Professional Documents

Culture Documents

Certified Material Test Report

Uploaded by

Nabilah HusnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certified Material Test Report

Uploaded by

Nabilah HusnaCopyright:

Available Formats

1801 Theurer Blvd. Winona MN 55987 Tel.

844-265-2658 Fax 507-494-9664

3939 W 56th St. Indianapolis IN 46254 Tel. 317-216-1189 Fax 317-280-2500

15009 Lee Road Houston, Texas 77032 Tel.713-460-4381 Fax.713-996-7342

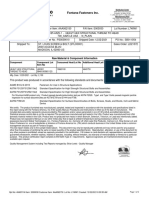

Certified Material Test Report

Certificate Number: B31595-4 Date Issued: March 18, 2024

INDUSTRIAL TECHNOLOGIES &

Customer Name: Customer Part Number: 7442415

SERVICES (POS)

Sold To: OAFL Customer P.O.: N/A

Description: FTSTUD 5/8" 11 tpi 4-1/4"/UNC-2A Marking: CNL B7

Finish: XYLAN 1014 BLUE Cardinal Part Number: 10475409

Quantity Shipped

Material: 4140 Production Lot Quantity: 58/58

SPECIFICATION / GRADE: ASTM A193/A193M-23; ASME SA193/SA193M-23 B7

SURFACE QUALITY: In accordance with ASTM F788/F788M-20ᵋ¹ PASS

COATING: XYLAN 1014 BLUE G4S-3252-01

CHEMISTRY – Heat Number: SF65967

Heat Composition (WT% Heat Analysis)

Element: C Mn P S Si Cr Mo

Minimum: 0.38 0.75 - - 0.15 0.80 0.15

Maximum: 0.48 1.00 0.035 0.040 0.35 1.10 0.25

Result: 0.40 0.79 0.008 0.005 0.20 0.95 0.18

MACROETCH (if required): ASTM E381-22; S1, R1, C1

*¹ Heat Treat Method: Quenching Temp. 875 ºC Time 30 minute; Tempering Temp. 615 ºC time 90 minute

Attribute Test Method Sample Size Requirement Result Acceptance

Core Hardness ASTM A370-2023 5 Max: 35 HRC 29-30 HRC PASS

Reduction of Area ASTM A370-2023 10 Min: 50 % 61-63 % PASS

Elongation (4D) ASTM A370-2023 10 Min: 16 % 21-23 % PASS

Yield (.2% Offset) ASTM A370-2023 10 Min: 105,000 PSI 120,000-121,000 PSI PASS

Tensile Strength ASTM A370-2023 10 Min: 125,000 PSI 134,000-135,000 PSI PASS

Page 1 of 2 November 1, 2023

This template was printed on March 18, 2024. Printed template are uncontrolled. Please check the document access location for the current revision:

\\Netapp02\hub_iso_doc$\CORP\Material Certification\COC's

1801 Theurer Blvd. Winona MN 55987 Tel. 844-265-2658 Fax 507-494-9664

3939 W 56th St. Indianapolis IN 46254 Tel. 317-216-1189 Fax 317-280-2500

15009 Lee Road Houston, Texas 77032 Tel.713-460-4381 Fax.713-996-7342

DIMENSIONAL INSPECTION: Per Cardinal Internal Inspection Plan

Sample

Dimension Data (1)

Size Min

Overall Length: 4-1/4" 1 4.2655

Thread Major: 0.6234 / 0.6113 1 0.6190

Thread Pitch: 0.5644 / 0.5589 1 0.5620

Thread Minor: 0.525 / 0.4999 1 0.5050

Compliancy Statement:

Cardinal Fastener hereby declares that the products supplied as represented in this test report are in compliance with the requirements of

the order as referenced above.

Comments:

Country of Origin: KOREA

*¹The Heat Treat Method Was Provided Based on Supplier’s’ Per Supplier Material Test Report.

Nabilah Husna Binti Hasbullah

Quality Assurance

Cardinal Fastener

This certified test report shall not be reproduced except in full, without the written approval of Cardinal Fastener. Any deviations or discrepancies that are

detected, or any departures from documented policies or procedures will be noted in the comment/notes section. We certify that the data reported above is a true

representation of the information provided and this test report conforms to DIN EN 10204 3.1. Parts mentioned in this test report were manufactured within

Fastenal’s quality management system. Fastenal is ISO 9001:2015 certified with TUV Rheinland of North America.

Page 2 of 2 November 1, 2023

This template was printed on March 18, 2024. Printed template are uncontrolled. Please check the document access location for the current revision:

\\Netapp02\hub_iso_doc$\CORP\Material Certification\COC's

You might also like

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Certified Material Test ReportDocument4 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Certified Material Test ReportDocument4 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Din933 A4l 8 X 80 MMDocument1 pageDin933 A4l 8 X 80 MMM K ANBUDURAINo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- FISHERDocument3 pagesFISHERPower Booster Sdn BhdNo ratings yet

- TC No 1201 StudDocument2 pagesTC No 1201 StudGaurav100% (1)

- 4130wog0913 - Rev14Document3 pages4130wog0913 - Rev14Quality controller100% (1)

- 0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableDocument3 pages0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableFacundo ArlistanNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- E-34088-32 HTX Products LLC R 24 SS316 Oval 38489Document1 pageE-34088-32 HTX Products LLC R 24 SS316 Oval 38489Frank Maldonado D'JesusNo ratings yet

- Perno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Document1 pagePerno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Naomi Mascco VilchezNo ratings yet

- Zhongyuan Internatoinal Material Specification: ZyicoDocument2 pagesZhongyuan Internatoinal Material Specification: ZyicoAbozar BilanNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- RecafcoDocument1 pageRecafcom.aliNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- 114486-UT-008 Attemperator Outlet T-PieceDocument2 pages114486-UT-008 Attemperator Outlet T-PieceDave CheungNo ratings yet

- TTU Fittings Ttu Industrial Corp., LTD.: Manufacturer'S CertificateDocument1 pageTTU Fittings Ttu Industrial Corp., LTD.: Manufacturer'S CertificateMohamed RaafatNo ratings yet

- Certif Tu inDocument18 pagesCertif Tu inSri GangaNo ratings yet

- MS Sheets MTCDocument6 pagesMS Sheets MTCAmit Kumar OjhaNo ratings yet

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- L&t-Ut-Se-1678 - R1 30-03-2023Document1 pageL&t-Ut-Se-1678 - R1 30-03-2023SamirNo ratings yet

- CTX 400Document5 pagesCTX 400Brzata PticaNo ratings yet

- Varilla B7 3-8 X 144 MT (B7)Document1 pageVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoNo ratings yet

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Test Report: Work Order No. JSA-19-05651Document3 pagesTest Report: Work Order No. JSA-19-05651SantoshNo ratings yet

- Tuerca Hex Inox M-5Document1 pageTuerca Hex Inox M-5luisquirica20No ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Wire PDFDocument3 pagesWire PDFm.aliNo ratings yet

- Tech Spec Spiral Pipe For Faide Project.r1Document5 pagesTech Spec Spiral Pipe For Faide Project.r1Delshad DuhokiNo ratings yet

- 1-Pwq Iso Grup 1 Wi'89Document25 pages1-Pwq Iso Grup 1 Wi'89Ir FankovicNo ratings yet

- 10 MM Test CertificateDocument1 page10 MM Test CertificatesimbamikeNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Scan Plan Paut-Mc-01-Corregido-2Document4 pagesScan Plan Paut-Mc-01-Corregido-2Carlos TijerinaNo ratings yet

- Title: MODEC Doc. Ref. No: Supplier Document NumberDocument2 pagesTitle: MODEC Doc. Ref. No: Supplier Document NumberSales FlometriqNo ratings yet

- B 202 TW 042 - 201105 00406 - EnglishDocument1 pageB 202 TW 042 - 201105 00406 - EnglishNavid DavaniNo ratings yet

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- 114486-UT-001 HP Steam Drum (Internal)Document1 page114486-UT-001 HP Steam Drum (Internal)Dave CheungNo ratings yet

- 42TPM IOM - tcm478-51410Document16 pages42TPM IOM - tcm478-51410Abhilash C SNo ratings yet

- Cert Perno Hex A325 5.8 (11) X 1-1.2Document4 pagesCert Perno Hex A325 5.8 (11) X 1-1.2Abril SalinasNo ratings yet

- Test Certificate: CM/L-NO:5530357Document10 pagesTest Certificate: CM/L-NO:5530357TARUNKUMARNo ratings yet

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- BLQ Iiw T1 1018Document3 pagesBLQ Iiw T1 1018contacto.techndtNo ratings yet

- Material Test Report: Cert No: 697430Document1 pageMaterial Test Report: Cert No: 697430Abozar BilanNo ratings yet

- 2018091981-Inspection Report-Raigarh PDFDocument13 pages2018091981-Inspection Report-Raigarh PDFiprao50% (2)

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- MTC PipeDocument1 pageMTC PipeMathavan ABMNo ratings yet

- 4 - PREPARATION OF WPS - StudentDocument22 pages4 - PREPARATION OF WPS - Studentrazlan ghazaliNo ratings yet

- 114486-UT-006 HP Primary Superheater Outlet ManifoldDocument2 pages114486-UT-006 HP Primary Superheater Outlet ManifoldDave CheungNo ratings yet

- Material Test ReportDocument5 pagesMaterial Test ReportJuan Carlos Sua SuaNo ratings yet

- Perno A325 HDG 5-8 X 1 3-4 (Ciser+7599055)Document1 pagePerno A325 HDG 5-8 X 1 3-4 (Ciser+7599055)Alexander Ortiz CarrionNo ratings yet

- Welding Presentation by NoreastDocument78 pagesWelding Presentation by Noreastravi00098No ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Reporte Element T 47Document3 pagesReporte Element T 47Edson AragaNo ratings yet

- (Ronald Weed, John Von Heyking (Eds.) ) Civil ReligiDocument375 pages(Ronald Weed, John Von Heyking (Eds.) ) Civil ReligiskaspeNo ratings yet

- TNSTCDocument1 pageTNSTCMohamed MNo ratings yet

- Vo 1263 AaDocument8 pagesVo 1263 Aa801400No ratings yet

- Land PollutionDocument2 pagesLand PollutionmoniqueNo ratings yet

- Staircase & Ramps Duration (DAYS) Appendix StaircaseDocument7 pagesStaircase & Ramps Duration (DAYS) Appendix StaircaseLai ChungyiNo ratings yet

- Chapter8 SwitchingDocument60 pagesChapter8 SwitchingSalah AL-HakimiNo ratings yet

- Advantages of Solid-State Relays Over Electro-Mechanical RelaysDocument11 pagesAdvantages of Solid-State Relays Over Electro-Mechanical RelaysKen Dela CernaNo ratings yet

- 9 Cartesian System of CoordinatesDocument15 pages9 Cartesian System of Coordinatesaustinfru7No ratings yet

- DimensionsDocument103 pagesDimensionslaurariton100% (1)

- Medications: Jason Yu Discharge PlanDocument2 pagesMedications: Jason Yu Discharge PlanPhilip Royce EmpeñoNo ratings yet

- Assignment CHAP NO 1.... Computer Fundamentals by PK SinhaDocument7 pagesAssignment CHAP NO 1.... Computer Fundamentals by PK SinhaThreating King100% (2)

- 2019 AnalysisDocument3 pages2019 AnalysisVedalam VetriNo ratings yet

- 04 Dispersion MeasuresDocument17 pages04 Dispersion MeasuresMuhammad AbdullahNo ratings yet

- n 3n+1 5n−2 n (−1) n n 12n +73n −18n +9 25n +2n n n n +1 n 2 n 1 n n n n nπ 3Document1 pagen 3n+1 5n−2 n (−1) n n 12n +73n −18n +9 25n +2n n n n +1 n 2 n 1 n n n n nπ 3Prashanth SridharNo ratings yet

- Engineering Economy 15th Edition Sullivan Test BankDocument25 pagesEngineering Economy 15th Edition Sullivan Test BankDannyStaffordctbi100% (53)

- Design and Assembly Analysis of Piston, Connecting Rod & CrankshaftDocument12 pagesDesign and Assembly Analysis of Piston, Connecting Rod & CrankshaftD MasthanNo ratings yet

- Anatomy ST1Document2 pagesAnatomy ST1m_kudariNo ratings yet

- Tesla in ChinaDocument9 pagesTesla in ChinaÁi Nhân Huỳnh NguyễnNo ratings yet

- Write A Short Note On Carbon FiberDocument4 pagesWrite A Short Note On Carbon FiberMOJAHID HASAN Fall 19No ratings yet

- DIO 20. ZAŠTITA PRI RADU I SMJEŠTAJ POSADE Jan 2015Document44 pagesDIO 20. ZAŠTITA PRI RADU I SMJEŠTAJ POSADE Jan 2015Samo SpontanostNo ratings yet

- 1822 B.E Cse Batchno 154Document53 pages1822 B.E Cse Batchno 154maniuyyala65No ratings yet

- P.B.B.SC Nsg. Syllabus Original PDFDocument57 pagesP.B.B.SC Nsg. Syllabus Original PDFRajalakshmi SrinivasanNo ratings yet

- Sample Theory With Ques. - Organometallic Compounds (NET CH UNIT-3) PDFDocument26 pagesSample Theory With Ques. - Organometallic Compounds (NET CH UNIT-3) PDFPriyanshi VermaNo ratings yet

- Bright: Insidecrochet - Co.ukDocument100 pagesBright: Insidecrochet - Co.ukЕкатерина Матушинец100% (2)

- 07 GU - OC2021 - E03 - 1 GUL UniRAN Configuration 65PDocument65 pages07 GU - OC2021 - E03 - 1 GUL UniRAN Configuration 65PjedossousNo ratings yet

- Analytical Text 1Document11 pagesAnalytical Text 1RijayyyNo ratings yet

- EAU2 - I - 04 - Ruins of The Lost RealmDocument127 pagesEAU2 - I - 04 - Ruins of The Lost RealmHache73% (15)

- 80 MT Crawler CraneDocument40 pages80 MT Crawler CraneramyaNo ratings yet

- Lisa-Operation Manual: Installation and Operation Instructions (Part B)Document41 pagesLisa-Operation Manual: Installation and Operation Instructions (Part B)majdNo ratings yet

- Acetaldehyde Solution SDSDocument10 pagesAcetaldehyde Solution SDSJuan Carlos Blanco LeónNo ratings yet