Professional Documents

Culture Documents

Plate Columns

Uploaded by

K Srikanth0 ratings0% found this document useful (0 votes)

15 views3 pagesOriginal Title

PLATE COLUMNS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views3 pagesPlate Columns

Uploaded by

K SrikanthCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

By : Project:

Date : Client - Owner - Doc No.:

Chd : Job No. Office - Dept. - Subject: Prod-Block

Date : Sh of Rev No. 0

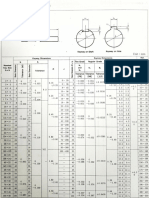

DESIGN OF PLATED COLUMNS SUBJECTED TO AXIAL COMPRESSION & BENDING

Design input:

Member No: B1

Axial load P in t = 0 Effective length about major axis Lz-z in m = 15.00 D = Depth of the section = 1000

Moment about major axis Mz-z in t-m = 172 Effective length about minor axis Ly-y in m = 7.50 T = thickness of flange = 25

Moment about major axis My-y in t-m = 0 Effective length of compression flange L in m = 7.50 t = thickness of web = 8

2

Shear force in t, q = 0 Yield stress of steel in N/mm fy = 345 B = Width of flange = 380

To find Moment of inertia of section: Unit-mm Allow. stress ratio = 1

2 2

Member Nos. Comp. No Section Area y A.y A.y I self (z) z A .z A.z I self (y) Remarks

A

B1 1 380 25 9500 12.5 1.2E+05 1.5E+06 4.9E+05 160 1.5E+06 2.4E+08 1.14E+08 Gable frame cols

2 8 960 7680 505 3.9E+06 2.0E+09 5.9E+08 160 1.2E+06 2.0E+08 4.10E+04 (LC-16)

3 380 25 9500 997.5 9.5E+06 9.5E+09 4.9E+05 160 1.5E+06 2.4E+08 1.14E+08

4 0 0 0.0E+00 0.0E+00 0.0E+00 0 0.0E+00 0.0E+00 0.00E+00 Yield stress fy for

5 0 0 0.0E+00 0.0E+00 0.0E+00 0 0.0E+00 0.0E+00 0.00E+00 IS:226 & IS:2062

6 0 0 0.0E+00 0.0E+00 0.0E+00 0 0.0E+00 0.0E+00 0.00E+00 Steels :-

8 0 0 0.0E+00 0.0E+00 0.0E+00 0 0.0E+00 0.0E+00 0.00E+00 250MPa - 6<t<20

0 0.0E+00 0.0E+00 0.0E+00 0.0E+00 0.0E+00 0.00E+00 240MPa-20<t<40

0 0.0E+00 0.0E+00 0.0E+00 0.0E+00 0.0E+00 0.00E+00 230MPa - t > 40

0 0.0E+00 0.0E+00 0.0E+00 0.0E+00 0.0E+00 0.00E+00 where t is the

S 26680 1.35E+07 1.14E+10 5.91E+08 4.27E+06 6.83E+08 2.29E+08 thickness of plate.

2 2

I1-1 =S Iself-z + S( A.y ) = 1.20E+10 I2-2 =S Iself-y+ S (A.z ) = 9.12E+08 Y

y- = S A.y / S A = 505.00 z- = S A.z / S A = 160.00 1 2 1 y - distance of cg

2 2 -

Iz-z = I1-1 - A . (y-) = 5.20E+09 Iy-y = I2-2 - A . (z-) = 2.29E+08 y of each component

- -

Zz-z = Iz-z / y = 1.03E+07 Zy-y = Iy-y / z = 1.43E+06 Z Z from axis 1-1

rz = sqrt(Iz-z / A) = 441.45 ry = sqrt (Iy-y / A) = 92.58 z - distance of cg

2

Permissible direct stress in compression: sac (N/mm ) of each component

Axial load P in t = 0 Effective length about major axis Lz-z in m = 15.00 from axis 2-2

As per IS:800-1984 Cl.3.5.2.2,(a) Effective length about minor axis Ly-y in m = 7.50 I1-1 = MI about 1-1

-

1440t/sqrt(fy)= 620.22 90t = 720 lz-z = Lz-z / rz = 33.98 Y z 2 I2-2 =MI about 2-2

Depth of web d1 in mm = 950 ly-y = Ly-y / ry = 81.01

d1<Min. of (1440t/sqrt(fy) or 90t) Maximum slenderness ratio l = 81.01 < 180

Change the thickness of web SAFE

800t/sqrt(fy)= 344.56 50t = 400

By : 0 SEMAC PVT LTD Project: 0

Date : 0 Client - 0 Owner - 0 Doc No.: 0

Chd : Job No. 0 Office - 0 Dept. - 0 Subject: Prod-Block

Date : Sh of Rev No. 0

If d1<Min of (800t/sqrt(fy) or 50t), Anet = A

else, Anet=A-{[d1-(Min.of (800t/sqrt(fy), 50t)]x t}

Anet = 21836.515

2

sac cal = P/Anet (N/mm ) = 0.00

5 2

Modulus of elasticity of steel E = 2.0x10 N/mm

2 2 2

Elastic critical stress in compression = fcc(N/mm ) = p E / l = 300.77

2

Yield stress of steel in N/mm fy = 345

n n 1/n

sac = ( 0.6 . fcc . fy) / [(fcc) + (fy) ] = 117.42 ( n = 1.4) Ref. IS:800-1984

2

Permissible bending compressive stress : sbcz (N/mm ) Cl.5.1.1

Moment about major axis Mz-z in t-m = 172

2

sbcz.cal = Mz-z / Zz-z (N/mm ) = 167.06

Effective length of compression flange L in m = 7.50

5 2

Y = (26.5 x 10 )/(L/ry) = 403.79 Refer IS:800-1984

T = Mean thickness of compression flange = 25 Cl. 6.2.4

D = Depth of the section = 1000

2

X = Y. Sqrt [1+1/20(L.T/ry.D) = 443.27

c1 = 500.00 k1 = 1

c2 = 500.00 k2 = 0 Based on "ω"

2

Elastic critical stress in bending in N/mm = fcb = k1(X+k2 .Y)c2/c1 = 443.27

T = thickness of flange = 25 T/t = 3.125 d1=D-2T= 950 d1 / t = 118.75

t = thickness of web = 8 1344/SQRT(fy) = 72.36

fcb = 443.27 (fcb is increased by 20% if T/t<2.0 & d1/t <1344/SQRT(fy) Refer IS:800-1984

2 2 2

Elastic critical stress in compression = fccz(N/mm ) = p E / lzz = 1709.67 Cl. 6.2.4.1

n n 1/n

sbcz = ( 0.66 . fcb . fy) / [(fcb) + (fy) ] = 155.60 ( n = 1.4 ) Refer IS:800-1984

2

Permissible bending compressive stress : sbcy (N/mm ) Cl. 6.2.3

Moment about minor axis My-y in t-m = 0.00

2

sbcy.cal = My-y / Zy-y (N/mm ) = 0.00

sbcy = 0.66 fy = 227.7

2 2 2

Elastic critical stress in compression = fccy(N/mm ) = p E / lyy = 300.77

By : 0 SEMAC PVT LTD Project: 0

Date : 0 Client - 0 Owner - 0 Doc No.: 0

Chd : Job No. 0 Office - 0 Dept. - 0 Subject: Prod-Block

Date : Sh of Rev No. 0

Check for combined stresses:

if σac,cal/σac ≥ 0.15 σac,cal/σac = 0 Refer IS:800-1984

(sac.cal / sac) + (Cmx . sbcz.cal ) / [{1 - (sac.cal / 0.60 . fccz)} sbcz] + (Cmy . sbcy.cal ) / [{1 - (sac.cal / 0.60 . fccy)} sbcy] ( Cm = 0.85 ) Cl. 7.1.1(a)

if σac,cal/σac ≤ 0.15 (σac,cal / σac)+(σbcz,cal / σbz) + (σbcy,cal / σ bcy)) = 1.07 Cl. 7.1.3

<1 UNSAFE

Check for shear:

Shear force (q) in t = 0 Refer IS:800-1984

Depth of web d1 in mm = 950 Cl. 6.4.2

Thickness of web t in mm = 8

2

Shear stress tva.cal (N/mm ) = q / d1 . t = 0.00 < 0.4.fy = 138

SAFE

Checks for welded plate girders:

The thickness of flange plates have been so choosen that the

projection of the plate beyond its connection to the web (x)mm is

kept within 256T/sqrt(fy) subject to a maximum of 16T.

x =B/2 - t/2 = 186

256T/sqrt(fy)=344.56 Refer IS:800-1984

16T = 400 Cl.3.5.2

x <= MIN. of (256T/sqrt(fy) and 16T) = 344.56 OK

For unstiffened webs the thickness of web plate shall be maximum of the following:

d1. sqrt(fy)/1344 = 13.13 Refer IS:800-1984

d1. sqrt(tva.cal)/816 = 0.00 Cl.6.7.3.1 (a)

d1/85 = 11.18

t > Max of the above values = Provide intermediate stiffners as per cl.6.7.4 of IS:800

END

You might also like

- HDPE Pipeline Installation and DesignDocument13 pagesHDPE Pipeline Installation and DesignYoungtae Kim100% (4)

- Design Calculations For Aluminium Profile-13794Document14 pagesDesign Calculations For Aluminium Profile-13794msiddiq175% (4)

- Reinforced Concrete StructureDocument388 pagesReinforced Concrete StructureKetsmy DesrosiersNo ratings yet

- Qatar Power Transmission Pile Design ReportDocument115 pagesQatar Power Transmission Pile Design ReportNauman Mumtaz100% (3)

- Base Plate Design As Per Is 800Document3 pagesBase Plate Design As Per Is 800K SrikanthNo ratings yet

- Introduction To Building Design (NSCP 2015)Document91 pagesIntroduction To Building Design (NSCP 2015)James JaboneroNo ratings yet

- Lecture 17: Design and Static Strength of Welded JointsDocument36 pagesLecture 17: Design and Static Strength of Welded Jointssprashant5No ratings yet

- Simple beam spreadsheetDocument65 pagesSimple beam spreadsheetKrishn DevNo ratings yet

- Raft Foundations Design and Analysis With A Practical ApproachDocument94 pagesRaft Foundations Design and Analysis With A Practical ApproachGilberto CarvalhoNo ratings yet

- Offshore Wind Turbine Foundation Design IssuesDocument42 pagesOffshore Wind Turbine Foundation Design IssuesLászló AranyNo ratings yet

- Design Compressive Stength For Channel With or Without Plate (As Per Is:800 2007)Document2 pagesDesign Compressive Stength For Channel With or Without Plate (As Per Is:800 2007)K SrikanthNo ratings yet

- Sample Railing Calculation To Euro CodeDocument4 pagesSample Railing Calculation To Euro CodeEric Ng S L100% (5)

- External Static Pressure CalculationDocument2 pagesExternal Static Pressure Calculationanwerquadri83% (12)

- Drive Shaft CalculationDocument106 pagesDrive Shaft CalculationMustu AkolawalaNo ratings yet

- Crankweb Deflections 9 Cyl ELANDocument2 pagesCrankweb Deflections 9 Cyl ELANСлавик МосинNo ratings yet

- Rdso Guide Lines FR BridgesDocument76 pagesRdso Guide Lines FR BridgesUtpal KantNo ratings yet

- Design of Rectangular Column Section by Limit-State MethodDocument44 pagesDesign of Rectangular Column Section by Limit-State Methodsridhar100% (1)

- IUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryDocument6 pagesIUPT17012 - KH RESIDENCE 2B+G+5+ROOF RESIDENTIAL BUILDING at DIP-Dubai, PLOT NO. 5981336 - TO SummaryTinh T. LeNo ratings yet

- Stress Analysis of Piping SystemsDocument108 pagesStress Analysis of Piping SystemsShijumon KpNo ratings yet

- Design Equations For FRP Structural BeamsDocument40 pagesDesign Equations For FRP Structural BeamsAmol Gole100% (1)

- Lehigh University Library Fritz Laboratory Reports - Shear Strength of Plate GirdersDocument62 pagesLehigh University Library Fritz Laboratory Reports - Shear Strength of Plate GirdersMaria FabianaNo ratings yet

- 3 CtoR1Document15 pages3 CtoR1kheang amgNo ratings yet

- Flat Keys and KeywaysDocument1 pageFlat Keys and KeywaysBarNo ratings yet

- Lincoln (Data Sheet) Murex E7024Document2 pagesLincoln (Data Sheet) Murex E7024PubcrawlNo ratings yet

- ERDS A2 SalDocument1 pageERDS A2 SalSaleem MohammedNo ratings yet

- General Laminate AnalysisDocument28 pagesGeneral Laminate AnalysisGilang Farhan Ramadhan MulyadiNo ratings yet

- Stair 01: 421802538.xls Page1 of 2 ST01Document2 pagesStair 01: 421802538.xls Page1 of 2 ST01Minh TanNo ratings yet

- Jack Portal ConnectionDocument24 pagesJack Portal ConnectionAfsal JhNo ratings yet

- Ginos Engineers Pty Ltd Beam B9 Deflection & Bending CheckDocument3 pagesGinos Engineers Pty Ltd Beam B9 Deflection & Bending CheckVinh DuongNo ratings yet

- Sructural Analysis and Design ReportDocument66 pagesSructural Analysis and Design ReportDessalegn GaminiNo ratings yet

- Steel Haunch Connection AISC 360-16 A5Document15 pagesSteel Haunch Connection AISC 360-16 A5kheang mengNo ratings yet

- Ship Hull Steel GuideDocument4 pagesShip Hull Steel GuideMa NaNo ratings yet

- Sect Prop 28Document4 pagesSect Prop 28abhi1789No ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument15 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- 3 CtoR1Document10 pages3 CtoR1kheang amgNo ratings yet

- PTFE Plate BearingDocument1 pagePTFE Plate BearingChoi Lai LonNo ratings yet

- Mbrf2080Ctl Schottky Rectifier: ApplicationsDocument5 pagesMbrf2080Ctl Schottky Rectifier: Applicationsmalucos123No ratings yet

- Hallite t58Document6 pagesHallite t58ShaneNo ratings yet

- EX Cercha Laminate CalculusDocument40 pagesEX Cercha Laminate CalculussarrpaNo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument22 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Freq. Rank: Acr. Meaning Freq. F Log (F)Document15 pagesFreq. Rank: Acr. Meaning Freq. F Log (F)andresNo ratings yet

- ConnectionDocument7 pagesConnectionSHOHAG DDMNo ratings yet

- Belgrave SherwinFINAL EXAM FALL 2020doneDocument4 pagesBelgrave SherwinFINAL EXAM FALL 2020doneÅkëëm MøøløøNo ratings yet

- En 10025-2-2004 BS HotRolledProductDocument7 pagesEn 10025-2-2004 BS HotRolledProductChrill DsilvaNo ratings yet

- 1036343-KEY 422-3D.SLDPRT - PDF - 30-P-205 - (PTD - REV-0000001037 - 1 - A1) - 1Document1 page1036343-KEY 422-3D.SLDPRT - PDF - 30-P-205 - (PTD - REV-0000001037 - 1 - A1) - 1SaeedAkbarzadehNo ratings yet

- Differential Temerature-ReverseDocument2 pagesDifferential Temerature-Reversemgr4.designNo ratings yet

- RCC53 Column DesignDocument2 pagesRCC53 Column DesignAgung WicaksanaNo ratings yet

- SOFiSTiK AG - Educational-Version - Cross Sections and Element DefinitionsDocument44 pagesSOFiSTiK AG - Educational-Version - Cross Sections and Element DefinitionsElaine BonaviaNo ratings yet

- PBL AssignmentDocument1 pagePBL AssignmentKashaf ZehraNo ratings yet

- Area of Steel Calculation: (Limit State)Document16 pagesArea of Steel Calculation: (Limit State)RAVI PRAKASH SAININo ratings yet

- Column NewDocument6 pagesColumn NewsugumarNo ratings yet

- Slab Templaet1Document10 pagesSlab Templaet1Engineeri TadiyosNo ratings yet

- Zero Ohm Jumper Chip Resistor: Type L 1F (01005) W C D T Dimensions InchesDocument2 pagesZero Ohm Jumper Chip Resistor: Type L 1F (01005) W C D T Dimensions InchesOlney JonerNo ratings yet

- Released 00011 P0007-000.002: Neosia Training CenterDocument1 pageReleased 00011 P0007-000.002: Neosia Training CenterJubah Syariat Asep SaefudinNo ratings yet

- SJ MEPLA Calculation Protocol:: Basic Form: QuadrangleDocument5 pagesSJ MEPLA Calculation Protocol:: Basic Form: QuadranglealbertoNo ratings yet

- STRAD Consultants (Pte) Ltd. Project No Project: Part of StructureDocument32 pagesSTRAD Consultants (Pte) Ltd. Project No Project: Part of StructureLakmal JayashanthaNo ratings yet

- IG 55 CalculationDocument11 pagesIG 55 CalculationNoridhamNo ratings yet

- Calculate The 3 Control Limits For X-Bar and R Charts Based On The First 12 Samples ReflectingDocument6 pagesCalculate The 3 Control Limits For X-Bar and R Charts Based On The First 12 Samples ReflectingRamzi SaeedNo ratings yet

- SJ MeplaDocument5 pagesSJ MeplaZaido Al HalabiNo ratings yet

- Impact of Transformer Inrush Current On Grid CodeDocument7 pagesImpact of Transformer Inrush Current On Grid CodeUTSHAB GHOSHNo ratings yet

- Jedinice Mera: Datoteka: 0001 ZA PREDAJU Ovaj - TWP Datum ProracunaDocument19 pagesJedinice Mera: Datoteka: 0001 ZA PREDAJU Ovaj - TWP Datum ProracunaKenan KajosevicNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterJOSE LOZADA MENDIETANo ratings yet

- Project Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENDocument8 pagesProject Data: Project Name Project Number Author Description Date 04-Nov-23 Design Code ENkheang amgNo ratings yet

- Parts Catalog: 0CD50-M03030ENDocument26 pagesParts Catalog: 0CD50-M03030ENliuzj7254No ratings yet

- Special Steels CB10FF: For Cold Deformation and BearingsDocument1 pageSpecial Steels CB10FF: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- Ig 55 Pipe CalculationDocument11 pagesIg 55 Pipe CalculationNoridhamNo ratings yet

- Transverse AnalysisDocument19 pagesTransverse AnalysisSulabh GuptaNo ratings yet

- Package Information - SC70-5: Surface Mounted, 5 Pin Package Package OutlineDocument3 pagesPackage Information - SC70-5: Surface Mounted, 5 Pin Package Package OutlinefurNo ratings yet

- Package Information - SSOP28: Surface Mounted, 28 Pin Package Package OutlineDocument3 pagesPackage Information - SSOP28: Surface Mounted, 28 Pin Package Package OutlinesdjayavelNo ratings yet

- Ilovepdf MergedDocument31 pagesIlovepdf MergedEr Shiva GuptaNo ratings yet

- Connection 4Document13 pagesConnection 4Der3'am Al m7armehNo ratings yet

- Vdocuments - MX - Pec Ac Resistance Reactance TableDocument2 pagesVdocuments - MX - Pec Ac Resistance Reactance TableJhoanna CalloNo ratings yet

- Greda - StolbDocument9 pagesGreda - StolbivanNo ratings yet

- Structural analysis of a reinforced concrete frameDocument20 pagesStructural analysis of a reinforced concrete frameoscarNo ratings yet

- SSB Purlin DesignDocument1 pageSSB Purlin DesignK SrikanthNo ratings yet

- Mass Foudnation CalculationsDocument1 pageMass Foudnation CalculationsK SrikanthNo ratings yet

- Bolt DetailsDocument5 pagesBolt DetailsK SrikanthNo ratings yet

- Advanced Strength of Materials - GDLC - 8851 PDFDocument12 pagesAdvanced Strength of Materials - GDLC - 8851 PDFabdullahaafaq33% (3)

- Pressure VesselDocument2 pagesPressure VesselbobNo ratings yet

- Syllabus For Mechanical Engineering (ME) - GATE 2013Document3 pagesSyllabus For Mechanical Engineering (ME) - GATE 2013Arun Anand A PNo ratings yet

- 0011 Static and Dynamic Analysis of Wind Turbine Blades Using The Finite Element MDocument18 pages0011 Static and Dynamic Analysis of Wind Turbine Blades Using The Finite Element MKhalil DeghoumNo ratings yet

- Corbel DesignDocument12 pagesCorbel DesignprsscribdNo ratings yet

- Module 6: Influence Lines Lecture 2:construction of Influence Lines Using Equilibrium MethodsDocument4 pagesModule 6: Influence Lines Lecture 2:construction of Influence Lines Using Equilibrium Methodschristi SNo ratings yet

- Gearless TransmissionDocument37 pagesGearless TransmissionTanvi KhuranaNo ratings yet

- Positive Moment Coefficients for Continuous BeamsDocument44 pagesPositive Moment Coefficients for Continuous BeamsCian ChanNo ratings yet

- Analysis of Soil Nailed Earth Slope by Discrete Element MethodDocument14 pagesAnalysis of Soil Nailed Earth Slope by Discrete Element Method池定憲No ratings yet

- Me2114-2 Combined Bending and Torsion Lab ReportDocument18 pagesMe2114-2 Combined Bending and Torsion Lab ReportLeonard100% (1)

- PTM 03Document1 pagePTM 03Zhongli MoraxNo ratings yet

- AWC DA6 BeamFormulas 01Document4 pagesAWC DA6 BeamFormulas 01Wong Chee LoongNo ratings yet

- Course Plan Steel StructureDocument7 pagesCourse Plan Steel StructureNabin Chandra SharmaNo ratings yet

- Modular Cantilever System SpecificationDocument14 pagesModular Cantilever System SpecificationMaddi vasuNo ratings yet

- Name of work:-LSD Design For Doubly Reinforced Simply Supported BeamDocument13 pagesName of work:-LSD Design For Doubly Reinforced Simply Supported BeamEngr SwapanNo ratings yet

- Steel and Timber Structures Part Two:: Design of Structural Steel MembersDocument51 pagesSteel and Timber Structures Part Two:: Design of Structural Steel MembersDhinesh KalaimaranNo ratings yet