Professional Documents

Culture Documents

1299 Ec1650

Uploaded by

Deepak HoleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1299 Ec1650

Uploaded by

Deepak HoleCopyright:

Available Formats

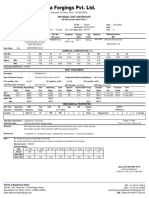

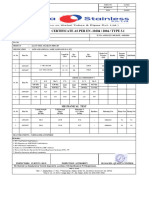

MATERIAL TEST CERTIFICATE

AS PER STD EN 10204 TYPE 3.1

Customer : TechnipFMC TC No. : EC1650 Date : 13.06.2023

Invoice No.: WIF/EX/23-24/ Date :

P.O. No.: 4500705714 Line Item: 00010 PO Date : 02.06.2023 Spec. Ref.: M25070 Rev. : F (Date:16.07.2021)

Die No. Description Part No. Condition Forging Qty Material Melting Practice

Drg. No. PSL Level Ratio Sr.No. Mill

BODY FORGING, ULT PLUG

1299 3257105 Rev K Forged, 30.47 : 1 970 Nos. AISI 4140 BF-EOF-LRF-VD-CCM

VALVE 1 ULT150 F/3 IN

Normalized,

UNION ENDS AISI 4140

Quenched &

- JSW STEEL

Tempered,

Heat Code: NSN DU500001271 Rev B Shot Blasted

CHEMICAL COMPOSITION ( % )

Heat No :- C Mn Si S P Cr Mo V Ni Grain Size

F12396 0.40 0.91 0.19 0.008 0.015 1.05 0.23 0.003 0.03 7

Specn. Min. 0.38 0.75 0.15 - - 0.80 0.15 - - 6

Max. 0.43 1.00 0.35 0.025 0.025 1.10 0.25 0.30 1.00 -

HEAT TREATMENT

Procedure :- Q00025 Rev S

Heat Treatment Furnace :- Continous Type Furnace (CHTF) Temperature Monitoring Method:- Side Thermocouples in the Working Zone ( Method A)

HT Load No. of N :- AF-979 HT Batch No. of Q&T:- AF-985 Qty :- 970 Nos.

Test Piece Heat Treatment :- Along with job QTC location:- Sacrificial QTC Size- Actual Part

Hot Working Normalising Time Hardening Time Quench Quench Bath Temp. 1st Temper Time

Ratio Temp. Hrs. Temp. Hrs. Media Start End Temp. Hrs.

QTC 30.47 : 1 900⁰C 3 Hrs 20 Min 870⁰C 3 Hrs 20 Min OIL 36°C 50°C 545°C 5 Hrs (Air Cool)

Forging 30.47 : 1 900⁰C 3 Hrs 20 Min 870⁰C 3 Hrs 20 Min OIL 36°C 50°C 545°C 5 Hrs (Air Cool)

Specn. Min. 870⁰C 840⁰C --- --- 540⁰C

Max. 925⁰C 900⁰C --- 80⁰C 700⁰C

MECHANICAL PROPERTIES

QTC Test Specimen QTC Test UTS YS Elg RA Charpy Impact

Specimen Orientation Hardness Temp. 0.2 % Offset Test ( Charpy ) J

Location after H.T. ⁰C PSI PSI % % Temp. Requirement 1 2 3 Average

Refer annexure for testing details

Test Piece Orientation:- Longitudinal & Transverse Charpy 'V' notch

Test Piece Size :- 8.75 mm Dia, 35 mm Gauge Length 10 mm X 10 mm X 55 mm LG

Remarks : All the jobs have been visually examined and are free from bursts, laps, seams, cracks, porosity.

All the jobs have been 100% checked for MPI test and found satisfactory.

Enclosures: 1) Steel Mill TC 2) Hardness report 3) Dimensional Report 4) Testing Annexure

Note :- We hereby guarantee no weld repairs performed.

. We hereby certify that the above figures are correct as contained in the records of the company

For Heat Treatment batch traceability point, "AF-985" stamped near to Heat code.

Furnace calibration done as per AMS 2750G and meets the requirements.

Forging Method - Closed Die Forging

Ajay Joshi (HEAD-MQC, HT & NDT)

Authorised Signatory

F-MQC-10 / Rev. 00 / 01-Apr-2016

Works & Registered Office Tel : +91-02137-679819

Gat No. 163, Hissa No.1, Pune-Nagar Road, Fax : +91-02137-679820

Sanaswadi, Tal. Shirur, Pune- 412208 (INDIA) customerservice@westernindiaforgings.com

www.westernindiaforgings.com CIN : U28910PN1981PTC024155

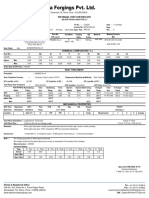

HARDNESS TEST REPORT

Customer:- TechnipFMC TC No: EC1650

P.O. No.:- 4500705714 Line Item: 00010 PO Date : 02.06.2023 Date : 13.06.2023

BODY FORGING, ULT PLUG VALVE 1

Item : Material : AISI 4140

ULT150 F/3 IN UNION ENDS AISI 4140

Part No.: 3257105 Rev K Heat No. : F12396

Drawing No.: DU500001271 Rev B Ambient Temp : 29°C

Die No.: 1299 Hardness Range:- 277 - 331 HBW

Qty.: 970 Nos. Test Method : Brinell Hardness Test

Vendor Sr.No.: - Equipment Used: Brinell Hardness Tester

HT Load No.: N: AF-979 QT: AF-985 Sr No.09/2021-036 | 2017/09

Reference Standard: ASTM E10 Machine Make: SAROJ | FSA

Load Applied: 3000 Kgs Calibration Agency: MTMS | MME

Cert. No.: MATRIX/CAL/2022-23/12/4205 |

Type of Penetrator: Dia 10 mm Carbide Ball

MME/CAL/63/23-24

Std Block Details: SH-2349/23 (Hardness value - 304.0 HBW) Calibrated On: 09.12.2022 | 10.02.2023

Entity Performing Test: WIF Sanaswadi Calibration Due On: 08.12.2023 | 09.08.2023

Hardness

Q03006 Rev. AC / Q03009 Rev. X Date of Test :- 04 & 05.05.2023

Procedure :-

Precise Measuring Method of HBW Impression : Type B : Hand-Held Microscope with fixed measuring lines.

Qty. Hardness in HBW

970 Nos. 285-321 HBW

Test Performed By Reviewed By Approved By :

Atul Jedhe Satish Gadgil (Sr.Manager HT) Ajay Joshi (HEAD-MQC, HT & NDT)

F-HT-10 / Rev. 00 / 01-Apr-2016

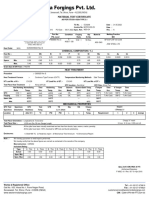

Mechanical Test Annexure

Die No.: 1299 Material Grade: AISI 4140

Heat No.: F12396 HT Lot No. : AF-985

Heat Code: NSN TC No. : EC1650

TENSILE TEST

QTC Test QTC Hardness after UTS YS Elg RA

Specimen Test Temp. NABL Lab Sample

Specimen H.T. 0.2 % Offset

Orientation (⁰C) Report No. No.

Location HBW KSI KSI % %

0.5" below

L 321, 321 Ambient B-23-629-P 1 148.39 127.53 17.66 60.58

HT Surface

277 - 331 Spec. Min. 120.00 100.00 16.00 35.00

IMPACT TEST

QTC Test

Specimen Requirement Test Temp. NABL Lab Sample

Specimen 1 2 3 Average

Orientation (⁰C) Report No. No.

Location

Avg. - 42 J Min

58 50 64 57.33

Single - 32 J Min

LE - 0.51 mm Min -29°C B-23-630-P 0.96 0.88 1.00 0.95

%Shear - Report 50 40 55 48.33

L

Avg. - 27 J Min

50 44 34 42.67

Single - 20 J Min

LE - Report -40°C B-23-631-P 0.75 0.68 0.54 0.66

%Shear - Report 40 35 25 33.33

0.5" below

Avg. - 28 J Min 1

HT Surface 34 36 44 38.00

Single - 18.7 J Min

LE - Report -29°C B-23-632-P 0.52 0.54 0.60 0.55

%Shear - Report 25 30 35 30.00

T

Avg. - 20 J Min

26 34 28 29.33

Single - 14 J Min

LE - Report -40°C B-23-633-P 0.37 0.46 0.39 0.41

%Shear - Report 20 25 20 21.67

Ajay Joshi (HEAD-MQC, HT & NDT)

Authorised Signatory

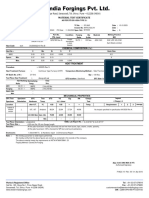

CERTIFICATE OF COMPLIANCE

Customer : TechnipFMC TC No.: EC1650

Date: 13.06.2023

Die No. : 1299 Heat Code : NSN

PO No : 4500705714 Line Item No : 00010

Offer Qty. : 970 Nos.

Part No/ Rev : 3257105 Rev K Drg No / Rev : DU500001271 Rev B

BODY FORGING, ULT PLUG VALVE

Part Name : Serial No. : -

1 ULT150 F/3 IN UNION ENDS AISI

4140

I. Material

A. Material Type : AISI 4140

B. Material Spec/ Rev. : As per Spec no : M25070 Rev No. F (Date:16.07.2021)

C. Material Test Report No : Mill Heat No : F12396

II. Dimensional

A. AQL : AS PER QUALITY PLAN B. Sample Size : 8 Nos.

III. Secondary Process : Heat Treatment

A. Process Name : Normalised

Heat Lot No. : AF-979 Process Spec : Q00025 Rev S

B. Process Name : QT

Heat Lot No. : AF-985 Process Spec : Q00025 Rev S

IV. NDE

A. Process Name : MPI

Certificate No : NA Process Spec : NA

B. Process Name : UT

Certificate No : NA Process Spec : NA

This is certified that subjected material is manufactured from material mentioned above &

verified by us as per written sample size & found conforming to requirements.

For Heat Treatment batch traceability point, "AF-985" stamped near to Heat code.

Sign with Stamp

Ajay Joshi (HEAD-MQC, HT & NDT)

You might also like

- HT 001Document1 pageHT 001Sam Raja100% (1)

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- STK/WIF/20-21/283 Bar No.: QTC With DespatchDocument58 pagesSTK/WIF/20-21/283 Bar No.: QTC With DespatchDeepak HoleNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Weld Acceptance Criteria1Document1 pageWeld Acceptance Criteria1sankarNo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Software Design and Development HSC NotesDocument77 pagesSoftware Design and Development HSC Notesjermaine jonesNo ratings yet

- Unit 3Document113 pagesUnit 3Jai Sai RamNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- VTB-600-2 A105n W1834221,235,230.QR PDFDocument1 pageVTB-600-2 A105n W1834221,235,230.QR PDFJoe KylaNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- 40NiCrMo7 PDFDocument2 pages40NiCrMo7 PDFAmy GriffinNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1485 - Ec0231Document6 pages1485 - Ec0231Deepak HoleNo ratings yet

- 1485 - Ec0216Document6 pages1485 - Ec0216Deepak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1485 - Ec0234Document5 pages1485 - Ec0234Deepak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- HT 002Document1 pageHT 002Sam RajaNo ratings yet

- HT 003Document1 pageHT 003Sam RajaNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- Messrs.: Specification For ApprovalDocument5 pagesMessrs.: Specification For Approvalg_1234No ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- 16 Ni CR 11Document2 pages16 Ni CR 11ceca nikolicNo ratings yet

- 0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611Document2 pages0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611JORGE BAENANo ratings yet

- Material Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical PropertiesDocument4 pagesMaterial Test Certificate EN 10204 3.1 Customer Name Date: Order No. Project: MTC No. Tensional Test Y.S Heat No. Specs MIN 170 Mechanical PropertiesŠâįf ÄhmāđNo ratings yet

- 39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test TemperingDocument1 page39nicrmo3 en 10083-3: 2006: End Quench Hardenability Test Temperingvo thanh lamNo ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- 41 CR 4Document2 pages41 CR 4Jhon ChitNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- MTC - A335 P22 Seamless PipeDocument1 pageMTC - A335 P22 Seamless PipeSri GangaNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- GR 70 32MMDocument1 pageGR 70 32MMquality nakodaNo ratings yet

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- 1.VFB-150-2 Tr.316 90601-077 QRDocument1 page1.VFB-150-2 Tr.316 90601-077 QRSurya ManaluNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- Messrs.: Specification For ApprovalDocument8 pagesMessrs.: Specification For ApprovalallendohorizontNo ratings yet

- 36NiCrMo16 PDFDocument2 pages36NiCrMo16 PDFAmy GriffinNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDocument3 pages4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDeepak HoleNo ratings yet

- Repayment-Deepak As On Date 07.12.2022Document2 pagesRepayment-Deepak As On Date 07.12.2022Deepak HoleNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanDeepak HoleNo ratings yet

- Deepak Dattatray HoleDocument2 pagesDeepak Dattatray HoleDeepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- F-HRA-05 On Job Training Record R04Document3 pagesF-HRA-05 On Job Training Record R04Deepak HoleNo ratings yet

- Htytdjhfjgk LJ K JKFTDRGBNDocument45 pagesHtytdjhfjgk LJ K JKFTDRGBNDeepak HoleNo ratings yet

- Addition To Forging Requirements QuestioniareDocument1 pageAddition To Forging Requirements QuestioniareDeepak HoleNo ratings yet

- Deviation Request - Raltech 10 10 2020Document1 pageDeviation Request - Raltech 10 10 2020Deepak HoleNo ratings yet

- Test ReportDocument1 pageTest ReportDeepak HoleNo ratings yet

- PD Nomenclature PDFDocument1 pagePD Nomenclature PDFDeepak HoleNo ratings yet

- Adwo PedDocument1 pageAdwo PedDeepak HoleNo ratings yet

- Customer Complaint Summery Sheet Updated 23.10.20 18.22Document1 pageCustomer Complaint Summery Sheet Updated 23.10.20 18.22Deepak HoleNo ratings yet

- Datasheet 40192BMS (Com Clock) )Document12 pagesDatasheet 40192BMS (Com Clock) )vanmarteNo ratings yet

- Bioresource Technology: Oscar Pardo-Planas, Hasan K. Atiyeh, John R. Phillips, Clint P. Aichele, Sayeed MohammadDocument8 pagesBioresource Technology: Oscar Pardo-Planas, Hasan K. Atiyeh, John R. Phillips, Clint P. Aichele, Sayeed Mohammadmohsen ranjbarNo ratings yet

- Kconfig LanguageDocument5 pagesKconfig Languagenheroq4No ratings yet

- Physics Semiconductor Device MCQDocument3 pagesPhysics Semiconductor Device MCQPradeep Singh ThakurNo ratings yet

- ECEA106L EXP1 MATLAB and Complex Numbers PDFDocument4 pagesECEA106L EXP1 MATLAB and Complex Numbers PDFRex Jose O. Bagain0% (1)

- Corekit User Manual EmulexDocument63 pagesCorekit User Manual Emulexprakashv44No ratings yet

- Unit 1Document57 pagesUnit 121ELB370MOHAMMAD AREEB HASAN KHANNo ratings yet

- 05-09-21 JR - Iit Star Co-Sc (Model-B) Jee Adv 2018 (P-I) Wat-18 QPDocument14 pages05-09-21 JR - Iit Star Co-Sc (Model-B) Jee Adv 2018 (P-I) Wat-18 QPIshita Reddy100% (1)

- Haqaik Ul Wasaiq - 1of2 - MasoomeenDocument444 pagesHaqaik Ul Wasaiq - 1of2 - MasoomeennasimNo ratings yet

- CHM170L Exp6 Heat of CombustionDocument5 pagesCHM170L Exp6 Heat of CombustionKaiser SaltoNo ratings yet

- TDS 1n32wakhs V0R2Document1 pageTDS 1n32wakhs V0R2Anissa SiliaNo ratings yet

- Front Wheel Brake, Brake Pad SensorDocument2 pagesFront Wheel Brake, Brake Pad SensorKifah ZaidanNo ratings yet

- Control Valves Data Sheet: Client: PlantDocument1 pageControl Valves Data Sheet: Client: PlantAnoNo ratings yet

- A Randomized, Placebo-Controlled Trial of Topical Retinol in The Treatment of CelluliteDocument6 pagesA Randomized, Placebo-Controlled Trial of Topical Retinol in The Treatment of Cellulitesario indriayaniNo ratings yet

- Do-254 CTS - FaqDocument5 pagesDo-254 CTS - FaqpremNo ratings yet

- Ohm's Law (Lab Report)Document7 pagesOhm's Law (Lab Report)yuta titeNo ratings yet

- Water TreatmentDocument12 pagesWater TreatmentSata AjjamNo ratings yet

- BNS-TCC Basler Time CurvesDocument8 pagesBNS-TCC Basler Time CurvesFelipeMoriNo ratings yet

- PErformance TEstDocument13 pagesPErformance TEstPraveen ChoudharyNo ratings yet

- EION VIP App148Document5 pagesEION VIP App148Javier QuirosNo ratings yet

- FCUBS Database Practices Db11gr2 Fc12.0.1Document38 pagesFCUBS Database Practices Db11gr2 Fc12.0.1cuonglunNo ratings yet

- Trick Flow Head StatsDocument15 pagesTrick Flow Head StatsdancaleyNo ratings yet

- Lesson 5 - Web DevelopmentDocument25 pagesLesson 5 - Web DevelopmentJoshua OmolewaNo ratings yet

- Liquidity Commonality in The Cryptocurrency MarketDocument16 pagesLiquidity Commonality in The Cryptocurrency MarketabhinavatripathiNo ratings yet

- 480-1 (Manski, Northwestern) PDFDocument3 pages480-1 (Manski, Northwestern) PDFInvestNo ratings yet