Professional Documents

Culture Documents

Din933 A4l 8 X 80 MM

Uploaded by

M K ANBUDURAIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Din933 A4l 8 X 80 MM

Uploaded by

M K ANBUDURAICopyright:

Available Formats

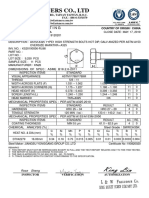

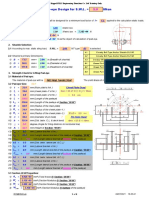

Cert no.:THB9070160-049 Page 1 of 1 Lot no.

: B951702702

Item no.:

Po# no.: B9032956

Inv. no.: B9070160

Issue date: Jul 31, 2019

Insp. date: May 17, 2019

Ship qty: 95 PCS

SS 316L; DIN 933 HEXAGON CAP SCREWS; FULL THREAD; Lot qty: 12,170 PCS

PASSIVATED; MARK "A4L-70 THE" Sampler: Ling

Mfr/Addr: Same as Lab

M8-1.25 X 80 Mfr. date: May 14, 2019

Characteristic Requirements Results S/S Pass Rej Specification*1 Test Method [Device*2] (Sample Plan*3)

Dimensional inspections

s Width Across Flats (mm) 12.730 - 13.000 12.800 - 12.820 4 4 0 DIN 933-1987

e Width Across Corners (mm) MIN 14.38 14.70 - 14.71 4 4 0 DIN 933-1987

k Head Height (mm) 5.150 - 5.450 5.288 - 5.295 4 4 0 DIN 933-1987

l Nominal Length (mm) 79.40 - 80.60 80.16 - 80.17 15 15 0 DIN 933-1987

d Major Diameter (mm) 7.760 - 7.972 7.812 - 7.814 15 15 0 ISO 965-2:1998

pd Functional Dia. Coarse 6g PASSED 15 15 0 ISO 965-2:1998

VA Visual Appearance PASSED 29 29 0 ISO 6157-1:1988

Mechanical properties

TS Tensile Strength (Mpa) MIN 700 700 - 705 4 4 0 ISO 3506-1:2009 ISO 3506-1:2009

YS Yield Strength (0.2% offset) (Mpa) MIN 450 559 - 564 4 4 0 ISO 3506-1:2009 ISO 3506-1:2009

EL Elongation after fracture (mm) MIN 3.20 11.34 - 11.94 4 4 0 ISO 3506-1:2009 ISO 3506-1:2009

Chemical composition %(Acc. to Material Inspection Certificate) Heat No.: 5X509 Material Source: TAIWAN

C Si Mn P S Ni Cr Mo Cu N

X100 X100 X100 X1000 X1000 X100 X100 X100 X100 X10000

2.3 42 142 29 3.1 1004 1623 205 35 406

Remark:

*1 Additional explain: N/A

*2 Device: [Cal]Vernier caliper [Mcr]Micrometer [Mtm]Material Testing Machine [Trg]Thread Ring Gauge

*3 Sample Plan: (14)ASTM F1470-2018 MECHANICAL TEST (18)ASME B18.18-2017 CATEGORY 2

1. This inspection certificate is issued according to EN 10204 3.1/DIN 50049 3.1. It must not be reproduced except in full and to the item(s) tested only.

2. Product meets the order requirements.

3. Whenever testing discrepancies are detected or departures from documented policies and procedure occur, they will be shown in remark.

4. If the products are needed to passivate,we confirm that all are passivated with slight liquid wax. Passivation test per ASTM A380-2006: Passed.

Y. L. SU (QA ENGINEER)

5. Approximate Rockwell Hardness Convertion Numbers From HRC or HRBW to HRA for Austenitic Stainless Steel,please refer to ASTM E140 Table 6.

49 of 204 AC065894 stacy 15:49:49

You might also like

- MTC For BoltDocument2 pagesMTC For Boltrizwan40% (5)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- "Circbase" - Steel Column Circular Base Plate Analysis: Program DescriptionDocument8 pages"Circbase" - Steel Column Circular Base Plate Analysis: Program Descriptionjigarshah21No ratings yet

- ASME HST-1 - Performance Standard For Electric Chain Hoists (2012) PDFDocument32 pagesASME HST-1 - Performance Standard For Electric Chain Hoists (2012) PDFMuhammad AriqNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Test Data Sheet: Ref: IS 1608-2005 / ISO: 6892-1998 Format No. F01 (5.4) Issue Date: 01.01.2018Document3 pagesTest Data Sheet: Ref: IS 1608-2005 / ISO: 6892-1998 Format No. F01 (5.4) Issue Date: 01.01.2018chandan mondalNo ratings yet

- 114486-UT-008 Attemperator Outlet T-PieceDocument2 pages114486-UT-008 Attemperator Outlet T-PieceDave CheungNo ratings yet

- Pittini Group Bars SPF291 B500BDocument2 pagesPittini Group Bars SPF291 B500BAamer MohammedNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- 0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableDocument3 pages0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableFacundo ArlistanNo ratings yet

- Reinforcement steel testDocument1 pageReinforcement steel testsimbamikeNo ratings yet

- Perno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Document1 pagePerno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Naomi Mascco VilchezNo ratings yet

- Certificado 5x20 BBDocument1 pageCertificado 5x20 BBFernando CercalNo ratings yet

- Tensile and Bend Testing of Metallic MaterialsDocument5 pagesTensile and Bend Testing of Metallic MaterialsChandan MondalNo ratings yet

- Perno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Document1 pagePerno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Alexander Ortiz CarrionNo ratings yet

- Metric Conversion ChartDocument2 pagesMetric Conversion ChartSafwan SahriNo ratings yet

- 21055-Acoustics India - 15nosDocument27 pages21055-Acoustics India - 15nosgowtham_venkat_4No ratings yet

- Varilla B7 3-8 X 144 MT (B7)Document1 pageVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoNo ratings yet

- Material Test & Inspection CertificateDocument1 pageMaterial Test & Inspection CertificateKato Megumi ChanNo ratings yet

- Stud Bolt SpecificationDocument8 pagesStud Bolt SpecificationsantoshblonkarNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE5633-3AB73-4FB0-Z Safe AreaSamir SabicNo ratings yet

- PlugDocument2 pagesPlugJalal AlbadriNo ratings yet

- V Viraj Profiles Limited (Fastener Division) : CustomerDocument1 pageV Viraj Profiles Limited (Fastener Division) : Customerqc4.saadalkaabiNo ratings yet

- 41 - PISTOLA DE IMPACTO NEUMATICA INGERSOLL 3955 SeriesDocument32 pages41 - PISTOLA DE IMPACTO NEUMATICA INGERSOLL 3955 SeriesJose Raschio CarpioNo ratings yet

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- RecafcoDocument1 pageRecafcom.aliNo ratings yet

- Lnm309h-Eng Stainless Steel Solid WireDocument1 pageLnm309h-Eng Stainless Steel Solid WiredantegimenezNo ratings yet

- CSC STEEL PRODUCT GUIDEDocument43 pagesCSC STEEL PRODUCT GUIDEedgarc999No ratings yet

- Test Certificate: YB Group of Industries PVT - LTDDocument5 pagesTest Certificate: YB Group of Industries PVT - LTDPradip GangardeNo ratings yet

- Itt Fluid Technology Asia: Model:3196 Xlti Size:8X10-13 Qty: 3Document9 pagesItt Fluid Technology Asia: Model:3196 Xlti Size:8X10-13 Qty: 3Suriyachai NiamsornNo ratings yet

- NT-410/NM-410 Stainless Steel Welding Rod SpecificationDocument2 pagesNT-410/NM-410 Stainless Steel Welding Rod SpecificationbowotriantoNo ratings yet

- Product Characteristics for Bolts and NutsDocument4 pagesProduct Characteristics for Bolts and NutsPınar YeloğluNo ratings yet

- 1-Pwq Iso Grup 1 Wi'89Document25 pages1-Pwq Iso Grup 1 Wi'89Ir FankovicNo ratings yet

- Tuerca Hex Inox M-5Document1 pageTuerca Hex Inox M-5luisquirica20No ratings yet

- Specifications: 14M and 16M Motor Graders Power TrainDocument40 pagesSpecifications: 14M and 16M Motor Graders Power Trainwilly1234512No ratings yet

- M12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Document1 pageM12X50 HDG GR 8.8 ISO 4017 Hex Bolt 2019HD-261Athul T.NNo ratings yet

- Perno A325 HDG 5-8 X 1 3-4 (Ciser+7599055)Document1 pagePerno A325 HDG 5-8 X 1 3-4 (Ciser+7599055)Alexander Ortiz CarrionNo ratings yet

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- PO28184-3-3156WA-10 (SWING CHECK VALVE 3in CLASS 150 316SS)Document3 pagesPO28184-3-3156WA-10 (SWING CHECK VALVE 3in CLASS 150 316SS)Francis Alberto Espinosa PerezNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- sdg4 - 9 - STAINLESS STEELDocument3 pagessdg4 - 9 - STAINLESS STEELJian Ming WongNo ratings yet

- Mechanical Properties: Chemical CompositionDocument1 pageMechanical Properties: Chemical CompositionHERSON FARID BUENO PIÑEROSNo ratings yet

- 3-Microtome Calibration CartificateDocument1 page3-Microtome Calibration Cartificatemba213No ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- Certified Material Test ReportDocument4 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- HS FSW01 00000088aec - CDocument5 pagesHS FSW01 00000088aec - CMarcoNo ratings yet

- 10148933Document1 page10148933kev YNo ratings yet

- Fisa Electrozi Bazici 7018 - EngDocument2 pagesFisa Electrozi Bazici 7018 - EngGeorgeBungarzescuNo ratings yet

- Crgo MTCDocument4 pagesCrgo MTCGupta Gupta100% (1)

- 250kW VDFDocument3 pages250kW VDFalex.burgosNo ratings yet

- Golden Asia Industrial Co., Ltd. Proforma InvoiceDocument2 pagesGolden Asia Industrial Co., Ltd. Proforma InvoiceEdgar Rojas EspejoNo ratings yet

- STPF650 - (87307111) - SpacersDocument8 pagesSTPF650 - (87307111) - SpacersLucaNo ratings yet

- (JISF) : Japanes E IndustrialDocument19 pages(JISF) : Japanes E IndustrialTrịnh Thanh TùngNo ratings yet

- L&W Fasteners Co. Test Report for 3/4-10 x 1-1/2 Hex Cap ScrewsDocument1 pageL&W Fasteners Co. Test Report for 3/4-10 x 1-1/2 Hex Cap ScrewsJosé Carlos Camino GonzálezNo ratings yet

- Mill Certificate AnalysisDocument13 pagesMill Certificate AnalysisBert NiebresNo ratings yet

- 114486-UT-001 HP Steam Drum (Internal)Document1 page114486-UT-001 HP Steam Drum (Internal)Dave CheungNo ratings yet

- Dewpoint Copper DPC-0521-DDocument4 pagesDewpoint Copper DPC-0521-DTengku MunzirNo ratings yet

- Fastners MTCDocument18 pagesFastners MTCmaheshmalaichamy007No ratings yet

- 1le5533 3ab63 4ab3Document2 pages1le5533 3ab63 4ab3Whipman ArduinoNo ratings yet

- Battery Limits 1 Technical Offer A Scope of Delta Saras Piping PVT LTD 1. Delta Saras Scope of InstallationDocument8 pagesBattery Limits 1 Technical Offer A Scope of Delta Saras Piping PVT LTD 1. Delta Saras Scope of InstallationSmit BhivgadeNo ratings yet

- 20009-WELD CHECKDocument2 pages20009-WELD CHECKM K ANBUDURAINo ratings yet

- 20009-weld check 1Document3 pages20009-weld check 1M K ANBUDURAINo ratings yet

- Trunnion AnalysisDocument1 pageTrunnion AnalysisM K ANBUDURAINo ratings yet

- Iso 10684 Hot Dip Galvanized FastenersDocument27 pagesIso 10684 Hot Dip Galvanized FastenersM K ANBUDURAINo ratings yet

- 0148 9062 (78) 90883 5Document1 page0148 9062 (78) 90883 5M K ANBUDURAINo ratings yet

- Sign Convention - ProkonDocument1 pageSign Convention - ProkonM K ANBUDURAINo ratings yet

- Ribbed Slab Design TemplateDocument4 pagesRibbed Slab Design Templateyusuf abdinasir75% (4)

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument26 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksBALAJINo ratings yet

- Daftar Harga Satuan Bahan Tambahan TAHUN 2022Document3 pagesDaftar Harga Satuan Bahan Tambahan TAHUN 2022JUNI ARTANo ratings yet

- Universal Tool and Cutter Grinder Manual Low ResDocument16 pagesUniversal Tool and Cutter Grinder Manual Low ResDale Wade100% (1)

- Scurve Oil Tank PLTU ROPA W6Document1 pageScurve Oil Tank PLTU ROPA W6didik setiawanNo ratings yet

- DHP482 Makita PDFDocument72 pagesDHP482 Makita PDFatorresh090675No ratings yet

- Life MasterDocument36 pagesLife MasterclaokerNo ratings yet

- 2017 CATALOG: Pumps & AccessoriesDocument108 pages2017 CATALOG: Pumps & AccessoriesΓιωργος ΠαπαιωαννουNo ratings yet

- Condenser Br-Coi: Operating InstructionsDocument50 pagesCondenser Br-Coi: Operating Instructionslalit kashyap0% (1)

- Condition Survey Report of Jal Kiran Co-op Housing SocietyDocument14 pagesCondition Survey Report of Jal Kiran Co-op Housing SocietyHARISH NUTRAGANTINo ratings yet

- Wps Nasa AwsDocument14 pagesWps Nasa AwsFernando Alex Romero GomezNo ratings yet

- ITA Side Shift Spec SheetDocument8 pagesITA Side Shift Spec SheetSean CarvalhoNo ratings yet

- Bearing Isolator: Steam Turbine - Low TempDocument1 pageBearing Isolator: Steam Turbine - Low Tempbincoleto5536No ratings yet

- Shut in Procedure During Wireline OperationsDocument2 pagesShut in Procedure During Wireline OperationsGeorge Lamey100% (1)

- Eurotrakker Cursor 13 Air Brake System ManualDocument112 pagesEurotrakker Cursor 13 Air Brake System Manualdanielvep100% (1)

- Especificaciones Zapatas D3GDocument4 pagesEspecificaciones Zapatas D3GJose YatoNo ratings yet

- Adn-S Qos en 2020-10Document6 pagesAdn-S Qos en 2020-10izsofeaNo ratings yet

- Secure and stable lowering with DLHV valveDocument2 pagesSecure and stable lowering with DLHV valveEdwing GuerreroNo ratings yet

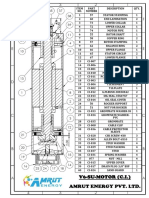

- Amrut Energy Pvt. Ltd. V6-SU-MOTOR (C.I.) V6-SU-MOTOR (C.I.)Document1 pageAmrut Energy Pvt. Ltd. V6-SU-MOTOR (C.I.) V6-SU-MOTOR (C.I.)IMTB MumbaiNo ratings yet

- Data Sheet Gate Valves: FlangedDocument1 pageData Sheet Gate Valves: Flangedbmanojkumar16No ratings yet

- 320g Soap Bar Machine ManualDocument19 pages320g Soap Bar Machine ManualRijaa ArshadNo ratings yet

- PDS01.11.001 - Wouter Witzel - EVFLDocument7 pagesPDS01.11.001 - Wouter Witzel - EVFLVilius BukysNo ratings yet

- Amerex Ansul Badger Ul Catalogo Por PartesDocument37 pagesAmerex Ansul Badger Ul Catalogo Por PartesPuma De La Torre ExtintoresNo ratings yet

- Style Ss1: Normal Range .40"Document1 pageStyle Ss1: Normal Range .40"Imtiyaz KhanNo ratings yet

- Acoplamiento DuraflexDocument12 pagesAcoplamiento DuraflexscribdviviNo ratings yet

- Introduzione MAM PDFDocument8 pagesIntroduzione MAM PDFLeonardo GussoNo ratings yet

- Pad-eye Design for 5 Mton Lifting LoadDocument2 pagesPad-eye Design for 5 Mton Lifting LoadPaulo MoreiraNo ratings yet

- Limit State Method Design of Singly Reinforced Beams PDFDocument4 pagesLimit State Method Design of Singly Reinforced Beams PDFMohammad Aatif Matoo NyXScllFvhNo ratings yet

- Landmark Towers 7-8 Cooling Load SummaryDocument17 pagesLandmark Towers 7-8 Cooling Load SummaryAdnan AttishNo ratings yet