Professional Documents

Culture Documents

Operators Wtpinsp

Uploaded by

Toufeeq Ahmed Latif0 ratings0% found this document useful (0 votes)

13 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesOperators Wtpinsp

Uploaded by

Toufeeq Ahmed LatifCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

PUBLIC HEALTH DIVISION

Drinking Water Program

For Water System Operators:

Preparing for a Water Treatment Plant Inspection

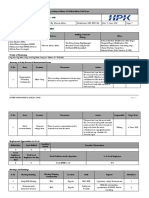

What to have available during the site visit:

Previous 12 months of the following data:

o Raw water turbidity data

o Settled water turbidity data (measured daily for 2.5-log WTPs)

o Individual filter turbidity data (IFE)

o Monthly operating reports

o Raw water alkalinity data (measured and recorded weekly if using alum)

o pH records for corrosion control treatment

o Membrane Filtration: Daily integrity testing data/records.

Records for the following:

o Chemical dosages records in mg/L

o Feed pump calibration records including pump curve graphs

o Turbidity profiles (on each filter after backwash quarterly)

o Turbidimeter calibration records (calibrated quarterly)

o Written decision making protocol for under-certified operators as established by the

Direct Responsible Charge Operator

o Standard WTP Operating Procedures

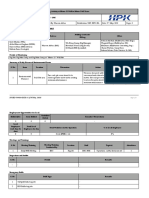

Be prepared to demonstrate the following during the site visit:

Combined Filter Effluent (CFE) turbidimeter draws water after all filter effluents combine

prior to storage.

If backwash water is recycled, the return location is prior to any chemical addition.

CTs are calculated using data from the most recent tracer study and pH/temp/chlorine

residual from the 1st user.

A flow meter is present on the effluent line of the clearwell.

The presence of an alarm on high turbidity levels and low chlorine residual (if serving

>3300 population) when plant is operated with no operators on site. Be knowledgeable of

Date: 2/2012 Page 1 of 2

what the set points are for the alarm for high turbidity, low chlorine and high chlorine

(when applicable).

Cartridge/Bag Filtration: Pressure gauges are present and functioning both before and

after the final cartridge or bag filter. Be knowledgeable about the psid in which the filters

are changed and why.

Slow Sand Filtration: Describe the scraping/cleaning/ripening protocol for the filters.

Membrane Filtration: Post filtration turbidimeters on each unit (i.e. each independently

piped section).

Diatomaceous Earth Filtration: Body feed is added with influent flow.

Other tips for good WTP operation:

Collect and record raw water turbidity data weekly.

Assure all chart (circle and strip charts) recorders document turbidity >5.5 NTU.

Assure all calibration standards are valid (not expired).

Measure flow through turbidimeters to assure it’s within the manufacturer’s recommended

range for accuracy.

Understand and be ready to describe how backwash cycles are initiated in your WTP.

Understand and be ready to describe the methods used to trigger chemical dosage

changes in your WTP.

Be able to demonstrate your knowledge of chemical dosage strengths (%) and ability to

convert dosages from mg/L to ml/min.

Understand and be ready to describe the data used in your WTP to determine the duration

of filter-to-waste cycles after backwash and what criteria are used to put a filter back on-

line.

For more information, call the OHA Drinking Water Program at (971) 673-0405 (M-F, 8am-5pm PT) or visit

www.healthoregon.org/dwp

Date: 2/2012 Page 2 of 2

You might also like

- Sample Commissioning PlanDocument36 pagesSample Commissioning Planvan81% (16)

- OQ Protocol For Purified WaterDocument5 pagesOQ Protocol For Purified WaterNorhasma Ismail100% (3)

- Gonzales-Jimenez Dental Clinic Wastewater ReportDocument12 pagesGonzales-Jimenez Dental Clinic Wastewater ReportLouie100% (5)

- Water System PQDocument47 pagesWater System PQsainzb8389% (9)

- Mes Ministry of Defense GoiDocument41 pagesMes Ministry of Defense GoiAbhay Sankar100% (1)

- Standard Operating Procedure, Flushing Water MainsDocument2 pagesStandard Operating Procedure, Flushing Water MainsJohnny Kao33% (3)

- Validation ProtocolDocument63 pagesValidation ProtocolIndústria Petys64% (22)

- Treatment Technology Report For Recycled WaterDocument47 pagesTreatment Technology Report For Recycled WatersfreigaNo ratings yet

- List of Questions and Answers For WastewaterDocument22 pagesList of Questions and Answers For WastewaterIR Ika EtyEtyka DoraNo ratings yet

- Filter Backwash Recycling Rule Recycle Notification FormDocument3 pagesFilter Backwash Recycling Rule Recycle Notification FormMuhammadUsmanNo ratings yet

- Managing Water Resources and QualityDocument48 pagesManaging Water Resources and Qualityjohne jossef medranoNo ratings yet

- Adv 885 Ro Pac M QuickrefguideDocument8 pagesAdv 885 Ro Pac M QuickrefguideAlejandroOdioCastilloNo ratings yet

- Drinking Water SamplingDocument176 pagesDrinking Water Samplingnermeen ahmedNo ratings yet

- 2 8 Seplol) : Office of The SecretaryDocument15 pages2 8 Seplol) : Office of The SecretaryZA TarraNo ratings yet

- 2019, EPA - Generating High-Quality Turbidity Data in Drinking Water Treatment Plants To Support System Optimization and MonitoringDocument17 pages2019, EPA - Generating High-Quality Turbidity Data in Drinking Water Treatment Plants To Support System Optimization and MonitoringMi doremiNo ratings yet

- Metito Qatar Case Study PDFDocument4 pagesMetito Qatar Case Study PDFMahmoud Abd El Lateef100% (1)

- Water Treatment Plant Spesification PDFDocument8 pagesWater Treatment Plant Spesification PDFrando85100% (1)

- Surface Water Treatment Operations Plan TemplateDocument8 pagesSurface Water Treatment Operations Plan TemplateSkid RowNo ratings yet

- Guideline For Clarifier and Granular Media Filter Ratings at Surface Water Treatment PlantsDocument9 pagesGuideline For Clarifier and Granular Media Filter Ratings at Surface Water Treatment PlantsHafidz MuzakkiNo ratings yet

- BP Guide Pharma ComplianceByDesign en Nov15Document12 pagesBP Guide Pharma ComplianceByDesign en Nov15Jessicalba LouNo ratings yet

- Iowa Online Turbidimeter Calibration and Verification GuidanceDocument9 pagesIowa Online Turbidimeter Calibration and Verification GuidancesajithNo ratings yet

- NEOPRSP001 - Rev. 01 - Pages 12 - Plant Operation Control ProcedureDocument11 pagesNEOPRSP001 - Rev. 01 - Pages 12 - Plant Operation Control Procedurealialharbi021No ratings yet

- Water Treatment Controlling SystemDocument12 pagesWater Treatment Controlling SystemMuhammad Faisal JazuliNo ratings yet

- Flow MeterDocument140 pagesFlow MeterSaravanan Rasaya100% (1)

- Section 11: Water Treatment and Related MattersDocument13 pagesSection 11: Water Treatment and Related MattersMauro Domingo'sNo ratings yet

- Water Treatment Plant Optimization Goals What Is Water Treatment Plant Optimization?Document2 pagesWater Treatment Plant Optimization Goals What Is Water Treatment Plant Optimization?Colleen MurphyNo ratings yet

- Water System PQDocument46 pagesWater System PQVeChrist PharmacistoLshop100% (3)

- SOP Sewer Collection SystemsDocument14 pagesSOP Sewer Collection SystemsdexterNo ratings yet

- Reverse Osmosis (RO) Preventive MaintenanceDocument5 pagesReverse Osmosis (RO) Preventive MaintenanceAmy FitzpatrickNo ratings yet

- From Start To Finish: Pharmaceutical Grade WaterDocument6 pagesFrom Start To Finish: Pharmaceutical Grade Watervenki_bee100% (1)

- 76e4 PDFDocument12 pages76e4 PDFSagar ApteNo ratings yet

- Ultrasonic WaterMeter Maintenance GuidanceDocument6 pagesUltrasonic WaterMeter Maintenance Guidancenorbu karbuluNo ratings yet

- Plasticizer OverviewDocument13 pagesPlasticizer Overviewzger15No ratings yet

- 14 Appendix ADocument108 pages14 Appendix ALi QiNo ratings yet

- Flow Measurement, Sampling, and Process ControlDocument8 pagesFlow Measurement, Sampling, and Process ControlMoucha JustdoitNo ratings yet

- Guidance on Slow Sand and Diatomaceous Earth FiltrationDocument118 pagesGuidance on Slow Sand and Diatomaceous Earth Filtrationjose03No ratings yet

- PCRP Report Executive SummaryDocument7 pagesPCRP Report Executive SummaryKathryn SmithNo ratings yet

- Tech Manual Record KeepingDocument4 pagesTech Manual Record KeepingRavi MadhavanNo ratings yet

- Project Profile Information FormDocument3 pagesProject Profile Information FormMuhammadUsmanNo ratings yet

- Effluent & Sewage Treatment Plant 110 KLD: Operation ManualDocument10 pagesEffluent & Sewage Treatment Plant 110 KLD: Operation ManualBinod DavisNo ratings yet

- Groundwater Sample Collection and Analysis Procedures: Petroleum Remediation ProgramDocument20 pagesGroundwater Sample Collection and Analysis Procedures: Petroleum Remediation ProgramDaniel JacksonNo ratings yet

- Sewage Treatment Plant Technical InstructionsDocument41 pagesSewage Treatment Plant Technical InstructionsPradeepBansal50% (2)

- MTPCL - WTP O&m ManualDocument62 pagesMTPCL - WTP O&m Manualm_ganesh1983100% (4)

- Diesel Exhaust Fluid Plant For Automotive Er800Document3 pagesDiesel Exhaust Fluid Plant For Automotive Er800indianepal420No ratings yet

- Annual Report TemplateDocument5 pagesAnnual Report TemplateJason LeBlancNo ratings yet

- Techno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridDocument9 pagesTechno-Commercial Offer 100 KLD STP, Betul Based On MBBR HybridTech MongerNo ratings yet

- Technical Specification SWRO 4x2500cmdDocument23 pagesTechnical Specification SWRO 4x2500cmdJeyakumar Arumugam100% (2)

- Quotation of RO Plant From AQUARO WATER SOUTIONS PDFDocument11 pagesQuotation of RO Plant From AQUARO WATER SOUTIONS PDFAlexander DoraisamyNo ratings yet

- Techcross Guidance For SamplingProcedureDocument17 pagesTechcross Guidance For SamplingProcedureRajish RNo ratings yet

- Wastewater Treatment Design Considerations and Case StudiesDocument117 pagesWastewater Treatment Design Considerations and Case StudiesAs Mih100% (1)

- FICHA TECNICA Opcion 1Document3 pagesFICHA TECNICA Opcion 1Victor Manuel Baldera VelasquezNo ratings yet

- Revised Pacifica Bandini Engineering's ReportDocument10 pagesRevised Pacifica Bandini Engineering's ReportGarry PonferradaNo ratings yet

- PressedDocument4 pagesPressedcharvi shinyNo ratings yet

- Aarti Drugs Audit Report Finds Issues with Change Management and EDC MonitoringDocument12 pagesAarti Drugs Audit Report Finds Issues with Change Management and EDC MonitoringVijay KotwalNo ratings yet

- CH2M HILL Wastewater Treatment Design OperationDocument10 pagesCH2M HILL Wastewater Treatment Design OperationpennywiserNo ratings yet

- (Da 2) Matulac, Reynee Shaira - Che423 Bsche4Document3 pages(Da 2) Matulac, Reynee Shaira - Che423 Bsche4Reynee Shaira Lamprea MatulacNo ratings yet

- Holding Tank 99Document14 pagesHolding Tank 99Mohammad J HaddadNo ratings yet

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- Chemical Marine Monitoring: Policy Framework and Analytical TrendsFrom EverandChemical Marine Monitoring: Policy Framework and Analytical TrendsNo ratings yet

- Reapplication Form June 2021 WEBDocument1 pageReapplication Form June 2021 WEBToufeeq Ahmed LatifNo ratings yet

- Software Request 2Document1 pageSoftware Request 2Toufeeq Ahmed LatifNo ratings yet

- E-Mail Address Request: QF-IT-027-3-2Document1 pageE-Mail Address Request: QF-IT-027-3-2Toufeeq Ahmed LatifNo ratings yet

- Test Accommodation Request FormDocument3 pagesTest Accommodation Request FormToufeeq Ahmed LatifNo ratings yet

- QEP Recertification Application: Institute of Professional Environmental PracticeDocument5 pagesQEP Recertification Application: Institute of Professional Environmental PracticeToufeeq Ahmed LatifNo ratings yet

- General Waste & Soak Pits Inspection Checklist (27th May, 2020)Document2 pagesGeneral Waste & Soak Pits Inspection Checklist (27th May, 2020)Toufeeq Ahmed LatifNo ratings yet

- General Environmental Checklist (21st March, 2020)Document4 pagesGeneral Environmental Checklist (21st March, 2020)Toufeeq Ahmed LatifNo ratings yet

- Fuels Oils and Chemicals Checklist - Latif-23 - 29th March, 2020Document2 pagesFuels Oils and Chemicals Checklist - Latif-23 - 29th March, 2020Toufeeq Ahmed LatifNo ratings yet

- PKUEP-500024-DER-24 (2nd June, 2020)Document7 pagesPKUEP-500024-DER-24 (2nd June, 2020)Toufeeq Ahmed LatifNo ratings yet

- Enviro - News ARAMCODocument56 pagesEnviro - News ARAMCOToufeeq Ahmed LatifNo ratings yet

- PKUEP-500024-DER-15 (29th March, 2020)Document5 pagesPKUEP-500024-DER-15 (29th March, 2020)Toufeeq Ahmed LatifNo ratings yet

- PKUEP-500024-DER-18 (27th May, 2020)Document6 pagesPKUEP-500024-DER-18 (27th May, 2020)Toufeeq Ahmed LatifNo ratings yet

- PKUEP-500024-DER-7 (21st March, 2020)Document5 pagesPKUEP-500024-DER-7 (21st March, 2020)Toufeeq Ahmed LatifNo ratings yet

- ETS Handbook 2020 - FinalWebDocument264 pagesETS Handbook 2020 - FinalWebToufeeq Ahmed LatifNo ratings yet

- MDR SafaniyaDocument1 pageMDR SafaniyaToufeeq Ahmed LatifNo ratings yet

- RC Fanateer Evaluation For HHDocument1 pageRC Fanateer Evaluation For HHToufeeq Ahmed LatifNo ratings yet

- 10 Environmental Justice IssuesDocument3 pages10 Environmental Justice Issuesapi-630278706No ratings yet

- Assessment of National and State Action Plans For Climate Change For The State of AssamDocument16 pagesAssessment of National and State Action Plans For Climate Change For The State of AssamKarthik GirishNo ratings yet

- Rain Water HarvestingDocument15 pagesRain Water HarvestingJagadỴshKrishnamurthyNo ratings yet

- Upsidc MLC Project ProgressDocument23 pagesUpsidc MLC Project ProgressSahil KhanNo ratings yet

- 4236.UNP.001.TKL.18 Merdare2 (Repaired) PDFDocument69 pages4236.UNP.001.TKL.18 Merdare2 (Repaired) PDFperfilma2013No ratings yet

- Introduction To Renewable Introduction To Renewable Energy EnergyDocument9 pagesIntroduction To Renewable Introduction To Renewable Energy EnergyYug VarshneyNo ratings yet

- Phytoremediation: An Environmentally Sound Technology For Pollution Prevention, Control and RemediationDocument11 pagesPhytoremediation: An Environmentally Sound Technology For Pollution Prevention, Control and RemediationAlejaAlvarezMontejoNo ratings yet

- TIGAS Haldor TopsoeDocument25 pagesTIGAS Haldor TopsoeGabriele CentiNo ratings yet

- Dairy Wastewater ETP Removes 94% of PollutantsDocument6 pagesDairy Wastewater ETP Removes 94% of PollutantsMortezaNo ratings yet

- Catalogue CSM PDFDocument4 pagesCatalogue CSM PDFFran IgledominguezNo ratings yet

- Rain Water Harvesting: Sardar Vallabhbhai Patel National Institute of Technology, SuratDocument25 pagesRain Water Harvesting: Sardar Vallabhbhai Patel National Institute of Technology, SuratPooja RathodNo ratings yet

- Environment Management - Question BankDocument4 pagesEnvironment Management - Question Bankkundanp48No ratings yet

- Energy Effecient Build - Solar KitchenDocument6 pagesEnergy Effecient Build - Solar KitchenyuvarajNo ratings yet

- CV - Environmental - Top - EEM - BrochureDocument8 pagesCV - Environmental - Top - EEM - BrochureLandryNo ratings yet

- Sewage - Meaning, Composition and DisposalDocument18 pagesSewage - Meaning, Composition and Disposalshailendra singhNo ratings yet

- Complaint/ Spill Report FormDocument1 pageComplaint/ Spill Report FormKristen NicoleNo ratings yet

- Solid Waste Management, Lec 1Document42 pagesSolid Waste Management, Lec 1প্রিন্স রেজাNo ratings yet

- Modular UASB for Anaerobic TreatmentDocument4 pagesModular UASB for Anaerobic TreatmentvdrishNo ratings yet

- Ecosystem StabilityDocument3 pagesEcosystem StabilityNirmala ChoudharyNo ratings yet

- Water Treatment Plant DesignDocument14 pagesWater Treatment Plant DesignIndunil Herath100% (2)

- ARCH 4263 Sustainable Design Methods: Dr. Khandoker Mahfuz Ud DarainDocument13 pagesARCH 4263 Sustainable Design Methods: Dr. Khandoker Mahfuz Ud Darainsadid sakibNo ratings yet

- Unit 2 - Energy & Environmental Engineering - WWW - Rgpvnotes.inDocument24 pagesUnit 2 - Energy & Environmental Engineering - WWW - Rgpvnotes.inHarshal BordiaNo ratings yet

- Project-Proposal-SLF Cell No. 4Document5 pagesProject-Proposal-SLF Cell No. 4neil_potter16No ratings yet

- ww20 Trickling Filter WB PDFDocument91 pagesww20 Trickling Filter WB PDFRenzo Cadag MacasilNo ratings yet

- HLCP 05 BrochureDocument11 pagesHLCP 05 BrochureResul UygunNo ratings yet

- Peatland HydrologyDocument87 pagesPeatland HydrologyAfita ainiNo ratings yet

- Chessman - 1995 (MZB) PDFDocument9 pagesChessman - 1995 (MZB) PDFHasriyani HafidNo ratings yet

- BHOPALDocument6 pagesBHOPALSmriti SNo ratings yet

- Submerged Aerobic Fixed Film BioreactorDocument12 pagesSubmerged Aerobic Fixed Film BioreactorRohit MaliNo ratings yet

- ACO Aeropur Plus 3 - 100Document8 pagesACO Aeropur Plus 3 - 100duga11No ratings yet