Professional Documents

Culture Documents

Heavy Duty Expansion Anchor Ce1: Codes and Dimensions

Uploaded by

Kenan AvdusinovicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heavy Duty Expansion Anchor Ce1: Codes and Dimensions

Uploaded by

Kenan AvdusinovicCopyright:

Available Formats

AB1 R120 SEISMIC C2

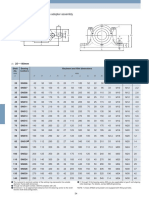

HEAVY DUTY EXPANSION ANCHOR CE1

• CE option 1 for cracked and uncracked concrete

• Seismic performance category C1 (M10-M16) and C2 (M12-M16)

• Electrogalvanized carbon steel

• Fire resistance R120

• Complete with nut and washer

• Suitable for dense materials

• Through fastening

• Torque-controlled expansion

CODES AND DIMENSIONS

CODE d = d0 Lt tfix h1,min hnom hef df SW Tinst pcs

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [Nm]

AB1875 M8 75 9 60 55 48 9 13 15 100

AB1895 M8 95 29 60 55 48 9 13 15 50

AB18115 M8 115 49 60 55 48 9 13 15 50

AB110115 M10 115 35 75 68 60 12 17 40 25

AB110135 M10 135 55 75 68 60 12 17 40 25

AB112100 M12 100 4 85 80 70 14 19 60 25

AB112120 M12 120 24 85 80 70 14 19 60 25

AB112150 M12 150 54 85 80 70 14 19 60 25

AB112180 M12 180 84 85 80 70 14 19 60 25

AB116145 M16 145 28 105 97 85 18 24 100 10

Tinst d anchor diameter

SW d0 hole diameter in the concrete support

tfix df Lt anchor length

t fix maximum fastening thickness

Lt h 1 minimum hole depth

h1 hef hnom nominal anchoring depth

hnom hef effective anchor depth

d f maximum hole diameter in the element to be fastened

SW wrench size

Tinst tightening torque

d0

ASSEMBLY

Tinst

90°

1 2 3 4 5

494 | AB1 | ANCHORS FOR CONCRETE

INSTALLATION

c s

hmin

AB1

Spacing and minimum distances M8 M10 M12 M16

Minimum spacing smin [mm] 50 60 70 85

Minimum edge distance cmin [mm] 50 60 70 85

Minimum thickness of concrete support hmin [mm] 100 120 140 170

Spacing and critical distances M8 M10 M12 M16

scr,N(1) [mm] 144 180 210 255

Critical spacing

(2)

scr,sp [mm] 288 300 350 425

ccr,N(1) [mm] 72 90 105 128

Critical edge distance

(2)

ccr,sp [mm] 144 150 175 213

For spacing and distances smaller than the critical ones, strength values have to be reduced depending on the installation parameters.

STATIC VALUES

Valid for a single anchor in thickened C20/25 grade concrete with a thin reinforcing layer when spacing and edge-distance

are not limiting parameters.

CHARACTERISTIC VALUES

UNCRACKED CRACKED

CONCRETE CONCRETE

tension(3) shear(4) tension(3) shear

NRk,p γMp VRk,s γMs NRk,p γMp VRk γM

[kN] [kN] [kN] [kN]

M8 9 1,8 11,0 1,25 6 1,8 12,0 γMc = 1,5(5)

M10 16 1,5 17,4 1,25 9 1,5 17,4 γMs = 1,25(4)

M12 25 1,5 25,3 1,25 16 1,5 25,3 γMs = 1,25(4)

M16 35 1,5 47,1 1,25 25 1,5 47,1 γMs = 1,25(4)

incremental factor for NRk,p(6)

C30/37 1,16

Ψc C40/50 1,31

C50/60 1,41

NOTES: GENERAL PRINCIPLES:

(1)

Breakage characteristics for formation of concrete cone for tensile loads. • Characteristic values according to ETA-17/0481.

(2)

Splitting failure mode for tensile loads. • The design values are obtained from the characteristic values as follows:

(3)

Pull-out failure mode. Rd=Rk /γ M

(4)

Steel failure mode. Coefficients γ M are listed in the table in accordance with the failure charac-

(5)

teristics and product certificates.

Pry-out failure mode.

(6)

• For the calculation of anchors with reduced spacing, or too close to the

Tensile-strength increment factor (excluding steel failure). edge, please refer to ETA. Similarly, in case of fastening on concrete-sup-

ports with a better-grade, limited thickness or a thick reinforcing layer

please see ETA.

• When designing anchors under seismic load please refer to the

ETA referral document and information in the EOTA Technical

Report 045.

• For the calculation of anchors subjected to fire refer to the ETA and the

Technical Report 020.

ANCHORS FOR CONCRETE | AB1 | 495

Powered by TCPDF (www.tcpdf.org)

You might also like

- Diwali Pujan BookletDocument10 pagesDiwali Pujan Bookletman_ishkumarNo ratings yet

- COUNTERS IN PLC - Portal PDFDocument88 pagesCOUNTERS IN PLC - Portal PDFAhwangg xGAMINGNo ratings yet

- 100 Yer PM PPM 0605Document40 pages100 Yer PM PPM 0605biplabpal2009No ratings yet

- EB-300 310 Service ManualDocument32 pagesEB-300 310 Service ManualVictor ArizagaNo ratings yet

- Hilti Manual For BoltDocument11 pagesHilti Manual For Boltcsengineer20% (1)

- Catalogue: Packer SystemDocument56 pagesCatalogue: Packer SystemChinmoyee Sharma100% (1)

- Tim Ingold - From The Transmission of Representations To The Education of Attention PDFDocument26 pagesTim Ingold - From The Transmission of Representations To The Education of Attention PDFtomasfeza5210100% (1)

- Tech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPDocument39 pagesTech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPEl Mundo De Yosed100% (1)

- Technical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315Document9 pagesTechnical Data Sheet For HSV Stud Anchor Technical Information ASSET DOC 2331315dcarunchioNo ratings yet

- Neka Mehanika Fizika PDFDocument778 pagesNeka Mehanika Fizika PDFKenan AvdusinovicNo ratings yet

- Mechanical Anchoring TruBoltDocument3 pagesMechanical Anchoring TruBoltwokeoooNo ratings yet

- Product Data Sheet-Le-ZnDocument5 pagesProduct Data Sheet-Le-ZnDavid SeeNo ratings yet

- 3 Hit-Hy150 HisnDocument9 pages3 Hit-Hy150 Hisndd160179No ratings yet

- Sika AnchorFix-1Document2 pagesSika AnchorFix-1TimoNo ratings yet

- Fix-Z-A4 Stainless Steel Design GuideDocument4 pagesFix-Z-A4 Stainless Steel Design GuidedineshNo ratings yet

- Wedge AnchorDocument10 pagesWedge AnchorDoreen PohNo ratings yet

- Example - Transformed Sections Fig. 1: A y A yDocument1 pageExample - Transformed Sections Fig. 1: A y A yThabiso MotalingoaneNo ratings yet

- Anchor Fastening Technology Manual: HSV M8 HSV M10 HSV M12 HSV M16 Application in ConcreteDocument10 pagesAnchor Fastening Technology Manual: HSV M8 HSV M10 HSV M12 HSV M16 Application in Concreteraju9991No ratings yet

- PI Fatigue HDA: TensionDocument11 pagesPI Fatigue HDA: TensionJaime Magno Gutierrez RamirezNo ratings yet

- FlangeDocument10 pagesFlangeNurul LailyahNo ratings yet

- HVU Adhesive With RebarDocument7 pagesHVU Adhesive With RebarBogdanBNo ratings yet

- BKL - R+W CouplingsDocument4 pagesBKL - R+W Couplingsgökhan tanrıseverNo ratings yet

- HIT-HY 150 Injection Mortar With HAS RodDocument10 pagesHIT-HY 150 Injection Mortar With HAS RodsahanNo ratings yet

- HSV-M Pub 5222370 000Document1 pageHSV-M Pub 5222370 000abhishek tiwariNo ratings yet

- CR Manual enDocument2 pagesCR Manual endenisNo ratings yet

- S.S. A4 m1tr Throughbolt TDS - MungoDocument7 pagesS.S. A4 m1tr Throughbolt TDS - MungoMohammed AnwarNo ratings yet

- +696wxgdqfkru: HSV Stud AnchorDocument9 pages+696wxgdqfkru: HSV Stud AnchorThang VoNo ratings yet

- Mhda Hollow Ceiling AnchorDocument1 pageMhda Hollow Ceiling AnchorMohammed AnwarNo ratings yet

- HHD - S.Technical - Information - ASSET - DOC - 2331274Document2 pagesHHD - S.Technical - Information - ASSET - DOC - 2331274Hoa Ly TrắngNo ratings yet

- 09 - Bolt PDFDocument2 pages09 - Bolt PDFShivam Shakti DubeyNo ratings yet

- 7MPa Concrete Blocks TDS - v2Document7 pages7MPa Concrete Blocks TDS - v2Slinky BillNo ratings yet

- Plummer Blocks SN5: Standard Type / For Bearing With Adapter AssemblyDocument10 pagesPlummer Blocks SN5: Standard Type / For Bearing With Adapter AssemblySenthil Thandavan CA DuraiNo ratings yet

- Stainless Steel Products: Bolt Anchor AN BZ Plus A4Document3 pagesStainless Steel Products: Bolt Anchor AN BZ Plus A4أبومحمدالزياتNo ratings yet

- He-Ho: Product InformationDocument20 pagesHe-Ho: Product Informationabhishek yadavNo ratings yet

- HIT-HY 150 Injection Mortar With RebarDocument8 pagesHIT-HY 150 Injection Mortar With RebarNguyễn AnhNo ratings yet

- HLS Sleeve Anchor: Anchor Fastening Technology ManualDocument5 pagesHLS Sleeve Anchor: Anchor Fastening Technology ManualHerli SiswoyoNo ratings yet

- Excalibur HSB 16mmDocument3 pagesExcalibur HSB 16mmlkokoNo ratings yet

- Tacos para TubosDocument21 pagesTacos para TubosPedro SantiagoNo ratings yet

- Rothoblaas - Abs Red - Technical Data Sheets - enDocument1 pageRothoblaas - Abs Red - Technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Rothoblaas - Ab7.technical Data Sheets - enDocument1 pageRothoblaas - Ab7.technical Data Sheets - enAndrei GheorghicaNo ratings yet

- Hydraulic Shears For Thick and Long Plates: WWW - Adira.ptDocument2 pagesHydraulic Shears For Thick and Long Plates: WWW - Adira.ptJohan SneiderNo ratings yet

- Maintenance Manual General Informations: Original InstructionsDocument8 pagesMaintenance Manual General Informations: Original InstructionsFer NuñezNo ratings yet

- Stiffeners: (MM) (MM) (MM)Document4 pagesStiffeners: (MM) (MM) (MM)Md Ahsanul KabirNo ratings yet

- Inova Ball Joints JBDocument2 pagesInova Ball Joints JBSympatyagaNo ratings yet

- MS Bolt-1Document2 pagesMS Bolt-1ariefNo ratings yet

- TAS - 3071 Shrink DiscDocument3 pagesTAS - 3071 Shrink DiscCarlyleNo ratings yet

- Kpz-Cylinder Compact PN 0822 392 304-Page 43Document89 pagesKpz-Cylinder Compact PN 0822 392 304-Page 43Jamin SmtpngNo ratings yet

- Hollow-Ceiling Anchor FHY: Technical DataDocument2 pagesHollow-Ceiling Anchor FHY: Technical DataimranNo ratings yet

- HKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EDocument8 pagesHKD Push-In Anchor: Basic Loading Data (For A Single Anchor) : HKD-S /-EsorengbhanuNo ratings yet

- 2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Document9 pages2014 88 Technical Data Sheet For HSL-GR Heavy Duty Anchor Technical Information ASSET DOC 2331127Difa LiuNo ratings yet

- Catalog PK AnchorDocument2 pagesCatalog PK AnchorkumuthaNo ratings yet

- Setting Information Setting Positions: A) HSL-3-SH, HSL-3-SK and HSL-3-SKR Can Only Be Set in Position 1Document1 pageSetting Information Setting Positions: A) HSL-3-SH, HSL-3-SK and HSL-3-SKR Can Only Be Set in Position 1Praveen Varma VNo ratings yet

- MN EnglishDocument2 pagesMN EnglishMohamed Ahmed ElFekyNo ratings yet

- Spit Multi-Max Metacrylato para Uso en Concreto No FisuradoDocument7 pagesSpit Multi-Max Metacrylato para Uso en Concreto No FisuradoduraeduNo ratings yet

- Heavy-Duty Anchor TA M: TAM Approved ForDocument3 pagesHeavy-Duty Anchor TA M: TAM Approved ForGökhan GülhanNo ratings yet

- 2 Pole LES 50Hz PDFDocument66 pages2 Pole LES 50Hz PDFhrga.branzbsd55No ratings yet

- Epo-Fix Plus: High-Performance Epoxy Chemical AnchorDocument3 pagesEpo-Fix Plus: High-Performance Epoxy Chemical Anchormilivoj ilibasicNo ratings yet

- Chemical Epcon C8 Spit Bars Tec TD en 01Document4 pagesChemical Epcon C8 Spit Bars Tec TD en 01osama aNo ratings yet

- 1031.5 - Thru-Bolt PRO Approved TDSDocument8 pages1031.5 - Thru-Bolt PRO Approved TDShexensohnNo ratings yet

- Crosscut Chisels: Inch Length Weight PUDocument2 pagesCrosscut Chisels: Inch Length Weight PURatheesh KumarNo ratings yet

- Anclaje HHD-SDocument2 pagesAnclaje HHD-SIngeniero Miguel VillarroelNo ratings yet

- Index of Bearing Tables: Split TypeDocument19 pagesIndex of Bearing Tables: Split TypeLenyn SanchezNo ratings yet

- TITAN S-En-Technical-Data-SheetDocument13 pagesTITAN S-En-Technical-Data-SheetSlayde TanaNo ratings yet

- Stainless StudsDocument4 pagesStainless StudsNestramiNo ratings yet

- CrimpinformationsheetDocument12 pagesCrimpinformationsheetTrần Long VũNo ratings yet

- ISO Pump 50Hz Technical Data Metric UnitsDocument29 pagesISO Pump 50Hz Technical Data Metric UnitsTimothy PopeNo ratings yet

- BEAM 14-15: Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument1 pageBEAM 14-15: Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument2 pagesTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument1 pageTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument2 pagesTower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- BEAM 4-5: Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsDocument2 pagesBEAM 4-5: Tower - 3D Model Builder 7.0 - x64 Edition Registered To Bios Radimpex - WWW - Radimpex.rsKenan AvdusinovicNo ratings yet

- Heavy Duty Expansion Anchor Ce1: Codes and DimensionsDocument2 pagesHeavy Duty Expansion Anchor Ce1: Codes and DimensionsKenan AvdusinovicNo ratings yet

- Reinforced Angle Brackets For Buildings: StrengthDocument4 pagesReinforced Angle Brackets For Buildings: StrengthKenan AvdusinovicNo ratings yet

- HBS SOFTWOOD-en-technical-data-sheetDocument4 pagesHBS SOFTWOOD-en-technical-data-sheetKenan AvdusinovicNo ratings yet

- Angle Brackets For Buildings: Complete RangeDocument6 pagesAngle Brackets For Buildings: Complete RangeKenan AvdusinovicNo ratings yet

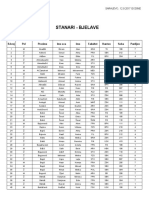

- Stan Ari Bjelave 1718Document12 pagesStan Ari Bjelave 1718Kenan AvdusinovicNo ratings yet

- The Explanation of The Fundamentals of Islamic BeliefDocument95 pagesThe Explanation of The Fundamentals of Islamic BeliefbooksofthesalafNo ratings yet

- The World S Finest Ideas in Cooling!: A Division ofDocument4 pagesThe World S Finest Ideas in Cooling!: A Division ofChiragNo ratings yet

- Class 28: Outline: Hour 1: Displacement Current Maxwell's Equations Hour 2: Electromagnetic WavesDocument33 pagesClass 28: Outline: Hour 1: Displacement Current Maxwell's Equations Hour 2: Electromagnetic Wavesakirank1No ratings yet

- 2UEB000487 v1 Drive On GeneratorDocument19 pages2UEB000487 v1 Drive On GeneratorSherifNo ratings yet

- Homophones WorksheetDocument3 pagesHomophones WorksheetAmes100% (1)

- TA308 616configurationDocument1 pageTA308 616configurationJesus AvilaNo ratings yet

- Visedo FPC-2016Document13 pagesVisedo FPC-2016Probonogoya Erawan SastroredjoNo ratings yet

- Organic Chemistry (Some Basic Principles and TechniquesDocument30 pagesOrganic Chemistry (Some Basic Principles and TechniquesNaveen SharmaNo ratings yet

- KZPOWER Perkins Stamford Genset Range CatalogueDocument2 pagesKZPOWER Perkins Stamford Genset Range CatalogueWiratama TambunanNo ratings yet

- Mathematics For Engineers and Scientists 3 PDFDocument89 pagesMathematics For Engineers and Scientists 3 PDFShailin SequeiraNo ratings yet

- AdPoe The Hunting of The HareDocument2 pagesAdPoe The Hunting of The HarePI CubingNo ratings yet

- Monthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)Document20 pagesMonthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)winda septiaraNo ratings yet

- Technical Methods and Requirements For Gas Meter CalibrationDocument8 pagesTechnical Methods and Requirements For Gas Meter CalibrationIrfan RazaNo ratings yet

- Output Process Input: Conceptual FrameworkDocument4 pagesOutput Process Input: Conceptual FrameworkCHRISTINE DIZON SALVADORNo ratings yet

- Stokerchapter25lipidmetabolism 160320032037Document29 pagesStokerchapter25lipidmetabolism 160320032037Dawlat SalamaNo ratings yet

- Soal Bahasa Inggris X - XiDocument6 pagesSoal Bahasa Inggris X - XiBydowie IqbalNo ratings yet

- Feature Writing EnglishDocument2 pagesFeature Writing EnglishAldren BababooeyNo ratings yet

- Cateora2ce IM Ch012Document9 pagesCateora2ce IM Ch012Priya ShiniNo ratings yet

- Adminstration of Intramusclar InjectionDocument3 pagesAdminstration of Intramusclar InjectionDenise CastroNo ratings yet

- Timer Relay ERV-09Document1 pageTimer Relay ERV-09wal idNo ratings yet

- DHT, VGOHT - Catloading Diagram - Oct2005Document3 pagesDHT, VGOHT - Catloading Diagram - Oct2005Bikas SahaNo ratings yet

- Tank Gauging TankvisionDocument31 pagesTank Gauging Tankvisionkhangduongda3No ratings yet

- What's The Use of Neuroticism?: G. Claridge, C. DavisDocument18 pagesWhat's The Use of Neuroticism?: G. Claridge, C. DavisNimic NimicNo ratings yet