Professional Documents

Culture Documents

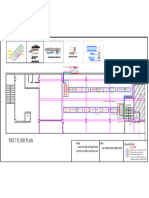

SEQ-SEW-1303-4 A: Seq Water Service Providers

Uploaded by

marklaforestOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEQ-SEW-1303-4 A: Seq Water Service Providers

Uploaded by

marklaforestCopyright:

Available Formats

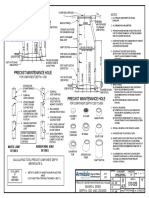

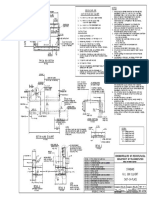

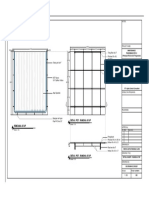

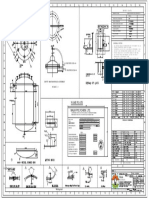

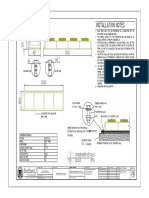

6 NOM

50 NOM. MAINTENANCE HOLE WALL

REINFORCEMENT

NOTES

S.S. WASHERS 100 MAX.

NEOPRENE AS REQUIRED GENERAL

FOR PACKING 4 M16 S.S. THREADED RODS WITH 14 DIA. HOLE 1. BRACKETS TO BE INSTALLED AT MAXIMUM 1500

GASKET 50x3

CLAMPING AND FIXING NUTS AND 4mm FOR M12 BOLT CENTRES BUT AT LEAST ONE AT TOP AND ONE AT

STRIP 'CLARK

RUBBER' OR PART B THICK S.S. PLATE WASHERS. COAT ALL BOTTOM OF DROP PIPE.

EQUIVALENT EXPOSED THREADS WITH 'DENSO' OR E E STAINLESS STEEL

EQUIVALENT SYSTEM. - - 2. STAINLESS STEEL WORK SHALL COMPLY TO

160 FOR DN100 uPVC DROP PIPE

AS1554.6-1994 OR APPROVED EQUIVALENT.

PART A S.S. FEMALE THREADED FERRULES 60 MIN. 190 FOR DN150 uPVC DROP PIPE

50 3 3 3. STAINLESS STEEL MATERIALS SHALL BE SUPPLIED TO

EMBEDMENT - WELD TO REINFORCEMENT MIN ASTM GRADE 316 OR EQUIVALENT.

SN8 UPVC 14 DIA. HOLE

IF DIRECTED BY SUPERINTENDENT. (90 4. WELDING SHALL COMPLY TO AUSTRALIAN WELDING

DROP PIPE FOR M12 BOLT

MIN. EMBEDMENT IF WELDED). RESEARCH ASSOCIATION TECHNICAL NOTE 16 -

OPTION 'A' WELDING STAINLESS STEELS.

20 THICK S.S.

5. WELDS SHALL BE 6mm CONTINUOUS FILLET WELDS

BASEPLATE

PE LINER PENETRATION TO BE (AWS A5.9 ELECTRODE (2209) UNLESS NOTED

OTHERWISE.

PE LINING SEALED WITH '3M DP-8005' A 6. ALL STORAGE, FABRICATION AND WELDING OF

ADHESIVE OR EQUIVALENT. REFER

210 NOM FOR DN100 uPVC

NOTES 12 AND 13. E E - STAINLESS STEEL SHALL BE CARRIED OUT IN AN AREA

6 NOM. 240 NOM FOR DN150 uPVC 66 SPECIFICALLY DEDICATED TO THE PARTICULAR GRADE

- - OF STAINLESS STEEL BEING USED.

M12 S.S. BOLT, 35 LONG WITH NUTS AND WASHERS. DO NOT

OVERTIGHTEN NUTS.TIGHTEN NUTS SUFFICIENTLY TO LIGHTLY

B 7. WELD SURFACE FINISH TO BE:

COMPRESS THE NEOPRENE GASKET ONLY. MAINTENANCE - (a) INTERNAL WELDS 1B, II

HOLE WALL (b) EXTERNAL WELDS 1B, I (200#)

NOTE: 6 8. USE OVERSIZE WASHERS AS REQUIRED FOR OVERSIZE

GLUE THE NEOPRENE GASKET TO THE BRACKET USING A SUITABLE CONTACT PART A PART B HOLES.

CEMENT. SIMILARLY GLUE ANY ADDITIONAL NEOPRENE GASKETS REQUIRED TO THE 9. ALL SHAFTS FOR OPTION 'B' AND AT LEAST ONE

R83

GASKET ALREADY INSTALLED. PIPE F FERRULE FOR OPTION 'A' SHALL BE WELDED TO

u PVC PE R58 OR DN

N15

0 C PI FOR 150 REINFORCEMENT WHERE BRACKETS ARE INSTALLED

PLAN RD uPV DN u

F O 0 0 100 PVC P WITHIN 60 METRES OF HIGH VOLTAGE ELECTRICAL

R83 DN1 uPV IPE

FOR CP

POWER TRANSMISSION TOWERS OR AS DIRECTED BY

R58 IPE THE AUTHORITY.

MAINTENANCE HOLE D B BASE DEAL

WALL REINFORCEMENT

- - 10. OPTION 'A' BASE IS APPLICABLE FOR PE-LINED

6 THICK MAINTENANCE HOLES.

S.S. PLATE 6 11. OPTION 'B' BASE IS APPLICABLE TO EXISTING OR NEW

MAINTENANCE HOLES NOT REQUIRING PE LINING.

6 PE LINER

12. THE FERRULES SHOULD BE INSTALLED THROUGH THE

ELEVATION A

D -

PE LINER IF NOT REQUIRED TO BE WELDED TO WALL

40

40

REINFORCEMENT. OTHERWISE, THE THREADED RODS

BRACKET ASSEMBLY - OPTION 'A' BASE 6

- SHOULD BE INSTALLED THROUGH THE PE LINER INTO

THE PRE-INSTALLED FERRULES. AT THE INTERFACE

50 6 40 3 3 6 THICK DIA. 36 S.S. ROUND BAR OR

BETWEEN THE PE-LINED WALL AND THE THREADED

40 80 40 S.S. PLATE M40 S.S. BOLT OR M40 S.S.

STAINLESS STEEL RODS, THE GAP SHALL BE SEALED

10 BOLT OR THREADED ROD

ALTERNATIVE

USING '3M'S DP-8005' ADHESIVE OR SIMILAR

SECTION E

APPROVED PRODUCT TO CREATE A GAS TIGHT SEAL,

55 FOR

40

BRACKET DETAILS - OPTION 'A' BASE

40

INSTALLED IN ACCORDANCE WITH THE

6

MANUFACTURER'S RECOMMENDATIONS (APPLYING A

CONTINUOUS BEAD AROUND THE INTERFACE POINT OF

DIA. 36 S.S. ROUND BAR THE THREADED ROD AND THE PE LINER).

6 DIA. 14 HOLE MAINTENANCE 13. OPERATORS SHOULD NOTE THAT '3M' DP-8005

OR M40 S.S. BOLT OR

HOLE WALL

40

THREADED ROD ADHESIVE HAS A VERY SHORT WORKING LIFE (3 TO 4

6 THICK

SECTION D MINUTES).

17

S.S. PLATE

80

-

DIRECT CHEMICAL GROUTING

6 50

6 IN CORED HOLE OR CAST INTO

WALL. REFER NOTE 9.

22

C C SECTION E

- - -

8

DIA. 20 OVERSIZE HOLE

40

SLOT END OF BAR

TO FIT WEB OF FOR M12 S.S. BOLT WITH

150 MIN. 4mm THICK PLATE 20

CLAMP 6

EMBEDMENT 6

WASHER

4 x 24 DIA.

20 THICK S.S. OVERSIZE HOLES 6 6

6

100 SQUARE S.S.

FOR 230 WALL ALTERNATIVE

BASEPLATE

6

BASEPLATE 16 THICK SECTION E

DIA. 36 S.S. ROUND BAR OR 6 THICK -

M40 S.S. BOLT OR THREADED SECTION A SECTION B 20 MAX. PRECISION S.S. PLATE

ROD - - GROUT DIRECT TO

OPTION 'B' BASE DETAIL

SECTION C CONCRETE

-

REV. No. DATE DESCRIPTION AUTH.

SEWERAGE STANDARD DRAWING GCCC LCC RCC QUU UW

SEQ WATER TYPICAL STAINLESS STEEL BRACKETS FOR

DRAWING No. VERSION

SERVICE PROVIDERS DN100 AND DN150 SEQ-SEW-1303-4 A

uPVC DROP PIPES

WORK PRACTICES MUST COMPLY WITH ALL APPLICABLE ORG DATE:

OCCUPATIONAL HEALTH & SAFETY LEGISLATION NOT TO SCALE 1/1/2013

You might also like

- Solution Manual For Microeconomics 16th Canadian Edition Christopher T S Ragan Christopher RaganDocument13 pagesSolution Manual For Microeconomics 16th Canadian Edition Christopher T S Ragan Christopher RaganChristopherRamosfgzoNo ratings yet

- Introduction to AS/NZS 2312.2 guide on HDG corrosion protectionDocument2 pagesIntroduction to AS/NZS 2312.2 guide on HDG corrosion protectionmarklaforestNo ratings yet

- Week 6 Homework Chi-Square TestsDocument58 pagesWeek 6 Homework Chi-Square TestsJasonNo ratings yet

- The OLOF Upsell FormulaDocument122 pagesThe OLOF Upsell FormulaBe move100% (1)

- IGCSE Economics Self Assessment Chapter 26 AnswersDocument3 pagesIGCSE Economics Self Assessment Chapter 26 AnswersDesreNo ratings yet

- 12.5-310-100 High Mast Lighting SystemDocument1 page12.5-310-100 High Mast Lighting SystemrituNo ratings yet

- QP10-Q-610 Rev0 Typical Yard Shaft - General ArrangementDocument1 pageQP10-Q-610 Rev0 Typical Yard Shaft - General ArrangementnawajhaNo ratings yet

- QP10-U-703 Rev0 Typical Line MarkerDocument1 pageQP10-U-703 Rev0 Typical Line MarkernawajhaNo ratings yet

- Exhaust Fan Mounting Detail A Refrigerant Pipe Insulation Detail B Pipe Thru Wall Detail CDocument1 pageExhaust Fan Mounting Detail A Refrigerant Pipe Insulation Detail B Pipe Thru Wall Detail CMark Anthony ValbuenaNo ratings yet

- Screenshot 2023-12-07 at 12.32.50 PMDocument1 pageScreenshot 2023-12-07 at 12.32.50 PMrashidkamal456No ratings yet

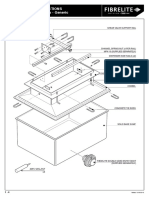

- Cover and Surround Maintenance Hole DesignDocument1 pageCover and Surround Maintenance Hole DesignHarsha nrNo ratings yet

- Design reinforcement for cast-in-place box culvertDocument13 pagesDesign reinforcement for cast-in-place box culvertPRAKASHNo ratings yet

- Rangka Atap Untuk Pustu IiDocument1 pageRangka Atap Untuk Pustu IiResya AstinNo ratings yet

- ELLIPTICAL SPIRAL DUCTABLE LAYOUT FOR THE ROCKS-23-ModelDocument1 pageELLIPTICAL SPIRAL DUCTABLE LAYOUT FOR THE ROCKS-23-ModelAbdullah.N FAAliNo ratings yet

- IPS-D-CE-150 Moment ConnectionDocument1 pageIPS-D-CE-150 Moment Connectionbabakfun2000No ratings yet

- C02-50-003 DROP MANHOLE DETAILSDocument1 pageC02-50-003 DROP MANHOLE DETAILSBoiki RabewuNo ratings yet

- 600mm Dia SS MANHOLE COVERDocument1 page600mm Dia SS MANHOLE COVERRenz ChuaNo ratings yet

- Roads and Earthen FirewallsDocument1 pageRoads and Earthen FirewallsMohamed ElsaneeNo ratings yet

- Notes:: Iranian Petroleum StandardsDocument1 pageNotes:: Iranian Petroleum Standardsbabakfun2000No ratings yet

- Lighting FixtureDocument1 pageLighting Fixtureahmed.abdelmegeed78No ratings yet

- Concrete Thrust BlockDocument1 pageConcrete Thrust Blocksertackocdag100% (1)

- Pismo ConceptualsiteplanDocument1 pagePismo ConceptualsiteplanldoustNo ratings yet

- Typical Slab Section (Two-Way)Document1 pageTypical Slab Section (Two-Way)operationextrastorageNo ratings yet

- Tanque Vu 570 m3 DSN-RCT275-50Document2 pagesTanque Vu 570 m3 DSN-RCT275-50Comercial FirenoNo ratings yet

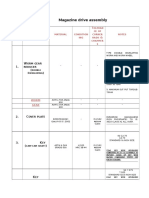

- Magazine & Magazine Drive AssemblyDocument13 pagesMagazine & Magazine Drive Assemblybodhas8924No ratings yet

- Saudi Arabian Oil Company: Table 1 Minimum Cover RequirementsDocument1 pageSaudi Arabian Oil Company: Table 1 Minimum Cover RequirementsAswin KurupNo ratings yet

- Inside Drop ManholeDocument1 pageInside Drop ManholeAtef MohamedenNo ratings yet

- R.C.C. End Details - Riya ShomeDocument1 pageR.C.C. End Details - Riya ShomeSam WilliamNo ratings yet

- ESC PilesDocument84 pagesESC PilesRon SantosNo ratings yet

- 3616A, B ModelDocument1 page3616A, B ModelVarun MalhotraNo ratings yet

- General Arrangements 2Document1 pageGeneral Arrangements 2isan.structural TjsvgalavanNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- Drainage and Infrastructure Design ElementsDocument1 pageDrainage and Infrastructure Design ElementsvincentnNo ratings yet

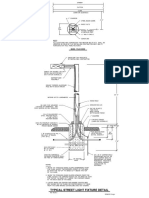

- Typical Street Light Fixture Detail: Base - Plan ViewDocument1 pageTypical Street Light Fixture Detail: Base - Plan ViewMedyouNo ratings yet

- Foam Outlet Solution Inlet Water: Vertical Bladder Tank CAPACITY - 1700 LtrsDocument1 pageFoam Outlet Solution Inlet Water: Vertical Bladder Tank CAPACITY - 1700 LtrsAdhya RazanNo ratings yet

- Pipe Trenching Details - 0Document1 pagePipe Trenching Details - 0tariro ndarowaNo ratings yet

- HPC1 X 1000Document1 pageHPC1 X 1000Shivam SharmaNo ratings yet

- Panelling ModelDocument1 pagePanelling ModelcharuNo ratings yet

- NF-SD-FF-NS-004Document1 pageNF-SD-FF-NS-004Adnan AkhtarNo ratings yet

- Fastener and material designations for roof panel penetrationsDocument1 pageFastener and material designations for roof panel penetrationsAhmed Saber NassarNo ratings yet

- Section A-A: Wall Cheq'D PlateDocument1 pageSection A-A: Wall Cheq'D PlateAL BASTAKI CONTRACTING L.L.C.50% (2)

- HPC 1x1000 EncasingDocument1 pageHPC 1x1000 EncasingShivam SharmaNo ratings yet

- 2019 PDFDocument1 page2019 PDFAL BASTAKI CONTRACTING L.L.C.No ratings yet

- Securedge 3000 Fascia Order /specification Form: (For Single-Ply Membrane)Document2 pagesSecuredge 3000 Fascia Order /specification Form: (For Single-Ply Membrane)Constantin GubavuNo ratings yet

- ESC General Catalogue 2017 2018 1st EditionDocument82 pagesESC General Catalogue 2017 2018 1st EditionArief Rachman0% (1)

- ADC Part 10Document1 pageADC Part 10Maung PDDNo ratings yet

- Installation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Document4 pagesInstallation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Camilo CorreaNo ratings yet

- Welded Steel Encasement Pipe InstallationDocument1 pageWelded Steel Encasement Pipe InstallationRamces AsisiNo ratings yet

- CondenserDocument1 pageCondenserKrizza Joyce AblolaNo ratings yet

- Roof Plan: Drawing NotesDocument3 pagesRoof Plan: Drawing NotesSanthoshkumar a.sNo ratings yet

- Cp4 - 2013 - Drainage Reserve Marker, Bollard and Posts & ChainDocument1 pageCp4 - 2013 - Drainage Reserve Marker, Bollard and Posts & ChainAjeeth RaviNo ratings yet

- Page 2 - Perimeter FenceDocument1 pagePage 2 - Perimeter FenceJet ToledoNo ratings yet

- All MR100Document18 pagesAll MR100Rakshit GoyalNo ratings yet

- Installation Guide For Securedge 300 Fascia: Approved Ansi/Spri Es-1 TestedDocument2 pagesInstallation Guide For Securedge 300 Fascia: Approved Ansi/Spri Es-1 TestedConstantin GubavuNo ratings yet

- H001 76-10526-Detail Design: Drainage Legend Standard Drainage Notes: Abbreviation Designation AbbreviationsDocument1 pageH001 76-10526-Detail Design: Drainage Legend Standard Drainage Notes: Abbreviation Designation AbbreviationsMazen IsmailNo ratings yet

- General Notes:: Typical Section of R.C.C. Storm Water DrainDocument2 pagesGeneral Notes:: Typical Section of R.C.C. Storm Water Drainbijnor officeNo ratings yet

- Nb7040 - Rules For Pipe Connections and Spools: Acc. Building Specification. Rev. 2, November 2016Document4 pagesNb7040 - Rules For Pipe Connections and Spools: Acc. Building Specification. Rev. 2, November 201624142414No ratings yet

- 81-1060 Cabezal de Descarga Plano - DetalleDocument1 page81-1060 Cabezal de Descarga Plano - DetalleRodolfo MerazNo ratings yet

- Strainer Simple Mod. 72 - 10-18 - 125#Document1 pageStrainer Simple Mod. 72 - 10-18 - 125#Francisco Xavier Geronimo GarciaNo ratings yet

- Slab Layout: DWG No 190811 DDocument14 pagesSlab Layout: DWG No 190811 DSaiful IslamNo ratings yet

- Service Installation Pole Mount (Shown) : Notes: Grounding SystemDocument1 pageService Installation Pole Mount (Shown) : Notes: Grounding SystemEnrique Hdez. E.No ratings yet

- STEEL SHEET PILE-ESC General Catalogue - CompressedDocument84 pagesSTEEL SHEET PILE-ESC General Catalogue - CompressedVan Cuong PhamNo ratings yet

- Standard Sidewalk Replacement/Installation DetailDocument19 pagesStandard Sidewalk Replacement/Installation DetailJuan Carlos ZordanNo ratings yet

- The Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeFrom EverandThe Vanishing Present: Wisconsin's Changing Lands, Waters, and WildlifeDonald M. WallerRating: 4 out of 5 stars4/5 (1)

- LMENIM2306 Enaq - PDDocument112 pagesLMENIM2306 Enaq - PDmarklaforestNo ratings yet

- Rtt-Ind-001 Rev 9 (No 13 Solvent) 11092017 JfoDocument11 pagesRtt-Ind-001 Rev 9 (No 13 Solvent) 11092017 JfomarklaforestNo ratings yet

- Rotork Profibus ControlDocument16 pagesRotork Profibus ControlmarklaforestNo ratings yet

- Rotork Profibus ControlDocument16 pagesRotork Profibus ControlmarklaforestNo ratings yet

- Iccons CIS Threaded Inserts TDSDocument2 pagesIccons CIS Threaded Inserts TDSmarklaforestNo ratings yet

- Specifications: Limitorque MX Selection DataDocument18 pagesSpecifications: Limitorque MX Selection DatamarklaforestNo ratings yet

- Queensland Government GazetteDocument53 pagesQueensland Government GazettemarklaforestNo ratings yet

- Bridco Load Rated 2016Document16 pagesBridco Load Rated 2016marklaforestNo ratings yet

- As Passavant Shut Off Devices en WEBDocument4 pagesAs Passavant Shut Off Devices en WEBmarklaforestNo ratings yet

- Bridco Load Rated 2016Document16 pagesBridco Load Rated 2016marklaforestNo ratings yet

- SS300 adhesive series property comparisonDocument2 pagesSS300 adhesive series property comparisonmarklaforestNo ratings yet

- Limitorque Actuation SystemsDocument16 pagesLimitorque Actuation SystemsmarklaforestNo ratings yet

- Constitution For Sample Pty LTDDocument20 pagesConstitution For Sample Pty LTDmarklaforestNo ratings yet

- Weld-On Structural Adhesives: Product Reference GuideDocument1 pageWeld-On Structural Adhesives: Product Reference GuidemarklaforestNo ratings yet

- Chemical Resistance Guide: Resin SelectionDocument4 pagesChemical Resistance Guide: Resin SelectionmarklaforestNo ratings yet

- VCB22 Series - Data Sheet (En)Document11 pagesVCB22 Series - Data Sheet (En)marklaforest0% (1)

- ISO Hole Tolerances ChartDocument1 pageISO Hole Tolerances ChartmarklaforestNo ratings yet

- SS300 React Vs TempDocument1 pageSS300 React Vs TempmarklaforestNo ratings yet

- Manual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066Document2 pagesManual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066marklaforestNo ratings yet

- Q LD Procurement PolicyDocument20 pagesQ LD Procurement PolicymarklaforestNo ratings yet

- TolerancesDocument9 pagesTolerancesAnugrah YudhaNo ratings yet

- Flange TableDocument0 pagesFlange TablemkstngrNo ratings yet

- Guide to Protecting Steel from CorrosionDocument17 pagesGuide to Protecting Steel from CorrosiondilrangiNo ratings yet

- CPV Process Valve ActuatorDocument12 pagesCPV Process Valve ActuatormarklaforestNo ratings yet

- TolerancesDocument9 pagesTolerancesariyarathneNo ratings yet

- Business Plan TemplateDocument37 pagesBusiness Plan TemplatemarklaforestNo ratings yet

- Linear Actuator LA37 Data Sheet EngpdfDocument28 pagesLinear Actuator LA37 Data Sheet EngpdfmarklaforestNo ratings yet

- CPV Process Valve ActuatorDocument12 pagesCPV Process Valve ActuatormarklaforestNo ratings yet

- Urgent road repair and maintenance tenderDocument10 pagesUrgent road repair and maintenance tenderBidhannagar Circle, PW Dte., Govt. of WB PWDNo ratings yet

- 1 Assignment 1 (General Equilibrium) : I I I I I I IDocument2 pages1 Assignment 1 (General Equilibrium) : I I I I I I IAnindita DeyNo ratings yet

- U74140GJ2011PTC068341Document1 pageU74140GJ2011PTC068341Laxmi ParmarNo ratings yet

- NTEICO CATALOG Pipe SupportDocument25 pagesNTEICO CATALOG Pipe Supportusama hanifNo ratings yet

- Finishing Construction Specification and Bill of Quantities for Debre Birhan EthiopiaDocument11 pagesFinishing Construction Specification and Bill of Quantities for Debre Birhan EthiopiaMulugeta BezaNo ratings yet

- Tug & Barge - Daily Activity Report - Tug AgentDocument40 pagesTug & Barge - Daily Activity Report - Tug AgentArdiansyah BekaNo ratings yet

- Linear Regression Model to Calculate Economic Value of an EcosystemDocument5 pagesLinear Regression Model to Calculate Economic Value of an Ecosystemwayan tabahNo ratings yet

- 4202 Export SampleDocument36 pages4202 Export SampleTrade Info SolutionsNo ratings yet

- Eco Test 1 Prep NotesDocument3 pagesEco Test 1 Prep NotesadzwinjNo ratings yet

- Goods and Services To Be Produced and The Quantity To Be Produced of Each Selected CommodityDocument2 pagesGoods and Services To Be Produced and The Quantity To Be Produced of Each Selected CommodityNoelle Lei ReyesNo ratings yet

- Chapter 8 Managing ChangeDocument35 pagesChapter 8 Managing Changemohamedabdulkadir767No ratings yet

- Collapsible Core Injection MoldingDocument11 pagesCollapsible Core Injection MoldingagniflameNo ratings yet

- Abda LKT Des 2014Document119 pagesAbda LKT Des 2014sleepy platoNo ratings yet

- Ecotrics (PR) Panel Data ReferenceDocument22 pagesEcotrics (PR) Panel Data ReferenceArka DasNo ratings yet

- 05 Budgeting QuestionsDocument5 pages05 Budgeting QuestionsWynie AreolaNo ratings yet

- B-BBMD001 - Gantt Chart - Business Plan 2023Document5 pagesB-BBMD001 - Gantt Chart - Business Plan 2023Anthony PrincipioNo ratings yet

- Process For Materials and ConversionDocument4 pagesProcess For Materials and ConversionShahzaib NaseerNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument12 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceKanyaka PriyadarsiniNo ratings yet

- Trimegah Company Focus 3Q23 JSMR 14 Dec 2023 Maintain Buy HigherDocument10 pagesTrimegah Company Focus 3Q23 JSMR 14 Dec 2023 Maintain Buy HigheredwardlowisworkNo ratings yet

- Ship Chandling Flow ChartDocument3 pagesShip Chandling Flow Chartavon1276No ratings yet

- UNICAP Investments Limited: Portfolio StatementDocument1 pageUNICAP Investments Limited: Portfolio StatementAbraham LinkonNo ratings yet

- Engine Cadet CV Seeks PositionDocument1 pageEngine Cadet CV Seeks PositionPatrisNo ratings yet

- Confirmation 2Document2 pagesConfirmation 2Ruthessa LeyrosNo ratings yet

- Study On Gas Market Upgrading and ModernisationDocument206 pagesStudy On Gas Market Upgrading and ModernisationDaiuk.DakNo ratings yet

- Value Stream Mapping: Array Architects January 16, 2014Document30 pagesValue Stream Mapping: Array Architects January 16, 2014puphNo ratings yet

- Applied Statistics in Business and Economics 4th Edition Doane Solutions ManualDocument19 pagesApplied Statistics in Business and Economics 4th Edition Doane Solutions Manualmarcuscannonornzmyaeqd100% (23)