Professional Documents

Culture Documents

Angle Brackets For Buildings: Complete Range

Uploaded by

Kenan AvdusinovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angle Brackets For Buildings: Complete Range

Uploaded by

Kenan AvdusinovicCopyright:

Available Formats

WBR ETA

ANGLE BRACKETS FOR BUILDINGS

COMPLETE RANGE

A simple but effective component. Available in a full range of sizes, mak-

ing it suitable for numerous applications.

CERTIFIED STRENGTH

Ideal for structural joints which require tensile,shear and rocking capacity.

TIMBER AND CONCRETE

Due to the quantity and arrangement of the fastening holes, it can be

used for both timber to timber, and timber to concrete connections.

CHARACTERISTICS

FOCUS shear and tension fastening

HEIGHT from 70 to 170 mm

THICKNESS from 1,5 to 3,0 mm

FASTENERS LBA, LBS, SKR, VIN-FIX PRO

MATERIAL

Bright zinc plated carbon steel three dimen-

sional perforated plate.

FIELD OF USE

Timber-to-concrete and timber-to-timber

joints

• solid timber and glulam

• CLT, LVL

• framed structures (platform frame)

• timber based panels

340 | WBR | ANGLE BRACKETS, HANGERS AND PERFORATED PLATES

POINT-TO-POINT SOLUTION

The wide selection of sizes makes it a perfect

solution for point-to-point applications, even

for the most unusual ones.

SAFE

Suitability of use and safety are guaranteed by

the CE mark according to the ETA. Values cer-

tified on the basis of tests on the product.

ANGLE BRACKETS, HANGERS AND PERFORATED PLATES | WBR | 341

CODES AND DIMENSIONS

WBR 70-90-100 S250

GALV

H

H

H

P P

1 P B 2 B 3 B

CODE B P H s n Ø5 n Ø11 n Ø13 pcs

[mm] [mm] [mm] [mm] pcs pcs pcs

1 WBR070 55 70 70 2,0 14 2 - 100

2 WBR090 65 90 90 2,5 20 2 - 100

3 WBR100 90 100 100 3,0 28 4 2 50

WBR 90110-170 DX51D

GALV

B

P P B

1 2

CODE B P H s n Ø5 n Ø13 pcs

[mm] [mm] [mm] [mm] pcs pcs

1 WBR90110 110 50 90 3,0 21 6 50

2 WBR170 95 114 174 3,0 53 9 25

WBR THIN 70-90-100 S250

GALV

H

H

P P P B

1 B 2 B 3

CODE B P H s n Ø5 n Ø11 pcs

[mm] [mm] [mm] [mm] pcs pcs

1 WBR07015 55 70 70 1,5 16 2 100

2 WBR09015 65 90 90 1,5 20 2 100

3 WBR10020 90 100 100 2,0 24 4 50

342 | WBR | ANGLE BRACKETS, HANGERS AND PERFORATED PLATES

MATERIAL AND DURABILITY EXTERNAL LOADS

WBR - WBR THIN 70-90-110:

carbon steel S250GD+Z275. F1

F1

To be used in service classes 1 and 2 (EN 1995-1-1).

WBR 90110-170: carbon steel DX51D+Z275. F5 F4

To be used in service classes 1 and 2 (EN 1995-1-1). F2 F3

F1

F1

F5 F4

FIELD OF USE F2 F3

• Timber-to-timber joints

• Timber-to-concrete joints

• Timber-to-steel joints

ADDITIONAL PRODUCTS - FASTENING

type description d support page

[mm]

LBA Anker nail 4 548

LBS screw for plates 5 552

SKR screw anchor 10 488

EPO-FIX PLUS chemical anchor M10 - M12 517

STATIC VALUES | TIMBER-TO-TIMBER JOINT

WBR 70-90-100

1 2 3

FASTENING NUMBER CHARACTERISTIC VALUES

holes fastening Ø5

R2/3,k R1,k R4/5,k*

CODE type ØxL nv

[mm] pcs [kN] [kN] [kN]

1 WBR070 LBA nails Ø4,0 x 60 12 3,9 1,7 2,0

2 WBR090 LBA nails Ø4,0 x 60 18 5,6 3,1 3,7

3 WBR100 LBA nails Ø4,0 x 60 26 8,9 3,8 4,6

* 2 angle brackets per joint

ANGLE BRACKETS, HANGERS AND PERFORATED PLATES | WBR | 343

STATIC VALUES | TIMBER-TO-TIMBER JOINT

WBR 90110-170

1 2

FASTENING NUMBER CHARACTERISTIC VALUES

holes fastening Ø5 R2/3,k R1,k R4/5,k*

CODE type ØxL nv R2/3,k timber R1,k timber R1,k steel R4/5,k timber R4/5,k steel

[mm] pcs [kN] [kN] [kN] [kN] [kN]

1 WBR90110 LBA nails Ø4,0x60 17 7,1 2,5 3,4 10,4 10,9

2 WBR170 LBA nails Ø4,0x60 49 11,0 1,7 3,7 12,4 9,2

* 2 angle brackets per joint

WBR THIN 70-90-100

1 2 3

FASTENING NUMBER CHARACTERISTIC VALUES

holes fastening Ø5

R2/3,k R1,k R4/5,k*

CODE type ØxL nv

[mm] pcs [kN] [kN] [kN]

1 WBR07015 LBA nails Ø4,0x60 16 5,1 4,8 11,1

2 WBR09015 LBA nails Ø4,0x60 20 6,7 5,3 11,7

3 WBR10020 LBA nails Ø4,0x60 24 10,2 7,5 12,4

* 2 angle brackets per joint

344 | WBR | ANGLE BRACKETS, HANGERS AND PERFORATED PLATES

STATIC VALUES | TIMBER-TO-CONCRETE JOINT

1 2 3 4

FASTENING NUMBER CHARACTERISTIC VALUES

holes holes holes

fastening Ø5 fastening Ø11 fastening Ø13

R2/3,k

CODE type ØxL nv nH nH R2/3,k Bolt 2/3(1)

[mm] pcs pcs pcs [kN] kt⊥

1 WBR100 LBA nails Ø4,0x60 26 2 - 8,9 1,11

2 WBR10020 LBA nails Ø4,0x60 26 2 - 10,2 0,63

3 WBR90110 LBA nails Ø4,0x60 17 - 2 7,1 0,71

4 WBR170 LBA nails Ø4,0x60 49 - 4 11,0 0,65

Characteristic values calculated by distributing part of the moment given by eccentricity on the nails. Other hypotheses can be calculated

by the designer.

NOTES: GENERAL PRINCIPLES:

(1)

Fastening to concrete supports shall be verified according to anchor load • Characteristic values are consistent with EN 1995-1-1 and in accordance

which can

Fbolt//,d = be

kt evaluated

F1,d through the coefficients kt// and kt⊥ listed in the with ETA.

table. The load acting on the anchor can be obtained as follows: • The design values are obtained from the characteristic values as follows:

Fbolt,d = kt Fd Rk,timber kmod

γM

kt coefficient of eccentricity Rd = min

Fd design external load acting on the angle bracket Rk,steel

The group of anchors check is satisfied when the design tensile strength, γsteel

obtained considering the boundary effects, is greater than the design exter-

nal load: Rd ≥ Fd. γsteel should be taken as γ M0

• The strength values of the connection system are valid under the calcula- • Coefficients γ M0, γ M and kmod must be taken according to the current regu-

tion hypotheses listed in the table; for different boundary conditions shall lations used for the calculation.

be verified.

• Dimensioning and verification of timber and concrete elements must be

carried out separately.

ANGLE BRACKETS, HANGERS AND PERFORATED PLATES | WBR | 345

Powered by TCPDF (www.tcpdf.org)

You might also like

- Reinforced Angle Brackets For Buildings: StrengthDocument4 pagesReinforced Angle Brackets For Buildings: StrengthKenan AvdusinovicNo ratings yet

- U-Bolt Range: Technical Information SheetDocument2 pagesU-Bolt Range: Technical Information SheetBrian VisserNo ratings yet

- Radius, Taper and Welding GaugeDocument1 pageRadius, Taper and Welding GaugeArief AmirudinNo ratings yet

- KOP en Technical Data SheetDocument6 pagesKOP en Technical Data SheetmcbluedNo ratings yet

- 14.72 KL PP FRP TankDocument24 pages14.72 KL PP FRP TankmaheshdgavaliNo ratings yet

- Evermark LTDDocument9 pagesEvermark LTDRakibul islamNo ratings yet

- Primer Painted PDFDocument1 pagePrimer Painted PDFMandiri 045No ratings yet

- About WELDA Anchor PlateDocument1 pageAbout WELDA Anchor PlateFircijevi KurajberiNo ratings yet

- Lock T - en - 02-20 PDFDocument14 pagesLock T - en - 02-20 PDFmilivoj ilibasicNo ratings yet

- Full Cone Series 490Document4 pagesFull Cone Series 490erdi.eksiNo ratings yet

- SBD en Technical Data SheetDocument8 pagesSBD en Technical Data SheetJonathanFallasNo ratings yet

- "T" Shaped Post Base: InvisibleDocument6 pages"T" Shaped Post Base: Invisiblemilivoj ilibasicNo ratings yet

- Self-Drilling Dowel: Steel and AluminumDocument6 pagesSelf-Drilling Dowel: Steel and AluminumLucas SeñaNo ratings yet

- 4.82 KL PP FRP TanksDocument24 pages4.82 KL PP FRP TanksmaheshdgavaliNo ratings yet

- HBS SOFTWOOD-en-technical-data-sheetDocument4 pagesHBS SOFTWOOD-en-technical-data-sheetKenan AvdusinovicNo ratings yet

- Comparison of Pipe Lengths CS & SSDocument2 pagesComparison of Pipe Lengths CS & SSSumantra ChattopadhyayNo ratings yet

- Lock T Evo - en - 02-20 PDFDocument10 pagesLock T Evo - en - 02-20 PDFmilivoj ilibasicNo ratings yet

- Schedule of Quantity - Proposal Schedule of Quantity - EngineeringDocument1 pageSchedule of Quantity - Proposal Schedule of Quantity - EngineeringSumantra ChattopadhyayNo ratings yet

- Bw100de Hochleistungswerkstoffe Fuer Die Luft - Und RaumfahrtDocument12 pagesBw100de Hochleistungswerkstoffe Fuer Die Luft - Und RaumfahrtKrisNo ratings yet

- BBBB BB BBBBBBBBBBDocument3 pagesBBBB BB BBBBBBBBBBEr Rakesh SharmaNo ratings yet

- TITAN S-En-Technical-Data-SheetDocument13 pagesTITAN S-En-Technical-Data-SheetSlayde TanaNo ratings yet

- Schedule of Doors and WindowsDocument14 pagesSchedule of Doors and WindowsOdinde Dabon EncaroNo ratings yet

- Ke 10spbof 2Document1 pageKe 10spbof 2Peerasut ChaisrimaneepanNo ratings yet

- CBN End Mill Series, The Ultimate Choice For Finish Machining MouldsDocument6 pagesCBN End Mill Series, The Ultimate Choice For Finish Machining MouldsbspgitamNo ratings yet

- Welding SymbolsDocument56 pagesWelding SymbolsaminibleachNo ratings yet

- TICO Pipe SupportsDocument8 pagesTICO Pipe SupportsEjeantengNo ratings yet

- Details 5 of 3 StoreysDocument13 pagesDetails 5 of 3 StoreysEdison MamintaNo ratings yet

- Schedule of Beams & Girders: Beam Detail PlanDocument1 pageSchedule of Beams & Girders: Beam Detail PlanVerna Balang MartinezNo ratings yet

- ButtWeld Solid Flange - ISO-6162Document2 pagesButtWeld Solid Flange - ISO-6162nemi90No ratings yet

- 02 (1) Plinth Level DetailsDocument1 page02 (1) Plinth Level Detailssri projectssNo ratings yet

- Poly V PulleysDocument12 pagesPoly V Pulleyskevin YachaNo ratings yet

- Deco-Copper Tube Pipe & Fittings Catalogue - A4-20p - PVDocument10 pagesDeco-Copper Tube Pipe & Fittings Catalogue - A4-20p - PViohc.tsewNo ratings yet

- HBS en Technical Data SheetDocument14 pagesHBS en Technical Data SheetJonathanFallasNo ratings yet

- 2019 BYG Bucket Protection Accessories SHANPARTSDocument1 page2019 BYG Bucket Protection Accessories SHANPARTSAliasgar-Shantilal C. MehtaNo ratings yet

- Victaulic Carbon Steel Couplings and Grooved FittingsDocument16 pagesVictaulic Carbon Steel Couplings and Grooved FittingsAnonymous 7I5qQ0eAxgNo ratings yet

- Full Threaded Screw With Cylindrical Head: TensionDocument24 pagesFull Threaded Screw With Cylindrical Head: TensionSichen DongNo ratings yet

- Heat & Control-14kl Leg Tank CastingDocument4 pagesHeat & Control-14kl Leg Tank CastingRPM ENGINEERS INDIA LTDNo ratings yet

- Catalogo Honnen FundicionDocument131 pagesCatalogo Honnen FundicionFEDERICONo ratings yet

- S.No Item Description QTY Unit Rate Amount 1 Distribution BoardsDocument3 pagesS.No Item Description QTY Unit Rate Amount 1 Distribution Boardsranjeet.globalgreenNo ratings yet

- BRE-N Valva EvacuareDocument1 pageBRE-N Valva EvacuareVlad Nicolae SebastianNo ratings yet

- Rawlbolt: Shield Anchor Loose BoltDocument6 pagesRawlbolt: Shield Anchor Loose BoltAvish GunnuckNo ratings yet

- EVRO - PROFIL-Steel Profile CatalogDocument12 pagesEVRO - PROFIL-Steel Profile CatalogOleksandrMISNo ratings yet

- Beam Mark Beam Cross Longitudinal Erinforcement Width Depth Discont. A BAR DiaDocument6 pagesBeam Mark Beam Cross Longitudinal Erinforcement Width Depth Discont. A BAR DiaMark Christian EsguerraNo ratings yet

- Bar Bending Calc r2Document14 pagesBar Bending Calc r2Sana Ullah HashemiNo ratings yet

- Ch8. Welding Symbols PDFDocument66 pagesCh8. Welding Symbols PDFMEHMET SIDDIK TEKDEMİRNo ratings yet

- Style 490: Installation Instructions Harness LugDocument2 pagesStyle 490: Installation Instructions Harness Lugocean_220No ratings yet

- HBS en Technical Data SheetDocument20 pagesHBS en Technical Data SheetManistaNo ratings yet

- Welding Symbol 14 Nov 2023Document24 pagesWelding Symbol 14 Nov 2023achmad kurniawan ZakariaNo ratings yet

- R-Series Coriolis Flow Density MetersDocument16 pagesR-Series Coriolis Flow Density MetersMojtaba AdhamiNo ratings yet

- Foot ValveDocument2 pagesFoot ValveHari BharathiNo ratings yet

- Color-Keyed Connectors: Color-Keyed Special Lugs For Special Problems - Angled, Shaped and Flared The Way You Need ThemDocument5 pagesColor-Keyed Connectors: Color-Keyed Special Lugs For Special Problems - Angled, Shaped and Flared The Way You Need ThemsoayNo ratings yet

- TLTK Tê ỐpDocument1 pageTLTK Tê ỐpLuân LeNo ratings yet

- Katalog ProdukDocument20 pagesKatalog ProdukWaridi RidiNo ratings yet

- JIS B2311 Steel Butt Welding Pipe Fittings For Ordinary UseDocument24 pagesJIS B2311 Steel Butt Welding Pipe Fittings For Ordinary Usense mcxNo ratings yet

- Pipe Spigot Bend: Polypropylene Push-Fit Waste SystemDocument1 pagePipe Spigot Bend: Polypropylene Push-Fit Waste SystemBoraNo ratings yet

- Raw Mill Items Follow Up RecordDocument9 pagesRaw Mill Items Follow Up RecordvinodsnNo ratings yet

- Timber Screws CapacitiesDocument6 pagesTimber Screws CapacitiesΘανάσης ΓεωργακόπουλοςNo ratings yet

- Rothoblaas - HBS ScrewsDocument6 pagesRothoblaas - HBS ScrewsGuillaumeHNONo ratings yet

- Pulley SKFDocument84 pagesPulley SKFNguyễn NhẫnNo ratings yet

- BEAM 14-15: Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument1 pageBEAM 14-15: Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument2 pagesTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument1 pageTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- HBS SOFTWOOD-en-technical-data-sheetDocument4 pagesHBS SOFTWOOD-en-technical-data-sheetKenan AvdusinovicNo ratings yet

- Heavy Duty Expansion Anchor Ce1: Codes and DimensionsDocument2 pagesHeavy Duty Expansion Anchor Ce1: Codes and DimensionsKenan AvdusinovicNo ratings yet

- Stan Ari Bjelave 1718Document12 pagesStan Ari Bjelave 1718Kenan AvdusinovicNo ratings yet

- Neka Mehanika Fizika PDFDocument778 pagesNeka Mehanika Fizika PDFKenan AvdusinovicNo ratings yet

- Pages From 0-Fan Coil Unit (Zamil) - 2Document1 pagePages From 0-Fan Coil Unit (Zamil) - 2Vic BayotNo ratings yet

- Basic + Qee + Trigo With SolutionsDocument11 pagesBasic + Qee + Trigo With SolutionsArsh DhawanNo ratings yet

- Experiment Beyond Syllabus Experiment - 14: 15eel38 Electrical Lab - IDocument6 pagesExperiment Beyond Syllabus Experiment - 14: 15eel38 Electrical Lab - IsanjuNo ratings yet

- Ficha Tecnica Unid Evaporadora TC SMSVDocument12 pagesFicha Tecnica Unid Evaporadora TC SMSVAsistente MantenimientoNo ratings yet

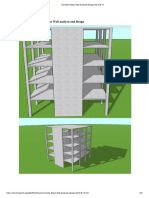

- RC Shear Wall Analysis and DesignDocument24 pagesRC Shear Wall Analysis and DesignGifari ZulkarnaenNo ratings yet

- Hull House PDFDocument7 pagesHull House PDFlestari bmNo ratings yet

- Test Bank: This Is Chapter 6, Problem 3Document6 pagesTest Bank: This Is Chapter 6, Problem 3miladNo ratings yet

- Modern Chemistry Chapter 3Document39 pagesModern Chemistry Chapter 3Ruby GallowayNo ratings yet

- Stability of Buildings Part 3 Shear WallsDocument61 pagesStability of Buildings Part 3 Shear Wallsalextse100% (5)

- Practical Exams Time Table-2nd Sem B.Sc. - PCM & PMCS Students-2022-23 - JulyDocument3 pagesPractical Exams Time Table-2nd Sem B.Sc. - PCM & PMCS Students-2022-23 - JulyHemanth N vNo ratings yet

- CWI-Module 4 - Weld Joint Geometry & Welding Symbols (Compatibility Mode)Document80 pagesCWI-Module 4 - Weld Joint Geometry & Welding Symbols (Compatibility Mode)thanhtung156No ratings yet

- A Force Field of Li+, Na+, K+, Mg2+, Ca2+, CL, and in Aqueous Solution Based On The TIP4P/2005 Water Model and Scaled Charges For The IonsDocument17 pagesA Force Field of Li+, Na+, K+, Mg2+, Ca2+, CL, and in Aqueous Solution Based On The TIP4P/2005 Water Model and Scaled Charges For The IonsSaeed AbdNo ratings yet

- Cycles of Time An Extraordinary New View of The Universe by Roger Penrose B004dephtiDocument5 pagesCycles of Time An Extraordinary New View of The Universe by Roger Penrose B004dephtijohnNo ratings yet

- Design of Box Culvert Type Section (E-E)Document4 pagesDesign of Box Culvert Type Section (E-E)ask.kulkarni KulkarniNo ratings yet

- RCD Integral Calculus 2 May 2017Document1 pageRCD Integral Calculus 2 May 2017jj012586No ratings yet

- Simultaneous Heat and Mass Transfer (SHMT) : CHE-402 Date: 08/11/2016Document23 pagesSimultaneous Heat and Mass Transfer (SHMT) : CHE-402 Date: 08/11/2016Atif MehfoozNo ratings yet

- Lecture-10 Impulse Response & Convolution Sum in DT LTI SystemDocument40 pagesLecture-10 Impulse Response & Convolution Sum in DT LTI SystemThe LifeNo ratings yet

- Performance Task Physics 10 1st GradingDocument2 pagesPerformance Task Physics 10 1st GradingIvan TabanagNo ratings yet

- (Lecture Notes of The Les Houches Summer School 103, August 2014) Claudio Chamon, Mark O. Goerbig, Roderich Moessner, Leticia F. Cugliandolo - Topological Aspects of Condensed Matter Physics (201 PDFDocument705 pages(Lecture Notes of The Les Houches Summer School 103, August 2014) Claudio Chamon, Mark O. Goerbig, Roderich Moessner, Leticia F. Cugliandolo - Topological Aspects of Condensed Matter Physics (201 PDFOmar Perez VelozNo ratings yet

- Excimer Basics: An Overview of Excimer Laser TechnologyDocument3 pagesExcimer Basics: An Overview of Excimer Laser Technologypartha sarathi padhiNo ratings yet

- DV-X Calculation of X-Ray Emission SpectraDocument25 pagesDV-X Calculation of X-Ray Emission SpectraJuan CogolludoNo ratings yet

- Memoria de Calculo SismicoDocument2 pagesMemoria de Calculo SismicoRodrigoNo ratings yet

- Cloud Gary - Optical Methods of Engineering Analysis (1998) PDFDocument517 pagesCloud Gary - Optical Methods of Engineering Analysis (1998) PDFDavid Alejandro TorresNo ratings yet

- Computational and Data Sciences: FacultyDocument2 pagesComputational and Data Sciences: FacultyAmarjeet KrishhnanNo ratings yet

- A. Y. 2023/2024 Entry RequirementsDocument2 pagesA. Y. 2023/2024 Entry RequirementsMOHAMMAD SULEMAN ALIAS ISRAR AHMEDNo ratings yet

- OTC 27289 MS - FinalDocument19 pagesOTC 27289 MS - FinalnsaifulNo ratings yet

- Joint Sealants For Airport Pavements: DOT/FAA/CT-94/53Document151 pagesJoint Sealants For Airport Pavements: DOT/FAA/CT-94/53Phạm Thanh PhươngNo ratings yet

- EXCETEKDocument21 pagesEXCETEKLegi YangNo ratings yet

- Wa0010.Document6 pagesWa0010.Ali SalmanNo ratings yet

- History and Philosophy of Science and TechnologyDocument6 pagesHistory and Philosophy of Science and TechnologyPhilip LaraNo ratings yet