Professional Documents

Culture Documents

Rear Axle Drive and Rear Axle Shafts

Uploaded by

Shrikrushna Mali0 ratings0% found this document useful (0 votes)

65 views38 pagesThis document discusses rear axle drive systems and components. It describes the Hotchkiss drive system, which uses leaf springs to locate the rear axle and transmit driving torque. It is a simple and inexpensive design. The document also discusses torque tube drives, which directly couple the rear differential to the transmission via an enclosed drive shaft. Finally, it covers different types of rear axle shafts, including semi-floating, full-floating, and three-quarter floating designs.

Original Description:

Original Title

REAR AXLE DRIVE AND REAR AXLE SHAFTS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses rear axle drive systems and components. It describes the Hotchkiss drive system, which uses leaf springs to locate the rear axle and transmit driving torque. It is a simple and inexpensive design. The document also discusses torque tube drives, which directly couple the rear differential to the transmission via an enclosed drive shaft. Finally, it covers different types of rear axle shafts, including semi-floating, full-floating, and three-quarter floating designs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views38 pagesRear Axle Drive and Rear Axle Shafts

Uploaded by

Shrikrushna MaliThis document discusses rear axle drive systems and components. It describes the Hotchkiss drive system, which uses leaf springs to locate the rear axle and transmit driving torque. It is a simple and inexpensive design. The document also discusses torque tube drives, which directly couple the rear differential to the transmission via an enclosed drive shaft. Finally, it covers different types of rear axle shafts, including semi-floating, full-floating, and three-quarter floating designs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 38

PRESENTATION ON

REAR AXLE DRIVE

AND

REAR AXLE SHAFTS

Forces on rear

⚫ Wt. of the body

axle

⚫ Driving trust

⚫Torque reaction :driving or braking

⚫Side thrust

⚫The Hotchkiss drive is a system of power

transmission .

⚫It was the dominant form of power transmission

for front-engine, rear-wheel drive layout cars in the

20th century

⚫ Simplest and most widely used type of rear axle drive .

⚫ The spring besides taking weight of the body also take

the torque reaction , driving thrust and side thrust .

⚫ propeller shaft is provided with two universal

joints also a sliding joint .

⚫ The front end of the spring is fixed rigidly on the frame

while the rear end and is supported in the shackle .

⚫In a Hotchkiss layout,

⚫the axle is suspended by a pair of longitudinally

mounted semi-elliptical leaf springs, which serve to

locate the axle, as well as supporting the weight of

the body.

⚫The front portion of each spring functions like a

trailing arm, transmitting drive torque to the body .

⚫ The rear portion of the spring acts as a leading

arm, resisting wheel hop under braking.

⚫The stiffness of the springs also serves to resist

lateral motions. By making the springs perform

multiple duties, Hotchkiss drive is very simple, and

thus very cheap.

⚫ Since it has few parts, it's also very sturdy,

which is useful for heavy-duty vehicles like

trucks.

⚫ The differentiating characteristic of the

Hotchkiss drive is the fact that it uses universal

joints at both ends of the driveshaft, which

is not enclosed .

⚫ The use of two universal joints, properly phased

and with parallel alignment of the drive and driven

shafts, allows the use of simple cross-type universals

.

⚫Used in pick-up trucks and sport utility vehicles

.

⚫ The design problem that the torque tube solves is

how to get the traction forces generated by the

wheels to the car frame .

⚫ The "torque tube" transmits this force by directly

coupling the axle differential to the transmission and

therefore propels the car forward by pushing on the

engine and then through the engine mounts to the

car frame .

⚫In contrast, the Hotchkiss drive has the traction

forces transmitted to the car frame by using other

suspension components such as leaf springs or

trailing arms .

⚫ A ball and socket type of joint called a "torque

ball" is used at one end of the torque tube to allow

relative motion between the axle and transmission

due to suspension travel

⚫ Since the torque tube does not constrain the

axle in the lateral (side-to-side) direction a

panhard rod is often used for this purpose.

⚫ The combination of the panhard rod and the

torque tube allows the easy implementation of soft

coil springs in the rear to give good ride quality .

Torque tubes differ from the Hotchkiss design in that

a solid drive shaft is enclosed in a hollow

torque tube and rotates within a support bearing to

prevent whipping

⚫In both types of drive shafts the side thrust is taken

the leaf springs .

⚫A separate member is employed to overcome

this situation : Panhard Rod

⚫it is fixed parallel to wheel axis with one end pivoted

to the axle and other to chassis frame

EXAMPLES OF THE TORQUE

TUBE

⚫American cars of the Ford brand up through 1948,

which used the less expensive transverse springs

that could not take the thrust.

⚫The C5 and C6 Chevrolet Corvette , Mercedes-

Benz SLS AMG

Loads on rear axle

⚫Shearing force due to wt. of vehicle .

shafts

⚫Bending moment on account of load applied

through spring seats .

⚫End thrust caused by side forces on account

of cornering , side wind

⚫Bending moment by end thrust and its reaction

offered by tyres on ground

⚫Driving torque

Types of rear axle

⚫Semi floating axle

shaft .

⚫Full floating axle .

⚫Three quarter floating

type.

SEMI FLOATING

AXLE

⚫With a semi-float axle, the axle shaft both carries

the weight and transmits torque.

⚫ The wheel is often bolted directly to the flange

on the axle.

⚫ Semi-float axles are seen on cars and light duty

trucks.

⚫Semi floats are more limited in capacity, but

lighter and cheaper to manufacture.

FULL FLOATING

AXLE

⚫the weight of the vehicle is supported by the axle

housing- more specifically, a bearing spindle attached

to the axle housing , and a set of bearings in a

separate wheel hub.

⚫Torque is transmitted by a separate axle shaft that

carries no weight.

⚫As commonly built, full-floaters are considerably

heavier, but also much stronger

Full floating Axle

THREE QUARTER FLOATING

TYPE

THREE QUARTER FLOATING

TYPE

⚫ A three-quarter floating axle is the same as semi-floating,

with one difference. The outer bearing is moved to the

outside of the outer end of the axle tube, supporting a hub

assembly via the bearing's outer circumference edge.

⚫ The splined or keyed shaft drives this hub, to which the wheel

is attached.

The shaft now supports minimal vehicle weight (so has

much reduced radial load), but still locates the wheel

axially, and transfers axial cornering loads (side thrust) to

the axle inner bearing.

You might also like

- Presentation On: Rear Axle Drive AND Rear Axle ShaftsDocument47 pagesPresentation On: Rear Axle Drive AND Rear Axle ShaftsmharitmsNo ratings yet

- Drive LinesDocument30 pagesDrive LinesRITESH ROHILLANo ratings yet

- Automobile Engg AssignmentDocument9 pagesAutomobile Engg AssignmentTAHIR QAMARNo ratings yet

- 3.4 Differential and Rear Axle, Hotchkiss Drive and Torque Tube Drive.Document9 pages3.4 Differential and Rear Axle, Hotchkiss Drive and Torque Tube Drive.DEEPAK S SEC 2020No ratings yet

- Design and Assembly AnalysisDocument96 pagesDesign and Assembly AnalysisVinayak RaoNo ratings yet

- 3) Suspension SystemDocument44 pages3) Suspension Systempadhaai karoNo ratings yet

- Unit Iii Chassis and Sub-Systems: Presented by A.Mohsin Ahmed Ap/AutoDocument67 pagesUnit Iii Chassis and Sub-Systems: Presented by A.Mohsin Ahmed Ap/AutoMohsin EngrNo ratings yet

- 7.propeller Shaft, Slip Joints, Universal JointsDocument30 pages7.propeller Shaft, Slip Joints, Universal JointsThulasi RamNo ratings yet

- Unit 1-At6402 Automotive ChassisDocument39 pagesUnit 1-At6402 Automotive ChassisSathis KumarNo ratings yet

- Functions of The Suspension SystemDocument27 pagesFunctions of The Suspension SystemMohamed AbdelmagedNo ratings yet

- Vehicle Axles: Structural FeaturesDocument3 pagesVehicle Axles: Structural Featurespawarag9995No ratings yet

- AxlesDocument17 pagesAxlesP.Prem Kumar AP - I - MechanicalNo ratings yet

- 15ae302 - Rear Axle and Suspension System PDFDocument71 pages15ae302 - Rear Axle and Suspension System PDFAahana KhannaNo ratings yet

- For Other Uses, See - Not To Be Confused With or .: Axle (Disambiguation) Axl (Disambiguation) Axel (Disambiguation)Document4 pagesFor Other Uses, See - Not To Be Confused With or .: Axle (Disambiguation) Axl (Disambiguation) Axel (Disambiguation)sreejith008No ratings yet

- 2-Drive To WheelsDocument11 pages2-Drive To WheelsLowry GuettaNo ratings yet

- Unit2 ChassisDocument31 pagesUnit2 ChassisMarthandeNo ratings yet

- Chapter - Suspension System - Chasis-1Document9 pagesChapter - Suspension System - Chasis-1karanragav12No ratings yet

- Automotive Transmission: Abhishek Bhattacharya Assistant Professor Mechanical Engineering DepartmentDocument17 pagesAutomotive Transmission: Abhishek Bhattacharya Assistant Professor Mechanical Engineering DepartmentAbhishak BhattacharyaNo ratings yet

- Suspension SystemsDocument37 pagesSuspension SystemsPankajj PokhriyalNo ratings yet

- Automotive Suspension ModifiedDocument46 pagesAutomotive Suspension Modifiedregassa rajiNo ratings yet

- Suspension - Day OneDocument97 pagesSuspension - Day OneDeepak C. Rajwar100% (1)

- Suspension Control SystemsDocument39 pagesSuspension Control SystemsKRISHNAPRIYANo ratings yet

- Car Suspension - An Introduction!Document54 pagesCar Suspension - An Introduction!Siddharth Garkhail100% (1)

- Front Suspension SystemDocument26 pagesFront Suspension SystemAngelic AlmaydaNo ratings yet

- Vehicle Structure and Engines: Unit IDocument52 pagesVehicle Structure and Engines: Unit IchezhianbabuNo ratings yet

- Automobile Suspension, Wheels and TyresDocument56 pagesAutomobile Suspension, Wheels and TyresHRBNo ratings yet

- It Is The Total Mechanism That Transmit The Power Developed of The Engine Going To The Drive Wheels of The VehicleDocument90 pagesIt Is The Total Mechanism That Transmit The Power Developed of The Engine Going To The Drive Wheels of The VehicleManny AnacletoNo ratings yet

- Soy Automotive Technology Act 2Document6 pagesSoy Automotive Technology Act 2JOHN STEVEN SOYNo ratings yet

- Hotch Kiss DriveDocument50 pagesHotch Kiss DriverajmehaNo ratings yet

- Front Axle and Suspension SystemDocument58 pagesFront Axle and Suspension SystemPIET MECHANICAL HOD HODNo ratings yet

- Propeller Shaft & Universal JointDocument22 pagesPropeller Shaft & Universal JointaaraNo ratings yet

- A496658235 - 19350 - 25 - 2020 - Unit-II Suspension SystemDocument63 pagesA496658235 - 19350 - 25 - 2020 - Unit-II Suspension SystemDeepu SadasivuniNo ratings yet

- ACS Notes 1Document63 pagesACS Notes 1roy rockNo ratings yet

- Automobile Underchassis Servicing, Repair and Maintenance: James D. Artista AETC 2101Document11 pagesAutomobile Underchassis Servicing, Repair and Maintenance: James D. Artista AETC 2101Kirito CabelNo ratings yet

- Rear Axle Shaft DesignDocument11 pagesRear Axle Shaft DesignSandeep Chauhan100% (3)

- Bma4723 Vehicle Dynamics Chap 7Document63 pagesBma4723 Vehicle Dynamics Chap 7Fu HongNo ratings yet

- ShaftsDocument12 pagesShaftsKingsly JasperNo ratings yet

- Front Axle & Steering SystemsDocument35 pagesFront Axle & Steering SystemsVishnu Rajeswaran100% (1)

- Semi Float Vs Full FloatDocument2 pagesSemi Float Vs Full FloatsagbhiNo ratings yet

- Ch-4 Propeller Shaft & Universal Joint: By, Deep Shah Sub: ATM (3330202)Document24 pagesCh-4 Propeller Shaft & Universal Joint: By, Deep Shah Sub: ATM (3330202)mharitmsNo ratings yet

- ChassisDocument70 pagesChassisamitav_chak9523No ratings yet

- Rear Axle Operation PDFDocument4 pagesRear Axle Operation PDFparchure123No ratings yet

- Semi Float Vs Full FloatDocument16 pagesSemi Float Vs Full FloatadamtuongNo ratings yet

- Automotive Suspension SystemDocument32 pagesAutomotive Suspension SystemMoniruzzaman Shuvo100% (2)

- Suspension SystemsDocument118 pagesSuspension SystemsEZHILARASAN R100% (1)

- Automotive Chassis 2Document360 pagesAutomotive Chassis 2Mohammmed Farooq100% (1)

- A Practical Traning Report ON Microtek Forging L.T.D: Submitted in Partial Fulfillment For The Award of The Degree ofDocument13 pagesA Practical Traning Report ON Microtek Forging L.T.D: Submitted in Partial Fulfillment For The Award of The Degree ofraopetroNo ratings yet

- Chap 7 Suspension SystemsDocument25 pagesChap 7 Suspension Systemszetseat100% (2)

- Aayush Sable Mechanical EngineeringDocument40 pagesAayush Sable Mechanical EngineeringAshish RawatNo ratings yet

- Vehicle Systems: Lecture Notes Assoc. Prof. Dr. Levent YÜKSEKDocument49 pagesVehicle Systems: Lecture Notes Assoc. Prof. Dr. Levent YÜKSEKNeerajNo ratings yet

- Automobile: Semi Floating Suspension System in AutomobileDocument30 pagesAutomobile: Semi Floating Suspension System in AutomobileFarhanNo ratings yet

- Module 3 AU205Document35 pagesModule 3 AU205Sreeram HNo ratings yet

- Wheel Set AssemblyDocument7 pagesWheel Set AssemblysumantlNo ratings yet

- AT - 3 and 4Document14 pagesAT - 3 and 4vandanaharikumarNo ratings yet

- Automotive TransmissionDocument146 pagesAutomotive TransmissionTony Neal100% (1)

- Theory Da1Document13 pagesTheory Da1sanchit sawantNo ratings yet

- AT6501 UwDocument132 pagesAT6501 UwAjithNo ratings yet

- Seminarof Sumeet - CHDocument23 pagesSeminarof Sumeet - CHapoorv1992No ratings yet

- Equation and Knowledge BasedDocument20 pagesEquation and Knowledge BasedShrikrushna MaliNo ratings yet

- Tentative Final Year B.Tech. Mechanical-29 June 2022Document73 pagesTentative Final Year B.Tech. Mechanical-29 June 2022Shrikrushna MaliNo ratings yet

- Trellis Chassis AnalysisDocument3 pagesTrellis Chassis AnalysisShrikrushna MaliNo ratings yet

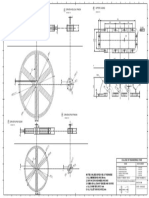

- Final Assembly DrawingDocument1 pageFinal Assembly DrawingShrikrushna MaliNo ratings yet

- Ajm SBPDocument28 pagesAjm SBPShrikrushna MaliNo ratings yet

- Theory of Metal CuttingDocument162 pagesTheory of Metal CuttingShrikrushna MaliNo ratings yet

- Part Drawing Sheet1Document1 pagePart Drawing Sheet1Shrikrushna MaliNo ratings yet

- Part Drawing Sheet2Document1 pagePart Drawing Sheet2Shrikrushna MaliNo ratings yet

- BreakingDocument64 pagesBreakingShrikrushna MaliNo ratings yet

- ClutchDocument50 pagesClutchShrikrushna MaliNo ratings yet

- Gear BoxDocument38 pagesGear BoxShrikrushna MaliNo ratings yet

- Mass BenchmarkingDocument13 pagesMass BenchmarkingShrikrushna MaliNo ratings yet

- Cummins c1675 d5 Spec Sheet With Kta50 Specs Appended Ado PDFDocument3 pagesCummins c1675 d5 Spec Sheet With Kta50 Specs Appended Ado PDFAdil Elyousfaoui100% (1)

- Spare PartsDocument6 pagesSpare Partslakshmiearthmovers01No ratings yet

- FPFX 322-19 Manual Motor v8Document173 pagesFPFX 322-19 Manual Motor v8João Paulo Paschoarelli VeigaNo ratings yet

- Bull No A Pina X Fuera, B Pina X Dentro AB Pina X AB, D Mixta, E Pareja, Dir Direccion D1/2 (MM.)Document60 pagesBull No A Pina X Fuera, B Pina X Dentro AB Pina X AB, D Mixta, E Pareja, Dir Direccion D1/2 (MM.)mhiguitaNo ratings yet

- Selection Guide 2020 Final VersionDocument73 pagesSelection Guide 2020 Final VersionNurburgringo BZHNo ratings yet

- International Service Manual ELECTRICAL CIRCUIT DIAGRAMS PDFDocument114 pagesInternational Service Manual ELECTRICAL CIRCUIT DIAGRAMS PDFAdal Vera0% (1)

- Vehicle Technology EbookDocument528 pagesVehicle Technology Ebookdeepak RNo ratings yet

- Bike Repair One Page Cheat SheetDocument1 pageBike Repair One Page Cheat SheetAndy P ParsonsNo ratings yet

- Impreza Service ManualDocument95 pagesImpreza Service ManualTaxiarhis ZoubosNo ratings yet

- Stihl 029Document30 pagesStihl 029David HelmsNo ratings yet

- SANY Motor Grader STG SeriesDocument7 pagesSANY Motor Grader STG Seriesanwar salimNo ratings yet

- SRT55D操保手册 ENDocument344 pagesSRT55D操保手册 ENindralukeNo ratings yet

- Caddy Error CodesDocument59 pagesCaddy Error CodesАндрей ЛозовойNo ratings yet

- Mercury Four & Six Cylinder (1955-1965) Old Outboard MotorDocument14 pagesMercury Four & Six Cylinder (1955-1965) Old Outboard MotorLinusNo ratings yet

- 2018 2020 MV SerieDocument1,762 pages2018 2020 MV SeriePablo Porras100% (1)

- Kross Katalog2019 en Net PDFDocument194 pagesKross Katalog2019 en Net PDFcavasque100% (1)

- OVERHAUL - Engine Kits 1 PDFDocument2 pagesOVERHAUL - Engine Kits 1 PDFDenisNo ratings yet

- Bwts Aftermarketfolder 766 908 PDFDocument2 pagesBwts Aftermarketfolder 766 908 PDFMohd NajmanNo ratings yet

- Manual Industrial Stationary 43L 57L LPG CNGDocument37 pagesManual Industrial Stationary 43L 57L LPG CNGCarlaNo ratings yet

- 08 Hammer and Jackpot Including Ness ModelDocument476 pages08 Hammer and Jackpot Including Ness ModelRon RobichaudNo ratings yet

- 2003 Audi A4 Wiring DiagramsDocument132 pages2003 Audi A4 Wiring Diagramsmike100% (3)

- 嘉沃车业AUTOTOP 2022 7 26Document674 pages嘉沃车业AUTOTOP 2022 7 26Auto LED Light VSNo ratings yet

- Ac Compressor Oil CheckingDocument19 pagesAc Compressor Oil Checkingsonny1234No ratings yet

- Electronically Controlled Suspension (ECS), System DescriptionDocument15 pagesElectronically Controlled Suspension (ECS), System DescriptionAbo Fraj100% (3)

- Transmission - Disassemble: Disassembly and AssemblyDocument31 pagesTransmission - Disassemble: Disassembly and AssemblyMbahdiro KolenxNo ratings yet

- Etacs BLDocument74 pagesEtacs BLMohd FairusNo ratings yet

- DACOTA 97 AnDocument439 pagesDACOTA 97 AnRodrigo Antonio Cuevas Troncoso50% (2)

- Fire Pump Drive EnginesDocument159 pagesFire Pump Drive Enginesfernando100% (1)

- 4L40E (A4S 200R) BMW 98 On. 5L40E (A5S 360R) BMW 98 On & Cadillac 03 OnDocument9 pages4L40E (A4S 200R) BMW 98 On. 5L40E (A5S 360R) BMW 98 On & Cadillac 03 OnMichaelm8No ratings yet

- Diagrama Modulos de EncendidoDocument8 pagesDiagrama Modulos de EncendidoJesús Rafael León MartínezNo ratings yet