Professional Documents

Culture Documents

Material Test Certificate: Technipfmc

Uploaded by

Deipak HoleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Test Certificate: Technipfmc

Uploaded by

Deipak HoleCopyright:

Available Formats

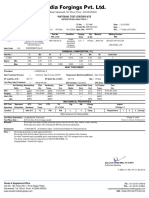

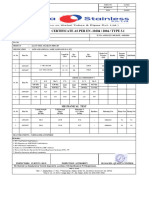

MATERIAL TEST CERTIFICATE

AS PER STD EN 10204 TYPE 3.1

Customer : TechnipFMC TC No. : E8550 Date : 07.11.2021

Invoice No.: WIF/EX/21-22/ Date :

P.O. No.: 4500544691 Line Item: 10 PO Date : 01.07.2021 Spec. Ref.: M25070 Rev. : F (Date:16.07.2021)

Die No. Description Part No. Condition Forging Qty Material Melting Practice

Drg. No. 502 PSL Level Ratio Sr.No. Mill

BODY FORGING, ULT F/

1299 PLUG VALVE 1 ULT150 F/3 3257105 Rev K 17.68 800 Nos. AISI 4140 BF-EOF-LRF-VD-CCM

NQT/SB

IN UNION ENDS AISI 4140

- JSW STEEL LIMITED

Heat Code: LHK DU500001271 Rev B

CHEMICAL COMPOSITION ( % )

Heat No :- C Mn Si S P Cr Mo Grain Size

F00913 0.40 0.91 0.21 0.009 0.01 1.06 0.22 7.0

Specn. Min. 0.38 0.75 0.15 - - 0.80 0.15 6

Max. 0.43 1.00 0.35 0.025 0.025 1.10 0.25 -

HEAT TREATMENT

Procedure :- Q00025 Rev Q

Heat Treatment Furnace :- Continous Type Furnace (CHTF) Temperature Monitoring Method:- Side Thermocouples in the Working Zone ( Method A)

HT Load No. of N :- AD-285 HT Batch No. of Q&T:- AD-288 Qty :- 800 Nos.

Test Piece Heat Treatment :- Along with job QTC location:- Sacrificial QTC Size- Actual Part

Hot Working Normalising Time Hardening Time Quench Quench Bath Temp. 1st Temper Time

Ratio Temp. Hrs. Temp. Hrs. Media Start End Temp. Hrs.

QTC 17.68 900⁰C 3.20 870⁰C 3.20 OIL 36°C 49°C 570°C 5 (Air Cool)

Forging 17.68 900⁰C 3.20 870⁰C 3.20 OIL 36°C 49°C 570°C 5 (Air Cool)

Specn. Min. 870⁰C 840⁰C --- --- 540⁰C

Max. 925⁰C 900⁰C --- 80⁰C 700⁰C

MECHANICAL PROPERTIES

QTC Test Specimen QTC Test UTS YS Elg RA Charpy Impact

Specimen Orientation Hardness Temp. 0.2 % Offset Test ( Charpy ) J

Location after H.T. ⁰C PSI PSI % % Temp. Requirement 1 2 3 Average

Refer annexure for testing details

Test Piece Orientation:- Longitudinal & Transverse Charpy 'V' notch

Test Piece Size :- 8.75 mm Dia, 35 mm Gauge Length 10 mm X 10 mm X 55 mm LG

Remarks : All the jobs have been visually examined and are free from bursts, laps, seams, cracks, porosity.

All the jobs have been 100% checked for MPI test and found satisfactory.

Enclosures: 1) Steel Mill TC 2) Hardness report 3) Dimensional Report 4) Testing Annexure

Note :- We hereby guarantee no weld repairs performed.

. We hereby certify that the above figures are correct as contained in the records of the company

For Heat Treatment batch traceability point, "AD-288" stamped near to Heat code.

Mr. Ajay Joshi (HEAD-MQC, HT & NDT)

Authorised Signatory

F-MQC-10 / Rev. 00 / 01-Apr-2016

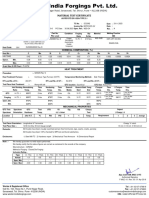

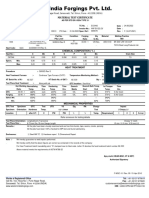

HARDNESS TEST REPORT

Customer:- TechnipFMC TC No: E8550

P.O. No.:- 4500544691 Line Item: 10 PO Date : 01.07.2021 Date : 07.11.2021

BODY FORGING, ULT PLUG VALVE 1 ULT150 F/3

Item : IN UNION ENDS AISI 4140 Material : AISI 4140

Part No.: 3257105 Rev K Heat No. : F00913

Drawing No.: DU500001271 Rev B Ambient Temp : 28°C

Die No.: 1299 Hardness Range:- 277 - 331 HBW

Qty.: 800 Nos. Test Method : Brinell Hardness Test

Vendor Sr.No.: - Equipment Used: Brinell Hardness Tester

HT Load No.: N: AD-285 QT: AD-288 Sr No.19/05/007

Reference Standard: ASTM E10 Machine Make: SAROJ

Load Applied: 3000 Kgs Calibration Agency: MM Engineers

Type of Penetrator: Dia 10 mm Carbide Ball Certificate No.: MME/CAL/261/21-22

Std Block Details: SH-266 (Hardness value - 295.0 HBW) Calibrated On: 14.08.2021

Entity Performing Test: WIF Sanaswadi Calibrated Due On:13.02.2022

Hardness

Q03006 Rev. AC / Q03009 Rev. X Date of Test :- 23.10.2021

Procedure :-

Precise Measuring Method of HBW Impression : Type B : Hand-Held Microscope with fixed measuring lines.

Qty. Hardness in HBW

800 Nos. 285-321 HBW

Test Performed By Reviewed By Approved By :

Atul Jedhe Satish Gadgil (Sr.Manager HT) Mr. Ajay Joshi (HEAD-MQC, HT & NDT)

F-HT-10 / Rev. 00 / 01-Apr-2016 Page 1

Mechanical Test Annexure

Die No.: 1299 Material Grade: AISI 4140

Heat No.: F00913 HT Lot No. : AD-288

Heat Code: LHK TC No. : E8550

TENSILE TEST

QTC Test QTC Hardness after UTS YS Elg RA

Specimen Test Temp. NABL Lab Sample

Specimen H.T. 0.2 % Offset

Orientation (⁰C) Report No. No.

Location HBW KSI KSI % %

0.5" below

L 302, 311 Ambient G/21/2485/P 1 148.07 125.97 20.09 62.60

HT Surface

277 - 331 Spec. Min. 120.00 100.00 16.00 35.00

IMPACT TEST

QTC Test

Specimen Requirement Test Temp. NABL Lab Sample

Specimen 1 2 3 Average

Orientation (⁰C) Report No. No.

Location

Avg. - 42 J Min

88 74 78 80.00

Single - 32 J Min

LE - 0.51 mm Min -29°C 1.02 0.86 0.91 0.93

%Shear - Report 65 60 60 61.67

L Avg. - 27 J Min

38 40 42 40.00

Single - 20 J Min

LE - Report -40°C 0.51 0.53 0.55 0.53

%Shear - Report 25 30 30 28.33

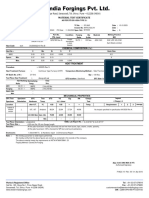

0.5" below

Avg. - 28 J Min 1

HT Surface 72 80 48 66.67

Single - 18.7 J Min

-29°C

LE - Report 0.85 0.93 0.60 0.79

%Shear - Report 60 60 35 51.67

T

Avg. - 20 J Min

36 30 38 34.67

Single - 14 J Min

LE - Report -40°C 0.48 0.41 0.51 0.47

%Shear - Report 25 20 25 23.33

Mr. Ajay Joshi (HEAD-MQC, HT & NDT)

Authorised Signatory

Certificate of Compliance

Customer : TechnipFMC TC No.: E8550

Date: 07.11.2021

Die No. : 1299 Heat Code : LHK

PO No : 4500544691 Line Item No : 10

Offer Qty. : 800 Nos.

Part No/ Rev : 3257105 Rev K Drg No / Rev : DU500001271 Rev B

BODY FORGING, ULT PLUG VALVE

Part Name : Serial No. : -

1 ULT150 F/3 IN UNION ENDS AISI

4140

I. Material

A. Material Type : AISI 4140

B. Material Spec/ Rev. : As per Spec no : M25070 Rev No. F (Date:16.07.2021)

C. Material Test Report No : Mill Heat No : F00913

II. Dimensional

A. AQL : AS PER QUALITY PLAN B. Sample Size : 8 Nos.

III. Secondary Process : Heat Treatment

A. Process Name : Normalised

Heat Lot No. : AD-285 Process Spec : Q00025 Rev Q

B. Process Name : QT

Heat Lot No. : AD-288 Process Spec : Q00025 Rev Q

IV. NDE

A. Process Name : MPI

Certificate No : NA Process Spec : NA

B. Process Name : UT

Certificate No : NA Process Spec : NA

This is certified that subjected material is manufactured from material mentioned above &

verified by us as per written sample size & found conforming to requirements.

For Heat Treatment batch traceability point, "AD-288" stamped near to Heat code.

Sign with Stamp

Mr. Ajay Joshi (HEAD-MQC, HT & NDT)

You might also like

- Inspection certificate for spiral wound gaskets and reducersDocument3 pagesInspection certificate for spiral wound gaskets and reducersRaul Esteban Jaimes GalvisNo ratings yet

- Adequacy of Materials For Civil WorksDocument25 pagesAdequacy of Materials For Civil Workshari vNo ratings yet

- BS 31 Steel Conduit and Fittings For Electrical Wiring PDFDocument36 pagesBS 31 Steel Conduit and Fittings For Electrical Wiring PDFEddy Volao100% (3)

- HT 001Document1 pageHT 001Sam Raja100% (1)

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Design Calculation Oil Cooler MaK 2011 v2Document8 pagesDesign Calculation Oil Cooler MaK 2011 v2Fauzan Rusmayadi ReharderNo ratings yet

- IB Chemistry SL Topic1 Questions and Answers 1.: (Total 1 Mark)Document240 pagesIB Chemistry SL Topic1 Questions and Answers 1.: (Total 1 Mark)emmaNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- 16 MM MS Plate 355 JR - India-MTCDocument1 page16 MM MS Plate 355 JR - India-MTCQc QatarNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5armin heidariNo ratings yet

- C 14 SuspensionsDocument12 pagesC 14 SuspensionsAli Uy100% (1)

- Certified Material Test Report for EN 19-T Steel ForgingsDocument4 pagesCertified Material Test Report for EN 19-T Steel ForgingsashokNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- DVS Technical Codes On Plastic Joining Technologies PDFDocument11 pagesDVS Technical Codes On Plastic Joining Technologies PDFSAVAG1No ratings yet

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- Ambra-Akcela Oil Specs PDFDocument1 pageAmbra-Akcela Oil Specs PDFJUNA RUSANDI S100% (1)

- Solvay Paint AdditivesDocument106 pagesSolvay Paint AdditivesMohamed HalemNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- ASTM C 109 C109M-16aDocument10 pagesASTM C 109 C109M-16aMohammed AliNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- Fishbone Diagram GeneratorDocument19 pagesFishbone Diagram GeneratormfernandNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1299 - EC0583Document5 pages1299 - EC0583Deipak HoleNo ratings yet

- 1466 - EC0044Document5 pages1466 - EC0044Deipak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 1426-EC1942Document3 pages1426-EC1942Deipak HoleNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- HT 002Document1 pageHT 002Sam RajaNo ratings yet

- HT 003Document1 pageHT 003Sam RajaNo ratings yet

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Hamilton Metals Inspection CertificateDocument1 pageHamilton Metals Inspection CertificateColinNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- Material Test Report: Cert No: 697430Document1 pageMaterial Test Report: Cert No: 697430Abozar BilanNo ratings yet

- Gate Valve 3in 150 XMK1020754308-27Document5 pagesGate Valve 3in 150 XMK1020754308-27Mygame 1402No ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- NST 3.1 PDFDocument1 pageNST 3.1 PDFPankaj RaneNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNo ratings yet

- Inspection Certificate Test ResultsDocument1 pageInspection Certificate Test ResultsCricri CriNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- PIEZO BUZZER SPECIFICATION AND TESTINGDocument5 pagesPIEZO BUZZER SPECIFICATION AND TESTINGg_1234No ratings yet

- NE6188CZDocument9 pagesNE6188CZhobolghaniNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Inspection Report - Motor+16701004051+KT - 12V1600G80SDocument1 pageInspection Report - Motor+16701004051+KT - 12V1600G80SChristopherNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- MTC_A335 P22 Seamless PipeDocument1 pageMTC_A335 P22 Seamless PipeSri GangaNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document5 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Muhammed Ali CangürNo ratings yet

- P5 T5 Engl PDFDocument3 pagesP5 T5 Engl PDFshantilalNo ratings yet

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- Messrs.: Specification For ApprovalDocument8 pagesMessrs.: Specification For ApprovalallendohorizontNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- Page 3 Tsi MTC Plate (MTC - 249)Document2 pagesPage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- MS SHEETS MTCDocument6 pagesMS SHEETS MTCAmit Kumar OjhaNo ratings yet

- 1335 - EC1904Document1 page1335 - EC1904Deipak HoleNo ratings yet

- 1433 Ec0442Document6 pages1433 Ec0442Deepak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 456 PDFDocument4 pages456 PDFDeipak HoleNo ratings yet

- Cameron CompDocument14 pagesCameron CompDeipak HoleNo ratings yet

- Untitled Document2 PDFDocument1 pageUntitled Document2 PDFDeipak HoleNo ratings yet

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocument3 pagesWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleNo ratings yet

- SC SIT Order 120911Document10 pagesSC SIT Order 120911Ranganaathan SoundararajanNo ratings yet

- Zora Test Astm A770Document1 pageZora Test Astm A770Deipak HoleNo ratings yet

- PD FileDocument3 pagesPD FileDeipak HoleNo ratings yet

- MPI Yoke QuotationDocument4 pagesMPI Yoke QuotationDeipak HoleNo ratings yet

- StdReport10286 (7) 13.07.2019Document695 pagesStdReport10286 (7) 13.07.2019Deipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- 4.01.1 Fish Bone Diagram InvoicesDocument22 pages4.01.1 Fish Bone Diagram InvoicesDeipak HoleNo ratings yet

- Zora Test Astm A770 PDFDocument126 pagesZora Test Astm A770 PDFDeipak HoleNo ratings yet

- मतदाता सूचना/Voter InformationDocument1 pageमतदाता सूचना/Voter InformationDeipak HoleNo ratings yet

- MQC RM Approval ModuleDocument5 pagesMQC RM Approval ModuleDeipak HoleNo ratings yet

- Customer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDocument1 pageCustomer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDeipak HoleNo ratings yet

- Module No. 11: Piping Systems Difference Between Pipe and TubeDocument8 pagesModule No. 11: Piping Systems Difference Between Pipe and TubeGeoffrey GolbequeNo ratings yet

- Engineering Properties of Laterite Stone Scrap Blocks: S.K. Jain, P.G. Patil, N.J. ThakorDocument11 pagesEngineering Properties of Laterite Stone Scrap Blocks: S.K. Jain, P.G. Patil, N.J. ThakorchethanNo ratings yet

- Sight GlassDocument2 pagesSight GlassLorenzoNo ratings yet

- Textile Vision - Fayyaz Industry Support CellDocument596 pagesTextile Vision - Fayyaz Industry Support CellTaimur Shan100% (1)

- PROTECTIVE COATING FOR CONCRETE & STEELDocument2 pagesPROTECTIVE COATING FOR CONCRETE & STEELkhrisna.dipa.utamaNo ratings yet

- Machinery and Systems for Paper Industry Vibrating ScreensDocument2 pagesMachinery and Systems for Paper Industry Vibrating ScreensSIL PROJECTSNo ratings yet

- 2.1.3 Dinakar 2012Document9 pages2.1.3 Dinakar 2012shanmugapriyasudhaswNo ratings yet

- Iron Types (Page 1), Gray & Ductile Irons - Metal Casting InstituteDocument31 pagesIron Types (Page 1), Gray & Ductile Irons - Metal Casting InstituteWalid Ben AmirNo ratings yet

- B660 15Document25 pagesB660 15diego rodriguez100% (1)

- Carbonate Aggregates as Concrete AlternativeDocument12 pagesCarbonate Aggregates as Concrete AlternativeElber Cuya PillacaNo ratings yet

- Part RQ Qualification RequirementsDocument8 pagesPart RQ Qualification RequirementsMARCIONo ratings yet

- Material Science and Engineering Midterm NotesDocument15 pagesMaterial Science and Engineering Midterm Notesyiye rubyNo ratings yet

- TE Mechanical 2019 Pattern 302052-A: Composite Materials End Sem Exam Question BankDocument5 pagesTE Mechanical 2019 Pattern 302052-A: Composite Materials End Sem Exam Question Bankprathamesh nikamNo ratings yet

- Study of Energy-Saving Reform in Garment Production EnterprisesDocument342 pagesStudy of Energy-Saving Reform in Garment Production EnterprisesAlemayehu AsinoNo ratings yet

- Industries in JejuriDocument2 pagesIndustries in JejuriMAkesh0% (1)

- VENDORS LIMITATIONS # 9COM 6000000013 - DocxDocument6 pagesVENDORS LIMITATIONS # 9COM 6000000013 - DocxBIPIN BALANNo ratings yet

- Risks and Management of Textile WasteDocument25 pagesRisks and Management of Textile WasteAbril MonsalveNo ratings yet

- BR 30 StrengtheningDocument1 pageBR 30 Strengtheningdesign MridcNo ratings yet

- Carbon Fiber's Strengths for ConstructionDocument11 pagesCarbon Fiber's Strengths for ConstructionAdarsh SooryaNo ratings yet

- STEELDocument14 pagesSTEELLance LacapNo ratings yet

- Dross Inclusions and Galvanized SteelDocument2 pagesDross Inclusions and Galvanized SteelcurtisvaleroNo ratings yet

- A Review of Reverse Osmosis Membrane Materials For DesalinationDocument22 pagesA Review of Reverse Osmosis Membrane Materials For DesalinationFrancisca Rojas100% (1)