Professional Documents

Culture Documents

Procedure For Correction and Corrective Action

Uploaded by

Sharif Khan0 ratings0% found this document useful (0 votes)

24 views2 pagesCORRECTIVE ACTION

Original Title

Procedure for Correction and corrective action

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCORRECTIVE ACTION

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views2 pagesProcedure For Correction and Corrective Action

Uploaded by

Sharif KhanCORRECTIVE ACTION

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Procedure for Correction & Corrective

Action

preteshbiswas Uncategorized December 22, 2018 2 Minutes

1. SCOPE

This procedure is to ensure any non-conforming situations identified internally / externally

that affect the quality of service delivered by the XXX are corrected or appropriate

corrective actions are initiated, recorded, reported, implemented & the effectiveness of the

action taken is verified.

2. PURPOSE

Management Representative has overall responsibility for the effective implementation of

this procedure. Non-compliance or non-fulfillment of any of the QMS requirements is

considered as a non-conformance and management responsible for the process is expected

to record such non-conformances using the “Correction / Corrective Action request form”

with the approval of the XXX Department Manager.

3. REFERENCE DOCUMENTS

3.1 XXX Quality Manual,

3.2 Procedure for Internal QMS Audit

4. TERMS & DEFINITIONS

NC- Non-conformance – Non-fulfilment of a requirement

CA-Corrective Action- Action to eliminate the cause of detected non-conformity

C- Correction- Action to eliminate a detected non-conformity

5. RESPONSIBILITY AND AUTHORITY

Management Representative has overall responsibility for the effective implementation of

this procedure. Non-compliance or non-fulfillment of any of the QMS requirements is

considered as a non-conformance and management responsible for the process is expected

to record such non-conformances using the “Correction / Corrective Action request form”

with the approval of the NGT Department Manager.

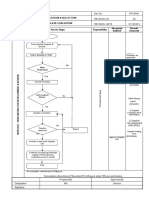

6. DETAILS OF PROCEDURE

6.1.Possible Input Sources for Corrective Actions

6.1.1 Non-conformities/non-compliances observed during Sales or operations and any other

non-fulfillment of the requirement in the XXX business process during the day-to-day

operations.

6.1.2 Complaints & feedback from customers

6.1.3 Internal / external audits

6.1.4 Any corrective action request for observations regarding a deviation found in the XXX

Quality management system.

6.2 Issuing a Correction, Corrective Action Request

6.2.1 A process owner who identifies nonconformity or a deficiency in the management

system must record it in the corrective action report form (QMS F 023) CORRECTIVE ACTION

REPORT shall be used to fill the findings and submit them to the Management

Representative.

6.2.2 Whoever originates a request shall ensure appropriate immediate corrections are

taken if the observations cause a direct impact on the process of customer satisfaction. No

Corrective action request shall be processed unless appropriate corrections are ensured. If

no Corrective Action required, the same shall be recorded in the form.

6.2.3 Review / complete the received Correction / Corrective Action request and approve its

requirement / adequacy. Definition of the problem / finding reported shall be genuine and

worth proceeding with the Corrective Action process.

6.2.4 Allocate a continuous Serial Number affixed with the year for each request and record

the same in the Corrective Action Tracking sheet, which will be used for updating the

progress of Root cause, Recommended action, Action was taken & effectiveness.

6.2.5 If the problem/finding reported is serious in nature, an investigation shall be initiated

with all involved parties to identify what caused the problem and root cause (s) are properly

described in the Corrective Action Request with the most appropriate recommended action.

6.2.6 Completed request is submitted to Department Manager for Approval

6.2.7 Verify the action taken is effective by means of auditing, reviewing sample records in

the future

6.2.8 Update the Corrective Action Tracking sheet and sign-off the corrective action request

raised.

6.2.9 In case of customer complaints received, the customer complaint form shall be used to

fill the complaints and attached with the Correction / Corrective Action request form.

7. RETAINED DOCUMENTED INFORMATION

7.1 Non-Conformance Report(QMS F 022)

7.2 Corrective Action Report(QMS F 023)

7.3 Corrective Action Tracker(QMS F 024)

7.4 Customer complaints (QMS F 025)

You might also like

- FMEA TemplateDocument28 pagesFMEA Templatekhawaja Ali100% (1)

- Procedure For Review of CustomerDocument3 pagesProcedure For Review of CustomerSharif KhanNo ratings yet

- Procedure For QADocument7 pagesProcedure For QASharif Khan100% (1)

- Procedure For TrainingDocument3 pagesProcedure For TrainingSharif Khan100% (1)

- Procedure For PurchasingDocument7 pagesProcedure For PurchasingSharif KhanNo ratings yet

- Procedure For ProductionDocument7 pagesProcedure For ProductionSharif Khan100% (1)

- Procedure For Management ReviewDocument3 pagesProcedure For Management ReviewSharif Khan100% (1)

- Procedure For Business Development and MarketingDocument6 pagesProcedure For Business Development and MarketingSharif KhanNo ratings yet

- Procedure For MonitoringDocument2 pagesProcedure For MonitoringSharif KhanNo ratings yet

- Procedure For MaintenanceDocument2 pagesProcedure For MaintenanceSharif KhanNo ratings yet

- Procedure For Control of DocumentedDocument3 pagesProcedure For Control of DocumentedSharif KhanNo ratings yet

- Procedure For Addressing Risk andDocument3 pagesProcedure For Addressing Risk andSharif KhanNo ratings yet

- Procedure For LogisticsDocument5 pagesProcedure For LogisticsSharif KhanNo ratings yet

- Procedure For ContractDocument6 pagesProcedure For ContractSharif KhanNo ratings yet

- Procedure For Design andDocument4 pagesProcedure For Design andSharif KhanNo ratings yet

- Incoming Quality Plan: NobelDocument1 pageIncoming Quality Plan: NobelSharif KhanNo ratings yet

- Design Review Report: Sr. No. Review CommentsDocument1 pageDesign Review Report: Sr. No. Review CommentsSharif KhanNo ratings yet

- Goods Received and Inspection Report: 2014-2015 GRN RECEIPTSDocument301 pagesGoods Received and Inspection Report: 2014-2015 GRN RECEIPTSSharif KhanNo ratings yet

- Design Review and Verification Report Rev 1Document2 pagesDesign Review and Verification Report Rev 1Sharif KhanNo ratings yet

- Company Name - MG Seating Systems PVT LTD Design & Development Plan For Crew SeatDocument4 pagesCompany Name - MG Seating Systems PVT LTD Design & Development Plan For Crew SeatSharif KhanNo ratings yet

- Design Inputs 01Document1 pageDesign Inputs 01Sharif KhanNo ratings yet

- List of SuppliersDocument2 pagesList of SuppliersSharif KhanNo ratings yet

- Procedure For MARKETINGDocument2 pagesProcedure For MARKETINGSharif KhanNo ratings yet

- List of Measuring InstrumentDocument6 pagesList of Measuring InstrumentSharif KhanNo ratings yet

- Location ChartDocument6 pagesLocation ChartSharif KhanNo ratings yet

- PurchasingDocument1 pagePurchasingSharif KhanNo ratings yet

- Procedure For Preventive Action (8.5.3)Document2 pagesProcedure For Preventive Action (8.5.3)Sharif KhanNo ratings yet

- Procedure For Evaluation and SelectionDocument2 pagesProcedure For Evaluation and SelectionSharif KhanNo ratings yet

- Procedure For Corrective Action (8.5.2)Document5 pagesProcedure For Corrective Action (8.5.2)Sharif KhanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CIGRE-Ciclo de Vida de InterruptoresDocument8 pagesCIGRE-Ciclo de Vida de InterruptoresRoland AvlsNo ratings yet

- FMS CommitteeDocument5 pagesFMS CommitteelinapalupiNo ratings yet

- Formative Assessment 1Document9 pagesFormative Assessment 1JESSA C. JOSEPHNo ratings yet

- SMMDocument500 pagesSMMbwalya_kakosa561350% (2)

- Case Study Writing WorkshopDocument24 pagesCase Study Writing Workshopkylexian1No ratings yet

- Goal SettingDocument4 pagesGoal Settingjohnrichardjasmine100% (2)

- Contemporary Teaching StrategiesDocument8 pagesContemporary Teaching StrategiesAmeerah Cabangal100% (2)

- Case Studies in Project Management The Glasgow Science Centre Tower ProjectDocument20 pagesCase Studies in Project Management The Glasgow Science Centre Tower ProjectThanh Hoang100% (2)

- Freshersnow Recruitments - 29.01.2022: Click HereDocument7 pagesFreshersnow Recruitments - 29.01.2022: Click HerePradip ChauhanNo ratings yet

- PFRS 6 - Here Are Problems and Solutions. There Are Some Theories As Well That May HelpDocument5 pagesPFRS 6 - Here Are Problems and Solutions. There Are Some Theories As Well That May HelpJezela CastilloNo ratings yet

- Evaluation and Performance Administration and Supervision ToDocument21 pagesEvaluation and Performance Administration and Supervision ToMildred Reyes MorenoNo ratings yet

- 8611 Assignment No.01Document20 pages8611 Assignment No.01Ahmedraza RazaNo ratings yet

- Presentation On Logistic System Analysis and DesignDocument9 pagesPresentation On Logistic System Analysis and DesignAnshuman ParasharNo ratings yet

- BTEC HND Level 5 Health and Social CareDocument11 pagesBTEC HND Level 5 Health and Social CareyasinmarfaniNo ratings yet

- JBI Critical Appraisal-Checklist For Quasi - Experimental StudiesDocument6 pagesJBI Critical Appraisal-Checklist For Quasi - Experimental Studiestitikkitti06No ratings yet

- Manual OnlineDocument82 pagesManual OnlineTushar Ranjan RoutNo ratings yet

- Final Year Project Format - UnerDocument5 pagesFinal Year Project Format - UnerDangyi GodSeesNo ratings yet

- Educational Context Development Plan-Snpg 955Document2 pagesEducational Context Development Plan-Snpg 955api-318695192No ratings yet

- 5 SDocument65 pages5 SArianne100% (1)

- Analysis of Summative Tests For EnglishDocument15 pagesAnalysis of Summative Tests For EnglishanjaniNo ratings yet

- Leadership Development - Best PracticesDocument24 pagesLeadership Development - Best PracticesYared AshagreNo ratings yet

- Fulltext01 PDFDocument67 pagesFulltext01 PDFdivya dawdaNo ratings yet

- Iso 90012000 Awareness TrainingDocument15 pagesIso 90012000 Awareness TrainingBrijesh KumarNo ratings yet

- SLIIT Lecture 2 Introduction To Project ManagementDocument2 pagesSLIIT Lecture 2 Introduction To Project ManagementV. OlukaNo ratings yet

- T4-Vojnic - IRIDocument11 pagesT4-Vojnic - IRIQuan PhamNo ratings yet

- Core Tools Forms V5cDocument118 pagesCore Tools Forms V5ciocephNo ratings yet

- Service Quality and Customer Satisfaction: Study of Indian Banks Using ServqualDocument15 pagesService Quality and Customer Satisfaction: Study of Indian Banks Using Servqualmanoj kumar DasNo ratings yet

- History of Quality PresentationDocument13 pagesHistory of Quality PresentationRitesh_Tandel_8603No ratings yet

- Monitoring and Evaluation of Health Services: Dr. Rasha SalamaDocument52 pagesMonitoring and Evaluation of Health Services: Dr. Rasha SalamaLibyaFlowerNo ratings yet

- ISO 9001:2008 To ISO 9001:2015: Summary of Changes Summary of ChangesDocument44 pagesISO 9001:2008 To ISO 9001:2015: Summary of Changes Summary of ChangesAndres RojasNo ratings yet