Professional Documents

Culture Documents

Model 350XL: Double Check Valve Assembly

Uploaded by

Richard RodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model 350XL: Double Check Valve Assembly

Uploaded by

Richard RodriguezCopyright:

Available Formats

Model 350XL

Double Check Valve Assembly

Application

Ideal for use where Lead-Free* valves are required. Designed

for installation on potable water lines to protect against both

backsiphonage and backpressure of polluted water into the

water supply. Assembly shall provide protection where a

potential health hazard does not exist.

Standards Compliance (Horizontal & Vertical)

• ASSE® Listed 1015

• IAPMO® Listed

• CSA® Certified B64.5

• AWWA Compliant C510 NSF/ANSI 61

• Approved by the Foundation for Cross Connection

Control and Hydraulic Research at the University of

Options

Southern California

(Suffixes can be combined)

• UL® Classified (less shut-off valves only) - with full port QT ball valves (standard)

• C-UL® Classified (less shut-off valves only) L - less ball valves, male pipe thread

• Meets the requirements of NSF/ANSI 61* S - with Model SXL lead-free bronze "Y" type

*(0.25% MAX. WEIGHTED AVERAGE LEAD CONTENT) strainer

FT - with integral male 45° flare SAE test fitting

Materials

Main valve body Low Lead Cast Bronze,

ASTM B 584 (3/4-1") Accessories

Housing Reinforced Nylon

Repair kit

Fasteners Stainless Steel, 300 Series

Thermal expansion tank (Model XT)

Elastomers Silicone (FDA Approved)

QT-SET Quick Test Fitting Set

Buna Nitrile (FDA Approved)

Winterizing Blow out/Flush fitting (RK34-350BOF,

Internals Delrin

RK1-350BOF or RK114-350-375BOF)

Springs Stainless Steel, 300 series

Ball Valves Low Lead Cast Bronze, ASTM B 584

Struts Stainless Steel, 300 Series

Handles Stainless Steel, 200 Series

Features

Sizes: 3/4", 1", 1-1/4", 1-1/2", 2"

Maximum working water pressure 175 PSI

Maximum working water temperature 180°F

Hydrostatic test pressure 350 PSI OPTIONAL LEAD-FREE STRAINER

End connections Threaded ANSI B1.20.1 (MODEL SXL)

H

E E

WILKINS 350XL

F F

W

DC

IL XL

KI

N

W

S

C

IL XL

KI

B

N

C

S

D A D

A

G G

(3/4" - 1") (1-1/4" - 2")

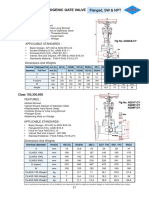

Dimensions & Weights (do not include pkg.)

DIMENSIONS (approximate) WEIGHT

MODEL

350XL B LESS WITH

SIZE A LESS BALL C D E F G H BALL BALL

VALVES VALVES VALVES

in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm in. mm lbs. kg lbs. kg

3/4 20 11 279 6 5/8 168 1 7/8 48 3 3/4 95 3 76 1 1/4 32 15 1/8 384 11 7/16 291 2.3 1.0 4.3 2.0

1 25 12 1/4 311 7 178 2 1/16 52 4 1/8 105 3 1/4 83 1 3/4 45 17 431 12 5/16 313 3.0 1.4 6.0 2.7

1-1/4 32 14 7/8 378 14 3/8 367 3 1/8 80 6 1/4 159 3 3/4 95 2 1/4 57 20 1/2 521 18 1/2 470 17.2 7.8 19 8.6

1-1/2 40 15 1/4 387 14 3/8 367 3 1/8 80 6 1/4 159 3 3/4 95 2 1/4 57 22 559 20 1/4 514 17 7.7 20 9.1

2 50 16 406 14 3/8 367 3 1/8 80 6 1/4 159 3 3/4 95 2 1/4 57 24 609 20 3/4 527 18 8.2 22 10

Zurn Industries, LLC | Wilkins Rev. K

1747 Commerce Way, Paso Robles, CA U.S.A. 93446 Ph. 855-663-9876, Fax 805-238-5766 Date: 12/19

Document No. BF-350XL

In Canada | Zurn Industries Limited Patent No. 7,434,593, 7,784,483, & 7,905,250

7900 Goreway Drive, Unit 10, Brampton, Ontario L6T 5W6, 877-892-5216 Product No. Model 350XL

www.zurn.com Page 1 of 2

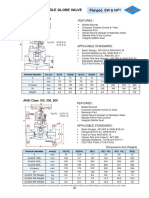

Flow Characteristics ⃟ Rated Flow (established by approval agencies)

MODEL 350XL 3/4" & 1" (STANDARD & METRIC)

FLOW RATES (l/s)

PRESSURE LOSS (PSIG) 0.00 1.26 2.52 3.79 5.05

PRESSURE LOSS (kpa)

15 3/4" (20mm)

103

1" (25mm)

10 69

5 34

0 0

0 20 40 60 80

FLOW RATES (GPM)

MODEL 350XL 1-1/4", 1-1/2" & 2" (STANDARD & METRIC)

FLOW RATES (l/s)

0.0 3.2 6.3 9.5 12.6 15.8

PRESSURE LOSS (PSIG)

PRESSURE LOSS (kpa)

15 103

2" (50mm)

1-1/4" (32mm)

10 1-1/2" (40mm) 69

5 34

0 0

0 50 100 150 200 250

FLOW RATES (GPM)

Typical Installation Capacity thru Schedule 40 Pipe

Local codes shall govern installation requirements. To be

installed in accordance with the manufacturers’ instructions and Pipe size 5 ft/sec 7.5 ft/sec 10 ft/sec 15 ft/sec

the latest edition of the Uniform Plumbing Code. Unless other- 1/2" 5 7 9 14

wise specified, the assembly shall be mounted at a minimum of 3/4" 8 12 17 25

12” (305mm) and a maximum of 30” (762mm) above adequate

1" 13 20 27 40

drains with sufficient side clearance for testing and mainte-

nance. If installed below grade, be certain adequate drainage is 1 1/4" 23 35 47 70

provided to prevent the device from being submerged. 1 1/2" 32 48 63 95

2" 52 78 105 167

PROTECTIVE

OPTIONAL LEAD-FREE STRAINER ENCLOSURE

(MODEL SXL)

DIRECTION OF FLOW

WILKINS 350XL

DC

W

IL XL

KIN

S

12" MIN.

30" MAX.

DIRECTION OF FLOW

INDOOR INSTALLATION OUTDOOR INSTALLATION

Specifications

The Double Check Valve Backflow Preventer shall be certified to NSF/ANSI 61, shall be ASSE® Listed 1015, rated to 180°F,

and supplied with full port ball valves. The main body shall be low lead Bronze for sizes 3/4" & 1", and Nylon for sizes 1-1/4" to

2". The housing shall be reinforced Nylon and the seat disc elastomers shall be silicone (FDA Approved). The first and second

checks shall be accessible for maintenance without removing the device from the line. The Double Check Valve Backflow

Preventer shall be a ZURN WILKINS Model 350XL.

Zurn Industries, LLC | Wilkins

1747 Commerce Way, Paso Robles, CA U.S.A. 93446 Ph. 855-663-9876, Fax 805-238-5766

In Canada | Zurn Industries Limited

7900 Goreway Drive, Unit 10, Brampton, Ontario L6T 5W6, 877-892-5216

www.zurn.com Page 2 of 2

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 4 - Check Valves MuellerDocument14 pages4 - Check Valves MuellerFIRSON ANDRES SerranoNo ratings yet

- 47XU Gate CraneFS DS p103 0620Document1 page47XU Gate CraneFS DS p103 0620Younis JanNo ratings yet

- Deluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVDocument5 pagesDeluge Solenoid Control Valve (Energize To Open) : MODEL 215-4DVmuthuvelaaNo ratings yet

- Manual Valvula de Alivio RciDocument3 pagesManual Valvula de Alivio RciGonzalo DominguezNo ratings yet

- 47XU F Gate CraneFS DS 1021 p103Document1 page47XU F Gate CraneFS DS 1021 p103Alexander HuamanNo ratings yet

- Page 31 34Document4 pagesPage 31 34ISHAN VERMANo ratings yet

- Brochure For AE3K 'True' Three-Way Block Body Threaded Ball ValvesDocument2 pagesBrochure For AE3K 'True' Three-Way Block Body Threaded Ball Valvesfrancis_15inNo ratings yet

- Steel Ball Valves: Trunnion Mounted Ball Design, Successfully Fire-TestedDocument23 pagesSteel Ball Valves: Trunnion Mounted Ball Design, Successfully Fire-TestedAntony MylvaganamNo ratings yet

- 04 Mobile Foam Cart CMFCDocument6 pages04 Mobile Foam Cart CMFCuki12345No ratings yet

- Table QW/QB-422 Ferrous and Nonferrous P-Numbers Grouping of Base Metals For QualificationDocument1 pageTable QW/QB-422 Ferrous and Nonferrous P-Numbers Grouping of Base Metals For QualificationArturo DuqueNo ratings yet

- Isv-Bt3b-Sb210.7 Val Bola TrunnionDocument4 pagesIsv-Bt3b-Sb210.7 Val Bola TrunnionBureau VeritasNo ratings yet

- Brochure For AE3K 'True' Three-Way Block Body Threaded Ball ValvesDocument2 pagesBrochure For AE3K 'True' Three-Way Block Body Threaded Ball ValvesAsa ReidNo ratings yet

- FT Valvula Acero 300 LBS Crane 33xu.fDocument1 pageFT Valvula Acero 300 LBS Crane 33xu.fFernando CarreñoNo ratings yet

- AWWA Swing Check Valves Technical DataDocument51 pagesAWWA Swing Check Valves Technical DataAllen Gutierrez FabricanteNo ratings yet

- Watsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapDocument2 pagesWatsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapbudi utomoNo ratings yet

- 13 - Check ValvesDocument14 pages13 - Check ValvesSiles LimberdsNo ratings yet

- Butterfly Valves - 250 Psi: SIZE 2" - 8"Document2 pagesButterfly Valves - 250 Psi: SIZE 2" - 8"thilina lakhithaNo ratings yet

- DSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesDocument32 pagesDSI Valves: Forged Steel Carbon, Stainless and Alloy Gate, Globe and Check ValvesJordan Magaña MoralesNo ratings yet

- Bronze Ball Valve 600 WOGDocument35 pagesBronze Ball Valve 600 WOGCarlos Luis Esquerdo MarcanoNo ratings yet

- TLV - Riduttore IsDocument5 pagesTLV - Riduttore IsPingu3No ratings yet

- Champion Dual Disc Wafer Check ValvesDocument8 pagesChampion Dual Disc Wafer Check ValvesShanghai koko ValvesNo ratings yet

- Copper Pipe C12200Document1 pageCopper Pipe C12200Yowhannes TsehayeNo ratings yet

- Gate ValvesDocument2 pagesGate ValvesArnold Ochochoque ArcosNo ratings yet

- Acv ZW205FPDocument3 pagesAcv ZW205FPSamy El-BeheryNo ratings yet

- Model: A100: Flushing RingDocument2 pagesModel: A100: Flushing RingTÀi VÕNo ratings yet

- Zurn FV-ZW4100Document3 pagesZurn FV-ZW4100Carlitos Way Golden BrainNo ratings yet

- BrooksBank GlobeValve FlangeAbove6Document3 pagesBrooksBank GlobeValve FlangeAbove6T KelvinNo ratings yet

- Clevis Type Insulator Fittings: Forged Steel Hot Dip GalvanizedDocument1 pageClevis Type Insulator Fittings: Forged Steel Hot Dip GalvanizedBams ArifinNo ratings yet

- Catalog Direct Acting 1 8 To 1 4 NPT Series 320 Asco en 7381674Document4 pagesCatalog Direct Acting 1 8 To 1 4 NPT Series 320 Asco en 7381674Ali KianersiNo ratings yet

- Caucho RecubrimientoDocument4 pagesCaucho RecubrimientoJhony MedranoNo ratings yet

- Quick Sheet: API 602 Forged Steel Gate ValveDocument3 pagesQuick Sheet: API 602 Forged Steel Gate ValveNaresh ANo ratings yet

- Series: GLV54-55: Specialist .Document3 pagesSeries: GLV54-55: Specialist .Peter KitchenNo ratings yet

- Bill of Materials N NDocument1 pageBill of Materials N Nchandraditya firmansyahNo ratings yet

- 07 Forged Cryogenic Gate GlobeDocument2 pages07 Forged Cryogenic Gate GlobeAndri AjaNo ratings yet

- Clasificacion A30aDocument2 pagesClasificacion A30aHenry AvilaNo ratings yet

- Valv. Comp. Ansi 150 Crane Fig. 47xuDocument2 pagesValv. Comp. Ansi 150 Crane Fig. 47xujulio sanchez camonesNo ratings yet

- Product Brochure Kennedy Guardian k81d K81a and K81am 3b54a01cDocument1 pageProduct Brochure Kennedy Guardian k81d K81a and K81am 3b54a01cAmjed HNo ratings yet

- PN 16 / CLASS 125: SpecificationDocument2 pagesPN 16 / CLASS 125: SpecificationKhiết trầnNo ratings yet

- Valvula de BolaDocument14 pagesValvula de BolaluisNo ratings yet

- Forged Steel Needle Globe Valve SpecsDocument1 pageForged Steel Needle Globe Valve SpecsAndri AjaNo ratings yet

- Piston ValvesDocument2 pagesPiston ValvesFlowBiz Exports Pvt. Ltd.No ratings yet

- Piping Engineering E PI 221Document5 pagesPiping Engineering E PI 221vikramNo ratings yet

- Valvula de Diluvio Watts 100D-BDocument2 pagesValvula de Diluvio Watts 100D-Beipt84No ratings yet

- KITZSteelBallValvesFloatingTypeISO5211 CAPE 201 08Document132 pagesKITZSteelBallValvesFloatingTypeISO5211 CAPE 201 08rusli bahtiarNo ratings yet

- 08.25 Victaulic® Knife Gate ValveDocument8 pages08.25 Victaulic® Knife Gate ValveMichał KisielewskiNo ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- Flange Adapters: Used Throughout The WorldDocument4 pagesFlange Adapters: Used Throughout The WorldfrdnNo ratings yet

- Water Distribution Materials SpecificationDocument26 pagesWater Distribution Materials SpecificationHarish RajaramNo ratings yet

- Manufacturing of MilkDocument3 pagesManufacturing of Milktilakthakar1No ratings yet

- BC08 Sand Trap LouverDocument20 pagesBC08 Sand Trap LouverFareethAbdullahNo ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- Series Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionDocument2 pagesSeries Cast Iron Full Port Class 125 Flanged Ball Valve: DescriptionLuisPortorelliZambranoNo ratings yet

- Construction of Petroleum Storage Depot at Pali, Rajasthan: Doc No.: NAYA-PALI-SP-80 Rev: 00 Date: 25-04-2019Document4 pagesConstruction of Petroleum Storage Depot at Pali, Rajasthan: Doc No.: NAYA-PALI-SP-80 Rev: 00 Date: 25-04-2019chintanNo ratings yet

- 20090327134609-Meba Steel BrochureDocument4 pages20090327134609-Meba Steel BrochurezhorvatovicNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- NYC Cross-Connection Handbook - May 2017Document90 pagesNYC Cross-Connection Handbook - May 2017Richard RodriguezNo ratings yet

- 30 Criteria For Detention Facility Design 06062012Document17 pages30 Criteria For Detention Facility Design 06062012Richard RodriguezNo ratings yet

- Design Consideration in FLood PRoofing PDFDocument52 pagesDesign Consideration in FLood PRoofing PDFManoj JaiswalNo ratings yet

- Stormwater Guidelines Overview 2012Document25 pagesStormwater Guidelines Overview 2012Richard RodriguezNo ratings yet

- HighRiseWaterSupplyDocument4 pagesHighRiseWaterSupplySonia Dogra0% (1)

- Laboratory Ventilation Flow Rates at Cornell: Rethinking The TraditionDocument25 pagesLaboratory Ventilation Flow Rates at Cornell: Rethinking The TraditionKhalid ImamNo ratings yet

- Carrier WSHPDocument72 pagesCarrier WSHPRichard RodriguezNo ratings yet

- ConEd Electric Bluebook 2015Document87 pagesConEd Electric Bluebook 2015Richard RodriguezNo ratings yet

- ASHRAE Seminar - Isolation Room HVAC DesignDocument29 pagesASHRAE Seminar - Isolation Room HVAC Designvalentinlupascu33100% (3)

- New York City 2011 Electrical CodeDocument103 pagesNew York City 2011 Electrical CodeBobGeorgeNo ratings yet

- Humidification Handbook PDFDocument180 pagesHumidification Handbook PDFatisz333100% (1)

- ADA Design Guide 2010Document7 pagesADA Design Guide 2010Jack BarkerNo ratings yet

- Big Dipper 51k Advanced Insert 3Document2 pagesBig Dipper 51k Advanced Insert 3Richard RodriguezNo ratings yet

- Appendix : New York City Stormwater ManualDocument121 pagesAppendix : New York City Stormwater ManualRichard RodriguezNo ratings yet

- NYS MultipleDwellingLawDocument161 pagesNYS MultipleDwellingLawRichard RodriguezNo ratings yet

- Installation & Operation Instructions For Big Dipper 51k Series Internal Strainer (IS) UnitsDocument20 pagesInstallation & Operation Instructions For Big Dipper 51k Series Internal Strainer (IS) UnitsRichard RodriguezNo ratings yet

- Nyc Fire Code GuideDocument100 pagesNyc Fire Code GuideRichard RodriguezNo ratings yet

- The M LX: AscotDocument6 pagesThe M LX: AscotRichard RodriguezNo ratings yet

- Big Dipper 51k Advanced Insert 3Document2 pagesBig Dipper 51k Advanced Insert 3Richard RodriguezNo ratings yet

- Title: Author: Rolando Efraín Hernández Ramírez: Luminescence Process of LuminolDocument2 pagesTitle: Author: Rolando Efraín Hernández Ramírez: Luminescence Process of LuminolEfraínNo ratings yet

- Ceramill Zolid Folder EnbDocument4 pagesCeramill Zolid Folder EnbDusan RisticNo ratings yet

- SPM 2018 Chemistry QuestionsDocument4 pagesSPM 2018 Chemistry QuestionsSAUFIANNo ratings yet

- Angle Brackets For Buildings: Complete RangeDocument6 pagesAngle Brackets For Buildings: Complete RangeKenan AvdusinovicNo ratings yet

- Astm C109-16Document10 pagesAstm C109-16Travis TwaddellNo ratings yet

- Phenol-formaldehyde runaway reaction case study analyzedDocument6 pagesPhenol-formaldehyde runaway reaction case study analyzedMary Grace VelitarioNo ratings yet

- JTTEE 3:184-190: International Test for Coating Adhesion on Flat SubstratesDocument7 pagesJTTEE 3:184-190: International Test for Coating Adhesion on Flat SubstratesNgo BinhNo ratings yet

- Ijmet: ©iaemeDocument14 pagesIjmet: ©iaemeIAEME PublicationNo ratings yet

- General Q Resin KIBITON Characteristics PB-5903: November 13, 2013Document1 pageGeneral Q Resin KIBITON Characteristics PB-5903: November 13, 2013DiegoTierradentroNo ratings yet

- Fatigue of MaterialsDocument54 pagesFatigue of Materialsc_gaspard0% (1)

- Post Weld Heat Treatment Inspection Question and AnswersDocument2 pagesPost Weld Heat Treatment Inspection Question and AnswersRajesh Kumar RaviNo ratings yet

- ChemistryDocument75 pagesChemistrysureshNo ratings yet

- Polymer Matrix CompositesDocument121 pagesPolymer Matrix CompositesHitesh Shah100% (6)

- Prestressed Structural Concrete: New Developments and ApplicationsDocument17 pagesPrestressed Structural Concrete: New Developments and Applicationspyay kanung kyawNo ratings yet

- Geas Final CoachingDocument2 pagesGeas Final Coachingkalos stratiotesNo ratings yet

- Water Auditing : An Approach For Water ConservationDocument32 pagesWater Auditing : An Approach For Water ConservationSugeeth 107No ratings yet

- Electrochemical Production and Use of Chlorinated Oxidants For The Treatment of Wastewater Contaminated by Organic Pollutants and DisinfectionDocument7 pagesElectrochemical Production and Use of Chlorinated Oxidants For The Treatment of Wastewater Contaminated by Organic Pollutants and DisinfectionJessica CamilaNo ratings yet

- Osmium - Os: Chemical Properties of Osmium Health Effects of Osmium Environmental Effects of OsmiumDocument15 pagesOsmium - Os: Chemical Properties of Osmium Health Effects of Osmium Environmental Effects of Osmiumshoaibansari641No ratings yet

- Calculations by Yg Plot 55 & 56 01.02.23Document63 pagesCalculations by Yg Plot 55 & 56 01.02.23Shanil BussooaNo ratings yet

- Vetotop CS536: Premixed 30 To 100 MM Thick Cementitious ScreedDocument2 pagesVetotop CS536: Premixed 30 To 100 MM Thick Cementitious ScreedSHAIK ASIMUDDINNo ratings yet

- Tle 7 - Q1 - Wk1-EditedDocument13 pagesTle 7 - Q1 - Wk1-EditedMichael Amores67% (3)

- DAXXXDocument11 pagesDAXXXMichael WoodNo ratings yet

- Pollution Prevention Handbook GlossaryDocument17 pagesPollution Prevention Handbook GlossaryOkky Assetya PNo ratings yet

- DDS 03b (20190620) Final Structural Drawings-2Document11 pagesDDS 03b (20190620) Final Structural Drawings-2Kevin RojasNo ratings yet

- The Rewards of Patience, Scheffel 2006Document9 pagesThe Rewards of Patience, Scheffel 2006NatitoPazGonzalezArmijoNo ratings yet

- Chitin, Chitosan, and Co-Products: Chemistry, Production, Applications, and Health EffectsDocument43 pagesChitin, Chitosan, and Co-Products: Chemistry, Production, Applications, and Health EffectsMartin Raynaldi SimanjuntakNo ratings yet

- Handbook of Residual StressDocument8 pagesHandbook of Residual StressDownNo ratings yet

- 2m-E Static DischargeDocument3 pages2m-E Static DischargeDENNIS JOEL HARICNo ratings yet

- Test Sieves Kumar BrandDocument1 pageTest Sieves Kumar BrandKOOL KINGNo ratings yet

- Saic Q 1013Document5 pagesSaic Q 1013Hussain Nasser Al- NowiesserNo ratings yet