Professional Documents

Culture Documents

Case Study Holcim Cement Plant

Uploaded by

Aiman DadoushCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study Holcim Cement Plant

Uploaded by

Aiman DadoushCopyright:

Available Formats

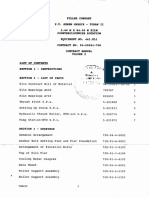

SUCCESS STORY:

CEMENT CASE STUDY

IMPROVING THE COAL-FEEDING CONVEYING

SYSTEM IN A HOLCIM CEMENT PLANT

Background:

AERZEN, as a specialist in cement applications, improves

the pneumatic conveying coal feeding system to the main

burner in Holcim Colombia Plant. The plant located in

Nobsa, a small town 2.5 hours away from Bogota. The plant

capacity is about 3Mt/year of cement and a market share in

Colombia of 12% with high growth expectation after Lafarge

Holcim joint venture in 2015. AERZEN started operations in

Colombia in 2008 as a daughter entity from AERZEN Head

Quarters in Germany with the primary purpose of supporting

existing customers, such as Holcim, with Aerzen machinery

in their processes. The Holcim Colombia plant uses AERZEN

technology in all eight (8) main applications that required oil-

free, low-pressure air supply, from the raw mill pneumatic

conveying to the raw meal silos up to the bagging systems Process Coal-Feeding Pneumatic

for finished cement. Thanks to AERZEN specific knowledge Conveying System

in cement applications, an upgrade was successfully

implemented in the coal feeding system to the main burner Problem High energy usage and noise levels

that brings savings in energy consumption, noise reduction with unstable air flow.

and more stable and laminar air flow that helps the burner

stability. Solution Aerzen Delta Hybrid D62S

Initial Situation: Result Operational costs reduced by 40%,

In 2014 an AERZEN Application Sales Team identified an 40,000 hours MTBR, with 10% more

upgrading opportunity in the coal pneumatic conveying performance than conventional

transport to the main burner, also known as the Pfister tri-lobe blowers. Process stability with

system. In this application, two AERZEN GM 35S tri-lobe a more laminar flow

blowers from the ‚90s were in operation. Each machine

operated at an intake volume flow of 37.4m3/min, differential Company AERZEN USA

pressure of 600mbar and 75kW (100HP) electric motor. The 108 Independence Way

noise generated was calculated at 102dB since the machines Coatesville, PA 19320 - United States

didn’t have acoustic hoods (local Colombian regulations T +1 800-444-1692

defines 80dB as the maximum allowed noise level). Power T +1 610 380 0244

consumption demand for the system was measured in an F +1 610 380 0278

average of 54kW/h per machine that represented a yearly www.aerzen.com/en-us

energy cost of USD 78,00 (considering a kW cost of 0.1 USD

and 20.000 hours MTBR*). Contact David Salazar

Regional Application Manager Cement

Cell: +57 313 4563849

david.salazar@aerzen.com

In Holcim Colombia, each production area is independent in pulsations when the flow is conveyed, delivering a more

their operation. This makes easier the upgrading projects for laminar flow, which makes the burning process more smooth.

specific applications. In Holcim, the corporate policy claims

that every kW counts. * MTBR (Mean Time Between Repairs) Total Cost Of Ownership (TCO) Project evaluation:

In addition to the obvious advantages for upgrading the

Delta Hybrid, AERZEN technology applied to the cement technology, for Holcim, it was important to have a TCO

industry evaluation of the new machines in the system. AERZEN

AERZEN’s commitment as an application specialist presented delivers a 5-year projection that by using the Delta Hybrid

a technology upgrade solution with Delta Hybrid Blowers, Blowers operational costs will be reduced by 40% and will

model D62S, that were selected specifically for this application operate a 40,000 hours MTBR, with 50% more performance

with the primary purpose of improving the following aspects: than conventional tri-lobe blowers.

Noise level reduction to fulfill Colombian regulation of 80dB.

The D62S operate at 72dB under the same operational Testimonial:

conditions with a 10% energy consumption reduction that Javier Forero, Pfister Area Manager, indicates the results after

represents savings of around USD 7.800 yearly. one year of operation with the new technology, “10% energy

consumption reduction, about 20% noise level reduction in

Installed power reduction was achieved with the Delta Hybrid the operating area thanks to the improved acoustic hoods,

performance by replacing the existing 75kW motors for 55kW better control of the coal flow into the burner which improves

IE3 premium efficiency motors. Process stability improved our kiln operation”.

due to the Delta Hybrid’s operating principle that reduces

See the case study video:

www.youtube.com/c/AerzenUSA

You might also like

- Kiln Start-Up Procedures - Infinity For Cement EquipmentDocument1 pageKiln Start-Up Procedures - Infinity For Cement Equipmenteng_mhassan1No ratings yet

- Special Group Training Programm On Energy Audit and ConservationDocument37 pagesSpecial Group Training Programm On Energy Audit and ConservationBir SinghNo ratings yet

- Kiln PDFDocument134 pagesKiln PDFpanji akbarNo ratings yet

- Eu en Oil Flooded 7 45 KW Brochure CompressedDocument12 pagesEu en Oil Flooded 7 45 KW Brochure Compressedandre_silva_camposNo ratings yet

- COT1-SOLPESCC25200 MezcladorDocument60 pagesCOT1-SOLPESCC25200 MezcladorJhon PalaciosNo ratings yet

- Ind Central QLD ServicecentreDocument4 pagesInd Central QLD ServicecentresstrattonNo ratings yet

- Energy Efficiency Trend & OpportunitiesDocument40 pagesEnergy Efficiency Trend & OpportunitiesVenkatagiri K SNo ratings yet

- Microsoft Word - Control Philosophy For Reclaimer PDFDocument7 pagesMicrosoft Word - Control Philosophy For Reclaimer PDFVijayakumar SamyNo ratings yet

- 1 s2.0 S2211464522000690 MainDocument14 pages1 s2.0 S2211464522000690 MainyasminNo ratings yet

- 03 Lm2500 CourseDocument86 pages03 Lm2500 CourseSerg MarushkoNo ratings yet

- Attachment Components For Hammermill FD - Pneumatic - ExportDocument39 pagesAttachment Components For Hammermill FD - Pneumatic - ExportĐức Nguyễn100% (1)

- Leaflet Diverter Valve WZKDocument2 pagesLeaflet Diverter Valve WZKLorenzo Antonio Vera GonzalezNo ratings yet

- Training Report 1 JindalDocument22 pagesTraining Report 1 JindalPoonam vaishnavNo ratings yet

- Minral Processing Lab ManualDocument45 pagesMinral Processing Lab ManualPoorvi Manker100% (1)

- Design of Ladle Shroud For Minimum Turbulence in Tundish Surface During Continuous Casting of SteelDocument5 pagesDesign of Ladle Shroud For Minimum Turbulence in Tundish Surface During Continuous Casting of SteelInternational Journal of Technology and Emerging Sciences (IJTES)No ratings yet

- 04.01 LQTS Free Lime Analysis by Complexometry Method - ENGDocument12 pages04.01 LQTS Free Lime Analysis by Complexometry Method - ENGrupesh soniNo ratings yet

- OptimizingRawMillsPerformance theMaterialsWAY 1670142333901Document17 pagesOptimizingRawMillsPerformance theMaterialsWAY 1670142333901YhaneNo ratings yet

- PDF Summer Training Report of Shree CementDocument28 pagesPDF Summer Training Report of Shree CementRaghav AroraNo ratings yet

- Weighing and Feeding Guide SolutionsDocument20 pagesWeighing and Feeding Guide SolutionsalisuseNo ratings yet

- Girth Gear Run Out Holcim 1607570289Document32 pagesGirth Gear Run Out Holcim 1607570289Mohamed ZayedNo ratings yet

- Maaggear CpuDocument8 pagesMaaggear Cpuhumayun121No ratings yet

- Smartfill: Do You Already Have Enough Information On Your Grinding Process?Document2 pagesSmartfill: Do You Already Have Enough Information On Your Grinding Process?youssef tabetNo ratings yet

- ZKG4-2022 How To Save Electric Energy in Maerz PFR Lime KilnsDocument6 pagesZKG4-2022 How To Save Electric Energy in Maerz PFR Lime KilnsSiroos Yousefi100% (1)

- and 330425 Accelerometer User Guide - 127088Document22 pagesand 330425 Accelerometer User Guide - 127088Hady Abdel HadyNo ratings yet

- Annex 2 Equipment Specification Alt50Document279 pagesAnnex 2 Equipment Specification Alt50MKPashaPashaNo ratings yet

- Ceplattyn KG 10 LCDocument5 pagesCeplattyn KG 10 LCDAvid Alvarez CastilloNo ratings yet

- How To Control The False Air in The Preheater: PyroprocessingDocument4 pagesHow To Control The False Air in The Preheater: Pyroprocessingrupesh soniNo ratings yet

- UltraTech AFR Presentation PDFDocument11 pagesUltraTech AFR Presentation PDFRandeep YadavNo ratings yet

- Activity 1.2.3.3 Report-EPA-07 Hetauda Cement Industries-20130812-Finaldraft-1Document42 pagesActivity 1.2.3.3 Report-EPA-07 Hetauda Cement Industries-20130812-Finaldraft-1rishav khanalNo ratings yet

- Fan Secimi HesabıDocument11 pagesFan Secimi HesabıOguzhanKNo ratings yet

- Mr. Vijay S. Pawar - (NIA1D13697449) : The New India Assurance Co. Ltd. (Government of India Undertaking)Document1 pageMr. Vijay S. Pawar - (NIA1D13697449) : The New India Assurance Co. Ltd. (Government of India Undertaking)cletusNo ratings yet

- Preparing The Dig in MP - ESDocument10 pagesPreparing The Dig in MP - ESFran jimenezNo ratings yet

- Ramco Cements Corporate Presentation 2021 1a5936c1eeDocument60 pagesRamco Cements Corporate Presentation 2021 1a5936c1ee21BCH101 AbineshNo ratings yet

- Global Cement ArticleDocument3 pagesGlobal Cement Articleskb25No ratings yet

- 21C MPT Surface Reconditioning For Roller Jackets and Table Plates in Vertical Roller MillsDocument23 pages21C MPT Surface Reconditioning For Roller Jackets and Table Plates in Vertical Roller MillsCamilo CamposNo ratings yet

- Mets 2 Tutorial 5Document43 pagesMets 2 Tutorial 5Saurav AryanNo ratings yet

- 071 How To Maintain Hydraulic SystemDocument10 pages071 How To Maintain Hydraulic Systemhaziq100% (1)

- Rubber Belt ConveyorDocument4 pagesRubber Belt ConveyorMohamed ShehataNo ratings yet

- 800xa 5.1 Ac 800m Controller Data SheetDocument4 pages800xa 5.1 Ac 800m Controller Data Sheetrmsr_7576100% (1)

- FINDER Catalogue 2014-15Document564 pagesFINDER Catalogue 2014-15Yiannis MinoglouNo ratings yet

- Energy Efficient Turbo BlowersDocument11 pagesEnergy Efficient Turbo BlowersnishanandNo ratings yet

- 3300 02 Transient Data Manual 167388Document148 pages3300 02 Transient Data Manual 167388eko deddyNo ratings yet

- Board of Directors: Shree CementDocument5 pagesBoard of Directors: Shree CementChandan AgarwalNo ratings yet

- DFE 3 118 (2003) ManualDocument70 pagesDFE 3 118 (2003) ManualStephan SalmenNo ratings yet

- Advancingindustry 40 Inplasticswithhydraulicfluids 1540892358026Document14 pagesAdvancingindustry 40 Inplasticswithhydraulicfluids 1540892358026Sly LumbaNo ratings yet

- Cemcap: Grant Agreement NumberDocument35 pagesCemcap: Grant Agreement NumberSiraj AL sharifNo ratings yet

- Companybrochure UsaDocument8 pagesCompanybrochure UsaJoseNo ratings yet

- Global Cement Oct2022Document80 pagesGlobal Cement Oct2022Artem KozinetsNo ratings yet

- Rawmill BagfilterDocument683 pagesRawmill BagfilterIrfan381No ratings yet

- 2017 Bengaluru DSR TEXTILEDocument61 pages2017 Bengaluru DSR TEXTILEMAYANK AGARWALNo ratings yet

- Presentacion Lubrilog PDFDocument6 pagesPresentacion Lubrilog PDFFrancisca DiazNo ratings yet

- Weight FeederDocument4 pagesWeight Feedercakhokhe100% (1)

- Transfer of Solids: 5.1. Slurry TransportDocument8 pagesTransfer of Solids: 5.1. Slurry TransportKevin Alberto Tejera PereiraNo ratings yet

- Balluf BTL0324 PDFDocument2 pagesBalluf BTL0324 PDFEwin ApriansyahNo ratings yet

- BVD 2462 GBDocument2 pagesBVD 2462 GBAnonymous P18XRitOPPNo ratings yet

- Manual Fls Montajes de CoronasDocument42 pagesManual Fls Montajes de CoronasFran JimenezNo ratings yet

- Assiut Cement PlantDocument17 pagesAssiut Cement PlantMahmoud RashadNo ratings yet

- 102-41260 HPGR Chapitre A Introduction AnglaisDocument17 pages102-41260 HPGR Chapitre A Introduction AnglaismahdieNo ratings yet

- Ammonia TechnologyDocument7 pagesAmmonia TechnologyAbhiyan Anala ArvindNo ratings yet

- Case Study S&S Chettinad CementDocument4 pagesCase Study S&S Chettinad CementMohammed AbdoNo ratings yet

- Emmodbus PDFDocument36 pagesEmmodbus PDFpiyushpandeyNo ratings yet

- Erweiterung Der AERtronic Flyer en Web-1Document4 pagesErweiterung Der AERtronic Flyer en Web-1Aiman DadoushNo ratings yet

- Erweiterung Der AERtronic Flyer en Web-1Document4 pagesErweiterung Der AERtronic Flyer en Web-1Aiman DadoushNo ratings yet

- Manuel Profibus Aertronic Aerzener G2 V107Document15 pagesManuel Profibus Aertronic Aerzener G2 V107Diana ConsstantinNo ratings yet

- Screw CompressorsDocument21 pagesScrew CompressorsAiman Dadoush100% (1)

- Glaciogenic: Hydrocarbon SystemsDocument2 pagesGlaciogenic: Hydrocarbon SystemsAHMEDNo ratings yet

- Transport Phenomena 18.4.CDocument3 pagesTransport Phenomena 18.4.CDelyana RatnasariNo ratings yet

- Paul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Document817 pagesPaul S. Adler - Paul Du Gay - Glenn Morgan - Michael Reed (Eds.) - The Oxford Handbook of Sociology, Social Theory, and Organization Studies - Contemporary Currents-Oxford University Press, USA (2014)Andreea Dobrita67% (3)

- Philippine First Insurance V HartiganDocument3 pagesPhilippine First Insurance V HartiganAlexander Genesis DungcaNo ratings yet

- Subsistence and Travel FormsDocument3 pagesSubsistence and Travel FormsAnonymous YRLhQY6G6jNo ratings yet

- HR Q and ADocument87 pagesHR Q and Asanjeeb88No ratings yet

- Craske - Mastering Your Fears and FobiasDocument174 pagesCraske - Mastering Your Fears and Fobiasjuliana218No ratings yet

- 3.1-7 Printer Deployment - Copy (Full Permission)Document18 pages3.1-7 Printer Deployment - Copy (Full Permission)Hanzel NietesNo ratings yet

- As 3789.2-1991 Textiles For Health Care Facilities and Institutions Theatre Linen and Pre-PacksDocument9 pagesAs 3789.2-1991 Textiles For Health Care Facilities and Institutions Theatre Linen and Pre-PacksSAI Global - APACNo ratings yet

- ASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth ResistanceDocument5 pagesASTM G165-99 (R2005) Standard Practice For Determining Rail-To-Earth Resistance曾乙申100% (1)

- 02Document257 pages02shaney navoaNo ratings yet

- Project Report EP-1Document9 pagesProject Report EP-1Nikita NawleNo ratings yet

- Learning Activity Sheet Science 10 Second Quarter - Week 8Document4 pagesLearning Activity Sheet Science 10 Second Quarter - Week 8Eller Jansen AnciroNo ratings yet

- Stryker Endoscopy SDC Pro 2 DVDDocument2 pagesStryker Endoscopy SDC Pro 2 DVDWillemNo ratings yet

- University of Nottingham Department of Architecture and Built EnvironmentDocument43 pagesUniversity of Nottingham Department of Architecture and Built EnvironmentDaniahNo ratings yet

- CPI As A KPIDocument13 pagesCPI As A KPIKS LimNo ratings yet

- Unit 1: Exercise 1: Match The Words With The Pictures. Use The Words in The BoxDocument9 pagesUnit 1: Exercise 1: Match The Words With The Pictures. Use The Words in The BoxĐoàn Văn TiếnNo ratings yet

- TreeSize Professional - Folder Contents of - CDocument1 pageTreeSize Professional - Folder Contents of - CHenrique GilNo ratings yet

- Exercise Guide - Broad Crested WeirDocument18 pagesExercise Guide - Broad Crested Weirvipul anandNo ratings yet

- LG+32LX330C Ga LG5CBDocument55 pagesLG+32LX330C Ga LG5CBjampcarlosNo ratings yet

- Non-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDocument2 pagesNon-Hazardous Areas Adjustable Pressure Switch: 6900P - Piston SensorDiana ArredondoNo ratings yet

- Current Matching Control System For Multi-Terminal DC Transmission To Integrate Offshore Wind FarmsDocument6 pagesCurrent Matching Control System For Multi-Terminal DC Transmission To Integrate Offshore Wind FarmsJackie ChuNo ratings yet

- AMCHAM Press ReleaseDocument1 pageAMCHAM Press ReleaseAnonymous FnM14a0No ratings yet

- UK LL M Thesis - Builders' Liability in UK Law Under TortDocument16 pagesUK LL M Thesis - Builders' Liability in UK Law Under TortRajan UppiliNo ratings yet

- 032017Document107 pages032017Aditya MakwanaNo ratings yet

- (Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFDocument317 pages(Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFSneha SinghNo ratings yet

- LAW 107 - Ganaway vs. Quillen (G.R. No. 18619)Document2 pagesLAW 107 - Ganaway vs. Quillen (G.R. No. 18619)Danielle AbuelNo ratings yet

- cv20672778 Prashanth - Sadak Operations-ManagerDocument4 pagescv20672778 Prashanth - Sadak Operations-ManagerBhasker NiftyNo ratings yet

- Bid Evaluation Report Sample TemplateDocument2 pagesBid Evaluation Report Sample Templatemarie100% (8)

- Far160 Pyq Feb2023Document8 pagesFar160 Pyq Feb2023nazzyusoffNo ratings yet