Professional Documents

Culture Documents

1466 - EC0044

Uploaded by

Deipak HoleCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1466 - EC0044

Uploaded by

Deipak HoleCopyright:

Available Formats

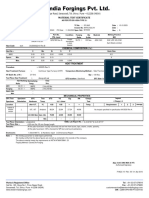

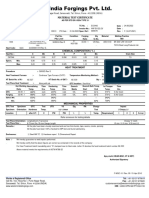

MATERIAL TEST CERTIFICATE

AS PER STD EN 10204 TYPE 3.1

Customer : TechnipFMC TC No. : EC/22-23/0044 Date : 23.04.2022

Invoice No.:WIF/EX/22-23/ Date :

P.O. No.: 4500602722 Line Item: 0010 PO Date : 06.01.2022 Spec. Ref.: M25028 Rev. : B (Date:10.06.2010)

Die No. Description Part No. Condition Forging Qty Material Melting Practice

Drg. No. PSL Level Ratio Sr.No. Mill

NUT FORGING UNION 3 FIG F/

1466 P565679 Rev D 17.91 1000 Nos. AISI 4140 BF-EOF-LRF-VD-CCM

1502 MAX AISI 4140 ALLOY NQT/SB

STEEL PER SPEC M25028

15000 CWP - JSW STEEL

Heat Code: MEV DU500047082 Rev C

CHEMICAL COMPOSITION ( % )

Heat No :- C Mn Si S P Cr Mo Grain Size

F04617 0.40 0.90 0.17 0.006 0.013 1.04 0.22 7

Specn. Min. 0.38 0.75 0.15 - - 0.80 0.15 6

Max. 0.43 1.00 0.35 0.040 0.035 1.10 0.25 -

HEAT TREATMENT

Procedure :- Q00025 Rev R

Heat Treatment Furnace :- Continous Type Furnace (CHTF) Temperature Monitoring Method:- Side Thermocouples in the Working Zone ( Method A)

HT Load No. of N :- AE-120 HT Batch No. of Q&T:- A Qty :- 1000 Nos.

Test Piece Heat Treatment :- Along with job QTC location:- Sacrificial QTC Size- Actual Part

Hot Working Normalising Time Hardening Time Quench Quench Bath Temp. 1st Temper Time

Ratio Temp. Hrs. Temp. Hrs. Media Start End Temp. Hrs.

QTC 17.91 900⁰C 3.20 870⁰C 3.20 OIL 30°C 51°C 580°C 5 (Air Cool)

Forging 17.91 900⁰C 3.20 870⁰C 3.20 OIL 30°C 51°C 580°C 5 (Air Cool)

Specn. Min. 870⁰C 840⁰C --- --- 480⁰C

Max. 925⁰C 900⁰C --- 80⁰C 650⁰C

MECHANICAL PROPERTIES

QTC Test Specimen QTC Test UTS YS Elg RA Charpy Impact

Specimen Orientation Hardness Temp. 0.2 % Offset Test ( Charpy ) J

Location after H.T. ⁰C PSI PSI % % Temp. Requirement 1 2 3 Average

Refer annexure for testing details

Test Piece Orientation:- Longitudinal & Transverse Charpy 'V' notch

Test Piece Size :- 6.25 mm Dia, 25 mm Gauge Length 10 mm X 10 mm X 55 mm LG

Remarks : All the jobs have been visually examined and are free from bursts, laps, seams, cracks, porosity.

All the jobs have been 100% checked for MPI test and found satisfactory.

Enclosures: 1) Steel Mill TC 2) Hardness report 3) MPI Report 4) Dimensional Report 5) Testing Annexure

Note :- We hereby guarantee no weld repairs performed.

. We hereby certify that the above figures are correct as contained in the records of the company

For Heat Treatment batch traceability point, "A" stamped near to Heat code. Parts heat treated in batch number AE-121

Above material meets the requirements of ASTM A788-22

Mr. Ajay Joshi (Head - MQC, HT & NDT)

Authorised Signatory

F-MQC-10 / Rev. 00 / 01-Apr-2016

Works & Registered Office Tel : +91-02137-679819

Gat No. 163, Hissa No.1, Pune-Nagar Road, Fax : +91-02137-679820

Sanaswadi, Tal. Shirur, Pune- 412208 (INDIA) customerservice@westernindiaforgings.com

www.westernindiaforgings.com CIN : U28910PN1981PTC024155

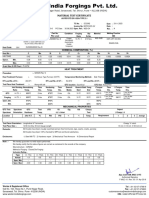

HARDNESS TEST REPORT

Customer:- TechnipFMC TC No: EC/22-23/0044

P.O. No.:- 4500602722 Line Item: 0010 PO Date : 06.01.2022 Date : 23.04.2022

NUT FORGING UNION 3 FIG 1502 MAX AISI

Item : 4140 ALLOY STEEL PER SPEC M25028 Material : AISI 4140

15000 CWP

Part No.: P565679 Rev D Heat No. : F04617

Drawing No.: DU500047082 Rev C Ambient Temp : 25°C

Die No.: 1466 Hardness Range:- 277-321 HBW

Qty.: 1000 Nos. Test Method : Brinell Hardness Test

Vendor Sr.No.: - Equipment Used: Brinell Hardness Tester

HT Load No.: N: AE-120 QT: A Machine Sr. No. 2017/09

Reference Standard: ASTM E10 Machine Make: SAROJ

Load Applied: 3000 Kgs Calibration Agency: M.M. Engineers

Type of Penetrator: Dia 10 mm Carbide Ball Certificate No.: MME/CAL/072/22-23

Std Block Details: SH-2005/22 (Hardness value - 297.6 HBW) Calibrated On: 14.02.2022

Entity Performing Test: WIF Sanaswadi Calibrated Due On:13.08.2022

Hardness

Q03006 Rev. AC / Q03009 Rev. X Date of Test :- 18.04.2022

Procedure :-

Precise Measuring Method of HBW Impression : Type B : Hand-Held Microscope with fixed measuring lines.

Qty. Hardness in HBW

1000 Nos. 285 - 321 HBW

Test Performed By Reviewed By Approved By :

Atul Jedhe Satish Gadgil (Sr.Manager HT) Mr. Ajay Joshi (Head - MQC, HT & NDT)

F-HT-10 / Rev. 00 / 01-Apr-2016

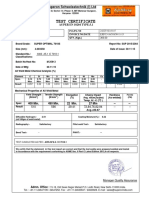

MAGNETIC PARTICLE EXAMINATION REPORT

Customer : TechnipFMC

PO No. : 4500602722 Line Item : 0010 Report No : EC/22-23/0044 Date : 23.04.2022

PO Date : 06.01.2022 Test Date : 18, 19 & 20.04.2022

NUT FORGING UNION 3 FIG 1502 MAX AISI 4140

Description : Die No. : 1466 MEV

ALLOY STEEL PER SPEC M25028 15000 CWP

Part No. : P565679 Rev D Qty. : 1000 Nos.

Material : AISI 4140 Sr. No. : -

Heat No. : F04617 Heat Load No : N AE-120 QT A

Drg. No. : Stage of

DU500047082 Rev C F/NQT/SB

Examination :

Standard / Acceptance

Spec. / Q00207 Rev D , ASTM E 709 (2021) Standard / Q00207 Rev D Cl no 5.0

Procedure : Criteria :

Magnetic Particle Equipment : Magnaflux Model : AD 945DC

Calibration Date: 02.01.2022 : Calibration Due Date: 01.07.2022

Machine Sr. No : '26431017043785

Bath Concentration - 0.1 to 0.4 ml/ 100 ml Bath : 0.30 ml/ 100 ml Bath

UV-A Lamp irradiance Intensity - 1000 µWatt / cm² Minimum : 2800µWatt / cm² Make: NDT Consultant (UK) Sr no: 2137

(UV-A + LUX Meter) Calibrated on:

Ambient Visible illumination Intensity - 21.5 LUX Max. : 01 LUX 10.01.2022 Due on:10.07.2022

Type Of Magnetic Particle Material : Wet fluroscent

Magnetic Particle Used : MG 410 Magnaflux Make Batch no: 21K22 / Dec-2021

Bath Medium : Pansol 65 Carrier oil - Batch no: 605 / 2021-22

Surface Condition : As Shot Blasted

Area to be examined : 100 % of accessible Surfaces

Magnetizing Process / Method : Wet Continuous Method

Means Of Establishing Magnetization : Head Shot (Internal Conductor dia 50 mm) + Coil Shot

: 52 Gauss - Digital Hall Effect Probe Sr no:6050 Make: NDT Consultant

Observed Field Strength (Tangential)

(UK) Calibrated on: 10.01.2022 Due on:10.07.2022

Magnetization Field : Circular + Longitudinal MT Technique Sheet - MT/TS/238

Applied Current : Circular : 2800 Amp , Longitudinal : 2000 AMP

Sensitivity ensured By : Ketos Ring & SHIMS CX-230

: Within (± 3 Gauss) - Make: GNAT, DRFI Digital Gauss Meter

Residual field ensured after Demagnetization

Sr no:218001 Calibrated on:23.08.2021 Due on:23.02.2022

Result : No linear or rounded indication observed.

Remark : Material is accepted

Examined By Reviewed & Accepted By

Sign Sign

Name : Anil Thorat Name : Hemant Takawale

Cert. Type & Level - NDE Level II MT Cert. Type & Level - NDE Level II UT,MT,PT,VT As

As Per SNT-TC-1A. Per SNT-TC-1A.

Doc. No:- F-NDT-03 Rev-02 / 09 July- 2018

Certificate of Compliance

Customer : TechnipFMC TC No.: EC/22-23/0044

Date: 23.04.2022

Die No. : 1466 Heat Code : MEV

PO No : 4500602722 Line Item No : 0010

Offer Qty. : 1000 Nos.

Part No/ Rev : P565679 Rev D Drg No / Rev : DU500047082 Rev C

NUT FORGING UNION 3 FIG 1502

Part Name : Serial No. : -

MAX AISI 4140 ALLOY STEEL PER

SPEC M25028 15000 CWP

I. Material

A. Material Type : AISI 4140

B. Material Spec/ Rev. : As per Spec no : M25028 Rev No. : B (Date:10.06.2010)

C. Material Test Report No : Mill Heat No : F04617

II. Dimensional

A. AQL : AS PER QUALITY PLAN B. Sample Size : 13 Nos.

III. Secondary Process : Heat Treatment

A. Process Name : Normalised

Heat Lot No. : AE-120 Process Spec : Q00025 Rev R

B. Process Name : QT

Heat Lot No. : A Process Spec : Q00025 Rev R

IV. NDE

A. Process Name : MPI

Q00207 Rev D ,

Certificate No : EC/22-23/0044 Process Spec :

ASTM E 709 (2021)

B. Process Name : UT

Certificate No : NA Process Spec : NA

This is certified that subjected material is manufactured from material mentioned above &

verified by us as per written sample size & found conforming to requirements.

For Heat Treatment batch traceability point, "A" stamped near to Heat code. Parts heat treated in batch number

AE-121

Above material meets the requirements of ASTM A788-22

Sign with Stamp

Mr. Ajay Joshi (Head - MQC, HT & NDT)

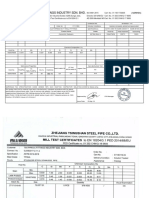

Mechanical Test Annexure

Die No.: 1466 Material Grade: AISI 4140

Heat No.: F04617 HT Lot No. : A

Heat Code: MEV TC No.: EC/22-23/0044

TENSILE TEST

QTC Test QTC Hardness after UTS YS Elg RA

Specimen Test Temp. NABL Lab Sample

Specimen H.T. 0.2 % Offset

Orientation (⁰C) Report No. No.

Location HBW PSI PSI % %

Midwall L A-22-2146-P 149020 130811 19.44 59.21

section of

311, 321 Ambient 1

heaviest

cross section T A-22-2147-P 141675 123614 18.60 52.32

277-321 Spec. Min. 130000.00 110000.00 16.00 35.00

IMPACT TEST

QTC Test

Specimen Requirement Test Temp. NABL Lab Sample

Specimen 1 2 3 Average

Orientation (⁰C) Report No. No.

Location

Avg. - 42 J Min

64 96 92 84.00

Single - 32 J Min

L LE - 0.38 mm Min 0.77 1.10 0.75 0.87

%Shear - Report 55 65 55 58.33

-29°C

Avg. - 28 J Min

60 70 56 62.00

Single - 18.7 J Min

Midwall T LE - Report 0.80 0.88 0.76 0.81

section of %Shear - Report A-22-2146-P 50 60 45 51.67

heaviest & 1

Avg. - 27 J Min

cross A-22-2147-P 46 76 60 60.67

Single - 20 J Min

section L

LE - Report 0.65 0.93 0.80 0.79

%Shear - Report 40 60 50 50.00

-40°C

Avg. - 20 J Min

52 56 56 54.67

Single - 13.5 J Min

T LE - Report 0.72 0.77 0.77 0.75

%Shear - Report 45 45 45 45.00

Mr. Ajay Joshi (Head - MQC, HT & NDT)

Authorised Signatory

You might also like

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 - EC0583Document5 pages1299 - EC0583Deipak HoleNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- 1426-EC1942Document3 pages1426-EC1942Deipak HoleNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- HT 003Document1 pageHT 003Sam RajaNo ratings yet

- HT 002Document1 pageHT 002Sam RajaNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- Material Test Report: Cert No: 697430Document1 pageMaterial Test Report: Cert No: 697430Abozar BilanNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- MTC_A335 P22 Seamless PipeDocument1 pageMTC_A335 P22 Seamless PipeSri GangaNo ratings yet

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- NST 3.1 PDFDocument1 pageNST 3.1 PDFPankaj RaneNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5armin heidariNo ratings yet

- Inspection Certificate Test ResultsDocument1 pageInspection Certificate Test ResultsCricri CriNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNo ratings yet

- HT 001Document1 pageHT 001Sam Raja100% (1)

- Hamilton Metals Inspection CertificateDocument1 pageHamilton Metals Inspection CertificateColinNo ratings yet

- Gate Valve 3in 150 XMK1020754308-27Document5 pagesGate Valve 3in 150 XMK1020754308-27Mygame 1402No ratings yet

- 0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611Document2 pages0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611JORGE BAENANo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Bosch EP test values for diesel fuel injection equipmentDocument3 pagesBosch EP test values for diesel fuel injection equipmentTamer Moustafa100% (1)

- Page 3 Tsi MTC Plate (MTC - 249)Document2 pagesPage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNo ratings yet

- 21app0808 MTR-14Document1 page21app0808 MTR-14gmendoza.logistica3No ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- GR 70 32MMDocument1 pageGR 70 32MMquality nakodaNo ratings yet

- PIEZO BUZZER SPECIFICATION AND TESTINGDocument5 pagesPIEZO BUZZER SPECIFICATION AND TESTINGg_1234No ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- Inspection Report - Motor+16701004051+KT - 12V1600G80SDocument1 pageInspection Report - Motor+16701004051+KT - 12V1600G80SChristopherNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Document1 page7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强No ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- 1.VFB-150-2 Tr.316 90601-077 QRDocument1 page1.VFB-150-2 Tr.316 90601-077 QRSurya ManaluNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- CC - Cot 90g S-S (Cotss) 73.03x7.01 304 Tras LRDocument2 pagesCC - Cot 90g S-S (Cotss) 73.03x7.01 304 Tras LRNarcis NarteaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 1433 Ec0442Document6 pages1433 Ec0442Deepak HoleNo ratings yet

- 1335 - EC1904Document1 page1335 - EC1904Deipak HoleNo ratings yet

- 456 PDFDocument4 pages456 PDFDeipak HoleNo ratings yet

- Cameron CompDocument14 pagesCameron CompDeipak HoleNo ratings yet

- Untitled Document2 PDFDocument1 pageUntitled Document2 PDFDeipak HoleNo ratings yet

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocument3 pagesWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleNo ratings yet

- SC SIT Order 120911Document10 pagesSC SIT Order 120911Ranganaathan SoundararajanNo ratings yet

- Zora Test Astm A770Document1 pageZora Test Astm A770Deipak HoleNo ratings yet

- PD FileDocument3 pagesPD FileDeipak HoleNo ratings yet

- MPI Yoke QuotationDocument4 pagesMPI Yoke QuotationDeipak HoleNo ratings yet

- StdReport10286 (7) 13.07.2019Document695 pagesStdReport10286 (7) 13.07.2019Deipak HoleNo ratings yet

- Fishbone Diagram GeneratorDocument19 pagesFishbone Diagram GeneratormfernandNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- 4.01.1 Fish Bone Diagram InvoicesDocument22 pages4.01.1 Fish Bone Diagram InvoicesDeipak HoleNo ratings yet

- Zora Test Astm A770 PDFDocument126 pagesZora Test Astm A770 PDFDeipak HoleNo ratings yet

- मतदाता सूचना/Voter InformationDocument1 pageमतदाता सूचना/Voter InformationDeipak HoleNo ratings yet

- MQC RM Approval ModuleDocument5 pagesMQC RM Approval ModuleDeipak HoleNo ratings yet

- Customer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDocument1 pageCustomer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDeipak HoleNo ratings yet

- TEK 12-6 Reinforcement & Connectors (2007)Document6 pagesTEK 12-6 Reinforcement & Connectors (2007)B0B_PNo ratings yet

- Chapter 4Document44 pagesChapter 4Ping LeungNo ratings yet

- Postal Service Practice Exam 2 Gcs 21 MinDocument9 pagesPostal Service Practice Exam 2 Gcs 21 MinSheccid NavarreteNo ratings yet

- Annexure IV - ET-P26-G1 Guidelines For Protection Energy Meter Requirements For Power Supply To B PDFDocument72 pagesAnnexure IV - ET-P26-G1 Guidelines For Protection Energy Meter Requirements For Power Supply To B PDFannuvyas0% (1)

- AP Music Theory - Summer Work Packet (Ada)Document28 pagesAP Music Theory - Summer Work Packet (Ada)pj.sulls1234No ratings yet

- Topographical SurveysDocument27 pagesTopographical SurveysRomeo ZsurzsNo ratings yet

- Mtmtipmbprima30gb 091020035130 Phpapp01Document49 pagesMtmtipmbprima30gb 091020035130 Phpapp01Udo Iheanacho100% (4)

- Product Details for 42CrMo4 SteelDocument2 pagesProduct Details for 42CrMo4 SteelGABRIEL IORDACHINo ratings yet

- Apr24-3g CDocument4 pagesApr24-3g COscar Payan ViamonteNo ratings yet

- D 313Document4 pagesD 313fajar328No ratings yet

- Instruction Sheet 579 163: Simulation ABS/Ti, STE 2/50Document1 pageInstruction Sheet 579 163: Simulation ABS/Ti, STE 2/50Billel TalbiNo ratings yet

- Chemistry Investigatory Project: Name: Mengulhounuo Keretsu Class: 12 (Science) School: Maple Tree SchoolDocument23 pagesChemistry Investigatory Project: Name: Mengulhounuo Keretsu Class: 12 (Science) School: Maple Tree SchoolmengulhounuoNo ratings yet

- Spontaneous Heating and Fire in Coal Mines: SciencedirectDocument13 pagesSpontaneous Heating and Fire in Coal Mines: SciencedirectTamil VananNo ratings yet

- Syllabus PHYS110 Fall2015 PDFDocument4 pagesSyllabus PHYS110 Fall2015 PDFPadmaja SundaramNo ratings yet

- AmwayDocument14 pagesAmwayAlpesh GajjarNo ratings yet

- Motherboard VX900-I - Manual PDFDocument52 pagesMotherboard VX900-I - Manual PDFJorge MunguiaNo ratings yet

- TriGem CognacDocument29 pagesTriGem CognacfostechNo ratings yet

- Analyzing Data Using Python - Cleaning and Analyzing Data in PandasDocument81 pagesAnalyzing Data Using Python - Cleaning and Analyzing Data in Pandasmartin napangaNo ratings yet

- Cooling Tower CalculationeditedDocument3 pagesCooling Tower CalculationeditedMark LouieNo ratings yet

- Mech 2 Module 1 Unit 3 (Position, Velocity and Acceleration)Document8 pagesMech 2 Module 1 Unit 3 (Position, Velocity and Acceleration)Zamantha DomingoNo ratings yet

- AdobeDocument26 pagesAdobebolatbek batmunhkNo ratings yet

- AM054KNMDCH1AZDocument3 pagesAM054KNMDCH1AZaandresleo86No ratings yet

- Previous Year Questions - Polynomials - Notes - Class 10Document6 pagesPrevious Year Questions - Polynomials - Notes - Class 10Azhaan ParyNo ratings yet

- Mega - Operating Instructions PDFDocument12 pagesMega - Operating Instructions PDFAshish TIwariNo ratings yet

- Exocytosis and Endocytosis: © 2012 Pearson Education, IncDocument49 pagesExocytosis and Endocytosis: © 2012 Pearson Education, IncGlein CenizaNo ratings yet

- Arraystorm Consolidated Product CatalogueDocument44 pagesArraystorm Consolidated Product Cataloguesuhasacharya117No ratings yet

- Semi-Final Test - Math7-Math10Document10 pagesSemi-Final Test - Math7-Math10JUVELYN BELLITANo ratings yet

- Biological Buffer SystemDocument4 pagesBiological Buffer SystemSharm Jarin-AlonzoNo ratings yet

- Block chain secures IoT dataDocument10 pagesBlock chain secures IoT datashravan amudalaNo ratings yet