Professional Documents

Culture Documents

PIPE Vs TUBE

Uploaded by

SIL PROJECTSCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PIPE Vs TUBE

Uploaded by

SIL PROJECTSCopyright:

Available Formats

PIPE Vs TUBE

What is a Pipe?

Pipes are used for transporting fluids and gases in Chemical, Petrochemical, Power

Plants, Refineries, Storage units, Compressed air systems, Plumbing systems, etc.

They are circular in cross-section and specified by Nominal Pipe Size.

What is a Tube?

Tubes are used for mechanical applications (Heat Exchanger, Fired heater, Boiler,

etc.), for instrumentation systems (used for measuring instruments); for structural

applications, etc and could be rigid or flexible. They are specified by their outer

diameter and tube wall thickness, in inches or in millimetres.

Differences between Pipe and Tube

From a layman’s viewpoint, Both Pipe and Tube seem to be the same as they have

many similarities like both are hollow, usually made from metals, can transfer fluids,

etc. Many a time, these terms are used interchangeably. But in actual practice Tubes

and Pipes are not the same as both possess different features.

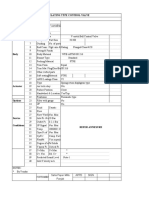

Sr.

Parameter Pipe Characteristics Tube Characteristics

No

Tubes are usually

cylindrical in shape.

However, tubes of

Pipes are always cylindrical or round in

1 Shape different other shapes

shape

like square,

rectangular, etc. are

available.

The size of the Tubes is

A pipe is Specified by Nominal Pipe specified in millimetres

2 Size

Size (NPS) or Nominal Bore (NB). or in inches by outside

diameter.

The outside diameter of

The outside diameter of pipe up to size

tubes is numerically

3 Diameter 12” is numerically larger than the

equal to the

corresponding pipe size

corresponding size.

Tube Wall thickness is

Pipe Wall thickness is expressed in expressed in

4 Thickness schedule numbers that can be converted millimetres, inches, or

into mm or inches. BWG (Birmingham

wire gauge.)

The thickness of tubes

Thickness Pipe thickness depends on the schedule, increases in standard

5

Increment so there is no fixed increment increments such as 1

mm or 2 mm

6 Application Pipes are extensively used in all Tubes are used in

Process, Power & Utility lines to carry tracing lines, tubes for

fluids. heat exchangers &

fired heaters &

instrument connections.

They are more

prevalent in the

medical area,

construction, structural,

or load bearing.

Normally small-bore

tube is used in process

Pipes are available as the small bore

7 Availability piping. For structural

and the big bore

use, tubes are available

in custom sizes.

Tubes are available as

rigid as well as flexible

depending on the

application. Rigid tubes

Structural Pipes are always rigid and resistant to

8 are normally used in

Rigidity bending

structural applications

whereas copper and

brass tubes can be

flexible.

Tubes can be joined

quickly and easily with

Joining pipes is more labor intensive as

Joining and flaring, brazing, or

9 it requires flanges, welding, threading,

Stability couplings, but for this

etc.

reason, they don’t offer

the same stability

Tolerances are very

strict with tubes

compared to pipes and

10 Tolerance Pipe tolerances are not too restrictive.

tubes are often more

expensive to produce

than pipes

Tubes need more

Pipe manufacturing is easier as cumbersome tests,

11 Manufacturing

compared to tubes inspection, and quality

control than pipes.

12 Cost Cheaper Costlier

Tubes are usually

wrapped with a

Packing & Delivered in the bundle as a bulk item. wooden box or thin

13

Delivery Delivery time is short. film and delivered with

much care. Delivery

time is longer.

Tubes are produced in

Production Pipes are produced in mass quantity small quantities

14

Quantity and for long-distance applications. depending on

requirements.

Tubes are available

The end connection of pipes is

with coupling ends,

15 End Connection normally plain or bevelled for welding

irregular ends, special

purposes

screw thread, etc.

Tubes are

The inner and Outer surface of the pipe manufactured on both

16 Surface Finish

is rough in comparison to the tube the inner and outer

surfaces as smooth

The common tube

17 Common material Common pipe material is Carbon Steel

material is Alloy Steel

The Thickness of the pipe is decided as The thickness of tubes

Design Codes &

18 per governing codes like ASME B31.3/ is dependent on the use

Standards

B31.1/ B31.4/ B31.8 or IBR Codes thickness is decided.

You might also like

- Mechanical Aptitude TestDocument82 pagesMechanical Aptitude TestContinuous Improvement Projects100% (1)

- Electronic Fuel InjectionDocument18 pagesElectronic Fuel InjectionDannydonNo ratings yet

- Long Span TrussDocument26 pagesLong Span Trussakhtar0% (1)

- Piping ComponentsDocument26 pagesPiping ComponentsVarun Patel100% (1)

- SM HD785-7 Sen01274-14Document1,815 pagesSM HD785-7 Sen01274-14Lucio Valderrama100% (2)

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Document84 pagesKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdNo ratings yet

- Piping Components EbookDocument45 pagesPiping Components Ebooksrinivasanssc100% (2)

- PE Lecture 9 FittingsDocument57 pagesPE Lecture 9 FittingsFauzaan KhanNo ratings yet

- #5 Maintenance CostDocument49 pages#5 Maintenance CostKhoirul Be100% (1)

- Flow Conditioning PLatesDocument8 pagesFlow Conditioning PLatesGeethaNo ratings yet

- G12 Module Working With ConduitsDocument28 pagesG12 Module Working With ConduitsHarold Vernon MartinezNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Kamel BelhibaNo ratings yet

- Pipes vs. Tubes - Is There A Difference?: Posted On August 30th, 2013 byDocument1 pagePipes vs. Tubes - Is There A Difference?: Posted On August 30th, 2013 bywelding inspectorNo ratings yet

- Rexa Troubleshoot ManualDocument338 pagesRexa Troubleshoot Manual1904sofia100% (2)

- Air Filtration ParkerDocument20 pagesAir Filtration Parkerpanosh12No ratings yet

- 15 Difference Between Pipe and TubeDocument5 pages15 Difference Between Pipe and TubeFebrianto Edy PratamaNo ratings yet

- Comparison of Pipe and TubeDocument3 pagesComparison of Pipe and TubeharishcsharmaNo ratings yet

- Module No. 11: Piping Systems Difference Between Pipe and TubeDocument8 pagesModule No. 11: Piping Systems Difference Between Pipe and TubeGeoffrey GolbequeNo ratings yet

- Pipe Vs Tube, 10 Basic DifferencesDocument1 pagePipe Vs Tube, 10 Basic DifferencesManasNo ratings yet

- Bending and Forming of TubingDocument2 pagesBending and Forming of TubingcavnqnNo ratings yet

- Module 5 - Pipe Cutting and JoiningDocument14 pagesModule 5 - Pipe Cutting and JoiningKrizia InteligandoNo ratings yet

- Pipes Vs TubesDocument2 pagesPipes Vs TubesKara Sheen BatayolaNo ratings yet

- Pipes Vs Tube - Good OneDocument3 pagesPipes Vs Tube - Good OneStephanie FlemingNo ratings yet

- Prochem: Stainless Steel SpecialistsDocument15 pagesProchem: Stainless Steel SpecialistsPooja ThaparNo ratings yet

- PART 113 Pipe & Tube What Is DifferenceDocument2 pagesPART 113 Pipe & Tube What Is Differenceravindra_jivaniNo ratings yet

- 346-Installing and Maintaining Tubing and Hose SystemsDocument80 pages346-Installing and Maintaining Tubing and Hose SystemsatagucaNo ratings yet

- Chapter 491Document28 pagesChapter 491pc mishraNo ratings yet

- Different Types of Pipes: Salve A. Ventura ABUTLI1S/ARC186-ADocument6 pagesDifferent Types of Pipes: Salve A. Ventura ABUTLI1S/ARC186-ASalv'zVenturaNo ratings yet

- Bending The RulesDocument2 pagesBending The RuleskikiuNo ratings yet

- PLUMBING MATERIALS Water SupplyDocument12 pagesPLUMBING MATERIALS Water SupplyjarellebyncsNo ratings yet

- Diferencias Entre Un Pipe y Un TubeDocument4 pagesDiferencias Entre Un Pipe y Un TubeÀngel RodriguezNo ratings yet

- KRAH PIPES - Brochure LayoutDocument9 pagesKRAH PIPES - Brochure LayoutFELNo ratings yet

- Bu 1 Semi FinalsDocument9 pagesBu 1 Semi FinalsNadine PascoNo ratings yet

- Aryan Arora Assignment 4Document13 pagesAryan Arora Assignment 4Vinay RaghavNo ratings yet

- Iepg 103Document9 pagesIepg 103Zandrex S. AguillonNo ratings yet

- Pipes Valve Connections and Fittings ESDocument41 pagesPipes Valve Connections and Fittings ESMinjdeDiosNo ratings yet

- Wrought Iron (WI) Pipes - : Flooring, Roofing, Plumbing and Sanitary Material 133Document2 pagesWrought Iron (WI) Pipes - : Flooring, Roofing, Plumbing and Sanitary Material 133niluNo ratings yet

- Group-5 ReportDocument11 pagesGroup-5 Reportexterminating.doggggNo ratings yet

- ANSI B16.9, ANSI B16.28, MSS-SP-43, MSS-SP-95, MSS-SP-97: 45° LR Elbows 90° LR ElbowsDocument5 pagesANSI B16.9, ANSI B16.28, MSS-SP-43, MSS-SP-95, MSS-SP-97: 45° LR Elbows 90° LR ElbowsMAZM17No ratings yet

- Weatherford CORODDocument6 pagesWeatherford CORODclass 96No ratings yet

- Header LateralsDocument2 pagesHeader LateralsRuvi MuhammadNo ratings yet

- Ovalizazzione Nozioni PDFDocument5 pagesOvalizazzione Nozioni PDFAngelo CeccatoNo ratings yet

- Difference Between Pipe and TubeDocument3 pagesDifference Between Pipe and TubeAnonymous fQAeGFNo ratings yet

- Common Pipes Used in ConstructionDocument8 pagesCommon Pipes Used in ConstructionJoseph ManalangNo ratings yet

- WelcomeDocument18 pagesWelcomeSK. Sazzad HossainNo ratings yet

- Local Media7116658732129643288Document25 pagesLocal Media7116658732129643288Hector TañamorNo ratings yet

- Bernal Bsar3b PlumbingDocument30 pagesBernal Bsar3b PlumbingAidyl Kate BernalNo ratings yet

- Assignment 3Document1 pageAssignment 3Aaron PinedaNo ratings yet

- Caterpillar: Confidential GreenDocument1 pageCaterpillar: Confidential GreenMahendravarman ChinnasamyNo ratings yet

- Clamps Buying GuideDocument8 pagesClamps Buying GuidegauravNo ratings yet

- Armado de TubingDocument13 pagesArmado de TubingCarlosCazarinVillanuevaNo ratings yet

- New Era University: Engineering Utilities 2 (CE 225-18)Document8 pagesNew Era University: Engineering Utilities 2 (CE 225-18)Ruzzel BuhayNo ratings yet

- GOODDocument25 pagesGOODNilang boreNo ratings yet

- F The 221 Activity1 PlumbingDocument13 pagesF The 221 Activity1 PlumbingLULU, JocelynNo ratings yet

- The Nominal Pipe DiameterDocument2 pagesThe Nominal Pipe DiameterImran AhmedNo ratings yet

- Pipe FittingsDocument26 pagesPipe FittingsJaypal SindhaNo ratings yet

- TEMA Basics of Construction - 07 10Document8 pagesTEMA Basics of Construction - 07 10Zeeshan SajidNo ratings yet

- 1.UPVC Column Casing Pipes CatalogDocument22 pages1.UPVC Column Casing Pipes Catalogsris802No ratings yet

- FittingDocument18 pagesFittingAkash SinghNo ratings yet

- Unit 1-Part C-Water Supply IDocument35 pagesUnit 1-Part C-Water Supply IShloka RaoNo ratings yet

- Coupler PresentationDocument70 pagesCoupler PresentationSmart ShivaNo ratings yet

- B 107 - B 107M - 00 - Qjewny9cmta3tqDocument18 pagesB 107 - B 107M - 00 - Qjewny9cmta3tqramonaNo ratings yet

- Understanding Pipe Threads: Types and Designations: by Mark SchmidtDocument5 pagesUnderstanding Pipe Threads: Types and Designations: by Mark Schmidtدانيا الأبراجNo ratings yet

- Materials Fittings and FixturesDocument60 pagesMaterials Fittings and Fixtureslanie mondiaNo ratings yet

- PipesDocument12 pagesPipesYasas LiyanageNo ratings yet

- Pipeline Design For Pigging: Pipeline Dimention Pipeline Materials DivertersDocument13 pagesPipeline Design For Pigging: Pipeline Dimention Pipeline Materials DivertersSazzadNo ratings yet

- Banking InformationDocument1 pageBanking InformationSIL PROJECTSNo ratings yet

- IBR - 1950 - Reg. 43Document2 pagesIBR - 1950 - Reg. 43SIL PROJECTSNo ratings yet

- Ball Valve On-Off TypeDocument1 pageBall Valve On-Off TypeSIL PROJECTSNo ratings yet

- Knife Gate Valve 12 INCH 10Document1 pageKnife Gate Valve 12 INCH 10SIL PROJECTSNo ratings yet

- HV 1013Document4 pagesHV 1013SIL PROJECTSNo ratings yet

- Ippta JournalDocument83 pagesIppta JournalSIL PROJECTSNo ratings yet

- IBR - 1950 - Reg. 56 ADocument3 pagesIBR - 1950 - Reg. 56 ASIL PROJECTSNo ratings yet

- HV 1212Document4 pagesHV 1212SIL PROJECTSNo ratings yet

- Envelop Cover Address Print FormatDocument1 pageEnvelop Cover Address Print FormatSIL PROJECTSNo ratings yet

- 100 V-Notch (Pulp)Document1 page100 V-Notch (Pulp)SIL PROJECTSNo ratings yet

- 50 V-Notch Valve2Document1 page50 V-Notch Valve2SIL PROJECTSNo ratings yet

- 11 - Vibrating Screens VSTDocument2 pages11 - Vibrating Screens VSTSIL PROJECTSNo ratings yet

- V Notch Ball ValveDocument1 pageV Notch Ball ValveSIL PROJECTSNo ratings yet

- 18 (1) .03.08 Satia LTI MailDocument2 pages18 (1) .03.08 Satia LTI MailSIL PROJECTSNo ratings yet

- Butterfly Valve With DiaphragmDocument1 pageButterfly Valve With DiaphragmSIL PROJECTSNo ratings yet

- For Paper Industry: Approach Flow Screen SPCDocument2 pagesFor Paper Industry: Approach Flow Screen SPCSIL PROJECTSNo ratings yet

- UntitledDocument5 pagesUntitledSIL PROJECTSNo ratings yet

- UntitledDocument27 pagesUntitledSIL PROJECTSNo ratings yet

- TS Curve RPHDocument2 pagesTS Curve RPHSIL PROJECTS0% (1)

- Uttam U: EnergyDocument1 pageUttam U: EnergySIL PROJECTSNo ratings yet

- 16 - Chest and TowerDocument2 pages16 - Chest and TowerSIL PROJECTSNo ratings yet

- E20 Green Fuel - Single Line Diagram (22.02.22)Document1 pageE20 Green Fuel - Single Line Diagram (22.02.22)SIL PROJECTSNo ratings yet

- For Paper Industry: Deflakers DSTDocument2 pagesFor Paper Industry: Deflakers DSTSIL PROJECTSNo ratings yet

- Preliminary: DescriptionDocument1 pagePreliminary: DescriptionSIL PROJECTSNo ratings yet

- 02 - Pulper Washer PWCDocument2 pages02 - Pulper Washer PWCSIL PROJECTSNo ratings yet

- 19 - Rectifier RollsDocument2 pages19 - Rectifier RollsSIL PROJECTSNo ratings yet

- 05 - High Density Pulpers PADDocument2 pages05 - High Density Pulpers PADSIL PROJECTSNo ratings yet

- 03 - Trommel TLVDocument2 pages03 - Trommel TLVSIL PROJECTSNo ratings yet

- 04 - Medium Density Pulpers PMDDocument2 pages04 - Medium Density Pulpers PMDSIL PROJECTSNo ratings yet

- 01 - Low Density Pulpers PBDDocument2 pages01 - Low Density Pulpers PBDSIL PROJECTSNo ratings yet

- Introduction To DC Machine: by Dr. Shubhobrata RudraDocument129 pagesIntroduction To DC Machine: by Dr. Shubhobrata RudraBhabani sankar KishanNo ratings yet

- Introduction To NC and CNC Machines CNC Controls and RS274 ProgrammingDocument36 pagesIntroduction To NC and CNC Machines CNC Controls and RS274 ProgrammingAnonymous ztnAl2No ratings yet

- Management Process IIDocument200 pagesManagement Process IIPeeka Prabhakara RaoNo ratings yet

- Product Recommendation Toyota (EU) Yaris XP10 Yaris 1.3 16V VVT-i (2003-2005)Document3 pagesProduct Recommendation Toyota (EU) Yaris XP10 Yaris 1.3 16V VVT-i (2003-2005)marranNo ratings yet

- 651Document26 pages651riskraj1984No ratings yet

- Thermoacoustics: Creating Sound With Heat: 2004 Project SummaryDocument1 pageThermoacoustics: Creating Sound With Heat: 2004 Project SummaryNᎥຮhanτ࿐No ratings yet

- Atoll 1100Document2 pagesAtoll 1100Cesar Ventura100% (1)

- Types of Forces and Laws - pdf-89Document8 pagesTypes of Forces and Laws - pdf-89shashankNo ratings yet

- Scedule Maintenance KBN Mill 2020Document9 pagesScedule Maintenance KBN Mill 2020slamet supriyadiNo ratings yet

- Fluid Power Technology by Ram SrivatsaDocument194 pagesFluid Power Technology by Ram SrivatsaPuja Ningrat WibowoNo ratings yet

- TM 9-2320-361-10Document404 pagesTM 9-2320-361-10bigcheapfunNo ratings yet

- Further Analysis and Extrusion Defects: 1.1 Strain Rate in Hot ExtrusionDocument7 pagesFurther Analysis and Extrusion Defects: 1.1 Strain Rate in Hot ExtrusionMark SternNo ratings yet

- Electrical Control Valves EX4 / EX5 / EX6 / EX7 / EX8Document9 pagesElectrical Control Valves EX4 / EX5 / EX6 / EX7 / EX8Ruben MarichalNo ratings yet

- Beam Details For Longitudinal Reinforcement: A Max 0.24 F F BD, 0.85 F BDDocument19 pagesBeam Details For Longitudinal Reinforcement: A Max 0.24 F F BD, 0.85 F BDSijan AdhikariNo ratings yet

- Spectacle Blinds - Closed Blinds Open Blinds (Ring Spacer)Document2 pagesSpectacle Blinds - Closed Blinds Open Blinds (Ring Spacer)Widiyanto WiwidNo ratings yet

- Fracture Formation PressureDocument7 pagesFracture Formation Pressuredekra abdoNo ratings yet

- TLE TVL SHIELDED METAL ARC WELDING NCI ACTIVITY SHEET NO. 2 2nd QuarterDocument6 pagesTLE TVL SHIELDED METAL ARC WELDING NCI ACTIVITY SHEET NO. 2 2nd QuarterMaricar CarandangNo ratings yet

- Rolling Contact BearingDocument44 pagesRolling Contact BearingMuhammad Waleed Khan 940-FET/BSME/F20No ratings yet

- S03 Drill FeedDocument35 pagesS03 Drill FeedTony GonzalezNo ratings yet

- Final Report: Early Generation Seam WeldsDocument53 pagesFinal Report: Early Generation Seam WeldsiMaJeniDeasNo ratings yet

- Catalogo Zaxis 470Document32 pagesCatalogo Zaxis 470Alberto Ferradás0% (1)

- TVRIIDocument52 pagesTVRIIDavid ZuñigaNo ratings yet

- Effect of Fillet Radius PDFDocument24 pagesEffect of Fillet Radius PDFadj adjNo ratings yet