Professional Documents

Culture Documents

Crack Width For MX - Outer - Max

Uploaded by

mhazarath murariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crack Width For MX - Outer - Max

Uploaded by

mhazarath murariCopyright:

Available Formats

Project Spreadsheets to EC2 The Concrete Centre

Client Advisory Group Made by Date Page

Location CRACK WIDTH FOR MX IN OUTER SHELL-MAX HM 28-Mar-21 NA

FLEXURAL CRACK WIDTH CALCULATION to BS EN 1992-1 : 2004 Checked Revision Job No

Originated from TCC14.xls v4.1 on CD © 2002-2005 BCA for RCC RECTANGULAR TMS - 1184

LEGEND

INPUT

fck = 45 MPa Area of tension steel, As = 5359 mm2

fyk = 500 MPa d= 1092 mm

b= 1000 mm Area of compression steel, As2 = 5359 mm2

h= 1183 mm d2 = 75 mm

QP moment, M = 1010 KNm Maxmum tension bar spacing, S = 150 mm

Age at cracking = 28 days Max tension bar dia, Øeq = 32 mm

Cement type = R (S, N, or R) Short term or long term ? L (S or L)

Creep factor, φ = 2.0 Cover to As, c = 75 mm

CALCULATIONS

modulus of elasticity of concrete = 22[(fck+8)/10]0.3 Ecm = 36.3 GPa

moduli of elasticity of steel Es = 200.0 GPa

Modular ratio αe = 16.54

mean concrete strength at cracking fcm,t = 53.00 MPa

mean concrete tensile strength fct,eff = 3.80 MPa

uncracked neutral axis depth

[bh²/2+(αe-1)(Asd+As2d2)]/[bh+(αe-1)(As+As2)] xu = 590.51 mm

nd

uncracked 2 moment of area

4 6

bh³/12+bh(h/2-x)²+(αe-1)[As(d-x)²+As2(x-d2)²] Iu = 181033 mm 10

cracking moment = fctI/(h-x) Mcr = 1159.69 kNm

> 1010 kNm → section is uncracked

fully cracked neutral axis depth

(-Asαe-As2(αe-1)+[{Asαe+As2(αe-1)}²-2b{Asαed-As2d2(αe-1)}]½)/b xc = 313.48 mm

concrete stress = M/[bx(d-x/3)/2+(αe-1)As2(d-d2)(x-d2)/x] σc = 4.608 MPa

stress in tension steel = σc∙αe(d-x)/x σs = 189.2 MPa

2

effective tension area = min[2.5(h-d), (h-x)/3, h/2]b - As Ac,eff = 222141 mm

As /Ac,eff ρp,eff = 0.0241

max final crack spacing = min[1.3/(h-x),3.4c+0.17Ø/ρp,eff)] sr,max = 480.5 mm

average strain for crack width calculation εsm-εcm = 567.7 μstrain

CALCULATED CRACK WIDTH Wk = 0.000 mm

You might also like

- (2017) A Frame Work To Assess Structural Integrity of Ageing Offshore Jacket Structures For Life ExtensionDocument23 pages(2017) A Frame Work To Assess Structural Integrity of Ageing Offshore Jacket Structures For Life ExtensionRaghu MahadevappaNo ratings yet

- Pile Foundations Dec 18Document84 pagesPile Foundations Dec 18kesharinareshNo ratings yet

- Modi Ed Ohio's Curves: A Rapid Estimation of Compaction Curves For Coarse - and Fine-Grained SoilsDocument12 pagesModi Ed Ohio's Curves: A Rapid Estimation of Compaction Curves For Coarse - and Fine-Grained SoilsApoorva Agarwal100% (1)

- Design For Combined Axial and Bending (Columns EC2) PDFDocument1 pageDesign For Combined Axial and Bending (Columns EC2) PDFdhanya1995No ratings yet

- 01-Slides-D & C of Driven RC Piles-7 Aug 18-BriefDocument144 pages01-Slides-D & C of Driven RC Piles-7 Aug 18-BriefFreddie KooNo ratings yet

- OMAE2017-62059: Guidelines For Estimating Remaining Fatigue Life of Ageing Offshore Jacket StructuresDocument9 pagesOMAE2017-62059: Guidelines For Estimating Remaining Fatigue Life of Ageing Offshore Jacket Structuresklop disposableNo ratings yet

- Construction TechniquesDocument8 pagesConstruction TechniquesManasAroraNo ratings yet

- Evaluation of Shear Lag in Standard H I SectionsDocument72 pagesEvaluation of Shear Lag in Standard H I SectionsaerosanthNo ratings yet

- Real Life Examples in A Solid Mechanics CourseDocument9 pagesReal Life Examples in A Solid Mechanics Coursedeathjester1No ratings yet

- Introduction To Piling: Icon LegendDocument2 pagesIntroduction To Piling: Icon LegendVijayNo ratings yet

- Causes of Cracking of Culverts On Filled Soil and Their Performance After RepairDocument12 pagesCauses of Cracking of Culverts On Filled Soil and Their Performance After Repairlphuong_20No ratings yet

- Guidelines for Floor Openings in Two-Way Concrete SlabsDocument7 pagesGuidelines for Floor Openings in Two-Way Concrete Slabsgulilero_yoNo ratings yet

- Design and Analysis of Heavily Loaded RC Link BeamDocument17 pagesDesign and Analysis of Heavily Loaded RC Link BeamWasin WaiyasusriNo ratings yet

- Structural Engineer - Issue 9 - 2010Document76 pagesStructural Engineer - Issue 9 - 2010ntatar90No ratings yet

- Timber Joist Design BS5268Document3 pagesTimber Joist Design BS5268Zheny FortinNo ratings yet

- GE Sept 2011 A Simple Stability Check For Piling Rigs CorkeDocument3 pagesGE Sept 2011 A Simple Stability Check For Piling Rigs CorkepaulombatistaNo ratings yet

- Evaluarea IncarcarilorDocument8 pagesEvaluarea IncarcarilorAndrei BoraNo ratings yet

- Performance of Reinforced Soil Wall on Stone ColumnsDocument9 pagesPerformance of Reinforced Soil Wall on Stone ColumnsMuhammad RoslanNo ratings yet

- Piling Rig PlatformDocument15 pagesPiling Rig PlatformTarek AbulailNo ratings yet

- Back To Basics For Foundation Design of Monopile (Krolis)Document48 pagesBack To Basics For Foundation Design of Monopile (Krolis)Pavan Kumar0% (1)

- T04 3D Seismic DesignDocument22 pagesT04 3D Seismic Designqatarstructz30100% (1)

- DESIGN OF PLATE GIRDERSDocument57 pagesDESIGN OF PLATE GIRDERSkumuthaNo ratings yet

- Manual CalculationDocument67 pagesManual CalculationChh Song ZpermzNo ratings yet

- End BlockDocument16 pagesEnd Blockdon2hmrNo ratings yet

- MTC PDFDocument63 pagesMTC PDFabdullahNo ratings yet

- 8) HaunchDocument8 pages8) HaunchHarjasa AdhiNo ratings yet

- Failure Of Structures: Common Causes And Case StudiesDocument7 pagesFailure Of Structures: Common Causes And Case StudiesRajarshi ChakrabortyNo ratings yet

- SL Chan FacadeDocument29 pagesSL Chan FacadeKayBee DatilesNo ratings yet

- Geoguide 1 PDFDocument155 pagesGeoguide 1 PDFExile PeachNo ratings yet

- Driven Pipe Piles in Dense Sand Field TestsDocument11 pagesDriven Pipe Piles in Dense Sand Field TestsmarcvenzNo ratings yet

- 1.d. Overall Damping For Piled Offshore Support StructuresDocument4 pages1.d. Overall Damping For Piled Offshore Support StructuresShokoofeAlaviNo ratings yet

- Vsol, The New Retainer Waldstadion Lift Three Girders in SantiagoDocument32 pagesVsol, The New Retainer Waldstadion Lift Three Girders in SantiagoDrPadipat ChaemmangkangNo ratings yet

- Earthquake Resistant Design of Concrete Buildings According To Eurocode 8Document17 pagesEarthquake Resistant Design of Concrete Buildings According To Eurocode 8정진교No ratings yet

- Analysis and Design of Stiffened Raft FoundationDocument270 pagesAnalysis and Design of Stiffened Raft FoundationKemoH0% (1)

- Strength of Shotcrete PDFDocument399 pagesStrength of Shotcrete PDFMelissaRicoNo ratings yet

- Seismic Design of Concrete Buildings According To EC8Document6 pagesSeismic Design of Concrete Buildings According To EC8GeEs AnggaNo ratings yet

- 10 Plate Girder - Part 2Document36 pages10 Plate Girder - Part 2Imran Saikat100% (1)

- Comparison of Calculation Methods For Cross Wind VibrationDocument11 pagesComparison of Calculation Methods For Cross Wind VibrationBitbitterNo ratings yet

- Design Manual for Deep Mixing Excavation SupportDocument211 pagesDesign Manual for Deep Mixing Excavation SupportDao Ba ThanhNo ratings yet

- The Effects of Scour On The Design of Offshore Wind TurbinesDocument9 pagesThe Effects of Scour On The Design of Offshore Wind TurbinesZadeh NormanNo ratings yet

- Implementation and Enforcement in Adopting Eurocode 2 For Concrete Structures Design in MalaysiaDocument13 pagesImplementation and Enforcement in Adopting Eurocode 2 For Concrete Structures Design in MalaysiaAhmad Mensa100% (1)

- 120:BS EN 15257-外文Document30 pages120:BS EN 15257-外文你giao哥No ratings yet

- MSL Rubber BrochureDocument33 pagesMSL Rubber BrochureInspektur Gadget100% (1)

- Design of Foundations For Wind TurbinesDocument161 pagesDesign of Foundations For Wind TurbinesjomoranNo ratings yet

- Finite Element Analysis of Shell StructuresDocument1 pageFinite Element Analysis of Shell Structuresfat470No ratings yet

- Crack Width Check BS5400 4Document5 pagesCrack Width Check BS5400 4saravanan4286100% (1)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- Towards A Unified Soil Mechanics Theory: The Use of Effective Stresses in Unsaturated Soils, Revised EditionFrom EverandTowards A Unified Soil Mechanics Theory: The Use of Effective Stresses in Unsaturated Soils, Revised EditionNo ratings yet

- Crack WidthDocument21 pagesCrack WidthBalaji HariNo ratings yet

- Crack Width Calculation in Reinforced Concrete BeamDocument1 pageCrack Width Calculation in Reinforced Concrete BeamGautham AllimuthuNo ratings yet

- Crack Width - BS en 1992 Base SlabDocument3 pagesCrack Width - BS en 1992 Base SlabVinoth KumarNo ratings yet

- Crack Width Cal-T Beam-Euro CodeDocument10 pagesCrack Width Cal-T Beam-Euro CodeGautham AllimuthuNo ratings yet

- Aci Beam Crack Width Bot ZDocument2 pagesAci Beam Crack Width Bot ZParthiban ArivazhaganNo ratings yet

- Aci Beam Crack Width Top XDocument2 pagesAci Beam Crack Width Top XParthiban ArivazhaganNo ratings yet

- Calculo de Ancho de Grieta: Curso Patología Grid Line 1 Carvajal 13-Oct-2008 1Document1 pageCalculo de Ancho de Grieta: Curso Patología Grid Line 1 Carvajal 13-Oct-2008 1YalimarLoboCNo ratings yet

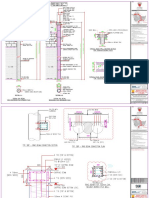

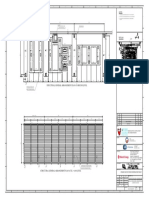

- Pedestal Details: General NotesDocument1 pagePedestal Details: General Notesmhazarath murariNo ratings yet

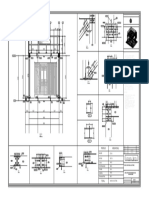

- St-Riffa-05 Sectional DetailsDocument1 pageSt-Riffa-05 Sectional Detailsmhazarath murariNo ratings yet

- I Ki Matra Worksheet - 1Document2 pagesI Ki Matra Worksheet - 1mhazarath murariNo ratings yet

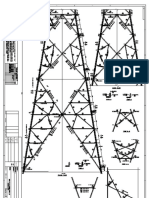

- ST-02 R4 Secant Pile Section DetailsDocument2 pagesST-02 R4 Secant Pile Section Detailsmhazarath murari100% (1)

- Pedestal Details: General NotesDocument1 pagePedestal Details: General Notesmhazarath murariNo ratings yet

- GC ST 01Document1 pageGC ST 01mhazarath murariNo ratings yet

- General notes for CO2 and N2 tank foundationDocument1 pageGeneral notes for CO2 and N2 tank foundationmhazarath murariNo ratings yet

- Practice Worksheet - 3Document1 pagePractice Worksheet - 3mhazarath murariNo ratings yet

- 1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevADocument2 pages1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevAmhazarath murariNo ratings yet

- Scaffolding CollapseDocument1 pageScaffolding Collapsemhazarath murariNo ratings yet

- CHP 4 - 4.3 Determinate Structural AnalysisDocument57 pagesCHP 4 - 4.3 Determinate Structural Analysismhazarath murariNo ratings yet

- Transcript Request FormDocument1 pageTranscript Request Formmhazarath murariNo ratings yet

- GC ST 01Document1 pageGC ST 01mhazarath murariNo ratings yet

- EVS Practice Worksheet for StudentsDocument1 pageEVS Practice Worksheet for Studentsmhazarath murariNo ratings yet

- CHP 4 - 4.5 Stresses On A Cross SectionDocument36 pagesCHP 4 - 4.5 Stresses On A Cross Sectionmhazarath murariNo ratings yet

- Student copy of PE course for Hazarathaiah MurarisettyDocument17 pagesStudent copy of PE course for Hazarathaiah Murarisettymhazarath murariNo ratings yet

- Engineering drawing template with title blockDocument3 pagesEngineering drawing template with title blockmhazarath murariNo ratings yet

- CHP 4 - 4.8 Column DesignDocument16 pagesCHP 4 - 4.8 Column Designmhazarath murariNo ratings yet

- ING10374D2X738 - STRUCTURAL G.A PLAN AT ROOF LEVEL - SHEET 1 OF 1-Rev - C-738Document1 pageING10374D2X738 - STRUCTURAL G.A PLAN AT ROOF LEVEL - SHEET 1 OF 1-Rev - C-738mhazarath murariNo ratings yet

- CHP 7 - 7.4 Structural Steel MaterialDocument17 pagesCHP 7 - 7.4 Structural Steel Materialmhazarath murariNo ratings yet

- CHP 4 - 4.4 Truss AnalysisDocument40 pagesCHP 4 - 4.4 Truss Analysismhazarath murariNo ratings yet

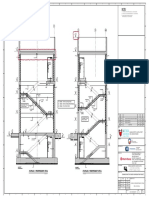

- ING10374D2X742 STAIRCASE DETAIL - SHEET 1 OF 1-Rev - C-742Document1 pageING10374D2X742 STAIRCASE DETAIL - SHEET 1 OF 1-Rev - C-742mhazarath murariNo ratings yet

- ING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741Document1 pageING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741mhazarath murariNo ratings yet

- Steel structure design drawingDocument1 pageSteel structure design drawingmhazarath murariNo ratings yet

- 1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevADocument2 pages1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevAmhazarath murariNo ratings yet

- Statcom transformer room designDocument1 pageStatcom transformer room designmhazarath murariNo ratings yet

- Louver framing and grating detailsDocument1 pageLouver framing and grating detailsmhazarath murariNo ratings yet

- 1jng10374d2x755 - Cooler Foundation and Roof Shed - Reva (1 of 2)Document1 page1jng10374d2x755 - Cooler Foundation and Roof Shed - Reva (1 of 2)mhazarath murariNo ratings yet

- My Outer Bar - MaxDocument1 pageMy Outer Bar - Maxmhazarath murariNo ratings yet

- Check For Uplift of The Inlet Pumping StationDocument23 pagesCheck For Uplift of The Inlet Pumping Stationmhazarath murariNo ratings yet

- Easyflex Flexible Hose DatasheetDocument2 pagesEasyflex Flexible Hose DatasheetzassssNo ratings yet

- Doka Formwork Catalogue 2011Document516 pagesDoka Formwork Catalogue 2011andrijapopovic82% (11)

- Metal Scaffolding - : Part 1: Tubes - Section 1.2 Specification For Aluminium TubeDocument8 pagesMetal Scaffolding - : Part 1: Tubes - Section 1.2 Specification For Aluminium TubeMix UpNo ratings yet

- 006-KPI-MPS-EXC-II-2022 - IFC - Rev.0 - Manufacturing Procedure Specification (MPS) For Concrete Weight Coating - AFC - SignedDocument21 pages006-KPI-MPS-EXC-II-2022 - IFC - Rev.0 - Manufacturing Procedure Specification (MPS) For Concrete Weight Coating - AFC - SignedAlfian ImaduddinNo ratings yet

- How mixed model assembly reduces inventory and demand variabilityDocument27 pagesHow mixed model assembly reduces inventory and demand variabilityTushar Ballabh BMLNo ratings yet

- Kajian Kegagalan Bendungan Berdasarkan Tipe Bendungan Dan Skenario KegagalanDocument19 pagesKajian Kegagalan Bendungan Berdasarkan Tipe Bendungan Dan Skenario KegagalanRobbi Shobri Rakhman100% (1)

- Proposal AlfonsoDocument2 pagesProposal AlfonsoZee De Vera LaderasNo ratings yet

- Directors Associated With Soc Pune Search Able 21092017Document282 pagesDirectors Associated With Soc Pune Search Able 21092017Satish VermaNo ratings yet

- Actron Vismin ReportDocument19 pagesActron Vismin ReportSirhc OyagNo ratings yet

- PVC Pipe and Fittings - An Excellent Solution For Your Commercial Needs (PPFA)Document8 pagesPVC Pipe and Fittings - An Excellent Solution For Your Commercial Needs (PPFA)mystrophanNo ratings yet

- Cumberland Poultry Slat ......... : ... The Only Pure Plastic FlooringDocument2 pagesCumberland Poultry Slat ......... : ... The Only Pure Plastic FlooringjavedNo ratings yet

- Pavement Design Example by Austroads MethodDocument12 pagesPavement Design Example by Austroads MethodZuraizNawazNo ratings yet

- 01 Maquinaria para Pavimentos FlexiblesDocument33 pages01 Maquinaria para Pavimentos FlexiblesbrayanNo ratings yet

- All Handil Profile PD50 3: A B C D E FDocument1 pageAll Handil Profile PD50 3: A B C D E FDer3'am Al m7armehNo ratings yet

- E1 External Corner DetailDocument1 pageE1 External Corner DetailRodrigo Andres Merellado BustosNo ratings yet

- A-Sub Structure: Site/Location: Bole Arabsa 5 Lot 1 and 2 Type of Work: Compound & Fence WorkDocument1 pageA-Sub Structure: Site/Location: Bole Arabsa 5 Lot 1 and 2 Type of Work: Compound & Fence Workbiniyymail.comNo ratings yet

- An Investigation On Climate Responsive Design StraDocument25 pagesAn Investigation On Climate Responsive Design Straangela vargasNo ratings yet

- Roofing Cost EstimationDocument38 pagesRoofing Cost EstimationTechMusic GuyNo ratings yet

- GTW Company Profile PDFDocument17 pagesGTW Company Profile PDFranjithjoyNo ratings yet

- Steelwise Web PDFDocument3 pagesSteelwise Web PDFpio.mirandaNo ratings yet

- Clean Column Design Calculations for Steel Beam ConnectionDocument5 pagesClean Column Design Calculations for Steel Beam ConnectionDaniel RabascallNo ratings yet

- Week 2 IBS Scoring SystemDocument51 pagesWeek 2 IBS Scoring SystemZeyad Tareq Al SaroriNo ratings yet

- Guidelines For Site Elements: S E S IDocument8 pagesGuidelines For Site Elements: S E S IdawitgggNo ratings yet

- Client: Method Statement For Construction of Civil WorksDocument17 pagesClient: Method Statement For Construction of Civil WorksAzharudin ZoechnyNo ratings yet

- Pages From IEC 62305-3Document1 pagePages From IEC 62305-3Mohamed ElnaggarNo ratings yet

- The RoofDek Range at A Glance PDFDocument6 pagesThe RoofDek Range at A Glance PDFThaung MyintNo ratings yet

- Handbook: Smart BricksDocument12 pagesHandbook: Smart Bricksvamsi NathNo ratings yet

- Penetron waterproofing detailsDocument7 pagesPenetron waterproofing detailsNguyễn ThanhNo ratings yet

- Dental lab floor plan for Dr. TanejaDocument1 pageDental lab floor plan for Dr. Tanejayashu tanejaNo ratings yet

- NCCC Supermarket Interior Fit-out Remaining WorksDocument2 pagesNCCC Supermarket Interior Fit-out Remaining WorksGD BERDINNo ratings yet