Professional Documents

Culture Documents

Craycoat Seal 32-17

Uploaded by

YASHICA VAITTIANATHANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Craycoat Seal 32-17

Uploaded by

YASHICA VAITTIANATHANCopyright:

Available Formats

CRAY SEAL 32-17

Product Data Sheet

DESCRIPTION TECHNICAL SPECIFICATION

Cray seal 32-17 is an aqua based, vapor barrier sealant

for low, medium and high pressure or high velocity – metal, Base Synthetic resin

fiberglass and flexible heating and air conditioning air ducts,

forming a durable seal against air leakage. Color White / Grey

Appearance Smooth paste

APPLICATION Density, kg/L 1.65 -1.75

• HVAC Application Viscosity Flow (ASTM C

Non- Sag

• It is also used as an adhesive to metal, aluminum, 639)

Ceramic, Concrete, mild steel, etc. + 5 °C - +85°C

Service Temperature, °C

• Conforms to ASTM C-411 (Hot Surface Performance of

High Temperature Thermal Insulation) Non-Sag bead free of air

• Conforms to ASTM C-732 (Aging Effects of Artificial Bead Consistency

bubbles

Weathering on Latex Sealants) Clean all tools with warm

• Conforms to ASTM D-2202 (Slump Test)

water & soap when wet.

• It does not contain Asbestos, Lead or Mercury Cleaning

compounds Mineral spirit when dry.

• It can be applied using a wide variety of power extrusion

equipment suitable for use with water base sealant.

HEALTH & SAFETY:

As with all chemicals, caution should always be exercised.

ADVANTAGES Protective clothing such as gloves and goggles should be

worn.

• Non-Flammable

• Excellent adhesion & High strength

• Highly resistance to extreme temperature changes and INHALATION: Inhalation of vapor or mist should be

aging. avoided. If inhaled symptoms include coughing,

• Suitable to Middle East climatic condition wheezing, laryngitis, and shortness of breath, headache,

• Highly resistance to mold & mildew nausea, and vomiting. Immediately shift victim to fresh air,

and, if needed immediately start artificial respiration. Give

• Highly Elastic

oxygen if breathing is labored. Get emergency medical

• Resistance to oil or grease

help.

• Mildly resistance to diluted alkalis and acids

EYE CONTACT: Flush eyes with water for 15 minutes and

DIRECTIONS FOR USE call for medical help.

The surface should be clean, dry, oil-free and sounded (To

clean surface use power blower). Apply by power extrusion INGESTION: Causes nausea, vomiting, and loss of

or trowel uniformly a 2” wide coat over the joint @ 2 to 2.2 consciousness. If accidentally swallowed do not induce

gal/100 ft2. Total coverage 40-55 ft2/gal. Allow the completed vomiting rather call for medical help immediately.

joint to dry at least 24 hours above 25°C before pressure

testing. High humidity (70%) and or cooler temp. may retard

SKIN CONTACT: Flush with water or soap and water until

drying. Total WFT to be 30-35 mils.

all traces have been removed. Seek medical attention if

required.

STORAGE: WARRANTY

The information given is based on our knowledge and

• Store under cover, protect from direct sunlight and performance of the material. Every precaution is taken in

high temperature ( > 30°C). the manufacture of the product and responsibility is limited

• Shelf life is up to 12 months in unopened container to the quality of supplies with no guarantee of results in the

when stored as directed. field, as manufacturer has no control over site conditions or

execution of work.

You might also like

- Craycoat Seal 32-17Document1 pageCraycoat Seal 32-17YASHICA VAITTIANATHANNo ratings yet

- l1) Steelshield1100 5833Document2 pagesl1) Steelshield1100 5833Syed FaridNo ratings yet

- Hyperdesmo®-Ady 610 - enDocument3 pagesHyperdesmo®-Ady 610 - enMajd M. KhalilNo ratings yet

- Coaltar Epoxy - Epilux5 - 0474Document2 pagesCoaltar Epoxy - Epilux5 - 0474GautamNo ratings yet

- Cray Coat: Product Data SheetDocument1 pageCray Coat: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- l2) Steelshield1200 3041Document2 pagesl2) Steelshield1200 3041Syed FaridNo ratings yet

- E3) Epimastic5100 4292Document2 pagesE3) Epimastic5100 4292Syed FaridNo ratings yet

- El Hyperdesmo-ClassicDocument4 pagesEl Hyperdesmo-ClassicΙοαννης ΡενκοNo ratings yet

- Crayglue: Product Data SheetDocument2 pagesCrayglue: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- Cermithane Tds en 2Document2 pagesCermithane Tds en 2Hawraz MuhammedNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Microsoft Word - L3_Epilux82.docDocument2 pagesMicrosoft Word - L3_Epilux82.docvitharvanNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- High Solids Coal Tar Epoxy Product SpecificationsDocument2 pagesHigh Solids Coal Tar Epoxy Product SpecificationsAbuhurairah MunshiNo ratings yet

- Epilux 155 SFDocument2 pagesEpilux 155 SFMohamed NasifNo ratings yet

- Demech Antistick TDSDocument4 pagesDemech Antistick TDSAtharva UlangwarNo ratings yet

- High Build Epoxy Anti-Corrosive Primer SpecsDocument2 pagesHigh Build Epoxy Anti-Corrosive Primer SpecsMuthuKumar100% (1)

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- Hyperdesmo 815Document5 pagesHyperdesmo 815Roger DaoudNo ratings yet

- k2) Luxatherm5200 5219Document2 pagesk2) Luxatherm5200 5219Syed FaridNo ratings yet

- Cray Coat: Product Data SheetDocument1 pageCray Coat: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- Epoxy Primer - Epilux610 - 4079Document2 pagesEpoxy Primer - Epilux610 - 4079GautamNo ratings yet

- Hyperdesmo Haa v2.1 - 0Document4 pagesHyperdesmo Haa v2.1 - 0Pro MNNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Bergerlac Aluminium Finish PDFDocument2 pagesBergerlac Aluminium Finish PDFMuthuKumarNo ratings yet

- k3) Luxatherm5600 7954Document2 pagesk3) Luxatherm5600 7954Syed FaridNo ratings yet

- LUXAPRIME 1200 Alkyd QD Primer SpecsDocument2 pagesLUXAPRIME 1200 Alkyd QD Primer SpecsGurdeep Sungh AroraNo ratings yet

- LiquidRubber DATASheetDocument2 pagesLiquidRubber DATASheettally3tallyNo ratings yet

- Dermaprimer: Product DescriptionDocument2 pagesDermaprimer: Product DescriptionSaud NawabNo ratings yet

- Luxaprime1300 Alkyd Zinc Chromate PrimerDocument2 pagesLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraNo ratings yet

- Hyperdesmo S 2k - v2.0Document3 pagesHyperdesmo S 2k - v2.0rasasiNo ratings yet

- TDS Pioneer-EpoxyClay-Aqua 022019Document2 pagesTDS Pioneer-EpoxyClay-Aqua 02201911111No ratings yet

- Hyperdesmo - Fr-Kit: Fire Retardant, Polyurethane Liquid Membrane For Waterproofing & ProtectionDocument4 pagesHyperdesmo - Fr-Kit: Fire Retardant, Polyurethane Liquid Membrane For Waterproofing & ProtectionGizem D.No ratings yet

- Al-Jazeera Cold PlasticDocument1 pageAl-Jazeera Cold PlasticMoh EbrahiemNo ratings yet

- Premium Grade Water Based High Velocity Duct Sealant: Low Brush Drag and SpreadabilityDocument2 pagesPremium Grade Water Based High Velocity Duct Sealant: Low Brush Drag and SpreadabilityMohsin RazaNo ratings yet

- B B B Berger Erger Erger Erger: Product SpecificationsDocument2 pagesB B B Berger Erger Erger Erger: Product SpecificationsSanjeev Reddy KasulaNo ratings yet

- 220 Amercoat - 0220 Styralux PDSDocument2 pages220 Amercoat - 0220 Styralux PDSMuniyappan TNo ratings yet

- Hyperdesmo®-Pb-Mono - enDocument3 pagesHyperdesmo®-Pb-Mono - enMajd M. KhalilNo ratings yet

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaNo ratings yet

- SuperThermoLay APPDocument3 pagesSuperThermoLay APPA R CNo ratings yet

- Holdtite - Leakproof liquid sealantDocument1 pageHoldtite - Leakproof liquid sealantAkshay NaikNo ratings yet

- Product Data Sheet: Product Description Technical SpecificationDocument2 pagesProduct Data Sheet: Product Description Technical SpecificationVaittianathan MahavapillaiNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- k1) Luxatherm1600 3171Document2 pagesk1) Luxatherm1600 3171Syed FaridNo ratings yet

- Product Data Sheet: WF AC-600Document1 pageProduct Data Sheet: WF AC-600Kamalakar SastryNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- d3) Epilux4 2763Document2 pagesd3) Epilux4 2763Salman KhanNo ratings yet

- 914 EuroCryl ARDocument3 pages914 EuroCryl ARRAVI SHANKER GopalakrishnanNo ratings yet

- Crayglue: Product Data SheetDocument2 pagesCrayglue: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- STARBOND UL-30-36 Waterproofing CoatDocument2 pagesSTARBOND UL-30-36 Waterproofing CoatabmopalhvacNo ratings yet

- Poly Foam PU031 10 TDS ENGDocument2 pagesPoly Foam PU031 10 TDS ENGVladimir DovalNo ratings yet

- g9) Berger Apcofine 905 - 8096Document2 pagesg9) Berger Apcofine 905 - 8096Wasek SarkerNo ratings yet

- Masterprotect 1813: Amine-Cured, Pitch Free EpoxyDocument2 pagesMasterprotect 1813: Amine-Cured, Pitch Free EpoxyGavriel Ng100% (1)

- Crayglue 81-10Document1 pageCrayglue 81-10YASHICA VAITTIANATHANNo ratings yet

- DC 688 Technical Data SheetDocument3 pagesDC 688 Technical Data SheetHoang ThiNo ratings yet

- MSDS - ASMACO RTV GasketDocument2 pagesMSDS - ASMACO RTV GasketadminNo ratings yet

- RAKAM 401-RAK Acrylic SealantDocument1 pageRAKAM 401-RAK Acrylic Sealantaliraza30921No ratings yet

- Corrocoat Di-ShieldDocument2 pagesCorrocoat Di-ShieldstelioskoNo ratings yet

- Role of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewDocument8 pagesRole of Pesticide Formulations For Sustainable Crop Protection and Environment Management: A ReviewYASHICA VAITTIANATHANNo ratings yet

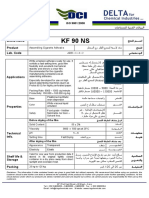

- KF 90 NS DatasheetDocument1 pageKF 90 NS DatasheetYASHICA VAITTIANATHANNo ratings yet

- Craybond 81-10 MSDSDocument4 pagesCraybond 81-10 MSDSYASHICA VAITTIANATHANNo ratings yet

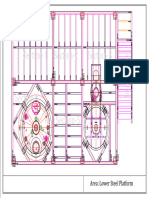

- Steel Platform DrawingDocument11 pagesSteel Platform DrawingYASHICA VAITTIANATHANNo ratings yet

- Cyber Saftey (Yaashica Vaittianathan, 2C)Document15 pagesCyber Saftey (Yaashica Vaittianathan, 2C)YASHICA VAITTIANATHANNo ratings yet

- Sika Anchorfix - 1Document5 pagesSika Anchorfix - 1YASHICA VAITTIANATHANNo ratings yet

- Giliomee Pesticidesin Fuggleand RabieDocument20 pagesGiliomee Pesticidesin Fuggleand RabieZuber JabreNo ratings yet

- MaterialData 196958Document1 pageMaterialData 196958YASHICA VAITTIANATHANNo ratings yet

- b28109788 PDFDocument822 pagesb28109788 PDFSiddhartha KumarNo ratings yet

- Sikagrout - 105Document3 pagesSikagrout - 105YASHICA VAITTIANATHANNo ratings yet

- Sikagrout Cable PtsaDocument3 pagesSikagrout Cable PtsaYASHICA VAITTIANATHANNo ratings yet

- Sikagrout Cable PTDocument3 pagesSikagrout Cable PTYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 214 SaDocument3 pagesSikagrout - 214 SaYASHICA VAITTIANATHANNo ratings yet

- SikaGrout-212 SA: Cementitious, Shrinkage Compensated GroutDocument3 pagesSikaGrout-212 SA: Cementitious, Shrinkage Compensated GroutYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 114 AeDocument3 pagesSikagrout - 114 AeYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 212 AeDocument3 pagesSikagrout - 212 AeYASHICA VAITTIANATHANNo ratings yet

- Sikagrout - 114Document3 pagesSikagrout - 114YASHICA VAITTIANATHANNo ratings yet

- Product Data Sheet: Product Description Technical SpecificationDocument1 pageProduct Data Sheet: Product Description Technical SpecificationYASHICA VAITTIANATHANNo ratings yet

- MSDS Starcem 2K-LIQUIDDocument5 pagesMSDS Starcem 2K-LIQUIDYASHICA VAITTIANATHANNo ratings yet

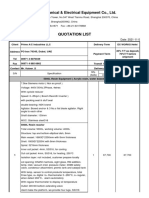

- Quotation List: Shanghai Sower Mechanical & Electrical Equipment Co., LTDDocument5 pagesQuotation List: Shanghai Sower Mechanical & Electrical Equipment Co., LTDYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance / Preparation and of The Company / UndertakingYASHICA VAITTIANATHANNo ratings yet

- TDS-Starfix C1-SLDocument3 pagesTDS-Starfix C1-SLYASHICA VAITTIANATHANNo ratings yet

- Safety Data Sheet for HVAC Duct Insulation CoatingDocument4 pagesSafety Data Sheet for HVAC Duct Insulation CoatingYASHICA VAITTIANATHANNo ratings yet

- Marble & Granite Glue: Product Data SheetDocument2 pagesMarble & Granite Glue: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- Kraton D1101 A - TDSDocument2 pagesKraton D1101 A - TDSYASHICA VAITTIANATHANNo ratings yet

- Starproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingDocument1 pageStarproof Rbe-F Product Data Sheet: Rubberized Bitumen Emulsion CoatingYASHICA VAITTIANATHANNo ratings yet

- Gum Rosin WW - TDS - HinataDocument1 pageGum Rosin WW - TDS - HinataYASHICA VAITTIANATHANNo ratings yet

- OH-POLYMER 107-80k TDSDocument1 pageOH-POLYMER 107-80k TDSYASHICA VAITTIANATHANNo ratings yet

- PDMS 350 TDSDocument1 pagePDMS 350 TDSYASHICA VAITTIANATHANNo ratings yet

- UOP Aromatics ComplexDocument4 pagesUOP Aromatics ComplexThắng Linh NguyễnNo ratings yet

- Gmail - Quality Grade 99.9% Virgin and Recycled Base Oil SN150, SN350, SN500, SN650 For Sale..Document4 pagesGmail - Quality Grade 99.9% Virgin and Recycled Base Oil SN150, SN350, SN500, SN650 For Sale..stalin fernandesNo ratings yet

- Addition of Nitrogen To GTAW Welding Duplex Steel 2205 and Its Effect On Fatigue Strength and Corrosion (2017)Document5 pagesAddition of Nitrogen To GTAW Welding Duplex Steel 2205 and Its Effect On Fatigue Strength and Corrosion (2017)Azizy ZidaneNo ratings yet

- Azo PigmentDocument9 pagesAzo PigmentTechn TecNo ratings yet

- Model 350XL: Double Check Valve AssemblyDocument2 pagesModel 350XL: Double Check Valve AssemblyRichard RodriguezNo ratings yet

- Chromium Copper Beryllium Copper Beryllium Copper Chemical CRDocument3 pagesChromium Copper Beryllium Copper Beryllium Copper Chemical CRSanjay MehtaNo ratings yet

- Engineering Properties AggregatesDocument4 pagesEngineering Properties AggregatessuryakantameNo ratings yet

- Titan OMB40: Bronze Fire Monitor Nominal Flow 4,000 L/minDocument2 pagesTitan OMB40: Bronze Fire Monitor Nominal Flow 4,000 L/minZhagiNo ratings yet

- Jun 12Document20 pagesJun 12phin easNo ratings yet

- Structural Beam ComputationsDocument12 pagesStructural Beam ComputationsJustine LedesmaNo ratings yet

- Ready Mix Concrete - An Overview of Manufacturing and AdvantagesDocument21 pagesReady Mix Concrete - An Overview of Manufacturing and AdvantagesranjitrajivNo ratings yet

- Tappi Tip 0402-28Document16 pagesTappi Tip 0402-28Haries Bugarin Garcia100% (1)

- Polymer Chemistry For B.SC - Sem-6th PDFDocument49 pagesPolymer Chemistry For B.SC - Sem-6th PDFSohel Ansari0% (1)

- Update On To Do ListDocument4 pagesUpdate On To Do ListnabeelNo ratings yet

- Centrifugal Spinning: An Alternative Approach To Fabricate Nanofibers at High Speed and Low CostDocument27 pagesCentrifugal Spinning: An Alternative Approach To Fabricate Nanofibers at High Speed and Low CostHiếu Hoàng HànhNo ratings yet

- Sika Viscocrete 1003 Pds enDocument3 pagesSika Viscocrete 1003 Pds enNugi AsmiNo ratings yet

- Rheywell Cables PumpsDocument12 pagesRheywell Cables PumpsMahmoud Al-SherbinyNo ratings yet

- Stoichiometric Calculations Involving GasesDocument22 pagesStoichiometric Calculations Involving GasesRyan PazonNo ratings yet

- Steelworks Products and Tinsmithing ToolsDocument39 pagesSteelworks Products and Tinsmithing ToolsEli SuarezNo ratings yet

- PTT Gas Separation Plant Fire Proofing StandardDocument18 pagesPTT Gas Separation Plant Fire Proofing StandardKanjana LeardrakNo ratings yet

- Ferrite Measurement PDFDocument2 pagesFerrite Measurement PDFESWARANM91No ratings yet

- JIS G3452: Carbon Steel Pipes For Ordinary PipingDocument1 pageJIS G3452: Carbon Steel Pipes For Ordinary PipingHoJienHauNo ratings yet

- 18 - 2017 - Covering Material PDFDocument4 pages18 - 2017 - Covering Material PDFvjdj100% (1)

- Ch. 23 Minerals and Natural Resources in IndiaDocument3 pagesCh. 23 Minerals and Natural Resources in Indiaamanag1997No ratings yet

- 1.civil-Concret Project TitlesDocument3 pages1.civil-Concret Project TitlesBhuvaneshwar BhunaNo ratings yet

- DFL E-25Document13 pagesDFL E-25Lea PesiganNo ratings yet

- Guidelines For Installing A MR - Steam Steambath SystemDocument24 pagesGuidelines For Installing A MR - Steam Steambath SystemnombreyoyoNo ratings yet

- PFD and PnID of Ethylene Oxide Production ProcessDocument9 pagesPFD and PnID of Ethylene Oxide Production ProcessKuatnNo ratings yet

- T Mech Clamp CatalogueDocument29 pagesT Mech Clamp CatalogueKABIR CHOPRANo ratings yet

- AFLAS Technical DatasheetDocument13 pagesAFLAS Technical DatasheetManual SourceNo ratings yet