubrication Control Unit Model 85307, Single Line SystemVictor Edy Facundo DelzoNo ratings yet

- 2.2 System Descript: On (Electrical)Document1 page2.2 System Descript: On (Electrical)Дмитрий МещерскихNo ratings yet

- XW263LDocument4 pagesXW263L270cdi aaNo ratings yet

- Cola Yard 3Document11 pagesCola Yard 3pupung182No ratings yet

- Dixell xw260lDocument4 pagesDixell xw260lMiftakhul KhoirNo ratings yet

- Model - Ylaa: Installation Checklist and Request For Authorized Startup EngineerDocument3 pagesModel - Ylaa: Installation Checklist and Request For Authorized Startup EngineerSergio Ito SunleyNo ratings yet

- Effer - Dmu 3000 Plus-Operator ManualDocument66 pagesEffer - Dmu 3000 Plus-Operator ManualPawełNo ratings yet

- FD113 Oil Pressure Safety ControlDocument4 pagesFD113 Oil Pressure Safety ControlOnofreNo ratings yet

- Selection of IRCON Temperature ControllersDocument4 pagesSelection of IRCON Temperature ControllersRamces ArandaNo ratings yet

- BSC Class II manual generico_Parte3Document5 pagesBSC Class II manual generico_Parte3CCVSNo ratings yet

- Autolube - Uc 1n e STDocument29 pagesAutolube - Uc 1n e STFata KickbalNo ratings yet

- BAC-002 ModbusDocument2 pagesBAC-002 ModbusAlfredo Ferrari Jr.No ratings yet

- Bombas ArmstrongDocument8 pagesBombas ArmstrongDinosaurio1990No ratings yet

- 117918 7Document1 page117918 7salinschi iulianNo ratings yet

- Water Level Limiter 933 (Instruction of Use)Document2 pagesWater Level Limiter 933 (Instruction of Use)Miraz RahmanNo ratings yet

- 42-694.16 Hermetically Sealed Switches Io PDFDocument12 pages42-694.16 Hermetically Sealed Switches Io PDFEVER RIVERANo ratings yet

- MOD 30ML Operation Lab 2: 2.1 ForewordDocument10 pagesMOD 30ML Operation Lab 2: 2.1 ForewordMario BozicevicNo ratings yet

- T o y o T A Avensis 2003. 2009 Theft Deterrent & Door Lock PDFDocument35 pagesT o y o T A Avensis 2003. 2009 Theft Deterrent & Door Lock PDFEladio NahuelhualNo ratings yet

- FHP Upm IDocument10 pagesFHP Upm IAbdulSattarNo ratings yet

- User's Manual User's Manual User's Manual User's Manual: Filename: Rev. 01 ID DocumentDocument26 pagesUser's Manual User's Manual User's Manual User's Manual: Filename: Rev. 01 ID Documentshakir tkNo ratings yet

- Ak-Cc 460Document30 pagesAk-Cc 460Øyvind SkulstadNo ratings yet

- Controlling Duct Pressure with UCM-420ADocument2 pagesControlling Duct Pressure with UCM-420AKumudu PereraNo ratings yet

- 4 Stage ThermostatDocument16 pages4 Stage ThermostatKrishnan GovindarajNo ratings yet

- PCCP - Simulator OperationDocument6 pagesPCCP - Simulator OperationnaveenNo ratings yet

- 6rshudwlqjlqvwuxfwlrqv: Multifunction Digital Controller For RefrigerationDocument4 pages6rshudwlqjlqvwuxfwlrqv: Multifunction Digital Controller For RefrigerationJennifer Eszter SárközyNo ratings yet

- Centro-Matic Flowmaster Rotary Driven Hydraulic Pump Model 85219 With Grease Model 85220 Without Grease Series ADocument8 pagesCentro-Matic Flowmaster Rotary Driven Hydraulic Pump Model 85219 With Grease Model 85220 Without Grease Series ASIDI ahmedou yahyaNo ratings yet

- Centro-Matic Flowmaster Rotary Driven Hydraulic Pump Models 85487 & 86258 Series BDocument8 pagesCentro-Matic Flowmaster Rotary Driven Hydraulic Pump Models 85487 & 86258 Series BSIDI ahmedou yahyaNo ratings yet

- Centro-Matic: Model 84050 (Series F ) Model 85460 (Series A ) Air Operated PumpDocument8 pagesCentro-Matic: Model 84050 (Series F ) Model 85460 (Series A ) Air Operated PumpSIDI ahmedou yahyaNo ratings yet

- Making The Supply Side Connection: Article 705: by Brian MehalicDocument3 pagesMaking The Supply Side Connection: Article 705: by Brian MehalicSIDI ahmedou yahyaNo ratings yet

- Air Operated Grease Pump 075Document4 pagesAir Operated Grease Pump 075SIDI ahmedou yahyaNo ratings yet

- International Electrotechnical Commission - World Voltage Frequency and Plug Type by LocationDocument20 pagesInternational Electrotechnical Commission - World Voltage Frequency and Plug Type by LocationSIDI ahmedou yahyaNo ratings yet

- Flowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ADocument11 pagesFlowmaster Rotary Driven Hydraulic Pump Models: 85480, 85481, 85482, 85483, Series B Models: 85247, 85610, 85586 Series ASIDI ahmedou yahyaNo ratings yet

- Senr8425senr8425 SisDocument2 pagesSenr8425senr8425 SisSIDI ahmedou yahyaNo ratings yet

- 15-16 en Cours FR1040 FR104A FR1050 Handbook 15-16Document50 pages15-16 en Cours FR1040 FR104A FR1050 Handbook 15-16SIDI ahmedou yahyaNo ratings yet

- By Engr. Sami Alalwani For RawaqDocument20 pagesBy Engr. Sami Alalwani For RawaqSIDI ahmedou yahyaNo ratings yet

- 15-16 en Cours FR1040 FR104A FR1050 Handbook 15-16Document50 pages15-16 en Cours FR1040 FR104A FR1050 Handbook 15-16SIDI ahmedou yahyaNo ratings yet

- By Engr. Sami Alalwani For RawaqDocument19 pagesBy Engr. Sami Alalwani For RawaqSIDI ahmedou yahyaNo ratings yet

- By Engr. Sami Alalwani For RawaqDocument20 pagesBy Engr. Sami Alalwani For RawaqSIDI ahmedou yahyaNo ratings yet

- INTER ROW SHADING Problem Logan UtahDocument10 pagesINTER ROW SHADING Problem Logan UtahSIDI ahmedou yahyaNo ratings yet

- Article 705: Interconnected Electric Power Production SourcesDocument3 pagesArticle 705: Interconnected Electric Power Production SourcesSIDI ahmedou yahyaNo ratings yet

- Making The Supply Side Connection: Article 705: by Brian MehalicDocument3 pagesMaking The Supply Side Connection: Article 705: by Brian MehalicSIDI ahmedou yahyaNo ratings yet

- Solar Pro Issue 8.2 - Distribution and Substation TransformersDocument11 pagesSolar Pro Issue 8.2 - Distribution and Substation TransformersSIDI ahmedou yahyaNo ratings yet

- Tracked: PV Array Systems & PerformanceDocument7 pagesTracked: PV Array Systems & PerformanceSIDI ahmedou yahyaNo ratings yet

- By Engr. Sami Alalwani For RawaqDocument19 pagesBy Engr. Sami Alalwani For RawaqSIDI ahmedou yahyaNo ratings yet

- PV System SimplifiedDocument9 pagesPV System SimplifiedSIDI ahmedou yahyaNo ratings yet

- Utilization Voltages 1,000 VDC: in Nonresidential PV ApplicationsDocument13 pagesUtilization Voltages 1,000 VDC: in Nonresidential PV ApplicationsSIDI ahmedou yahyaNo ratings yet

- International Electrotechnical Commission - World Voltage Frequency and Plug Type by LocationDocument20 pagesInternational Electrotechnical Commission - World Voltage Frequency and Plug Type by LocationSIDI ahmedou yahyaNo ratings yet

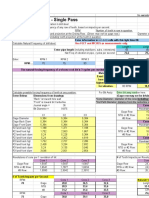

- Vibration Analysis - Single Pass: Use FEET and INCHES As Measurements OnlyDocument4 pagesVibration Analysis - Single Pass: Use FEET and INCHES As Measurements OnlySIDI ahmedou yahyaNo ratings yet

- Vibration Analysis - Single Pass: Use FEET and INCHES As Measurements OnlyDocument4 pagesVibration Analysis - Single Pass: Use FEET and INCHES As Measurements OnlySIDI ahmedou yahyaNo ratings yet

- Article 705: Interconnected Electric Power Production SourcesDocument3 pagesArticle 705: Interconnected Electric Power Production SourcesSIDI ahmedou yahyaNo ratings yet

- MCQs General Unit IDocument25 pagesMCQs General Unit IN1234m100% (1)

- Application of A CC-VSI For Active Filtering and Photovoltaic Energy Conversion With A 1-To-1 MPPT ControllerDocument6 pagesApplication of A CC-VSI For Active Filtering and Photovoltaic Energy Conversion With A 1-To-1 MPPT Controllerbeton2008No ratings yet

- Heladito O2Document2 pagesHeladito O2Pablo RagoNo ratings yet

- Wien-bridge oscillator circuits for signal generation and waveform shapingDocument1 pageWien-bridge oscillator circuits for signal generation and waveform shapingDIEGO ALEJANDRO QUIROGA ACOSTANo ratings yet

- Physics Investigatory ProjectDocument13 pagesPhysics Investigatory ProjectAnush DcostaNo ratings yet

- Modicon Quantum - 140ACI04000Document2 pagesModicon Quantum - 140ACI04000Miguel CasillasNo ratings yet

- Data Exchange Worksheet 1 BradleyDocument3 pagesData Exchange Worksheet 1 Bradleyapi-523316592No ratings yet

- Introduction to Electrical Circuits and DevicesDocument28 pagesIntroduction to Electrical Circuits and DevicesANo ratings yet

- Instruction Manual - LaboGene ScanSpeed 1730R - 9900900729Document12 pagesInstruction Manual - LaboGene ScanSpeed 1730R - 9900900729richard_luis_2No ratings yet

- TANKGARD-Corrosion Control For Tanks and VesselsDocument4 pagesTANKGARD-Corrosion Control For Tanks and Vesselsbello imamNo ratings yet

- JM C 7F反转速监测保护仪(中英文说明书)Document5 pagesJM C 7F反转速监测保护仪(中英文说明书)zhou NickyNo ratings yet

- FEM Based Design and Performance Analysis of 2-Poles Universal MotorDocument15 pagesFEM Based Design and Performance Analysis of 2-Poles Universal MotorBalaji DDNo ratings yet

- Understanding The Behavior of ExciterDocument4 pagesUnderstanding The Behavior of Exciterschauhan12No ratings yet

- SOFAR 3.3-12KTL-X User Manual 20200317-2Document14 pagesSOFAR 3.3-12KTL-X User Manual 20200317-2Jack martinNo ratings yet

- VersaLight: An Eco-Friendly Emergency LightDocument28 pagesVersaLight: An Eco-Friendly Emergency LightCHELSIE KAITLYN DE GUZMANNo ratings yet

- Power System Simulation Lab ManualDocument41 pagesPower System Simulation Lab ManualMary Morse100% (1)

- Transformer protection guideDocument195 pagesTransformer protection guideRafael Curiel MedinaNo ratings yet

- UK-Declaration - SINAMICS G120P 666.MNER - BT.40.2107.002Document15 pagesUK-Declaration - SINAMICS G120P 666.MNER - BT.40.2107.002sofianesedkaouiNo ratings yet

- VHF UHF Band Low Noise Amplifier Application: Maximum RatingsDocument5 pagesVHF UHF Band Low Noise Amplifier Application: Maximum RatingsIván Alexander Chero CabreraNo ratings yet

- Feasibility of installing piezoelectric flooring at Dadar stationDocument6 pagesFeasibility of installing piezoelectric flooring at Dadar stationRahul BoseNo ratings yet

- l149 Linear DriverDocument6 pagesl149 Linear DriverandrasorNo ratings yet

- Three Phase String Inverter 20-30 KW: CSI-20KTL-GI-FL - CSI-25KTL-GI-FL CSI-30KTL-GI-FLDocument2 pagesThree Phase String Inverter 20-30 KW: CSI-20KTL-GI-FL - CSI-25KTL-GI-FL CSI-30KTL-GI-FLGerson TorresNo ratings yet

- AC Ripple VoltageDocument5 pagesAC Ripple VoltageAgung Sugeng RiyadiNo ratings yet