Professional Documents

Culture Documents

GE MTU Installations

Uploaded by

Samuel SQ0 ratings0% found this document useful (0 votes)

17 views98 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views98 pagesGE MTU Installations

Uploaded by

Samuel SQCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 98

GEN I

OVERVIEW

•Installations

•Automatic transfer switch information (ASCO, Zenith)

•Controls (KASSEC, DGC Family)

•Generators/Voltage Regulators

•Fuel systems (diesel)

•Fuel systems (gaseous)

Seite 2 / MTU Onsite Energy /

Seite 3 / MTU Onsite Energy /

Air Intake Key Points

•Startup Form #8 and #9

•Sizing verification – 50 – 100% larger than effective opening

•Location/Direction of Flow

•Louver Types

•Environment/Obstruction

•Over/Undersizing

•Housed Units

•Modifications

•Reference Manual Page 33 (PDF pg. 20)

Seite 4 / MTU Onsite Energy /

AIR REQUIREMENTS

Seite 5 / MTU Onsite Energy /

Generator Room Ventilation

Seite 6 / MTU Onsite Energy /

Engine Room Ventilation

Seite 7 / MTU Onsite Energy /

Seite 8 / MTU Onsite Energy /

Seite 9 / MTU Onsite Energy /

INTAKE LOUVER

Intake duct or louver should be

50% to 100% larger in

EFFECTIVE opening than

Engine Radiator Core.

Seite 10 / MTU Onsite Energy /

Air Exhaust

•Startup Form #8 and #9

•Sizing verification – 25 – 50% larger than effective opening

•Ducting on Exhaust/Flex

•Environment/Obstruction

•Over/Undersizing

•Housed Units

•Modifications

Seite 17 / MTU Onsite Energy /

EXHAUST LOUVER

Exhaust cooling air ducting

EFFECTIVE opening should

be at least 25% to 50% larger

than Engine Radiator Core.

Seite 18 / MTU Onsite Energy /

Louver

Sizing

Exercise

Louver Sizing Summary

•Intake

•L x W = Area of Radiator Core

•Area * 1.50 / Efficiency = 50% larger

•Area * 2.00 / Efficiency = 100% larger

•Exhaust

•L x W = Area of Radiator Core

•Area * 1.25 / Efficiency = 25% larger

•Area * 1.50 / Efficiency = 50% larger

Seite 34 / MTU Onsite Energy /

Exhaust Systems

•Startup Form #19 to #27

•Components/Location

•Distance/Max-Min Back Pressure/90s, Elbows

•Maintenance

•Supports

•Extended Piping – Schedule 40 Black Iron Pipe Factory

Recommended

•Reference Manual – Page 37 (PDF pg. 24)

Seite 35 / MTU Onsite Energy /

Seite 36 / MTU Onsite Energy /

Fuel Systems

•Startup Form #11 to #18 – Manual Page 41 (PDF pg.28)

•Components/Location

•Dedicated Line

•Set-up/Flex

•Volume/Pressure

•No Galvanized Pipe

•Port to measure pressure

•Maintenance/Dry Fuel Strainer

•UL 2200

Seite 53 / MTU Onsite Energy /

Seite 54 / MTU Onsite Energy /

Seite 66 / MTU Onsite Energy /

Conventional Fuel Systems

•GM 8.1L 80 – 130 KW

•Air Fuel Ratio Set Up

•Flow Control Valve

•Idle and Load Adjust Valves

•NG, LP or Dual Fuel (NG Primary/LP Backup)

•**One 8.1L Model is not a Conventional System**

Seite 67 / MTU Onsite Energy /

Seite 77 / MTU Onsite Energy /

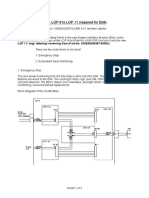

Zero Pressure Regulation (ZPR)

•Venture Style Mixers/Carburetors

•ZPR adjustment for Start ability

•MAS Adjustment screw for Run ability

•Mag Pickup

•NG or LP is Stem Up Spring In

Seite 78 / MTU Onsite Energy /

Seite 79 / MTU Onsite Energy /

Seite 85 / MTU Onsite Energy /

Electrical Systems

•Startup Form #28 to #32 – Manual Page 49 (PDF pg. 36)

•AC, DC and Custom Point to Point

•S Series terminal strip/heater & charger connection

•Modifications to systems

•Proper Wire/Cable Connections

•Flex Connections

•Wire # versus termination point

•(1) 2

•(1) = Wire Number

•2 = Termination Point

Seite 86 / MTU Onsite Energy /

Seite 94 / MTU Onsite Energy /

Installation Forms

Seite 97 / MTU Onsite Energy /

TEST

You might also like

- 5 Development and Operating Experience PDFDocument10 pages5 Development and Operating Experience PDFVijaya100% (2)

- 3412C 725 kVA Prime LowBsfc EU 50HzDocument6 pages3412C 725 kVA Prime LowBsfc EU 50Hzrbmr1No ratings yet

- Air Charge-Air Cooling: Diesel Generator SetDocument4 pagesAir Charge-Air Cooling: Diesel Generator Settctctc123No ratings yet

- Air Compressor Specifiction (Atlas Copco)Document3 pagesAir Compressor Specifiction (Atlas Copco)Phyu Mar Thein KyawNo ratings yet

- Gas Turbine TheoryDocument49 pagesGas Turbine Theorymmbataineh100% (2)

- Heimstaedt Smardt PresentationDocument58 pagesHeimstaedt Smardt PresentationChoon Seng100% (1)

- Unit-IV-Induction MotorsDocument57 pagesUnit-IV-Induction MotorssujithNo ratings yet

- Lecture 3Document33 pagesLecture 3Heleana Faye BundocNo ratings yet

- MTU 12V1600 DS660: Diesel Generator SetDocument5 pagesMTU 12V1600 DS660: Diesel Generator Setabdelmoumene djafer beyNo ratings yet

- Blower TechnologyDocument43 pagesBlower TechnologyKristian HutaurukNo ratings yet

- Basics of Motors & Control PanelDocument59 pagesBasics of Motors & Control PanelPraveen BalakrishnanNo ratings yet

- Creating Value from Steam PressureDocument16 pagesCreating Value from Steam PressureMohamed Salem100% (3)

- Auxiliary Power Reduction in Thermal Power PlantDocument27 pagesAuxiliary Power Reduction in Thermal Power PlantManoj Upadhyay100% (1)

- DIESEL GENERATOR OPTIMIZEDDocument6 pagesDIESEL GENERATOR OPTIMIZEDKhalid Jabal100% (1)

- 9 0 Development and OperatingDocument12 pages9 0 Development and OperatingAnu Partha100% (1)

- Model: R33 Diesel GensetDocument5 pagesModel: R33 Diesel Gensetjvaldivia82No ratings yet

- 3616 5875 kVA 50Hz Continuous LowbsfcDocument6 pages3616 5875 kVA 50Hz Continuous LowbsfcjokanovNo ratings yet

- Calibration 101 by Kim LyonDocument103 pagesCalibration 101 by Kim LyonnitishghosalNo ratings yet

- An Overview of Combined Cycle Power PlantDocument71 pagesAn Overview of Combined Cycle Power PlantDreamie Blue100% (2)

- 3612Document6 pages3612Chandrashekar PatigeNo ratings yet

- CATERPILLAR C9 300kw PDFDocument6 pagesCATERPILLAR C9 300kw PDFanthony7421No ratings yet

- The Tata Iron & Steel Company Ltd. Jamshedpur: Positional TrainingDocument23 pagesThe Tata Iron & Steel Company Ltd. Jamshedpur: Positional TrainingMahesh YadavNo ratings yet

- MTU 12V1600 DS660 400-230V 600 kVA Prime Power Diesel GeneratorDocument5 pagesMTU 12V1600 DS660 400-230V 600 kVA Prime Power Diesel GeneratordinukaeeNo ratings yet

- New Plants Be BuiltDocument83 pagesNew Plants Be BuiltMuhammad Ilyas KhanNo ratings yet

- Combined CycleDocument34 pagesCombined Cycleatulsemilo100% (2)

- AEMSDocument28 pagesAEMSGARVIT SRIVASTAVANo ratings yet

- Caterpillar 3606 2425kVA GensetDocument6 pagesCaterpillar 3606 2425kVA GensetMuhammad Irfan KhanNo ratings yet

- Fluid Coupling Presentation 11-13-12Document23 pagesFluid Coupling Presentation 11-13-12M. Ali ParvezNo ratings yet

- MTU 12V1600 DS660 400-230V 600 kVA Prime Power Diesel GeneratorDocument5 pagesMTU 12V1600 DS660 400-230V 600 kVA Prime Power Diesel GeneratorBao Le VietNo ratings yet

- Model: J300K Diesel GensetDocument5 pagesModel: J300K Diesel GensetJorge CarrascoNo ratings yet

- MTU 12V1600 DS730 400-230V 728 kVA Diesel GeneratorDocument5 pagesMTU 12V1600 DS730 400-230V 728 kVA Diesel GeneratorphuongNo ratings yet

- Standard generator set packageDocument2 pagesStandard generator set packagechhoan_nhunlinaNo ratings yet

- ParisonDocument35 pagesParisonMurann EzineNo ratings yet

- Advanced Propulsion For Tactical MissilesDocument28 pagesAdvanced Propulsion For Tactical MissilesLazos VretsidisNo ratings yet

- Gas Turbine Theory Gas Turbine TheoryDocument42 pagesGas Turbine Theory Gas Turbine TheoryIwan Ruhiyana100% (1)

- Turbin Gas Workshop FTMD 210127Document40 pagesTurbin Gas Workshop FTMD 210127Rizkyka AffiatyNo ratings yet

- Spec Sheet Mtu 16v4000 Ds2250 FCDocument6 pagesSpec Sheet Mtu 16v4000 Ds2250 FCMarison Saragih100% (1)

- Spec Sheet MTU 16V4000 DS2250 FC PDFDocument6 pagesSpec Sheet MTU 16V4000 DS2250 FC PDFMarison SaragihNo ratings yet

- A New Extrusion ConceptDocument18 pagesA New Extrusion ConceptLeonel VelasquezNo ratings yet

- 4M06 Series: Powerkit EngineDocument2 pages4M06 Series: Powerkit EngineLuis Miguel LimaNo ratings yet

- Unit III _ RETDocument46 pagesUnit III _ RETsagarpatil03012No ratings yet

- MTU 4R0080 DS55: Diesel Generator SetDocument5 pagesMTU 4R0080 DS55: Diesel Generator SetMarcial MilitanteNo ratings yet

- Diesel Electric Propulsion Plant - MANDocument26 pagesDiesel Electric Propulsion Plant - MANThomas St100% (1)

- Trane Split System 23-55 TonsDocument4 pagesTrane Split System 23-55 Tonsyadi_baeNo ratings yet

- 11kV Diesel Generator with Low Fuel ConsumptionDocument6 pages11kV Diesel Generator with Low Fuel ConsumptionMarioyfernanda Guerra Murua100% (1)

- Idamalayar Hydro Electric ProjectDocument100 pagesIdamalayar Hydro Electric ProjectRajesh TKNo ratings yet

- Demand and Diversity FactorsDocument20 pagesDemand and Diversity FactorsWRAI100% (1)

- Are VFDs Worth It for Pump ApplicationsDocument29 pagesAre VFDs Worth It for Pump Applicationsjuhi993No ratings yet

- Learning Objectives For Gas Turbine Power Generation (2500)Document12 pagesLearning Objectives For Gas Turbine Power Generation (2500)myvirtuNo ratings yet

- MTU 12V4000 DS1650 diesel generator setDocument6 pagesMTU 12V4000 DS1650 diesel generator setDanil MunandarNo ratings yet

- Efficiency Improvements in Compounding Extruders PDFDocument4 pagesEfficiency Improvements in Compounding Extruders PDFXuan Giang NguyenNo ratings yet

- Efficiency Improvements in Compounding ExtrudersDocument4 pagesEfficiency Improvements in Compounding ExtrudersXuan Giang Nguyen100% (1)

- INFORME DE MTTO JDocument22 pagesINFORME DE MTTO JJerson MeloNo ratings yet

- Diesel Power Plant PDFDocument12 pagesDiesel Power Plant PDFZaul tatingNo ratings yet

- DieselPower PlantDocument12 pagesDieselPower PlantJC ElarmoNo ratings yet

- Motor Protection Relay Setting GuideDocument175 pagesMotor Protection Relay Setting GuideThanigaivelan Govindhasamy100% (19)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Dongle KitDocument1 pageDongle KitSamuel SQNo ratings yet

- LOP - 8 - To - LOP 11 MODIFICACIONDocument3 pagesLOP - 8 - To - LOP 11 MODIFICACIONSamuel SQNo ratings yet

- Siglas MtuDocument12 pagesSiglas MtuSamuel SQNo ratings yet

- Manual S1600Document502 pagesManual S1600Samuel SQ100% (2)

- Smart Concepto MantoDocument47 pagesSmart Concepto MantoSamuel SQNo ratings yet

- Pre LubeDocument8 pagesPre LubeSamuel SQNo ratings yet

- Technical Data-OM471LA.E5-2-360 kW-2400 Nm-D471.945-Off Highway US Tier 4 (With DPF)Document6 pagesTechnical Data-OM471LA.E5-2-360 kW-2400 Nm-D471.945-Off Highway US Tier 4 (With DPF)Samuel SQNo ratings yet

- S60 Level IIDocument384 pagesS60 Level IISamuel SQNo ratings yet

- Goodyear OTR Databook 3Document170 pagesGoodyear OTR Databook 3Raburgess1No ratings yet

- PDE Injector Function Description - 030401eb-1Document16 pagesPDE Injector Function Description - 030401eb-1Risa GirasNo ratings yet

- Special Tools PolarisDocument36 pagesSpecial Tools PolarisAman kumar GuptaNo ratings yet

- WB156-5 y WB 156PS-5 Retros KomatsuDocument10 pagesWB156-5 y WB 156PS-5 Retros KomatsuEdith perezNo ratings yet

- TJM PaceDocument2 pagesTJM Pace9868257807No ratings yet

- Manual de Parte 793D Parte IDocument869 pagesManual de Parte 793D Parte IJuan Vargas CNo ratings yet

- 1948 56 Truck Parts CatalogDocument139 pages1948 56 Truck Parts CatalogBrian-Marti Boatright100% (1)

- Petrol CNG EvDocument6 pagesPetrol CNG EvChetanNo ratings yet

- Cab ExteriorDocument35 pagesCab Exteriorpetsamo_mNo ratings yet

- ZF Trans-1Document42 pagesZF Trans-1Dibas BaniyaNo ratings yet

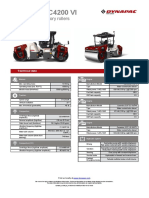

- Dynapac CC4200 VI Double Drum Vibratory Roller SpecsDocument2 pagesDynapac CC4200 VI Double Drum Vibratory Roller SpecsJaherNo ratings yet

- ASAS-Pallman-Filters-CrossReference Catalogue 1Document50 pagesASAS-Pallman-Filters-CrossReference Catalogue 1suraj pandey100% (1)

- Combustion Chambers in SI EnginesDocument12 pagesCombustion Chambers in SI EnginesKLUniveristy100% (1)

- Nissan History of EV TechnologyDocument47 pagesNissan History of EV Technology1SABNo ratings yet

- YOKOHAMA Motorsport Catalogue 2021Document6 pagesYOKOHAMA Motorsport Catalogue 2021Anthony Da Silva GuglielmettoNo ratings yet

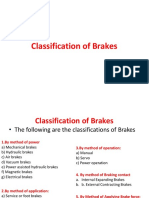

- 5 Classification of Brakes 160217042825Document39 pages5 Classification of Brakes 160217042825manipsg100% (1)

- 2006 Eclipse Part ListDocument121 pages2006 Eclipse Part ListFaris Ammar KalthamNo ratings yet

- EibachDocument48 pagesEibachunnotedNo ratings yet

- Catalago GP1 Cables BujiaDocument68 pagesCatalago GP1 Cables BujiaLORENANo ratings yet

- MAZDA B2200-B2600i COURIER 1987-1993 2WD-4WD REPAIR SERVICE MANUAL 1988 1989 190 1991 1992Document23 pagesMAZDA B2200-B2600i COURIER 1987-1993 2WD-4WD REPAIR SERVICE MANUAL 1988 1989 190 1991 1992MshiboniumNo ratings yet

- Instructiuni Montare Stand Next Level Racing DDDocument14 pagesInstructiuni Montare Stand Next Level Racing DDGaby XiuNo ratings yet

- A6-Headlight Adjustment ProcedureDocument5 pagesA6-Headlight Adjustment ProcedureChris WilkieNo ratings yet

- 2023 Subaru CrosstrekDocument504 pages2023 Subaru Crosstrekbnhdhbw347No ratings yet

- HBT6013C-5S Parts BookDocument197 pagesHBT6013C-5S Parts BookEvert Vargas Torrez75% (4)

- Isuzu Workshop Manual 2008my N Series General InformationDocument54 pagesIsuzu Workshop Manual 2008my N Series General InformationToanNo ratings yet

- Descifrar El VINDocument5 pagesDescifrar El VINSAYFUDDINSG100% (1)

- Gates X16xelDocument3 pagesGates X16xeldzadza2No ratings yet

- TBG 616Document4 pagesTBG 616sdiaman50% (2)

- Deac13uk10mm Uk Thermal Ac-Compressor Leaflet WebDocument2 pagesDeac13uk10mm Uk Thermal Ac-Compressor Leaflet Webcatur yulianaNo ratings yet

- VIMEC T09-T10 GBDocument8 pagesVIMEC T09-T10 GBDincu Ana MariaNo ratings yet