Professional Documents

Culture Documents

T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test Certificate

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test Certificate

Copyright:

Available Formats

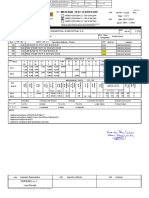

T.T.I. - Tubacex Tubos Inoxidables, S.A.

Registro Mercantil de Alava, Tomo 587, Folio 189, Hoja VI 2855 - N.I.F. A-01140227

Number: 895624 Rev: 0

MILL TEST CERTIFICATE Page: 1 / 1

EN 10204 3.1

Date : 15.01.2021 15.01.2021

TUBACEX

CUSTOMER : INTERNATIONAL STEEL CORPORATION PO : 6178 ISC-6341 OUR REFERENCE : L8537

STANDARD : ASTM A 312 / ASME SA 312 ED. 2015

ADDIT. SPECS : NACE MR0175-15/MR0103-15/ISO 15156-15

GRADE : TP 316L

DIMENSION : 25 NB X SCH 40

MATERIAL : SEAMLESS STAINLESS STEEL PIPE

HOT ROLLED; PICKLED-PASSIVATED;

PLAIN ENDS SQUARE CUT;

---- I T E M---- -HEAT- NO. OF ---WEIGHT-- -TOTAL LENGTH-

YOUR TTI. NO. PIECES KG. M --UNIT LENGTH--

256 412 79451 15 18320.00 90.00 5.0 - 7.0 MT

RAW MATERIAL

MELTING PROCESS : ELECTRIC FURNACE + A. O. D. FROM : ACERALAVA

PEELED BARS; MACROETCH TESTING : GOOD;

HEAT NO. C Mn Si P S Ni Cr Mo

Min. 0,000 0,000 0,000 0,000 0.000 10,000 16,000 2,000

Max. 0,030 2,000 1,000 0,045 0.030 14,000 18,000 3,000

79451 0,022 1,310 0,490 0,022 0,009 11,520 16,610 2,110

(1) L: LADLE; C: PRODUCT

HEAT TREATMENT

SOLUTION ANNEALED 1060 D.C. RAPIDLY COOLED

= TESTS = -------------------TENSILE-------------------I M P A C T T E S T S--HARDNESS

HEAT NO. TEST TEMP. ------- MPA ------- -- % % MINIMUM AVERAGE

UTS Y.S. ELONGATION Z TEMP. Charpy-(J) (HRC)

(GL=50mm)

79451 579 567 282 49.40 49.16 -28 OC 87 20

TECHNOLOGICALS - METALLURGICAL

FLATTENING TEST : GOOD

FLARING TEST : GOOD

NON DESTRUCTIVE TEST

NACE MR 0103 / 0175 : SATISFACTORY

100% HYDROSTATIC PRESSURE TESTED AT 2500 PSI; DURING 10 SEC. GOOD

STEEL GRADE CHECKED ON EACH PIPE BY SPECTROGRAPHY

DIMENSIONAL CHECKING ON EACH PIPE, SATISFACTORY

VISUAL INSPECTION ON EACH PIPE, SATISFACTORY

CORROSION TEST : ASTM A 262 / E : SATISFACTORY

PMI 100% OK

MARKS

TUBACEX ASTM A 312 TP 316L SEAMLESS 16” NB X SCH 80 HEAT NO. 79451 PMI

REMARKS

- GOODS ARE BEING IMPORTED UNDER OGL AS PER EXPORT-IMPORT POLICY

1997-2002 AND DOES NOT COME UNDER NEGATIVE LIST/CANALISED LIST.

we hereby certify that the material herein described has been

manufactured, sampled, tested and inspected in accordance with T.T.I.

above standards and specifications and satisfies the order's Tubacex Tubos Inoxidables, S. A.

requirements.

This certificate is issued by a computerized system and it is valid INGENIERIA DE CALIDAD

without signature. On the original certificate the responsible's

signature red coloured is stamped.

In case the owner of the original certificate would release a

copy of it, he must attest its conformity to the original one,

taking upon himself the responsibility for any unlawful or not Jon Altuna Zubero

allowed use.

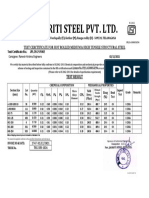

T.T.I. - Tubacex Tubos Inoxidables, S.A.

Registro Mercantil de Alava, Tomo 587, Folio 189, Hoja VI 2855 - N.I.F. A-01140227

Number: 902589 Rev: 0

MILL TEST CERTIFICATE Page: 1 / 1

EN 10204 3.1

Date : 21.01.2021 21.01.2021

TUBACEX

CUSTOMER : INTERNATIONAL STEEL CORPORATION PO : 6241 IPS-3613 OUR REFERENCE : L3913

STANDARD : ASTM A 312 / ASME SA 312 ED. 2015

ADDIT. SPECS : NACE MR0175-15/MR0103-15/ISO 15156-15

GRADE : TP 304L

DIMENSION : 15 NB X SCH 40

MATERIAL : SEAMLESS STAINLESS STEEL PIPE

HOT ROLLED; PICKLED-PASSIVATED;

PLAIN ENDS SQUARE CUT;

---- I T E M---- -HEAT- NO. OF ---WEIGHT-- -TOTAL LENGTH-

YOUR TTI. NO. PIECES KG. M --UNIT LENGTH--

306 479 81624 20 24420.00 120.00 5.0 - 7.0 MT

RAW MATERIAL

MELTING PROCESS : ELECTRIC FURNACE + A. O. D. FROM : ACERALAVA

PEELED BARS; MACROETCH TESTING : GOOD;

HEAT NO. C Mn Si P S Ni Cr

Min. 0,000 0,000 0,000 0,000 0.000 8,00 18,00

Max. 0,030 2,000 1,000 0,045 0.030 11,00 20,00

81624 0,026 1,723 0,366 0,026 0,006 8,51 18,62

(1) L: LADLE; C: PRODUCT

HEAT TREATMENT

SOLUTION ANNEALED 1060 D.C. RAPIDLY COOLED

= TESTS = -------------------TENSILE-------------------I M P A C T T E S T S--HARDNESS

HEAT NO. TEST TEMP. ------- MPA ------- -- % %

UTS Y.S. ELONGATION A Z TEMP. MINIMUM AVERAGE HRB

81624 579 582 267 47.30 48.72 74

TECHNOLOGICALS - METALLURGICAL

FLATTENING TEST : GOOD

FLARING TEST : GOOD

NON DESTRUCTIVE TEST

100% HYDROSTATIC PRESSURE TESTED AT 2500 PSI; DURING 10 SEC. GOOD

STEEL GRADE CHECKED ON EACH PIPE BY SPECTROGRAPHY

DIMENSIONAL CHECKING ON EACH PIPE, SATISFACTORY

VISUAL INSPECTION ON EACH PIPE, SATISFACTORY

CORROSION TEST : ASTM A 262 / E : SATISFACTORY

PMI TEST : OK

MARKS

TUBACEX ASTM A 312 TP 304L SEAMLESS 16” NB X SCH 80 HEAT NO. 81624 PMI

REMARKS

- GOODS ARE BEING IMPORTED UNDER OGL AS PER EXPORT-IMPORT POLICY

1997-2002 AND DOES NOT COME UNDER NEGATIVE LIST/CANALISED LIST.

we hereby certify that the material herein described has been

manufactured, sampled, tested and inspected in accordance with T.T.I.

above standards and specifications and satisfies the order's Tubacex Tubos Inoxidables, S. A.

requirements.

This certificate is issued by a computerized system and it is valid INGENIERIA DE CALIDAD

without signature. On the original certificate the responsible's

signature red coloured is stamped.

In case the owner of the original certificate would release a

copy of it, he must attest its conformity to the original one,

taking upon himself the responsibility for any unlawful or not Jon Altuna Zubero

allowed use.

T.T.I. - Tubacex Tubos Inoxidables, S.A.

Registro Mercantil de Alava, Tomo 587, Folio 189, Hoja VI 2855 - N.I.F. A-01140227

Number: 916587 Rev: 0

MILL TEST CERTIFICATE Page: 1 / 1

EN 10204 3.1

Date : 27.01.2021 27.01.2021

TUBACEX

CUSTOMER : INTERNATIONAL STEEL CORPORATION PO : 6374 IPS-3819 OUR REFERENCE : L6314

STANDARD : ASTM A 312 / ASME SA 312 ED. 2015

ADDIT. SPECS : NACE MR0175-15/MR0103-15/ISO 15156-15

GRADE : TP 304L

DIMENSION : 40NB X SCH 40

MATERIAL : SEAMLESS STAINLESS STEEL PIPE

HOT ROLLED; PICKLED-PASSIVATED;

PLAIN ENDS SQUARE CUT;

---- I T E M---- -HEAT- NO. OF ---WEIGHT-- -TOTAL LENGTH-

YOUR TTI. NO. PIECES KG. M --UNIT LENGTH--

356 579 82347 20 24430.00 120.00 5.0 - 7.0 MT

RAW MATERIAL

MELTING PROCESS : ELECTRIC FURNACE + A. O. D. FROM : ACERALAVA

PEELED BARS; MACROETCH TESTING : GOOD;

HEAT NO. C Mn Si P S Ni Cr

Min. 0,000 0,000 0,000 0,000 0.000 8,00 18,00

Max. 0,030 2,000 1,000 0,045 0.030 11,00 20,00

82347 0,023 1,480 0,490 0,025 0,010 8,42 18,09

(1) L: LADLE; C: PRODUCT

HEAT TREATMENT

SOLUTION ANNEALED 1060 D.C. RAPIDLY COOLED

= TESTS = -------------------TENSILE-------------------I M P A C T T E S T S--HARDNESS

HEAT NO. TEST TEMP. ------- MPA ------- -- % %

UTS Y.S. ELONGATION A Z TEMP. MINIMUM AVERAGE HRB

82347 284 589 287 45.74 44.75 75

TECHNOLOGICALS - METALLURGICAL

FLATTENING TEST : GOOD

FLARING TEST : GOOD

NON DESTRUCTIVE TEST

100% HYDROSTATIC PRESSURE TESTED AT 2500 PSI; DURING 10 SEC. GOOD

STEEL GRADE CHECKED ON EACH PIPE BY SPECTROGRAPHY

DIMENSIONAL CHECKING ON EACH PIPE, SATISFACTORY

VISUAL INSPECTION ON EACH PIPE, SATISFACTORY

CORROSION TEST : ASTM A 262 / E : SATISFACTORY

PMI TEST : OK

MARKS

TUBACEX ASTM A 312 TP 304L SEAMLESS 12” NB X SCH 160 HEAT NO. 82347 PMI

REMARKS

- GOODS ARE BEING IMPORTED UNDER OGL AS PER EXPORT-IMPORT POLICY

1997-2002 AND DOES NOT COME UNDER NEGATIVE LIST/CANALISED LIST.

we hereby certify that the material herein described has been

manufactured, sampled, tested and inspected in accordance with T.T.I.

above standards and specifications and satisfies the order's Tubacex Tubos Inoxidables, S. A.

requirements.

This certificate is issued by a computerized system and it is valid INGENIERIA DE CALIDAD

without signature. On the original certificate the responsible's

signature red coloured is stamped.

In case the owner of the original certificate would release a

copy of it, he must attest its conformity to the original one,

taking upon himself the responsibility for any unlawful or not Jon Altuna Zubero

allowed use.

You might also like

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmNo ratings yet

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Document1 pageASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- Mittal Corp Limited Test Certificate FinalDocument1 pageMittal Corp Limited Test Certificate FinalMehmet SoysalNo ratings yet

- 300 C SailDocument2 pages300 C Sailchandrabhushan kushwahaNo ratings yet

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- Flange 10 & 12 InchDocument2 pagesFlange 10 & 12 InchreniNo ratings yet

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema NandhNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- Offshore A312A358 R2Document1 pageOffshore A312A358 R2Prathamesh OmtechNo ratings yet

- LF' JLRDocument1 pageLF' JLRIslam SahafayatNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaNo ratings yet

- MTC FITTINGSDocument5 pagesMTC FITTINGSAzee TitouNo ratings yet

- SS SAW Welding Flux Sample MTCDocument1 pageSS SAW Welding Flux Sample MTCKunal AjgaonkarNo ratings yet

- Mill TC en 19 6.00MMDocument1 pageMill TC en 19 6.00MMKamal BhandariNo ratings yet

- Jyoti Engineering Works: Chemical AnalysisDocument8 pagesJyoti Engineering Works: Chemical AnalysisKristin CrawfordNo ratings yet

- Raw Material MTC - API 5L GR B PSL 2Document3 pagesRaw Material MTC - API 5L GR B PSL 2ClarkFedele27No ratings yet

- 30 MM Round Bar - EN8 - MTCDocument1 page30 MM Round Bar - EN8 - MTCMohammad Adil0% (1)

- OMR pipe fittings certificate analysisDocument1 pageOMR pipe fittings certificate analysisslimane AIT-IDIRNo ratings yet

- MTCDocument6 pagesMTCNauman Zia100% (1)

- SS304-1 2THK PDFDocument1 pageSS304-1 2THK PDFrajNo ratings yet

- QD62-H-103 DocumentationDocument16 pagesQD62-H-103 DocumentationAlam MD SazidNo ratings yet

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- MAHARASHTRA SEAMLESS LIMITED CERTIFICATE OF MANUFACTURE AND TEST FOR PIPESDocument1 pageMAHARASHTRA SEAMLESS LIMITED CERTIFICATE OF MANUFACTURE AND TEST FOR PIPESPetroPower OilandgasNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- 1613 00443 PDFDocument69 pages1613 00443 PDFzaheerNo ratings yet

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document2 pagesMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNo ratings yet

- Neway Gate 6 X 150 RFDocument6 pagesNeway Gate 6 X 150 RFcomercial 3No ratings yet

- Test Certification PDFDocument1 pageTest Certification PDFDany ChlNo ratings yet

- Vedanta Limited Integrated Field Plan Inspection ReportsDocument23 pagesVedanta Limited Integrated Field Plan Inspection ReportsPRAKASH PANDEYNo ratings yet

- Quality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Document9 pagesQuality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Sachin KumarNo ratings yet

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- Weflo Valve Co., LTD.: Material Test CertificateDocument1 pageWeflo Valve Co., LTD.: Material Test CertificateCarlosEduardoMorenoManceraNo ratings yet

- MTC - 274470Document2 pagesMTC - 274470sreejith123456No ratings yet

- BF20112602 English MTC PDFDocument2 pagesBF20112602 English MTC PDFSvetlana VujovićNo ratings yet

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- TV 100x100x5#S235JRDocument5 pagesTV 100x100x5#S235JRRazvan CristeaNo ratings yet

- Tata Steel Hot Rolled Coils Test CertificateDocument1 pageTata Steel Hot Rolled Coils Test CertificateMohd YaskeenNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- TTU Fittings Ttu Industrial LTD.: Manufacturer'SDocument1 pageTTU Fittings Ttu Industrial LTD.: Manufacturer'SMohamed RaafatNo ratings yet

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- CERTIFICATE OF QUALITY FOR STAINLESS STEEL SHEETDocument1 pageCERTIFICATE OF QUALITY FOR STAINLESS STEEL SHEETCarlos RomeroNo ratings yet

- 2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14Document8 pages2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14JORGE BAENA100% (1)

- 4140 Material For TubeDocument2 pages4140 Material For Tubesharafudheen_sNo ratings yet

- IS 10748_2004 Compliant HR Steel Coils CertificateDocument1 pageIS 10748_2004 Compliant HR Steel Coils CertificateravigurajapuNo ratings yet

- Tinita Engineering Pvt. LTD.: Material Identification Report For PipesDocument1 pageTinita Engineering Pvt. LTD.: Material Identification Report For PipesalokbdasNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Tubacex 10Document2 pagesTubacex 10Akash SinhaNo ratings yet

- 075P80-321 TubacexDocument1 page075P80-321 Tubacexsakshi patilNo ratings yet

- Health10 q3 Mod1 Healthtrendsissues v5Document27 pagesHealth10 q3 Mod1 Healthtrendsissues v5Wensyl Mae De GuzmanNo ratings yet

- Full Floating Clapper Assembly: Swing Check ValveDocument2 pagesFull Floating Clapper Assembly: Swing Check Valvemubarak aliNo ratings yet

- Periodontal IndicesDocument29 pagesPeriodontal IndicesFachrul Latif DentistNo ratings yet

- Meniere's Disease and Tinnitus in Nursing PractiseDocument5 pagesMeniere's Disease and Tinnitus in Nursing PractiseLizbeth MarinahNo ratings yet

- Why Check Valves SlamDocument2 pagesWhy Check Valves SlamBramJanssen76No ratings yet

- Supplementary Life Insurance - Enrolment FormDocument1 pageSupplementary Life Insurance - Enrolment FormjeevaNo ratings yet

- 3 Novec™ 1230 Fire Protection Fluid Data SheetDocument4 pages3 Novec™ 1230 Fire Protection Fluid Data SheetL ONo ratings yet

- GFT 4 Rail Installation Guide 20171219 1Document31 pagesGFT 4 Rail Installation Guide 20171219 1Comsip400No ratings yet

- Tle9agricropproduction q1 m5 ProvidingworksupportinaccordancewithOHSforhorticulturalproductionwork v3Document26 pagesTle9agricropproduction q1 m5 ProvidingworksupportinaccordancewithOHSforhorticulturalproductionwork v3Marycon Lao NacitoNo ratings yet

- 6 Review of Related LiteratureDocument2 pages6 Review of Related Literaturerusty0% (2)

- Panelboard O&M ManualDocument7 pagesPanelboard O&M Manualchris100% (1)

- STDs in Sangamon CountyDocument15 pagesSTDs in Sangamon CountyNewsTeam20No ratings yet

- HSI Calculator 3Document3 pagesHSI Calculator 3Diah Ayu Wulandari Sulistyaningrum0% (1)

- Operating Instructions for SUMI Lift TruckDocument27 pagesOperating Instructions for SUMI Lift TruckXe Nâng Hàng YaleNo ratings yet

- Diabetic Retinopathy: Basic InformationDocument12 pagesDiabetic Retinopathy: Basic InformationipkNo ratings yet

- Turabi Ltd income statement and balance sheetDocument7 pagesTurabi Ltd income statement and balance sheetFarwa SamreenNo ratings yet

- Tm1tEMPLATES-SWBL-Forms 1.1-1.4 (1) (Back Up)Document17 pagesTm1tEMPLATES-SWBL-Forms 1.1-1.4 (1) (Back Up)Norrodin MangatongNo ratings yet

- The Abreviated Ajahn Brahm - Concise Instructions For Skillful Meditation PDFDocument8 pagesThe Abreviated Ajahn Brahm - Concise Instructions For Skillful Meditation PDFJean Bessaudou Jan BessNo ratings yet

- Delhi-HC-Cruelty by WifeDocument19 pagesDelhi-HC-Cruelty by WifeSachin BansalNo ratings yet

- Analysis of A Healthcare Risk Management PlanDocument6 pagesAnalysis of A Healthcare Risk Management PlanGeralds B GeraldNo ratings yet

- Mag-Gage The Superior Magnetic Level Gauge: Process Level Technology, Ltd. 281.332.6241Document12 pagesMag-Gage The Superior Magnetic Level Gauge: Process Level Technology, Ltd. 281.332.6241BYRON ENRIQUE AGUILERA CHIMARRONo ratings yet

- Chapter - 08 Civics Confronting Marginalisation: Invoking Fundamental RightsDocument2 pagesChapter - 08 Civics Confronting Marginalisation: Invoking Fundamental Rightsnbs saraswathiNo ratings yet

- Ladipur EVA LiquidDocument2 pagesLadipur EVA LiquidKalki VermaNo ratings yet

- 3.14 Doxy PleurodesisDocument2 pages3.14 Doxy PleurodesisRheinald Joel BiscaroNo ratings yet

- Engineered Plastics GuideDocument1 pageEngineered Plastics GuideKmgsa BandaraNo ratings yet

- Supply Chain Operations Manager in Indianapolis IN Resume Robert McVeighDocument2 pagesSupply Chain Operations Manager in Indianapolis IN Resume Robert McVeighRobertMcVeighNo ratings yet

- Production of Non Ferrous MetalsDocument68 pagesProduction of Non Ferrous MetalsDrTrinath TalapaneniNo ratings yet

- Report 1690018110488Document2 pagesReport 1690018110488Krishna ChaitanyaNo ratings yet

- Ibat-ibang dulog sa paghawak ng klaseDocument2 pagesIbat-ibang dulog sa paghawak ng klaseJovito Limot100% (3)

- Brand New Milk Tea Market: Chinese Milk Tea Development and Brand AnalysisDocument9 pagesBrand New Milk Tea Market: Chinese Milk Tea Development and Brand AnalysisMariecel G. GuañoNo ratings yet