Professional Documents

Culture Documents

Medidas de Proteccionj

Uploaded by

OscarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Medidas de Proteccionj

Uploaded by

OscarCopyright:

Available Formats

Magnets and Contact Protection Measures

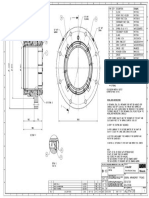

Magnets

90° 90° 90°

Ø9 Ø9 Ø9

red (S)

6

12,3

10

green (N)

Ø 3,5 Ø 4,3 Ø 4,3

Ø 20 Ø 20 Ø 23

with plastics

MR 6 N MR 10 sheathing MR 10 R

S S

90° 90° 90°

Ø 9 Ø 9 Ø 9

10

15

15

Ø 4,3 Ø 4,3 Ø 5

Ø 23 Ø 31 50

MV 35

6

R

MR 12 MR 15

N N

25

Contact Protection Measures

Magnets have the best effect if mounted on sheet metal; but they

must not be fixed with steel screws because this would mean a

magnetic short-circuit.

diode

load

1)

The life time of magnet switches with inert gas contacts (Reed

contacts) is very high, if they are not overstrained. The switching

capacity refers to mere resistive loads and that is not always

guaranteed. If required, contact protection measures have to be

taken:

load

R C 1) For inductive load and direct current a so-called recovery

2) diode must be switched parallel to the load.

2) For inductive load and alternating current a RC-circuit is laid

parallel to the contact. R = appr. R (load),

R C in µF = appr. I in A

(cable)

load

3) 3) For capacative load (e.g. caused by long cables) a resistor is

switched in series to the contact

4) For incandescent lamps the high inrush current may be

limited by a resistor as well. It is also possible to switch a

resistor parallel to the contact in order to pre-heat the

filament.

p. 86 Hans & Jos. Kronenberg GmbH

You might also like

- Etrade Bank-StatementDocument5 pagesEtrade Bank-StatementMark Galanty100% (4)

- Hinge TheoremDocument3 pagesHinge TheoremGlenda HernandezNo ratings yet

- Day 2 - Determining The Relevance and Truthfulness of Ideas Presented in The Material Viewed (3rd Quarter)Document12 pagesDay 2 - Determining The Relevance and Truthfulness of Ideas Presented in The Material Viewed (3rd Quarter)Ella VeronaNo ratings yet

- Magnet Switch MRK: Round Version With CableDocument2 pagesMagnet Switch MRK: Round Version With CableOscarNo ratings yet

- Single Bearing Block E: Accessories For Door InterlocksDocument2 pagesSingle Bearing Block E: Accessories For Door InterlocksOscarNo ratings yet

- Tanklenmen 218-A1 ModelDocument1 pageTanklenmen 218-A1 ModelJisoo KimNo ratings yet

- Belimo GRG DRG Installation-InstructionsDocument2 pagesBelimo GRG DRG Installation-Instructionsprashil.honeywellNo ratings yet

- Thermowell PDFDocument2 pagesThermowell PDFalisuseNo ratings yet

- Thermowell PDFDocument2 pagesThermowell PDFalisuseNo ratings yet

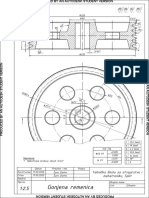

- Gonjena RemenicaDocument1 pageGonjena RemenicaZlatko ŽureNo ratings yet

- Assembly Elec Gland ESF4 Page1Document1 pageAssembly Elec Gland ESF4 Page1tututasNo ratings yet

- CADDDocument1 pageCADDMaria MaribbayNo ratings yet

- HenshawDocument1 pageHenshawFortune ArchibongNo ratings yet

- Subplates Sizes 10, 25 and 32 With Porting Pat-Tern To DIN 24340 Form D, ISO 5781 and ISO 6264Document4 pagesSubplates Sizes 10, 25 and 32 With Porting Pat-Tern To DIN 24340 Form D, ISO 5781 and ISO 6264chawkigenieNo ratings yet

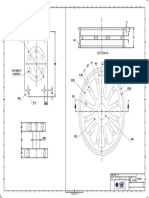

- BUIGRADIUSDocument1 pageBUIGRADIUSccc_wkkNo ratings yet

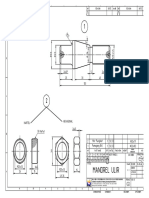

- Mandrel SWD IndustriDocument1 pageMandrel SWD IndustriDinsosnakertrans KudusNo ratings yet

- Gears LectureDocument4 pagesGears LectureEarl John JaymaNo ratings yet

- Din 975 - 70Document3 pagesDin 975 - 70Fabio Henrique SegattoNo ratings yet

- Comem Oil Level Gauges With Magnetic JointDocument8 pagesComem Oil Level Gauges With Magnetic Jointcahya303No ratings yet

- Max 15 LADocument1 pageMax 15 LAAslam Fajri MNo ratings yet

- CD 1.1 - P10.1 - Grade 12 - Mech Assembly Question - June 2019Document2 pagesCD 1.1 - P10.1 - Grade 12 - Mech Assembly Question - June 2019Siyabonga NdumisoNo ratings yet

- Page No. 4: 8 Holes of Ø5, On PCD 30Document1 pagePage No. 4: 8 Holes of Ø5, On PCD 30admam jonesNo ratings yet

- DeGuzman EX2FIGURESDocument2 pagesDeGuzman EX2FIGURESClarence MarcosNo ratings yet

- 737 Ovhd Fuel PanelDocument15 pages737 Ovhd Fuel Panelbondomargalitadze margalitadzeNo ratings yet

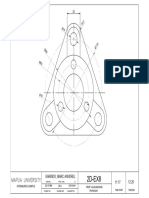

- Garrido 2dex2-8Document1 pageGarrido 2dex2-8Marc Anndrel GarridoNo ratings yet

- DIN-975 Threaded RodsDocument1 pageDIN-975 Threaded RodsVictor MacoveiNo ratings yet

- 1.clamp Arm: Clamp Mini Bench ViseDocument10 pages1.clamp Arm: Clamp Mini Bench VisexnumericallyNo ratings yet

- Section A-A: Page No. 10Document1 pageSection A-A: Page No. 10admam jonesNo ratings yet

- 1.traffic Signal PoleDocument1 page1.traffic Signal Polelibin513No ratings yet

- This Site: Site Development Plan SCALE 1:100 Vicinity Map Not To ScaleDocument1 pageThis Site: Site Development Plan SCALE 1:100 Vicinity Map Not To ScaleAngelbert QuidatoNo ratings yet

- Machine Design Practice July 2019 Assignment IIT MadrasDocument39 pagesMachine Design Practice July 2019 Assignment IIT MadrasVishwajit HegdeNo ratings yet

- Pull Rod Deflection E - ZU: Accessories For Door InterlocksDocument2 pagesPull Rod Deflection E - ZU: Accessories For Door InterlocksOscarNo ratings yet

- DIN-3962 Tol. For Cyl - Gear TeethDocument2 pagesDIN-3962 Tol. For Cyl - Gear TeethrajeskumarNo ratings yet

- PDA Data Analysis For Near Injection Region of 3-Hole Gasoline Direct InjectorDocument28 pagesPDA Data Analysis For Near Injection Region of 3-Hole Gasoline Direct InjectorAbdul Hadi ButtNo ratings yet

- Standaarddelen A3Document1 pageStandaarddelen A3Maxim WynantsNo ratings yet

- WSS220Document1 pageWSS220Favio Lopez MuñozNo ratings yet

- Welding Nipple: Material St.52.3: WRD/WRZ/WRH 52 WRD/WRZ/WRH 52Document4 pagesWelding Nipple: Material St.52.3: WRD/WRZ/WRH 52 WRD/WRZ/WRH 52FRANCISCONo ratings yet

- Proposed Site Development Plan: SPMC - Kidney CenterDocument1 pageProposed Site Development Plan: SPMC - Kidney Centeraireveuse1No ratings yet

- Motoman SG650: Picking, Packing & Handling With The SG-seriesDocument2 pagesMotoman SG650: Picking, Packing & Handling With The SG-seriesSilvio AguilarNo ratings yet

- N 1Document1 pageN 1mohamad hajjNo ratings yet

- Minirail 3 10Document8 pagesMinirail 3 10ahmetarslanNo ratings yet

- RD-M972 RD-M972: XTR Rear DerailleurDocument1 pageRD-M972 RD-M972: XTR Rear DerailleurJonah HexNo ratings yet

- RD-M972 RD-M972: XTR Rear DerailleurDocument1 pageRD-M972 RD-M972: XTR Rear DerailleurJonah HexNo ratings yet

- 172 Kg. 379 LBS.: Dowels Ø 10 MM Depth 20 MM by The Customer Dowels Ø 12 MM Depth 25 MM by The CustomerDocument1 page172 Kg. 379 LBS.: Dowels Ø 10 MM Depth 20 MM by The Customer Dowels Ø 12 MM Depth 25 MM by The CustomerLeonardo AlexNo ratings yet

- SBCF - Rnav Kimus 1a Rwy 34 - Star - 20210225Document1 pageSBCF - Rnav Kimus 1a Rwy 34 - Star - 20210225Gustavo GuguNo ratings yet

- Plano Mecanico - Tablero Arranque Directo 15 HPDocument1 pagePlano Mecanico - Tablero Arranque Directo 15 HPEnrique Renzo Ascencio PachecoNo ratings yet

- First Floor PlanDocument1 pageFirst Floor PlankamalsamplaNo ratings yet

- Bosch Spark Plug CodesDocument1 pageBosch Spark Plug CodesRafael RosasNo ratings yet

- B300 Plummer Blocks PDFDocument12 pagesB300 Plummer Blocks PDFl_aguilar_mNo ratings yet

- Homework 4 (2023)Document5 pagesHomework 4 (2023)Luhandre OlivierNo ratings yet

- Repair Parts Sheet: Repair Parts Sheet Revision Revision Date Product Code Beginning Reference Nr. L2852 Rev.A 04 /2009 CDocument2 pagesRepair Parts Sheet: Repair Parts Sheet Revision Revision Date Product Code Beginning Reference Nr. L2852 Rev.A 04 /2009 Cjose raulNo ratings yet

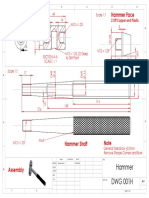

- Hammer Shaft - Sheet1Document1 pageHammer Shaft - Sheet1api-358072612No ratings yet

- Soporte: Do Not Scale DrawingDocument1 pageSoporte: Do Not Scale DrawingJhon Lewis LoraNo ratings yet

- HEAD CYLINDER BOM 43 AUBO ATC-D1 - DrawingDocument1 pageHEAD CYLINDER BOM 43 AUBO ATC-D1 - Drawingmahera wijaksaraNo ratings yet

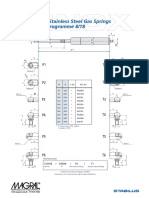

- Stabillus Gas - Inox 8 18Document1 pageStabillus Gas - Inox 8 18Anonymous jW9BkgbQmENo ratings yet

- PRACTICA Nro Modificacion de Dibujos Docente:Gabriela ManchegoDocument1 pagePRACTICA Nro Modificacion de Dibujos Docente:Gabriela ManchegoWillian Alejandro Chura ZapanaNo ratings yet

- Detail C - Cable Detail D - Height Detail A - : Routing Powertail/FeederDocument1 pageDetail C - Cable Detail D - Height Detail A - : Routing Powertail/Feedervinod 7No ratings yet

- Examen Fig 7.107 Bmvy 22090329Document1 pageExamen Fig 7.107 Bmvy 22090329Victor Yael Bahena MondragónNo ratings yet

- MOD. ECO 2017: Notice de Montage Assembling SchemeDocument8 pagesMOD. ECO 2017: Notice de Montage Assembling SchemeMariana IlieNo ratings yet

- Ø14 On 170 PCD K Salt Reactor Housing (Qty-3 Nos)Document1 pageØ14 On 170 PCD K Salt Reactor Housing (Qty-3 Nos)Ankur SinghNo ratings yet

- Machine Clamp UkkDocument1 pageMachine Clamp UkkFarid Salman Al-farisyiNo ratings yet

- Main CatDocument33 pagesMain CatOscarNo ratings yet

- Captureds Final2Document12 pagesCaptureds Final2OscarNo ratings yet

- Torin DriveDocument1 pageTorin DriveOscarNo ratings yet

- VLT® 2800 Series: The Perfect Solution ForDocument2 pagesVLT® 2800 Series: The Perfect Solution ForOscarNo ratings yet

- BLT - CHOI II Brochure Ilovepdf SmallDocument18 pagesBLT - CHOI II Brochure Ilovepdf SmallOscarNo ratings yet

- Pull Rod Deflection E - ZU: Accessories For Door InterlocksDocument2 pagesPull Rod Deflection E - ZU: Accessories For Door InterlocksOscarNo ratings yet

- Reversing Bearing Block U: Accessories For Door InterlocksDocument2 pagesReversing Bearing Block U: Accessories For Door InterlocksOscarNo ratings yet

- Wind Tunnel Technique Notes For Aeronautical Engineers TP 2Document6 pagesWind Tunnel Technique Notes For Aeronautical Engineers TP 2Ramji VeerappanNo ratings yet

- Stelma & Cameron PDFDocument35 pagesStelma & Cameron PDFCatarinaNo ratings yet

- Mindfulness For Two An Acceptance and Commitment TDocument5 pagesMindfulness For Two An Acceptance and Commitment TNilton SantosNo ratings yet

- A Guide To Become A Succesful Marine EngineerDocument99 pagesA Guide To Become A Succesful Marine EngineerTammam Hassan100% (1)

- Mds SM13CRM 110 enDocument5 pagesMds SM13CRM 110 enColinNo ratings yet

- Series Portable Oscilloscopes: Keysight DSO1000A/BDocument15 pagesSeries Portable Oscilloscopes: Keysight DSO1000A/BNestor CardenasNo ratings yet

- Module 4 - Community Health AssessmentDocument8 pagesModule 4 - Community Health AssessmentSteffi100% (1)

- Optimal Control Development System For ElectricalDocument7 pagesOptimal Control Development System For ElectricalCRISTIAN CAMILO MORALES SOLISNo ratings yet

- Amy CuddyDocument5 pagesAmy CuddygeetaNo ratings yet

- Bird Strike ThesisDocument7 pagesBird Strike Thesisarianadavishighpoint100% (2)

- Eng Essay For PresentationDocument8 pagesEng Essay For Presentationctn batrisyiaNo ratings yet

- Spring 2010 MidTerm OPKST CS101 Bc100200572Document6 pagesSpring 2010 MidTerm OPKST CS101 Bc100200572cs619finalproject.comNo ratings yet

- The Child and Adolescent Learners and Learning PrinciplesDocument8 pagesThe Child and Adolescent Learners and Learning PrinciplesAragon KhailNo ratings yet

- Filled System Temperature Recorders & Recorder Controllers: SpecificationDocument2 pagesFilled System Temperature Recorders & Recorder Controllers: SpecificationdencryNo ratings yet

- Winter Student Enrichment PacketDocument9 pagesWinter Student Enrichment PacketshelleyallynNo ratings yet

- Solar Water Heater MOU LaodiceaDocument2 pagesSolar Water Heater MOU LaodiceaZeeshan YasinNo ratings yet

- Gma 5013Document10 pagesGma 5013janurtpatNo ratings yet

- T. Murugan: Post Applied For Well Testing OperatorDocument5 pagesT. Murugan: Post Applied For Well Testing Operatorjohn MNo ratings yet

- Stylus - Pro - 4400 201 300 (067 100)Document34 pagesStylus - Pro - 4400 201 300 (067 100)Joso CepuranNo ratings yet

- Nature'S Numbers: - BasicbooksDocument39 pagesNature'S Numbers: - Basicbooksyeol pacisNo ratings yet

- Rociadores - FT - GFS-100B - GL SeriesDocument2 pagesRociadores - FT - GFS-100B - GL SeriesJimmy FernándezNo ratings yet

- Drone Survival GuideDocument2 pagesDrone Survival GuidevthiseasNo ratings yet

- Chapter Vii. Damascius and Hyperignorance: Epublications@BondDocument10 pagesChapter Vii. Damascius and Hyperignorance: Epublications@BondRami TouqanNo ratings yet

- EagleBurgmann H7N ENDocument5 pagesEagleBurgmann H7N ENlamtony2013No ratings yet

- Plaquette-Costronic en 2020Document2 pagesPlaquette-Costronic en 2020Jun OrtizNo ratings yet

- Present Simple Present ContinuousDocument3 pagesPresent Simple Present ContinuousFernando SabinoNo ratings yet

- Technical Data Sheet: BS-510 All Pressure Solvent CementDocument1 pageTechnical Data Sheet: BS-510 All Pressure Solvent CementBuwanah SelvaarajNo ratings yet

- AOC TFT-LCD Color Monitor 931Fwz Service ManualDocument54 pagesAOC TFT-LCD Color Monitor 931Fwz Service ManualtecnosomNo ratings yet