Professional Documents

Culture Documents

HT 002

Uploaded by

Sam Raja0 ratings0% found this document useful (0 votes)

8 views1 pageHT-002 HARDNESS REPORT

Original Title

HT-002

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHT-002 HARDNESS REPORT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageHT 002

Uploaded by

Sam RajaHT-002 HARDNESS REPORT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

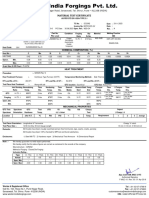

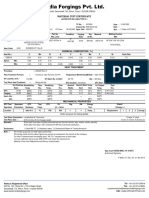

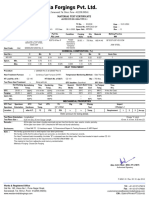

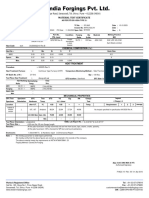

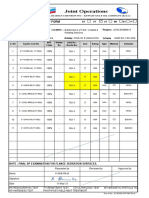

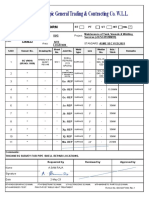

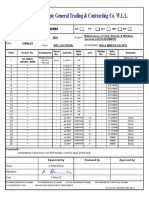

Gulf Spic General Trading & Contracting Co. W.L.L.

Heat Treatment Instructions and Report

Client JOINT OPERATIONS WAFRA Mfr. Sl. No 1058

PRESSURE VESSEL REPAIR

Job Description WORKS Report No. GS-ASME-002 Date 10-05-2023

SG V001A (THREE PHASE 670052-ICD-M-A0-001 SH 1 OF 1

Item No. / Tag No. Drawing No. REV.AB

PRODUCTION SEPARATOR)

Work Order No. 60875 (JO/SC459/MM19) Material CS (P1 )

Governing 11.13 mm for Nozzle wall

Governing Code ASME SEC VIII DIV-1 ED-2021

thickness thick (Refer attached Report)

Shell Plate Head Plate

42MM 50MM (Nominal)

Thickness Thickness

PWHT

Procedure Ref. GS/QP/093 Rev.0 620 ± 10°C

temperature

Loading Unloading

300°C 300°C

Temperature Temperature

No. of

Holding time 1 Hour 05 mints 4 NO’S

thermocouples

150°C Cooling rate 150°C

Heating rate (Max.)

From 300°C Up to 620°C (Max.) From 620°C Up to 300°C

Cooling rate

Heating rate (Max.)

From - Up to - (Max.) From - Up To -

Thermocouple attachment by Capacitor discharge unit

Thermocouple Removal by Removed by careful dressing followed by PT examination

Support Arrangement Adequately supported to prevent distortion

Thermocouple location and special instructions

3” NPS pipe diameter for 2 No’s (Nozzle Joints: Ja-1 & Jb-1) Neck to Flange joints.

The thermocouples shall be placed in soaking band and gradient band.

Soaking band shall cover complete nozzle width of soaking band, Heating band, Gradient control

band shall as per attached Annexure

Approved by QC Engineer

Post Weld heat treatment of the above vessel / item / component / has been carried out in accordance

with this instruction and the Chart is enclosed. Also enclosed are the calibration certificate of Time versus

temperature Chart recorders and Conformity certificate for thermocouples.

Reviewed & accepted by Reviewed by Reviewed by

Site QC Engineer AI TPI / Client

FORMAT NO: GS-ASME-025, Rev.0

You might also like

- HT 003Document1 pageHT 003Sam RajaNo ratings yet

- HT 001Document1 pageHT 001Sam Raja100% (1)

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 481 HT RecDocument11 pages481 HT RecMohammad MushtaqNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1299 - EC0583Document5 pages1299 - EC0583Deipak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1466 - EC0044Document5 pages1466 - EC0044Deipak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Bull's Eye PWHT Stress Relief ProcedureDocument11 pagesBull's Eye PWHT Stress Relief ProcedureJ.CarrascoNo ratings yet

- InsulationDocument23 pagesInsulationFabio TemporiniNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document12 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- R300 Sensor de TemperaturasDocument4 pagesR300 Sensor de TemperaturasFabián Roberto NoyaNo ratings yet

- PCN Notification for Fairchild Product Manufacturing ChangeDocument6 pagesPCN Notification for Fairchild Product Manufacturing ChangeFrank CoelhoNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- Larsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: ContentsDocument5 pagesLarsen & Toubro Limited MSQ (Epcc-1) Upgadation Project: Contentspunitg_2No ratings yet

- SWI - Procedure - Post Weld Heat Treatment For Astm A105 SteelDocument5 pagesSWI - Procedure - Post Weld Heat Treatment For Astm A105 SteelKhin Aung ShweNo ratings yet

- 1426-EC1942Document3 pages1426-EC1942Deipak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- Específicaciones Compresor HUAYI Cubigel GPY14NDbDocument5 pagesEspecíficaciones Compresor HUAYI Cubigel GPY14NDbAlexander InojosaNo ratings yet

- PWHT Chart Report N°007Document2 pagesPWHT Chart Report N°007mondher zrelliNo ratings yet

- Heat Treatment Procedure GuideDocument15 pagesHeat Treatment Procedure GuideVijay ShamNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- Rev1 General Heat Treatment Procedure PDFDocument45 pagesRev1 General Heat Treatment Procedure PDFLeah LarsonNo ratings yet

- Purpose: Steel Konnect (India) Pvt. Ltd. Procedure ManualDocument3 pagesPurpose: Steel Konnect (India) Pvt. Ltd. Procedure ManualmahendraNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document11 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- TCI PWHT Procedure For Bottom Crown (Electric) Rev. 01 - 08.07.2018Document7 pagesTCI PWHT Procedure For Bottom Crown (Electric) Rev. 01 - 08.07.2018abedo danklawyNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document11 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- PWHT Notes To JISDocument1 pagePWHT Notes To JISwdavidchristopherNo ratings yet

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document12 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- Ds Inox Virgo155phv3Document5 pagesDs Inox Virgo155phv3visanvalentin46No ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- NE6188CZDocument9 pagesNE6188CZhobolghaniNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Back Weld Repair Procedure QualificationDocument15 pagesBack Weld Repair Procedure QualificationFelipe Vásquez ArribasplataNo ratings yet

- Anexo 4 - Dimensionamiento PSV-7004 1Document2 pagesAnexo 4 - Dimensionamiento PSV-7004 1JairoVidalNo ratings yet

- Scan Preheat and PWHT ProcedureDocument11 pagesScan Preheat and PWHT ProcedureGandhi Kusuma100% (1)

- TCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)Document10 pagesTCM Division: Bull'S Eye Post Weld Heat Treatment (PWHT)J.CarrascoNo ratings yet

- 4130wog0913 - Rev14Document3 pages4130wog0913 - Rev14Quality controller100% (1)

- CS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3Document2 pagesCS PLATE-TS NO-SA-516-2-222051-R0 - Dish End Plate (Commented 3PRADEEP GAIKWADNo ratings yet

- PWHT ProcedureDocument10 pagesPWHT ProcedureMohammed Kamal100% (11)

- DS0256 Standard US ENDocument4 pagesDS0256 Standard US ENkicsnerNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- ButuDocument2 pagesButubiswajitkbNo ratings yet

- TL10PFM - 75P Dec182018Document1 pageTL10PFM - 75P Dec182018Anonymous pVoSWn8yh0No ratings yet

- MPS SampleDocument8 pagesMPS SampleMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Bolts Material SelectionDocument10 pagesBolts Material SelectionTaufik BinasrNo ratings yet

- A Single-Stage Heated Regulator With Robust Heat Transfer Technology!Document2 pagesA Single-Stage Heated Regulator With Robust Heat Transfer Technology!joe leeNo ratings yet

- MTC - 2046Document1 pageMTC - 2046tameem.p2023No ratings yet

- 5.4 Faculty RetentionDocument1 page5.4 Faculty RetentionSam RajaNo ratings yet

- Binder1 (1)Document3 pagesBinder1 (1)Sam RajaNo ratings yet

- Jo RT Request-13Document6 pagesJo RT Request-13Sam RajaNo ratings yet

- Mrir 036Document17 pagesMrir 036Sam RajaNo ratings yet

- DPT 166Document1 pageDPT 166Sam RajaNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- DPT 229Document1 pageDPT 229Sam RajaNo ratings yet

- Nde Request - Thickness SurveyDocument1 pageNde Request - Thickness SurveySam RajaNo ratings yet

- Fabrication and Welding General Requirements 103188871Document18 pagesFabrication and Welding General Requirements 103188871Sam RajaNo ratings yet

- Nde Request - HTDocument1 pageNde Request - HTSam RajaNo ratings yet

- DWR S 036Document1 pageDWR S 036Sam RajaNo ratings yet

- Nde Request - RTDocument1 pageNde Request - RTSam RajaNo ratings yet

- Nde Request - DPTDocument1 pageNde Request - DPTSam RajaNo ratings yet

- DPT 171Document1 pageDPT 171Sam RajaNo ratings yet

- Ang Pang - Ukol-WPS OfficeDocument18 pagesAng Pang - Ukol-WPS OfficeRiza Manalo LorenzoNo ratings yet

- De Bono 6 Action Shoesdoc - CompressDocument12 pagesDe Bono 6 Action Shoesdoc - CompressHazel RománNo ratings yet

- Study PDFDocument10 pagesStudy PDFDaniel Cano QuinteroNo ratings yet

- Urban Form FactorsDocument56 pagesUrban Form FactorsEarl Schervin CalaguiNo ratings yet

- Quantum ComputingDocument2 pagesQuantum Computingakshit100% (3)

- HD 9 Manual 5900123 Rev F 10 1 13Document60 pagesHD 9 Manual 5900123 Rev F 10 1 13Karito NicoleNo ratings yet

- Diploma in Cyber Security - Data Communication and NetworkingDocument57 pagesDiploma in Cyber Security - Data Communication and Networkingsrikant.singh62583No ratings yet

- Technical Datasheet 0027141131 003Document4 pagesTechnical Datasheet 0027141131 003Faizal SetiawanNo ratings yet

- How Society Is Organized Chapter 5Document18 pagesHow Society Is Organized Chapter 5Anne MoralesNo ratings yet

- 2011 2012 Machinery SubsidyDocument130 pages2011 2012 Machinery SubsidyanbugobiNo ratings yet

- 2008 Leonardoda Vinci AReviewDocument15 pages2008 Leonardoda Vinci AReviewOkeyman XlapatsasNo ratings yet

- Big Data Maturity ModelDocument6 pagesBig Data Maturity Modelkatherine976No ratings yet

- Echotrac Mkiii: Model DFDocument2 pagesEchotrac Mkiii: Model DFjonathansolverNo ratings yet

- Pedigree StudiesDocument4 pagesPedigree StudiesJonas WelliverNo ratings yet

- Espedosa Module3.5 AssignmentDocument2 pagesEspedosa Module3.5 AssignmentKhemgee EspedosaNo ratings yet

- CropWat 4 Windows calculates crop water requirementsDocument2 pagesCropWat 4 Windows calculates crop water requirementsadam_pengeranNo ratings yet

- Theosophical Quarterly v23 1925-1926Document424 pagesTheosophical Quarterly v23 1925-1926Joma SipeNo ratings yet

- Arguments in Ordinary LanguageDocument5 pagesArguments in Ordinary LanguageStephanie Reyes GoNo ratings yet

- List of Technical Documents: IRB Paint Robots TR-500 / TR-5000Document16 pagesList of Technical Documents: IRB Paint Robots TR-500 / TR-5000Weberth TeixeiraNo ratings yet

- Humour and IdentityDocument12 pagesHumour and IdentityLyann MartinezNo ratings yet

- Learning in Artificial IntelligenceDocument6 pagesLearning in Artificial IntelligenceAnikNo ratings yet

- MANAGEMENT CONTROL SYSTEMS IN NON-PROFITSDocument26 pagesMANAGEMENT CONTROL SYSTEMS IN NON-PROFITSPranita NarainNo ratings yet

- ARTIKEL - Baby Talk Hinders LearningDocument2 pagesARTIKEL - Baby Talk Hinders LearningZ E V A N Y ANo ratings yet

- Chapter 9 & Chapter 10 SolutionsDocument7 pagesChapter 9 & Chapter 10 SolutionsSaeed IqbalNo ratings yet

- Concept of Nation and Nationalism: Imagined Communities by Benedict AndersonDocument11 pagesConcept of Nation and Nationalism: Imagined Communities by Benedict AndersonANDREA TANNo ratings yet

- 2012 HCO Oriented Core ProceduresDocument30 pages2012 HCO Oriented Core ProceduresPancho Perez100% (1)

- 09 - Validation of Diagnostic Markers For Streak Virus Disease Resistance in MaizeDocument11 pages09 - Validation of Diagnostic Markers For Streak Virus Disease Resistance in MaizeNemanja NišavićNo ratings yet

- Applying The PROACT RCA Methodology.4.26.16Document30 pagesApplying The PROACT RCA Methodology.4.26.16Alexandar ApishaNo ratings yet

- 2.1.1.5 Packet Tracer - Create A Simple Network Using Packet Tracer PDFDocument15 pages2.1.1.5 Packet Tracer - Create A Simple Network Using Packet Tracer PDFTeixeira JorgeNo ratings yet

- GROUP 3 Questions Solved Problems in Gas Turbine and Geothermal Power PlantDocument62 pagesGROUP 3 Questions Solved Problems in Gas Turbine and Geothermal Power PlantCherry Obias0% (1)