Professional Documents

Culture Documents

Tubacex 10

Uploaded by

Akash SinhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tubacex 10

Uploaded by

Akash SinhaCopyright:

Available Formats

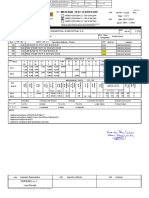

T.T.I. - Tubacex Tubos Inoxidables, S.A.

Registro Mercantil de Alava, Tomo 587, Folio 189, Hoja VI 2855 - N.I.F. A-01140227

Number: 725118 Rev: 0

MILL TEST CERTIFICATE Page: 1 / 1

EN 10204 3.1

Date : 20.06.2019 20.06.2019

TUBACEX

CUSTOMER : INTERNATIONAL STEEL CORPORATION PO : 2839 ISC-4612 OUR REFERENCE : L4920

STANDARD : ASTM A 312 / ASME SA 312 ED. 2015

ADDIT. SPECS : NACE MR0175-15/MR0103-15/ISO 15156-15

GRADE : TP 316/316L

DIMENSION : 1/2” NB X SCH 40

MATERIAL : SEAMLESS STAINLESS STEEL PIPE

HOT ROLLED; PICKLED-PASSIVATED;

PLAIN ENDS SQUARE CUT;

---- I T E M---- -HEAT- NO. OF ---WEIGHT-- -TOTAL LENGTH-

YOUR TTI. NO. PIECES KG. M --UNIT LENGTH--

84 196 87356 455 3470.00 2730.00 5.0 - 7.0 MT

RAW MATERIAL

MELTING PROCESS : ELECTRIC FURNACE + A. O. D. FROM : ACERALAVA

PEELED BARS; MACROETCH TESTING : GOOD;

HEAT NO. C Mn Si P S Ni Cr Mo

Min. 0,000 0,000 0,000 0,000 0.000 10,00 16,00 2,00

Max. 0,030 2,000 1,000 0,045 0.030 14,00 18,00 3,00

87356 0,022 1,180 0,426 0,027 0,008 10,90 16,95 2,17

(1) L: LADLE; C: PRODUCT

HEAT TREATMENT

SOLUTION ANNEALED 1040 o C G.C. RAPIDLY COOLED BY AIR

= TESTS = -------------------TENSILE-------------------I M P A C T T E S T S--HARDNESS

HEAT NO. TEST TEMP. ------- MPA ------- -- % % MINIMUM AVERAGE

UTS Y.S. ELONGATION Z TEMP. Charpy-(J) (HBN)

(GL=50mm)

87356 568 288 46 46 O C 211 213

TECHNOLOGICALS - METALLURGICAL

BEND TEST : GOOD

FLARING TEST : GOOD

NON DESTRUCTIVE TEST

NACE MR 0103 / 0175 : SATISFACTORY

100% HYDROSTATIC PRESSURE TESTED AT 2500 PSI; DURING 10 SEC. GOOD

STEEL GRADE CHECKED ON EACH PIPE BY SPECTROGRAPHY

DIMENSIONAL CHECKING ON EACH PIPE, SATISFACTORY

VISUAL INSPECTION ON EACH PIPE, SATISFACTORY

CORROSION TEST : ASTM A 923 / C : SATISFACTORY

PMI 100% OK

MARKS

TUBACEX ASTM A 312 TP 316/316L SEAMLESS 1/2” NB X SCH 40 HEAT NO. 87356 PMI

REMARKS

- GOODS ARE BEING IMPORTED UNDER OGL AS PER EXPORT-IMPORT POLICY

1997-2002 AND DOES NOT COME UNDER NEGATIVE LIST/CANALISED LIST.

we hereby certify that the material herein described has been

manufactured, sampled, tested and inspected in accordance with T.T.I.

above standards and specifications and satisfies the order's Tubacex Tubos Inoxidables, S. A.

requirements.

This certificate is issued by a computerized system and it is valid INGENIERIA DE CALIDAD

without signature. On the original certificate the responsible's

signature red coloured is stamped.

In case the owner of the original certificate would release a

copy of it, he must attest its conformity to the original one,

taking upon himself the responsibility for any unlawful or not Jon Altuna Zubero

allowed use.

T.T.I. - Tubacex Tubos Inoxidables, S.A.

Registro Mercantil de Alava, Tomo 587, Folio 189, Hoja VI 2855 - N.I.F. A-01140227

Number: 791482 Rev: 0

MILL TEST CERTIFICATE Page: 1 / 1

EN 10204 3.1

Date : 24.07.2019 24.07.2019

TUBACEX

CUSTOMER : INTERNATIONAL STEEL CORPORATION PO : 3789 ISC-3612 OUR REFERENCE : L3912

STANDARD : ASTM A 312 / ASME SA 312 ED. 2015

ADDIT. SPECS : NACE MR0175-15/MR0103-15/ISO 15156-15

GRADE : TP 316/316L

DIMENSION : 1” NB X SCH 40

MATERIAL : SEAMLESS STAINLESS STEEL PIPE

HOT ROLLED; PICKLED-PASSIVATED;

PLAIN ENDS SQUARE CUT;

---- I T E M---- -HEAT- NO. OF ---WEIGHT-- -TOTAL LENGTH-

YOUR TTI. NO. PIECES KG. M --UNIT LENGTH--

291 619 89347 265 3975.00 1590.00 5.0 - 7.0 MT

RAW MATERIAL

MELTING PROCESS : ELECTRIC FURNACE + A. O. D. FROM : ACERALAVA

PEELED BARS; MACROETCH TESTING : GOOD;

HEAT NO. C Mn Si P S Ni Cr Mo

Min. 0,000 0,000 0,000 0,000 0.000 10,000 16,000 2,000

Max. 0,030 2,000 1,000 0,045 0.030 14,000 18,000 3,000

89347 0,021 1,320 0,410 0,012 0,007 11,710 16,720 2,120

(1) L: LADLE; C: PRODUCT

HEAT TREATMENT

SOLUTION ANNEALED 1060 D.C. RAPIDLY COOLED

= TESTS = -------------------TENSILE-------------------I M P A C T T E S T S--HARDNESS

HEAT NO. TEST TEMP. ------- MPA ------- -- % %

UTS Y.S. ELONGATION A Z TEMP. MINIMUM AVERAGE HRB

89347 578 569 287 47.40 48.16 73

TECHNOLOGICALS - METALLURGICAL

BEND TEST : GOOD

FLARING TEST : GOOD

NON DESTRUCTIVE TEST

100% HYDROSTATIC PRESSURE TESTED AT 2500 PSI; DURING 10 SEC. GOOD

STEEL GRADE CHECKED ON EACH PIPE BY SPECTROGRAPHY

DIMENSIONAL CHECKING ON EACH PIPE, SATISFACTORY

VISUAL INSPECTION ON EACH PIPE, SATISFACTORY

CORROSION TEST : ASTM A 262 / E : SATISFACTORY

MARKS

TUBACEX ASTM A 312 TP 316/316L SEAMLESS 1” NB X SCH 40 HEAT NO. 89347 PMI

REMARKS

- GOODS ARE BEING IMPORTED UNDER OGL AS PER EXPORT-IMPORT POLICY

1997-2002 AND DOES NOT COME UNDER NEGATIVE LIST/CANALISED LIST.

we hereby certify that the material herein described has been

manufactured, sampled, tested and inspected in accordance with T.T.I.

above standards and specifications and satisfies the order's Tubacex Tubos Inoxidables, S. A.

requirements.

This certificate is issued by a computerized system and it is valid INGENIERIA DE CALIDAD

without signature. On the original certificate the responsible's

signature red coloured is stamped.

In case the owner of the original certificate would release a

copy of it, he must attest its conformity to the original one,

taking upon himself the responsibility for any unlawful or not Jon Altuna Zubero

allowed use.

You might also like

- TubacexDocument1 pageTubacexMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- Abnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Document1 pageAbnahmeprüefzeugnis Inspection Certificate: Date: 12 - 3 - 2021 Certificate No.: 0tte8236Mohamed RaafatNo ratings yet

- Universal 1-2 Clase 6000 Tipo 316Document2 pagesUniversal 1-2 Clase 6000 Tipo 316comercial 3100% (1)

- Certificado 3.1 y Calibracion Termopares - TecamDocument11 pagesCertificado 3.1 y Calibracion Termopares - TecamigorNo ratings yet

- Hollow Bar 304L Φ80ΧΦ50Document6 pagesHollow Bar 304L Φ80ΧΦ50Agoritsa100% (1)

- 075P80-321 TubacexDocument1 page075P80-321 Tubacexsakshi patilNo ratings yet

- Chandan Steel MTC for Stainless Steel Round Bars to ArgentinaDocument1 pageChandan Steel MTC for Stainless Steel Round Bars to ArgentinaAceros DessolNo ratings yet

- SS SAW Welding Flux Sample MTCDocument1 pageSS SAW Welding Flux Sample MTCKunal AjgaonkarNo ratings yet

- Neway Gate 6 X 150 RFDocument6 pagesNeway Gate 6 X 150 RFcomercial 3No ratings yet

- Check Valve 6in HT 6YF4Document1 pageCheck Valve 6in HT 6YF4Juan Pablo Perdomo OrtizNo ratings yet

- 3604 2Document17 pages3604 2Tiffany WilsonNo ratings yet

- Weflo Valve Co., LTD.: Material Test CertificateDocument1 pageWeflo Valve Co., LTD.: Material Test CertificateCarlosEduardoMorenoManceraNo ratings yet

- MTC Elbow 6inDocument1 pageMTC Elbow 6inhenryNo ratings yet

- 1000 Wog Ball ValveDocument1 page1000 Wog Ball ValveSandi AslanNo ratings yet

- WNRF 2 MFF ItalyDocument1 pageWNRF 2 MFF ItalyMohamed RaafatNo ratings yet

- Werkszeugnis Altena Blech Vom 17.06.PDF 1Document2 pagesWerkszeugnis Altena Blech Vom 17.06.PDF 1MuzammilNo ratings yet

- Teava Rect 50X50X3MM PDFDocument1 pageTeava Rect 50X50X3MM PDFCiprian ShaolinNo ratings yet

- Prime Fastener M20 Nut - MTCDocument1 pagePrime Fastener M20 Nut - MTCCyril J PadiyathNo ratings yet

- MTC - 274470Document2 pagesMTC - 274470sreejith123456No ratings yet

- OMR pipe fittings certificate analysisDocument1 pageOMR pipe fittings certificate analysisslimane AIT-IDIRNo ratings yet

- 1613 00443 PDFDocument69 pages1613 00443 PDFzaheerNo ratings yet

- Ball Valve Passport 10x8 2500#Document43 pagesBall Valve Passport 10x8 2500#Alejandro RojasNo ratings yet

- Flange 8 Inch RTJDocument3 pagesFlange 8 Inch RTJreniNo ratings yet

- Flange 24 InchDocument2 pagesFlange 24 InchreniNo ratings yet

- LF' JLRDocument1 pageLF' JLRIslam SahafayatNo ratings yet

- 9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFDocument1 page9q2fh6at-Brida BL Ac 300 A105 RF 2 MTFantonio larotta100% (1)

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- Presentation DelcorteDocument15 pagesPresentation Delcortecarlos2685No ratings yet

- Varilla B7 3-8 X 144 MT (B7)Document1 pageVarilla B7 3-8 X 144 MT (B7)Carlos Lluen AquinoNo ratings yet

- Material Test ReportDocument5 pagesMaterial Test ReportJuan Carlos Sua SuaNo ratings yet

- SS420, 12mm-RamDocument1 pageSS420, 12mm-RamganeshNo ratings yet

- Lithika - 001Document1 pageLithika - 001Harkesh RajputNo ratings yet

- TV 100x100x5#S235JRDocument5 pagesTV 100x100x5#S235JRRazvan CristeaNo ratings yet

- Material Test Report: ISO EN 10204 2004-3.1Document4 pagesMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNo ratings yet

- Certified Mill Test Report: S O L D T O S H I P T ODocument1 pageCertified Mill Test Report: S O L D T O S H I P T OMohamed RaafatNo ratings yet

- Esme TF Ger 1570527 00Document1 pageEsme TF Ger 1570527 00Fitroh MalikNo ratings yet

- Purchase Order: Number: 14 - SOODocument4 pagesPurchase Order: Number: 14 - SOOLê Đức ThiệnNo ratings yet

- LVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateDocument1 pageLVF SPA - GLOBE VALVE - A105N - EN10204 3.1 Material CertificateEMTC EMTCNo ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- hot rolled Φ60 AISI 304L (14.230)Document3 pageshot rolled Φ60 AISI 304L (14.230)A. ΒρατσισταNo ratings yet

- Fittings ThrededDocument2 pagesFittings ThrededreniNo ratings yet

- Certificados Pernos - Com. Pizarro - OkDocument5 pagesCertificados Pernos - Com. Pizarro - OkROLANDO BURGOSNo ratings yet

- Wenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicateDocument1 pageWenzhou Windmill Valve Co.,Ltd: Chemical Analysis of Material Certifaicate Inspection CertifaicatePerumal Govindan100% (1)

- The UL Certificate of The Gate Valve-JINAN MEIDEDocument5 pagesThe UL Certificate of The Gate Valve-JINAN MEIDEIRENENo ratings yet

- Standard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsedDocument4 pagesStandard Inspection and Test Plan For Api6D Valves: A GSL Company - Quality EndorsednithyaNo ratings yet

- Outokumpu: Si MN P S CR NiDocument3 pagesOutokumpu: Si MN P S CR NiDarkedgeNo ratings yet

- MTC 17 4PH Al20201127a174Document1 pageMTC 17 4PH Al20201127a174Ajeng PratiwiNo ratings yet

- Mustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetDocument7 pagesMustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetWattsNo ratings yet

- ASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Document1 pageASME SA234 - 2013 WPB: ASTM A234 - I 3e 1 WPB: ASME 816.9-2012 / ASME 816.25-2012 BS EN 10204 3. 1-2004Omar Bautista Díaz100% (1)

- JCOUSER03Document1 pageJCOUSER03Neem LalNo ratings yet

- Qtap 201901 0062, Pt. Wijaya Karya Rekayasa Konstruksi, 28-01-2019 PDFDocument2 pagesQtap 201901 0062, Pt. Wijaya Karya Rekayasa Konstruksi, 28-01-2019 PDFAddin Galih PrakosoNo ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- Material Product Data SheetDocument4 pagesMaterial Product Data SheethungNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaNo ratings yet

- MTC CertificatesDocument14 pagesMTC CertificatesfarjadulhaqNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- American Ultraminiature Component Parts Data 1965-66: Pergamon Electronics Data SeriesFrom EverandAmerican Ultraminiature Component Parts Data 1965-66: Pergamon Electronics Data SeriesNo ratings yet

- L02 ME1120 Scales ProjectionDocument47 pagesL02 ME1120 Scales ProjectionNawin KrishnaNo ratings yet

- Typical Civil BOQDocument11 pagesTypical Civil BOQMuhammad Wazim AkramNo ratings yet

- PC I Girder Posttensioned HS20 44 SIDocument5 pagesPC I Girder Posttensioned HS20 44 SIJavier Bosigas100% (1)

- Untitled PDFDocument283 pagesUntitled PDFbella anissaNo ratings yet

- RoseArts Phase 1 SubmittalDocument205 pagesRoseArts Phase 1 Submittalchristie zizoNo ratings yet

- BMD SFDDocument3 pagesBMD SFDShrinath ShetNo ratings yet

- PIP StandardDocument32 pagesPIP StandardRitesh Chauhan100% (5)

- Opa 960RKTB Im 0514Document4 pagesOpa 960RKTB Im 0514Analiza BariaNo ratings yet

- About Author: Building Materials & Construction by Saurabh Kumar Soni - DetailsDocument1 pageAbout Author: Building Materials & Construction by Saurabh Kumar Soni - DetailsMADUGULA CHANDRASEKHARNo ratings yet

- Install Outdoor Unit of Split AC ManualDocument29 pagesInstall Outdoor Unit of Split AC Manualei8htNo ratings yet

- Flexural Behavior of Aluminum Honeycomb Core Sandwich StructureDocument12 pagesFlexural Behavior of Aluminum Honeycomb Core Sandwich StructureParth LalNo ratings yet

- تقرير مادة التبريد والتكييفDocument5 pagesتقرير مادة التبريد والتكييفahmedytxzNo ratings yet

- Heat Load Estimation E20 Form SIDocument1 pageHeat Load Estimation E20 Form SISaul CastroNo ratings yet

- Simpack Wind 2010 Swe LoadsimulationsDocument26 pagesSimpack Wind 2010 Swe LoadsimulationsRamon Gutierrez100% (1)

- EN The Basic Concepts of Modelling RailwayDocument9 pagesEN The Basic Concepts of Modelling RailwayMarina GamaNo ratings yet

- 4 - Way Cassette Type: Engineering Data BookDocument26 pages4 - Way Cassette Type: Engineering Data BookProjects EngineerNo ratings yet

- Arthur Ravenel JR BridgeDocument3 pagesArthur Ravenel JR BridgeSoundMan56No ratings yet

- Method Statement Striking FormworkDocument3 pagesMethod Statement Striking FormworkSurya HeriwijayaNo ratings yet

- Formwork Calculation Report - Rev.Document49 pagesFormwork Calculation Report - Rev.Nishant Gaur0% (1)

- AIPL WMS Granite Flooring MethodDocument3 pagesAIPL WMS Granite Flooring MethodDeepak PatilNo ratings yet

- JOU - EQ Analysis of Structure by Base Isolation Technique in SAP PDFDocument10 pagesJOU - EQ Analysis of Structure by Base Isolation Technique in SAP PDFIlham Hussein RasyidNo ratings yet

- Tehnički Podaci Za Anker Vijke R-HPTII-ZF 2019 PDFDocument11 pagesTehnički Podaci Za Anker Vijke R-HPTII-ZF 2019 PDFPetar RudešNo ratings yet

- Fire Case StudyDocument39 pagesFire Case StudyAkanksha BhakareNo ratings yet

- Given Road Alignment.: (20 Marks)Document1 pageGiven Road Alignment.: (20 Marks)robert theNo ratings yet

- PVC Walls Panels Traders, Wholesalers and Buyers in DelhiDocument5 pagesPVC Walls Panels Traders, Wholesalers and Buyers in DelhisaaNo ratings yet

- Strap Footings - Concrete Design - Eurocode StandardsDocument2 pagesStrap Footings - Concrete Design - Eurocode StandardsJeffH100% (1)

- Wireline-Tools String ParvenDocument51 pagesWireline-Tools String ParvenDidik SafdaliNo ratings yet

- Calculation of Wind-Induced Dynamic Load of Transmission Tower Considering Coupled Vibration Affection of Conductors (Viento en Torre y Vano)Document5 pagesCalculation of Wind-Induced Dynamic Load of Transmission Tower Considering Coupled Vibration Affection of Conductors (Viento en Torre y Vano)David Matatan PérezNo ratings yet

- Pci Manual For The Design Hollow Core SlabsDocument141 pagesPci Manual For The Design Hollow Core Slabsmedodo100% (4)

- INTERPRETING CONCRETE TEST RESULTSDocument22 pagesINTERPRETING CONCRETE TEST RESULTSNurHaziqahNo ratings yet