Professional Documents

Culture Documents

DB 000 13510 0023 - 01

Uploaded by

israr khanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DB 000 13510 0023 - 01

Uploaded by

israr khanCopyright:

Available Formats

Remarks

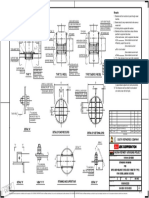

MIN 40 1. Blankets shall be in sections to pass through vessel manhole.

FB 50 x 12 "A"

2. Retaining and support bars shall be positioned at 90° to grid.

3. All bolting shall be supplied with washers.

4. For dimensions marked * refer to equipment data sheet.

SHELL ID 5. Materials shall be as listed below unless otherwise

specified in equipment data sheet.

D/4

50 25

· Wire mesh screen ; refer to equipment data sheet.

· Grid ; Same material as wire mesh

· Retaining, support bars and clip

D/4

UPPER GRID

; Same material as shell

BEARING PLATE : 25×6 · Bolt, nut and washer ; Same material as wire mesh

· Others ; Same material as wire mesh

CROSS BAR : Ø9 6. "D" = Outer diameter of wire mesh (After installation)

7. Horizontally slotted holes shall be provided at one end of retaining bar and

MIN support bar for adjustment.

PLAN VIEW OF RETAINING AND SUPPORT BAR 8. Shop assembled wire mesh shall be properly protected during transportation in

5 / 8 UNC(M16) horizontal position to prevent possible shrinkage in wire mesh pad resulting

150

(FOR TYPE "1") FASTEN WITH Ø1 to gaps between adjacent wire mesh pad sections.

BOLT W/ 2-HEX NUTS

9. For large diameter vessels (e.g. >3000mm), L50x50x9 shall be used for support

TIE WIRE OR Ø2 & WASHER bars to avoid buckling or deformation.

BENT STAPLES 10.For fixing of blanket with grid, tie rod may be used in place of wire or bent staple.

RETAINING BAR DETAIL "A" 11.The dimension shall be verified for removable of wire mesh screen with top and

APPROX. 150 PITCH bottom grids.

150

T.L

FILLER PLATE

TOP GRID

20

*

SAME THICKNESS

WIRE MESH SCREEN

AS SUPPORT RING

LOWER GRID BOTTOM GRID

(NOTE 11)

G

BEARING PLATE : 25×6

120

CROSS BAR : Ø9 "D" M10 316SS STUD BOLT

40

SUPPORT BAR W/ 2-HEX NUTS &WASHER

GRID CONSTRUCTION

TYPE "1" (FOR 2 SECTIONS) DETAIL "B"

WIRE MESH PAD WIDTH WIRE MESH PAD WIDTH

+ 25 (NOTE 9) + 25 (NOTE 9)

FB 75 x 15 FB 75 x 15 MAX.50

= = = =

(NOTE 8) 12 GAP 80 (NOTE 8) 12 GAP 80

"A" "A" SUPPORT RING

TYP. 40 TYP. 40

"B" "B"

"

MAX.100

"

D/ 3

"Y" "Y"

D/ 4

"Y" "Y"

"

"

D/ 4

"Z" "Z"

D/ 3

MAJOR SUPPORT 01 21-APR-21 ISSUED FOR CONSTRUCTION E.L H.M S.O

"

(DETAIL BY VENDOR) BOLT W/ 2-HEX NUTS 00 19-FEB-21 ISSUED FOR APPROVAL E.L H.M S.O

"

& WASHER REV DATE ISSUE PURPOSE PREP'D CHK'D APP'D

FB 75 x 15 FB 75 x 15

REVISIONS

(NOTE 8) (NOTE 8) VIEW "Z" - "Z"

PLAN VIEW OF RETAINING BAR PLAN VIEW OF SUPPORT BAR PLAN VIEW OF RETAINING BAR PLAN VIEW OF SUPPORT BAR SOUTH REFINERIES COMPANY

(FOR TYPE "2") AND SUPPORT RING (FOR TYPE "3") AND SUPPORT RING

(FOR TYPE "2") (FOR TYPE "3")

MAX.50

RETAINING BAR RETAINING BAR

SUPPORT RING BASRAH REFINERY UPGRADING PROJECT

TOP GRID T.L TOP GRID T.L CONTRACTOR JOB CODE

0-8494-20-0000

WIRE MESH SCREEN WIRE MESH SCREEN STANDARD DRAWING

*

*

FOR

BOTTOM GRID BOTTOM GRID

WIRE MESH BLANKET (FULL DIAMETER TYPE)

SUPPORT RING FASTEN WITH Ø1 SUPPORT RING FASTEN WITH Ø1 5/ 8 UNC(M16) FOR VERTICAL VESSEL (BELOW ACCESS)

SUPPORT BAR "D" TIE WIRE OR Ø2 SUPPORT BAR "D" TIE WIRE OR Ø2 BOLT W/ 2-HEX NUTS DOCUMENT CLASS SIZE SCALE

BENT STAPLES & WASHER Z A3 NONE

MAJOR SUPPORT BENT STAPLES CONTRACT NO.

APPROX. 150 PITCH APPROX. 150 PITCH 5360/B/2020

S1 TYPE "2" (FOR 3 AND 4 SECTIONS) TYPE "3" (FOR OTHER MULTI SECTIONS) VIEW "Y" - "Y"

J-DApM

PROJECT DWG NO. REV.

DB-000-13510-0023 01

r-202

26- TED 1/1

N PRIN and any attachment is confidential and is the property of JGC HOLDINGS CORPORATION and/or its affiliated undertakings. If you are not an authorized person by written permission of JGC HOLDINGS CORPORATION and/or its affiliated undertakings, you should not copy, trace, photograph, reproduce or use it for any purpose nor disclose its contents to any other person.

This Edocument

O L L ED WH

NCONTR

You might also like

- DD 011 13513 0007 - 01Document1 pageDD 011 13513 0007 - 01israr khanNo ratings yet

- 03 V 003 Depresurring Case 2Document364 pages03 V 003 Depresurring Case 2israr khanNo ratings yet

- Cooling Water Treatment PDFDocument56 pagesCooling Water Treatment PDFwaheed22860% (1)

- DB 000 13510 0025 - 01Document1 pageDB 000 13510 0025 - 01israr khanNo ratings yet

- DB 000 13510 0021 - 01Document1 pageDB 000 13510 0021 - 01israr khanNo ratings yet

- Tag No Nozzle Mark Nozzle Size Part No Reason For ChangeDocument1 pageTag No Nozzle Mark Nozzle Size Part No Reason For Changeisrar khanNo ratings yet

- The Weld Type For Nozzle To WN Falnge For CS Material Page 2 To 6Document18 pagesThe Weld Type For Nozzle To WN Falnge For CS Material Page 2 To 6israr khanNo ratings yet

- PPR 4 1stDocument10 pagesPPR 4 1stisrar khanNo ratings yet

- Design of Tail LugDocument34 pagesDesign of Tail LugPrajwal Shetty100% (1)

- ENPPI Pressure VesselsDocument47 pagesENPPI Pressure Vesselsisrar khan100% (2)

- Design of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-TipsDocument2 pagesDesign of Circular Flat Endplate With Stiffeners - Boiler and Pressure Vessel Engineering - Eng-Tipsisrar khanNo ratings yet

- Asme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)Document59 pagesAsme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)vuchinhNo ratings yet

- HVAC Cooling Load Procedure Guideline Lo0Document62 pagesHVAC Cooling Load Procedure Guideline Lo0api-385802594% (36)

- Still Column With Reflux - sht.01 To 02 PDFDocument2 pagesStill Column With Reflux - sht.01 To 02 PDFisrar khanNo ratings yet

- VIII 59 85 - UW 11a5bDocument2 pagesVIII 59 85 - UW 11a5bisrar khanNo ratings yet

- Eds A 9Document30 pagesEds A 9israr khanNo ratings yet

- Nozzle Reinforcement in Elliptical Head - Intergraph CADWorx & AnalysisDocument4 pagesNozzle Reinforcement in Elliptical Head - Intergraph CADWorx & Analysisisrar khanNo ratings yet

- CR4 - Thread - What Hydrostatic Test Pressure May Be Used To Test A 2000bar Pressure VesselDocument5 pagesCR4 - Thread - What Hydrostatic Test Pressure May Be Used To Test A 2000bar Pressure Vesselisrar khanNo ratings yet

- Nozzle Reinforcement in Elliptical Head - Intergraph CADWorx & AnalysisDocument4 pagesNozzle Reinforcement in Elliptical Head - Intergraph CADWorx & Analysisisrar khanNo ratings yet

- Mean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & AnalysisDocument3 pagesMean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & Analysisisrar khanNo ratings yet

- Qa VS QCDocument4 pagesQa VS QCisrar khanNo ratings yet

- CR4 - Thread - What Hydrostatic Test Pressure May Be Used To Test A 2000bar Pressure VesselDocument5 pagesCR4 - Thread - What Hydrostatic Test Pressure May Be Used To Test A 2000bar Pressure Vesselisrar khanNo ratings yet

- MATERIAL SA36 - ASME (Mechanical) Code Issues - Eng-TipsDocument2 pagesMATERIAL SA36 - ASME (Mechanical) Code Issues - Eng-Tipsisrar khanNo ratings yet

- Durlon Gasketing Technical HandbookDocument15 pagesDurlon Gasketing Technical Handbookisrar khanNo ratings yet

- CR4 - Thread - Heat Exchanger DesignDocument4 pagesCR4 - Thread - Heat Exchanger Designisrar khanNo ratings yet

- ML040150682 PDFDocument406 pagesML040150682 PDFjimmy_bikerNo ratings yet

- A694 F65 Flanges Manufactured To ASME B16Document2 pagesA694 F65 Flanges Manufactured To ASME B16israr khanNo ratings yet

- BIS 4503 1967 Shell and Tube Type Heat Exchangers PDFDocument72 pagesBIS 4503 1967 Shell and Tube Type Heat Exchangers PDFmahaveenNo ratings yet

- Tube Expansion Issues & MethodsDocument4 pagesTube Expansion Issues & MethodsSuleyman HaliciogluNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Etude Protections GPPDocument273 pagesEtude Protections GPPzahirtechNo ratings yet

- Growatt Arc Protection in PV System-2020!7!14Document3 pagesGrowatt Arc Protection in PV System-2020!7!14Tỷ Hồ HữuNo ratings yet

- Manual Uso Stanbay EnergyDocument2 pagesManual Uso Stanbay EnergyMarijoseNo ratings yet

- Overvoltage CategoryDocument5 pagesOvervoltage CategorypcNo ratings yet

- EIL Standard Specification PDFDocument107 pagesEIL Standard Specification PDFkalaiNo ratings yet

- Rayburn 460-499KB Serv 05-14 EINS 511642Document44 pagesRayburn 460-499KB Serv 05-14 EINS 511642ChristopherJones100% (2)

- TC9102 ManualDocument16 pagesTC9102 Manualأياام زمانNo ratings yet

- Multiple Continuity TesterDocument18 pagesMultiple Continuity TesterbnurkholisNo ratings yet

- Toyota QuoteDocument3 pagesToyota Quoteakhil.s .kumarNo ratings yet

- Rigging JSA SafetyDocument5 pagesRigging JSA SafetyaQiLGunawanNo ratings yet

- 0288194 - B02 (19010185《NICE3000new电梯一...Document320 pages0288194 - B02 (19010185《NICE3000new电梯一...Le Huynh LongNo ratings yet

- ERV Catalog PDFDocument34 pagesERV Catalog PDFErwin LouisNo ratings yet

- Yayasan Diponegoro Tumpang SMK Diponegoro TumpangDocument4 pagesYayasan Diponegoro Tumpang SMK Diponegoro TumpangYuli Dwi PratiwiNo ratings yet

- CLD1015 ManualDocument87 pagesCLD1015 ManualNayeLi HHrNo ratings yet

- SysLogic GBDocument18 pagesSysLogic GBsamir hacibNo ratings yet

- Honda CB Trigger - Ride ReportDocument23 pagesHonda CB Trigger - Ride ReportKristine ReyesNo ratings yet

- Brosur HT 20 P Silent HTGDocument1 pageBrosur HT 20 P Silent HTGalfan nashNo ratings yet

- LCD Sharp LC-60LE745U - LC-60C7450 - LC60C8470 - LC-60LE845 - LC-70LE745U - LC-70LE7450 - LC-70LE845 - LC-70LE845 - LC-708470 - LC-70LE847Document100 pagesLCD Sharp LC-60LE745U - LC-60C7450 - LC60C8470 - LC-60LE845 - LC-70LE745U - LC-70LE7450 - LC-70LE845 - LC-70LE845 - LC-708470 - LC-70LE847Sonu KumarNo ratings yet

- CTV Sva05a En603servicealertDocument6 pagesCTV Sva05a En603servicealertGustavo Scherman100% (3)

- Dokumen - Tips - User Manual WPC IIDocument230 pagesDokumen - Tips - User Manual WPC IIEdgar CruzNo ratings yet

- Frenic-Ace: Instruction ManualDocument161 pagesFrenic-Ace: Instruction ManualIfin BondetNo ratings yet

- 28 10 00 - Access Control and Intrusion Detection - 01Document18 pages28 10 00 - Access Control and Intrusion Detection - 01sherifNo ratings yet

- System Basis Chip T L E 6 2 6 6 G: Integrated LS CAN, LDO and LS - HS SwitchesDocument50 pagesSystem Basis Chip T L E 6 2 6 6 G: Integrated LS CAN, LDO and LS - HS Switchescork_ieNo ratings yet

- Eaton Control Panel Design Guide NewarkDocument36 pagesEaton Control Panel Design Guide NewarkDavid LucioNo ratings yet

- Dyson Cyclone V10 Absolute (Copper) - User Manual (Original File Name - ''Dyson-stick-V10-Absolute-Vacuum-user-guide - PDF'')Document16 pagesDyson Cyclone V10 Absolute (Copper) - User Manual (Original File Name - ''Dyson-stick-V10-Absolute-Vacuum-user-guide - PDF'')TalNo ratings yet

- CH430 01 02 IMA S223 651 en 02 PDFDocument33 pagesCH430 01 02 IMA S223 651 en 02 PDFferneyarrieta38100% (2)

- TEA1522PDocument17 pagesTEA1522PRjati devamNo ratings yet

- Outdoor Telecom Power Cabinet SystemsDocument21 pagesOutdoor Telecom Power Cabinet SystemsFanica Colbea0% (1)

- 7 Day Timer ESPAR ManualDocument5 pages7 Day Timer ESPAR ManualDaniele Gardellin100% (1)

- VRF Working PrincipleDocument51 pagesVRF Working PrincipleYe LinnNo ratings yet