Professional Documents

Culture Documents

1-Gauge 4-Wire Strain Measurement Method Leadwire Resistance

Uploaded by

Vitthal Deokate0 ratings0% found this document useful (0 votes)

27 views1 pageOriginal Title

1gauge4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views1 page1-Gauge 4-Wire Strain Measurement Method Leadwire Resistance

Uploaded by

Vitthal DeokateCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Developing Strain Gauges and Instruments

STRAIN GAUGE MEASUREMENT

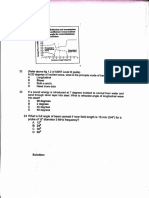

1-Gauge 4-Wire Strain measurement method

For strain gauge measurement, the Wheatstone bridge Leadwire resistance

circuit is employed according to the number of strain gauges In the conventional method, as thick and short leadwires as

to be used and measuring purpose. In a quarter bridge possible are recommended to keep the resistance of

configuration, three wire method is widely used to remove the leadwires lower. However, as the 1-gauge 4-wire method is

effect of temperature on gauge leadwire resistance. However, not influenced at all by the leadwire resistance, it is possible

some measuring error occurs owing to gauge factor caused to connect thin and long leadwires to strain gauges.

by leadwire resistance and variation in the contact resistance

when leadwires are connected to the bridge.

The TML 1-gauge 4-wire strain measurement method does not

Compares Quarter Bridge 3-Wire vs. 1-Gauge 4-Wire

use the Wheastone bridge circuit, but instead a simple series Quarter Bridge 3-wire

1-Gauge 4-Wire

circuit with gauge resistance (R) and reference resistance (Wheatstone Bridge)

(Rs) to measure the strain. Find the strain with voltage (V) Size of leadwire Thick Thin

generated in gauge resistance and voltage (Vs) generated

Weigt of leadwire Not less Less

in reference resistance. As the path where the current runs

and the path where the voltage is measured are different, it is Different lead-

Not available Available

wires

possible to perform a measurement without being affected by

leadwire resistance or contact resistance (r). Color of leadwire Planned Free

Load to specimen Not less Less

Carrying cost Not less Less

r1

R

r2 Strain gauges with leadwires and modular plug

V Most of our strain gauges can be supplied with the pre-

r3 E attached 4 leadwires and modular plug (RJ12) that make up

r4 our proprietary 1-Gauge 4-Wire system. Because a modular

i plug is attached to the end of the leadwires, soldering or

screwing connections to a measuring instrument is

Rs Vs unnecessary, but the instrument must be of TML make. The

4-wire leadwires are covered with polypropylene resin which

does not generate noxious gas even if exposed to fire.

where

R : Gauge resistance

Rs : Reference resistance Single element strain gauge with 4-wire paralleled leadwire

r1 ~ r4 : Leadwire resistance and contact resistance

i : Current flowing in gauge resistance and

reference resistance

E : Excitation voltage

V : Voltage of gauge resistance

Vs : Voltage of reference resistance

Not affected by contact resistance Three-element rectangular rosette strain gauge

Conventionally, leadwire extension and connection to a

measuring instrument are done by soldering or the use of With 6-wire paralleled leadwire and modular plug

specailly designed connectors. As the 1-gauge 4-wire method

is not affected at all by contact resistance, a modular plug can

be used. The modular plug makes leadwire extension and

connection to the instrument inexpensive and efficient while

With 4-wire paralleled leadwire and modular plug

preventing wiring mistakes are eliminated and also RoHS-

compliant lead free soldering is unnecessary.

Compares Quarter Bridge 3-Wire vs. 1-Gauge 4-Wire

Quarter Bridge 3-wire

(Wheatstone Bridge) 1-Gauge 4-Wire

Plug connection Not available Available

Soldering works Required Not required

Wiring time Required Less

Wiring error Occurs None

RoHS-directive Lead inclusive Lead free

Using commercial interconnection

adapter, leadwire extension can be

easily done.

12

You might also like

- Guide To Low Resistance Booklet-CROPICODocument39 pagesGuide To Low Resistance Booklet-CROPICObcqbaoNo ratings yet

- MENG2009 Lecture 4 11-12 S1 Strain Load MeasurementDocument70 pagesMENG2009 Lecture 4 11-12 S1 Strain Load Measurementxl.hall95No ratings yet

- OPGW Installation Manual GuideDocument19 pagesOPGW Installation Manual Guidecsudha100% (2)

- Unit Iv Bridges: Department of Ece Electronic Measurements & InstrumentationDocument5 pagesUnit Iv Bridges: Department of Ece Electronic Measurements & InstrumentationFarheenNo ratings yet

- Evaluating Pipeline Coating Patch Materials: Standard Test Method ForDocument5 pagesEvaluating Pipeline Coating Patch Materials: Standard Test Method ForCamilo GuardadoNo ratings yet

- 2561 Error in Low ResDocument1 page2561 Error in Low ResDharma GnaniNo ratings yet

- 3 Wire RTD Accuracy AssessmentDocument6 pages3 Wire RTD Accuracy AssessmentHirokNo ratings yet

- Low Resistance Measurement Guide PDFDocument34 pagesLow Resistance Measurement Guide PDFbill1022No ratings yet

- Scientech 2266Document33 pagesScientech 2266sarikapravinNo ratings yet

- CableDocument35 pagesCableAhmad MammadovNo ratings yet

- Cropico Guide To Low Resistance MeasurementDocument37 pagesCropico Guide To Low Resistance MeasurementacebouzouadNo ratings yet

- Electrical Services: Rising Mains Wires CablesDocument20 pagesElectrical Services: Rising Mains Wires Cablesrishav rajNo ratings yet

- What Is Cable Testing. How Is Cable Testing DoneDocument8 pagesWhat Is Cable Testing. How Is Cable Testing DoneAbdul JabbarNo ratings yet

- Experimental Stress Analysis Strain Gauges: Mechanical Engineering Amrita VishwavidyapeethamDocument14 pagesExperimental Stress Analysis Strain Gauges: Mechanical Engineering Amrita VishwavidyapeethamMuhammed SulfeekNo ratings yet

- Handbook On Plug in RelaysDocument45 pagesHandbook On Plug in RelaysSrinivas Enamandram100% (1)

- Evaluating Pipeline Coating Patch Materials: Standard Test Method ForDocument5 pagesEvaluating Pipeline Coating Patch Materials: Standard Test Method ForFernando Berrospi GarayNo ratings yet

- Ch14 Transmission LinesDocument29 pagesCh14 Transmission LinesGeoffrey AlleyneNo ratings yet

- GMAW Welding VariablesDocument16 pagesGMAW Welding VariablesrobinfanshaweNo ratings yet

- Dws Info Sheet Testing of Wirelines in ServiceDocument1 pageDws Info Sheet Testing of Wirelines in Serviceerwin atmadjaNo ratings yet

- Automotive Wiring and Circuit DiagramsDocument36 pagesAutomotive Wiring and Circuit Diagramsngelectronic522674% (27)

- CE5113 Lecture 2 - Geotechnical Instrumentation For Deep Excavation Works CITI (Color)Document90 pagesCE5113 Lecture 2 - Geotechnical Instrumentation For Deep Excavation Works CITI (Color)Nyan Oo100% (1)

- Electrical Power Transmission 4Document7 pagesElectrical Power Transmission 4FaisalSoNo ratings yet

- What Is Cable Testing. How Is Cable Testing DoneDocument8 pagesWhat Is Cable Testing. How Is Cable Testing DoneNaveed IrshadNo ratings yet

- Measure Resistance Accurately with 2, 3, or 4 Wire ConnectionsDocument4 pagesMeasure Resistance Accurately with 2, 3, or 4 Wire ConnectionsReymart ManablugNo ratings yet

- Conductor Astm StandardDocument33 pagesConductor Astm StandardWalter Cataldo100% (1)

- Mi Unit - IiiDocument54 pagesMi Unit - IiiJayaNo ratings yet

- DRM Wha B PDFDocument31 pagesDRM Wha B PDFzohebNo ratings yet

- ResistivityDocument56 pagesResistivityAdriiyan Escobar Finisco100% (1)

- Measurement of Resistance, Inductance and CapacitanceDocument64 pagesMeasurement of Resistance, Inductance and CapacitanceSiddhesh ShirshivkarNo ratings yet

- Sensor Dan Aktuator: Fakultas Ilmu Komputer Universitas BrawijayaDocument33 pagesSensor Dan Aktuator: Fakultas Ilmu Komputer Universitas BrawijayaCakra BhirawaNo ratings yet

- Wheatstone BridgeDocument4 pagesWheatstone BridgeScott50% (4)

- Measurements & Electronic Instruments Laboratory Experiment ManualDocument1 pageMeasurements & Electronic Instruments Laboratory Experiment ManualSohini RoyNo ratings yet

- Unit 2Document29 pagesUnit 2nikhill kundarNo ratings yet

- An 916Document10 pagesAn 916Socheat SonNo ratings yet

- Dry Type Transformer Testing ManualDocument23 pagesDry Type Transformer Testing Manualyalewlet tarekeggnNo ratings yet

- Strain Gauge Presentation PPTXDocument32 pagesStrain Gauge Presentation PPTXArun Raja K KNo ratings yet

- Probador de ContinuidadDocument4 pagesProbador de ContinuidadDiego García MedinaNo ratings yet

- Quality Wireline - Field Leakage TestDocument3 pagesQuality Wireline - Field Leakage TestADebeliusNo ratings yet

- Telecommunication Lab ManualDocument34 pagesTelecommunication Lab ManualPrashant Kulshreshtha100% (1)

- Difference Between 2, 3 and 4 Wire RTDsDocument5 pagesDifference Between 2, 3 and 4 Wire RTDsbilalNo ratings yet

- 1 1.Choosing-Installing RadarDocument5 pages1 1.Choosing-Installing RadarmeeNo ratings yet

- Choosing Installing Radar in Stilling Wells Bypass ChambersDocument18 pagesChoosing Installing Radar in Stilling Wells Bypass ChambersTrí NguyễnNo ratings yet

- RC Cable Lugs May2020Document140 pagesRC Cable Lugs May2020Whisnu BhuntoroNo ratings yet

- (Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Document6 pages(Backup) (Backup) LEEA ACADEMY STEP NOTES Foundation Aug2017 v1.7 Digital 114 119Khaled RaafatNo ratings yet

- Contactors-101 UNIT ACDocument10 pagesContactors-101 UNIT ACjose alberto nava martinezNo ratings yet

- Novel Method Detects Missing Bond-Wires in Microwave TransistorsDocument5 pagesNovel Method Detects Missing Bond-Wires in Microwave Transistorsbiastee7690No ratings yet

- 351 Neutral Sizing in Harmonic Rich InstallationsDocument12 pages351 Neutral Sizing in Harmonic Rich InstallationsHashirama SenjuNo ratings yet

- EIM 4 Lesson 6 Conductors For General WiringDocument65 pagesEIM 4 Lesson 6 Conductors For General WiringVictor RosalesNo ratings yet

- RTD Selection Guide: Everything You Need to Choose the Right ProbeDocument9 pagesRTD Selection Guide: Everything You Need to Choose the Right ProbeRoy RamosNo ratings yet

- Wheat Stone BridgeDocument3 pagesWheat Stone BridgeTejaSriNo ratings yet

- MA 821-070 BAUR Manual Cable Fault Location enDocument60 pagesMA 821-070 BAUR Manual Cable Fault Location enOsman Altun100% (2)

- Nonlinear Electronics 1: Nonlinear Dipoles, Harmonic Oscillators and Switching CircuitsFrom EverandNonlinear Electronics 1: Nonlinear Dipoles, Harmonic Oscillators and Switching CircuitsNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Radio Frequency Transistors: Principles and Practical ApplicationsFrom EverandRadio Frequency Transistors: Principles and Practical ApplicationsRating: 4 out of 5 stars4/5 (2)

- Draft PT Insted of MPTDocument1 pageDraft PT Insted of MPTVitthal DeokateNo ratings yet

- AERB Safety Status Report SubmissionDocument6 pagesAERB Safety Status Report SubmissionVitthal DeokateNo ratings yet

- Interaction of Radiation With CellsDocument37 pagesInteraction of Radiation With CellsVitthal DeokateNo ratings yet

- Physical Security Measures at IR RFs1Document38 pagesPhysical Security Measures at IR RFs1Vitthal DeokateNo ratings yet

- Radiation Detectors RT70Document38 pagesRadiation Detectors RT70Vitthal DeokateNo ratings yet

- Biological Effects of Ionizing RadiationDocument67 pagesBiological Effects of Ionizing RadiationVitthal DeokateNo ratings yet

- Survey Instrument CalibrationDocument3 pagesSurvey Instrument CalibrationVitthal DeokateNo ratings yet

- To, Tata Projects Limited, Mumbai Walchandnagar Industries LTD, WalchandnagarDocument1 pageTo, Tata Projects Limited, Mumbai Walchandnagar Industries LTD, WalchandnagarVitthal DeokateNo ratings yet

- Radiation Surveilance ProcedureDocument27 pagesRadiation Surveilance ProcedureVitthal DeokateNo ratings yet

- Update operational status radiation equipmentDocument2 pagesUpdate operational status radiation equipmentVitthal DeokateNo ratings yet

- Testing Procedures for Industrial Gamma RadiographyDocument17 pagesTesting Procedures for Industrial Gamma RadiographyVitthal DeokateNo ratings yet

- Radiation Interaction with CellsDocument24 pagesRadiation Interaction with CellsVitthal DeokateNo ratings yet

- Training Course On Barc Radiography Testing Level - 2: Lecture RT-T 13: X-Ray SourcesDocument6 pagesTraining Course On Barc Radiography Testing Level - 2: Lecture RT-T 13: X-Ray SourcesVitthal DeokateNo ratings yet

- Application Form 20201209162035497Document4 pagesApplication Form 20201209162035497Vitthal DeokateNo ratings yet

- Update operational status radiation equipmentDocument2 pagesUpdate operational status radiation equipmentVitthal DeokateNo ratings yet

- Update operational status radiation equipmentDocument2 pagesUpdate operational status radiation equipmentVitthal DeokateNo ratings yet

- Change Licensee 20190307112047849Document1 pageChange Licensee 20190307112047849Vitthal DeokateNo ratings yet

- Ut 11Document1 pageUt 11Vitthal DeokateNo ratings yet

- AERB Safety Status Report SubmissionDocument6 pagesAERB Safety Status Report SubmissionVitthal DeokateNo ratings yet

- Sensitivity calibration using ultrasound phantomsDocument1 pageSensitivity calibration using ultrasound phantomsVitthal DeokateNo ratings yet

- Security Plan For Industrial RadiographyDocument5 pagesSecurity Plan For Industrial RadiographyVitthal DeokateNo ratings yet

- A B C D: Ofldgitujinai - "R"Document1 pageA B C D: Ofldgitujinai - "R"Vitthal DeokateNo ratings yet

- Ut 6Document1 pageUt 6Vitthal DeokateNo ratings yet

- Ut 5Document1 pageUt 5Vitthal DeokateNo ratings yet

- 7Document11 pages7Va PolNo ratings yet

- Airport Engineering Multiple Choice QuestionsDocument1 pageAirport Engineering Multiple Choice QuestionsengineeringmcqsNo ratings yet

- SD WanDocument32 pagesSD WanAbdalrawoof AlsherifNo ratings yet

- MOA - NDMS Enterprise Inc.Document3 pagesMOA - NDMS Enterprise Inc.merlitamartinez8No ratings yet

- BIR Rule on Taxing Clubs OverturnedDocument2 pagesBIR Rule on Taxing Clubs OverturnedLucky JavellanaNo ratings yet

- High School Students' Characteristics Predict Science Club MembershipDocument4 pagesHigh School Students' Characteristics Predict Science Club MembershipNorma PanaresNo ratings yet

- Curran-Santos Complaint FiledDocument32 pagesCurran-Santos Complaint FiledJoe EskenaziNo ratings yet

- A Simple Digital Power-Factor CorrectionDocument11 pagesA Simple Digital Power-Factor CorrectionVinoth KumarNo ratings yet

- 0060200.installation Manual 546560Document36 pages0060200.installation Manual 546560Tríade MusicNo ratings yet

- Batch ManagementDocument166 pagesBatch ManagementMalik ImtiyazNo ratings yet

- Buildings Construction Final EXAM . 7/06/2006 ... Dr. Haitham Ayyad Time:2:30 MinDocument4 pagesBuildings Construction Final EXAM . 7/06/2006 ... Dr. Haitham Ayyad Time:2:30 MinHaitham AyyadNo ratings yet

- Catalytic Application of NanomaterialsDocument23 pagesCatalytic Application of NanomaterialsViji VijithaNo ratings yet

- Improve Asset Performance with Integrated Asset ManagementDocument12 pagesImprove Asset Performance with Integrated Asset ManagementArun KarthikeyanNo ratings yet

- Maintenance Manual For AC LHB CoachesDocument729 pagesMaintenance Manual For AC LHB Coachesdiiiiips100% (14)

- Pri Dlbt1201182enDocument2 pagesPri Dlbt1201182enzaheerNo ratings yet

- Section A-A: PLUNGER, LGA, 7X7, G3Document1 pageSection A-A: PLUNGER, LGA, 7X7, G3Ericson. TatlongmariaNo ratings yet

- 23NM60ND STMicroelectronicsDocument12 pages23NM60ND STMicroelectronicskeisinhoNo ratings yet

- Safe Operating Area Testing Without A Heat SinkDocument4 pagesSafe Operating Area Testing Without A Heat SinkCarlos MeloNo ratings yet

- String & Math FunctionsDocument38 pagesString & Math FunctionsThanu shreeNo ratings yet

- Codeigniter Library: 77 Free Scripts, Addons, Tutorials and VideosDocument6 pagesCodeigniter Library: 77 Free Scripts, Addons, Tutorials and VideosmbahsomoNo ratings yet

- Course: Basic Technical English Teacher: Lic. Victor Matienzo BustamanteDocument11 pagesCourse: Basic Technical English Teacher: Lic. Victor Matienzo BustamanteSelene FloresNo ratings yet

- iC60L Circuit Breakers (Curve B, C, K, Z)Document1 pageiC60L Circuit Breakers (Curve B, C, K, Z)Diego PeñaNo ratings yet

- TDL Reference ManualDocument628 pagesTDL Reference ManualhanifmitNo ratings yet

- Hershey's Milk Shake ProjectDocument20 pagesHershey's Milk Shake ProjectSarvesh MundhadaNo ratings yet

- International Journal of Hospitality ManagementDocument10 pagesInternational Journal of Hospitality ManagementrobertNo ratings yet

- Schools Division Office of BenguetDocument1 pageSchools Division Office of BenguetAna ConseNo ratings yet

- Compile C/C++ in Atom editorDocument2 pagesCompile C/C++ in Atom editorNishant KeswaniNo ratings yet

- Markov Model Predicts AttritionDocument16 pagesMarkov Model Predicts AttritionWojood AlkhanNo ratings yet

- Lecture PLCDocument30 pagesLecture PLCProsenjit Chatterjee100% (1)

- Ibert Concerto Tremolo Fingerings by Nestor Herszbaum PDFDocument2 pagesIbert Concerto Tremolo Fingerings by Nestor Herszbaum PDFAmedeo De SimoneNo ratings yet