Professional Documents

Culture Documents

11 - Vibrating Screens VST

Uploaded by

SIL PROJECTSOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 - Vibrating Screens VST

Uploaded by

SIL PROJECTSCopyright:

Available Formats

Machinery and Systems

for Paper Industry

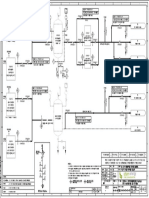

Vibrating screens VST

Vibrating screens VST

10/2015 Schio

www.zorattistudio.it

Vibrating screens are used whenever it is necessary to By a mobile weir it is possible to adjust the level inside

perform a screening to remove the light impurities con- the vibrating screen.

tained in the stock previously treated in the waste paper

The vibrating screen plate (special 316 solid stainless

and virgin pulp plants.

steel) is supported by means of 4 spiral springs on the

They are also suitable to remove impurities from waters vibrating screen body (manufactured also in solid s.s. 304

to be cleaned, fresh sludges or as last stage of screening or 316) .

systems.

The longitudinal shifting of the vibrating system is adju-

Vibrating screen, thanks to its vibrating movement, and stable by means of different positions of the motor/eccen-

washing action obtained through the barrier of washing tric mass assembled on the top of the vibrating frame.

water, allows total removal of contaminants which comes After welding, the whole structure is subjected to a stress

out virtually fiber free. relieving treatment.

The vibrating screen consists of a sieve with conical sha- Our vibrating screens, are available in three models sui-

ped holes (different measures accordingly to the appli- table for fluids from low consistency up to max. 5%.

cations) assembled on a frame for the collection of the

accepted stock.

The table with technical data indicates some indicative flow rates.

Model VST400 VST750 VST1500

Filtering surface [m²] 0,4 0,75 1,5

Flow rate (density 1,5 %) [l/min] 330 500 1000

Work consistency [%] 0,2 ÷ 5

S.T. MACCHINE SpA

via Calcara, 1 tel +39 0445 602688 www.stmacchine.it

36030 Monte di Malo (VI) Italy fax +39 0445 605452 info@stmacchine.it

You might also like

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Tapis TeknikDocument13 pagesTapis Teknikrizki arfiNo ratings yet

- Case Study Vibrating ScreenDocument14 pagesCase Study Vibrating Screenadb100% (2)

- Multi-Deck Horizontal Screening Machine: Series MHR - The Screening Machine For Fine ParticlesDocument4 pagesMulti-Deck Horizontal Screening Machine: Series MHR - The Screening Machine For Fine ParticlesFawad AhmedNo ratings yet

- For Paper Industry: Approach Flow Screen SPCDocument2 pagesFor Paper Industry: Approach Flow Screen SPCSIL PROJECTSNo ratings yet

- t30 Short WPR PDFDocument8 pagest30 Short WPR PDFSalem GarrabNo ratings yet

- Vibroscreen BrochureDocument12 pagesVibroscreen BrochureVarun MalhotraNo ratings yet

- ConthickDocument4 pagesConthickEray YILMAZNo ratings yet

- StrainerDocument5 pagesStrainerMohit BauskarNo ratings yet

- Diemme 2500x2500Document8 pagesDiemme 2500x2500Cristian Mena HidalgoNo ratings yet

- Brochure Break Duo - enDocument8 pagesBrochure Break Duo - enRoberto CecchinatoNo ratings yet

- MPDW EN CatalogDocument8 pagesMPDW EN CatalogGuntur SetyawanNo ratings yet

- Filtomat M300Document4 pagesFiltomat M300Sasa Jadrovski100% (1)

- 426 ScreeningDocument53 pages426 ScreeningmseaNo ratings yet

- Sismat Combined Pretreatment Unit SKP Brochure A4 SpreadsDocument5 pagesSismat Combined Pretreatment Unit SKP Brochure A4 SpreadsDado AliNo ratings yet

- Wastemaster Tsb4: Septic Tank Sludge Treatment PlantDocument4 pagesWastemaster Tsb4: Septic Tank Sludge Treatment PlantFelipe BrainNo ratings yet

- Pusher CentrifugeDocument4 pagesPusher Centrifugeberkay100% (1)

- CTM Catalogue 2015-2016Document100 pagesCTM Catalogue 2015-2016Anonymous dXcoknUNo ratings yet

- Brochure Larox PF Brochure 2022 WebDocument8 pagesBrochure Larox PF Brochure 2022 Webali floresNo ratings yet

- Jordy Maquilan TERDocument18 pagesJordy Maquilan TERHanah Kryss CastreNo ratings yet

- Sludge Dewatering Screw Press Szk1Document2 pagesSludge Dewatering Screw Press Szk1MariusCapraNo ratings yet

- Data Sheet ITE 3P2D Version1 0 EDocument2 pagesData Sheet ITE 3P2D Version1 0 EGeorgeNo ratings yet

- 105SADocument2 pages105SALuigi PolitoNo ratings yet

- Screening ConsiderationsDocument23 pagesScreening ConsiderationsJames MNo ratings yet

- Basics in Mineral Processing-Size ControlDocument24 pagesBasics in Mineral Processing-Size Controlmakedo33No ratings yet

- Waste Savi Datasheets RTV en 0516 EditDocument2 pagesWaste Savi Datasheets RTV en 0516 Editjhuerta888No ratings yet

- Jae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonDocument53 pagesJae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-Madisonscelo buthelezi100% (1)

- Vibrating ScreensDocument12 pagesVibrating ScreenssrinivasakumarNo ratings yet

- Salsnes-Detailer 2016 LRDocument10 pagesSalsnes-Detailer 2016 LRLubrication´s RoomNo ratings yet

- Vibro NetDocument4 pagesVibro NetMALELA70No ratings yet

- Sparkler Filter BrochureDocument4 pagesSparkler Filter BrochurekiranNo ratings yet

- Presentation On The Dms Plant: Compiled By: Ngonidzashe BakasaDocument10 pagesPresentation On The Dms Plant: Compiled By: Ngonidzashe BakasaFaith MacharagaNo ratings yet

- Diemme FiltrationDocument8 pagesDiemme FiltrationAbu Fathi Mifth Huda100% (1)

- Titan: Titan Flow Control - Standard Screen and Basket DesignsDocument4 pagesTitan: Titan Flow Control - Standard Screen and Basket Designs최승원No ratings yet

- Sand Washing PlantDocument5 pagesSand Washing PlantAfriza NurdiansyahNo ratings yet

- Types of Shot Blasting MachinesDocument9 pagesTypes of Shot Blasting MachinesBhavin DesaiNo ratings yet

- Milnor 48040F7J SpecificationsDocument4 pagesMilnor 48040F7J Specificationsmairimsp2003No ratings yet

- Highly Accurate Large Vertical Machining CenterDocument17 pagesHighly Accurate Large Vertical Machining Centerletrongthoai18No ratings yet

- Product Catalog: Compact Screen, Single Screen & Multi Screen FiltersDocument26 pagesProduct Catalog: Compact Screen, Single Screen & Multi Screen FiltersLuan NguyenNo ratings yet

- CMS Glass Machinery Insulated Glass Catalog enDocument40 pagesCMS Glass Machinery Insulated Glass Catalog enKamel NaitNo ratings yet

- Industrial ScreeningDocument68 pagesIndustrial ScreeningJohnKevinVillar100% (2)

- 22 Vibration Monitoring of Cold Rolling MillsDocument6 pages22 Vibration Monitoring of Cold Rolling Millssmwaqasimam100% (1)

- Zzb0955a WWD Filters Mar2022Document2 pagesZzb0955a WWD Filters Mar2022Raffless SadissNo ratings yet

- Bar Screening Environmental EngineeringDocument11 pagesBar Screening Environmental EngineeringRajat Kushwaha100% (1)

- Brandt VSM 300 Shaker: Incorporating Proven Technologies For Maximum Separation EfficiencyDocument2 pagesBrandt VSM 300 Shaker: Incorporating Proven Technologies For Maximum Separation EfficiencyMihai MateiNo ratings yet

- Comby Plants Rct1: Machine DescriptionDocument2 pagesComby Plants Rct1: Machine DescriptionFelipe BrainNo ratings yet

- For Paper Industry: Deflakers DSTDocument2 pagesFor Paper Industry: Deflakers DSTSIL PROJECTSNo ratings yet

- Micro CompactorDocument4 pagesMicro CompactorEnes BayramNo ratings yet

- Rockdonnell Presentation - INSSDC 2018Document47 pagesRockdonnell Presentation - INSSDC 2018Not FakeNo ratings yet

- Screen EquipmentDocument22 pagesScreen EquipmentmutiNo ratings yet

- Salsnes Fillter User ManualDocument10 pagesSalsnes Fillter User ManualMichael ElliottNo ratings yet

- Ote Fp-S Filter Press Eng Web PDFDocument8 pagesOte Fp-S Filter Press Eng Web PDFRegina Choque HuallpaNo ratings yet

- Máy Định Hình MonfongsDocument32 pagesMáy Định Hình MonfongsPhan Quốc ThịnhNo ratings yet

- DPF Oscillating ScreenDocument5 pagesDPF Oscillating ScreenolivefaNo ratings yet

- Con CastDocument5 pagesCon CastZubair AhmadNo ratings yet

- Particle Size Separator For Rectangular Filter: Operation ManualDocument2 pagesParticle Size Separator For Rectangular Filter: Operation ManualPaikama GuciNo ratings yet

- Float Purger Stock Cleaning SystemDocument4 pagesFloat Purger Stock Cleaning SystemoswaldoNo ratings yet

- Model Machine ADocument2 pagesModel Machine ALuigi PolitoNo ratings yet

- Filtration For Ballast Water TreatmentDocument22 pagesFiltration For Ballast Water Treatmentjoujoukos kritikosNo ratings yet

- Banking InformationDocument1 pageBanking InformationSIL PROJECTSNo ratings yet

- IBR - 1950 - Reg. 56 ADocument3 pagesIBR - 1950 - Reg. 56 ASIL PROJECTSNo ratings yet

- 100 V-Notch (Pulp)Document1 page100 V-Notch (Pulp)SIL PROJECTSNo ratings yet

- Envelop Cover Address Print FormatDocument1 pageEnvelop Cover Address Print FormatSIL PROJECTSNo ratings yet

- HV 1212Document4 pagesHV 1212SIL PROJECTSNo ratings yet

- IBR - 1950 - Reg. 43Document2 pagesIBR - 1950 - Reg. 43SIL PROJECTSNo ratings yet

- PIPE Vs TUBEDocument3 pagesPIPE Vs TUBESIL PROJECTSNo ratings yet

- Knife Gate Valve 12 INCH 10Document1 pageKnife Gate Valve 12 INCH 10SIL PROJECTSNo ratings yet

- Ippta JournalDocument83 pagesIppta JournalSIL PROJECTSNo ratings yet

- HV 1013Document4 pagesHV 1013SIL PROJECTSNo ratings yet

- V Notch Ball ValveDocument1 pageV Notch Ball ValveSIL PROJECTSNo ratings yet

- 18 (1) .03.08 Satia LTI MailDocument2 pages18 (1) .03.08 Satia LTI MailSIL PROJECTSNo ratings yet

- Butterfly Valve With DiaphragmDocument1 pageButterfly Valve With DiaphragmSIL PROJECTSNo ratings yet

- 50 V-Notch Valve2Document1 page50 V-Notch Valve2SIL PROJECTSNo ratings yet

- Ball Valve On-Off TypeDocument1 pageBall Valve On-Off TypeSIL PROJECTSNo ratings yet

- UntitledDocument5 pagesUntitledSIL PROJECTSNo ratings yet

- UntitledDocument27 pagesUntitledSIL PROJECTSNo ratings yet

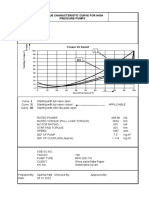

- TS Curve RPHDocument2 pagesTS Curve RPHSIL PROJECTS0% (1)

- Uttam U: EnergyDocument1 pageUttam U: EnergySIL PROJECTSNo ratings yet

- 16 - Chest and TowerDocument2 pages16 - Chest and TowerSIL PROJECTSNo ratings yet

- E20 Green Fuel - Single Line Diagram (22.02.22)Document1 pageE20 Green Fuel - Single Line Diagram (22.02.22)SIL PROJECTSNo ratings yet

- For Paper Industry: Deflakers DSTDocument2 pagesFor Paper Industry: Deflakers DSTSIL PROJECTSNo ratings yet

- Preliminary: DescriptionDocument1 pagePreliminary: DescriptionSIL PROJECTSNo ratings yet

- 02 - Pulper Washer PWCDocument2 pages02 - Pulper Washer PWCSIL PROJECTSNo ratings yet

- 19 - Rectifier RollsDocument2 pages19 - Rectifier RollsSIL PROJECTSNo ratings yet

- 05 - High Density Pulpers PADDocument2 pages05 - High Density Pulpers PADSIL PROJECTSNo ratings yet

- 03 - Trommel TLVDocument2 pages03 - Trommel TLVSIL PROJECTSNo ratings yet

- 04 - Medium Density Pulpers PMDDocument2 pages04 - Medium Density Pulpers PMDSIL PROJECTSNo ratings yet

- 01 - Low Density Pulpers PBDDocument2 pages01 - Low Density Pulpers PBDSIL PROJECTSNo ratings yet

- Assignment No. 1 Historical Antecedents in The WorldDocument5 pagesAssignment No. 1 Historical Antecedents in The Worldrommel benamirNo ratings yet

- 82 Ti SPC One Toolpl 0990 (Tirfox) 1 2Document3 pages82 Ti SPC One Toolpl 0990 (Tirfox) 1 2pradeeepgargNo ratings yet

- Gravity Wave Methodology With Explanations and DerivationsDocument15 pagesGravity Wave Methodology With Explanations and Derivationsnebp.educationNo ratings yet

- Pembuatan Dan Karakterisasi Ekstrak Kering Daun Salam (Syzigium Polyanthum (WIGHT) WALP.)Document11 pagesPembuatan Dan Karakterisasi Ekstrak Kering Daun Salam (Syzigium Polyanthum (WIGHT) WALP.)Ihsan Dwi MubarokNo ratings yet

- Standard Cycles - UPLOADDocument40 pagesStandard Cycles - UPLOADThisath MullakandaNo ratings yet

- MIKE SHE Advanced ExercisesDocument32 pagesMIKE SHE Advanced ExercisesQecil GamingNo ratings yet

- Liquid Penetrant TestingDocument32 pagesLiquid Penetrant TestingLeon Heart FCNo ratings yet

- A Ysis Pressure, Vessel Heads: Numerical Pro Cedurefor OFDocument122 pagesA Ysis Pressure, Vessel Heads: Numerical Pro Cedurefor OFMárcio De Melo AraújoNo ratings yet

- Haul Truck Tire Dynamics Due To Tire Condition PDFDocument12 pagesHaul Truck Tire Dynamics Due To Tire Condition PDFJo2020MeNo ratings yet

- Unit PlanDocument24 pagesUnit Planapi-373647228No ratings yet

- Catalogue Avalon Machines For Industry 2023Document11 pagesCatalogue Avalon Machines For Industry 2023gary draesNo ratings yet

- Quantum Computing A New Era of Computing Kuldeep Singh Kaswan All ChapterDocument67 pagesQuantum Computing A New Era of Computing Kuldeep Singh Kaswan All Chapterjanice.cooley249100% (5)

- Vibration LabDocument15 pagesVibration LabAngarajSharmaNo ratings yet

- WPH14 01 Que 20211020Document28 pagesWPH14 01 Que 20211020Hani Bayan AbushabanNo ratings yet

- A-A-59316 SpecDocument5 pagesA-A-59316 SpecddionatosNo ratings yet

- Coupler and SpliterDocument46 pagesCoupler and Splitersaad alwashNo ratings yet

- 17 Positive Displacement Machines PDFDocument40 pages17 Positive Displacement Machines PDFGiovanniNo ratings yet

- 2022 (30 Dec 2022) IJM-VG, AHA, NM, ISDocument12 pages2022 (30 Dec 2022) IJM-VG, AHA, NM, ISNaveen GulatiNo ratings yet

- Physical Quantities and Measurement STD 7 Physics NotesDocument6 pagesPhysical Quantities and Measurement STD 7 Physics NotesMyScribd_ieltsNo ratings yet

- AISC 1963 v01Document17 pagesAISC 1963 v01Ignacio Hiram M RoqueNo ratings yet

- Description Power Swing Rev 0Document5 pagesDescription Power Swing Rev 0soltaniNo ratings yet

- Numericals On Design of GearsDocument59 pagesNumericals On Design of GearsNAVEEN H V MENo ratings yet

- Building Ventilation: Building Physics and Architectural AerodynamicsDocument2 pagesBuilding Ventilation: Building Physics and Architectural AerodynamicsmgskumarNo ratings yet

- Activation Sequence Ror Smoke Exnuast Tans Smoke Exhaust Fan Status of Fan SZ-B1-01Document19 pagesActivation Sequence Ror Smoke Exnuast Tans Smoke Exhaust Fan Status of Fan SZ-B1-01kkmsNo ratings yet

- Instruction Manual: Shimadzu Analytical BalanceDocument169 pagesInstruction Manual: Shimadzu Analytical BalanceChanthar SoeNo ratings yet

- Chapter 3 - Examples of Mathematical Models of Chemical Engineering Systems. - Francisco Angel - AcademiaDocument17 pagesChapter 3 - Examples of Mathematical Models of Chemical Engineering Systems. - Francisco Angel - AcademiaAjay100% (2)

- ECA (BEE 302) & NA (BEC304) Module 4 Laplace TransformDocument11 pagesECA (BEE 302) & NA (BEC304) Module 4 Laplace Transformsachinksr007No ratings yet

- Ijser: Design and Fabrication of Frictionless Braking SystemDocument9 pagesIjser: Design and Fabrication of Frictionless Braking SystemShreyash IngleNo ratings yet

- CM36 Pattissery M20 Trial 1Document10 pagesCM36 Pattissery M20 Trial 1sudhakarthekingNo ratings yet

- How To Make Salvia ExtractDocument37 pagesHow To Make Salvia ExtractTinchenkoNo ratings yet