Professional Documents

Culture Documents

1485 - Ec0234

Uploaded by

Deepak HoleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1485 - Ec0234

Uploaded by

Deepak HoleCopyright:

Available Formats

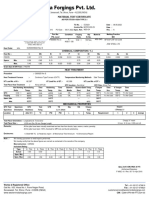

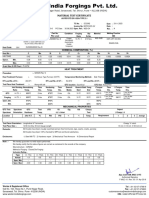

MATERIAL TEST CERTIFICATE

AS PER STD EN 10204 TYPE 3.1

Customer : TechnipFMC TC No. : EC0231 Date : 06.06.2022

Invoice No.: WIF/EX/22-23/ Date :

P.O. No.: 4500608712 Line Item: 0010 PO Date : 08.04.2022 Spec. Ref.: M25124 Rev. : A

Die No. Description Part No. Condition Forging Qty Material Melting Practice

Drg. No. PSL Level Ratio Sr.No. Mill

TOP ENTRY BODY FORGING, F/

1485 P565885 Rev C 5.02 : 1 40 Nos. BF-EOF-LRF-VD-CCM

CHECK VALVE, MAX TOP ENTRY, NQDT / SB

3 15000 CWP AISI 4340 ALLOY AISI 4340

STEEL SPEC M25124 - JSW STEEL LTD

Heat Code: MGG DU500049322 Rev B

CHEMICAL COMPOSITION ( % )

Heat No :- C Mn Si S P Cr Ni Mo Sn As Sb

F05377 0.40 0.74 0.23 0.006 0.009 0.84 1.80 0.24 0.004 0.0020 0.0010

Specn. Min. 0.38 0.65 0.15 - - 0.70 1.65 0.20 - - -

Max. 0.43 0.85 0.35 0.025 0.025 0.90 2.00 0.30 - - -

Grain Size (6 OR Finer) : 7 ASTM

HEAT TREATMENT

Procedure :- Q00025 Rev S

Heat Treatment Furnace :- Continous Type Furnace (CHTF) Temperature Monitoring Method:- Side Thermocouples in the Working Zone ( Method A)

HT Load No. of N :- CX-239 HT Load No. of QT :- CX-240 HT Load No. of DT :- CX-242-B Qty :- 40 Nos.

Test Piece Heat Treatment :- Along with job QTC location:- Sacrificial QTC Size- Actual Part

Hot Working Normalising Time Hardening Time Quench Quench Bath Temp. I Temper Time II Temper Time

Ratio Temp. Hrs. Temp. Hrs. Media Start End Temp. Hrs. Temp. Hrs.

QTC 5.02 : 1 900⁰C 4.40 870⁰C 4.40 OIL 28°C 66°C 610°C 7 (Air Cool) 590°C 7 (Air Cool)

Forging 5.02 : 1 900⁰C 4.40 870⁰C 4.40 OIL 28°C 66°C 610°C 7 (Air Cool) 590°C 7 (Air Cool)

Specn. Min. 870⁰C 840⁰C --- --- 580⁰C --

Max. 925⁰C 900⁰C -- 80⁰C 680⁰C --

MECHANICAL PROPERTIES

QTC Test Specimen QTC Test UTS YS Elg RA Charpy Impact

Specimen Orientation Hardness Temp. 0.2 % Offset Test ( Charpy ) J

Location after H.T. ⁰C PSI PSI % % Temp. Requirement 1 2 3 Average

Test Piece Orientation:- Longitudinal & Transverse Charpy 'V' notch

Test Piece Size :- 12.50 mm Dia, 50 mm Gauge Length 10 mm X 10 mm X 55 mm LG

Remarks : All the jobs have been visually examined and are free from bursts, laps, seams, cracks, porosity.

All the jobs have been 100% checked for MPI test and found satisfactory.

Enclosures: 1) Steel Mill TC 2) Hardness report 3) Mechanical Test Annexure 4) Dimensional Report

Note :- We hereby guarantee no weld repairs performed.

. We hereby certify that the above figures are correct as contained in the records of the company

Macrostructure - C2R2S2

Inclusion Rating -

Type A - Thin A - Thick B - Thin B - Thick C - Thin C - Thick D - Thin D - Thick

Actual 1.00 0.50 0.50 - - - 1.00 0.00

Spec. Min - - - - - - - -

Spec. Max 2.00 1.50 2.00 1.00 1.00 1.00 1.50 1.00

Ajay Joshi (GM, MQC & HT)

Authorised Signatory

F-MQC-10 / Rev. 00 / 01-Apr-2016

Works & Registered Office Tel : +91-02137-679819

Gat No. 163, Hissa No.1, Pune-Nagar Road, Fax : +91-02137-679820

Sanaswadi, Tal. Shirur, Pune- 412208 (INDIA) customerservice@westernindiaforgings.com

www.westernindiaforgings.com CIN : U28910PN1981PTC024155

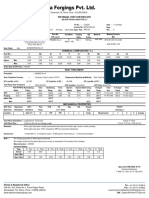

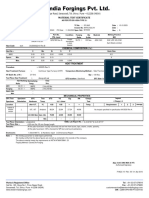

HARDNESS TEST REPORT

Customer:- TechnipFMC TC No: EC0231

P.O. No.:- 4500608712 Line Item: 0010 PO Date : 08.04.2022 Date : 06.06.2022

TOP ENTRY BODY FORGING, CHECK

Item : VALVE, MAX TOP ENTRY, 3 15000 CWP Material : AISI 4340 EC0191

AISI 4340 ALLOY STEEL SPEC M25124

Part No.: P565885 Rev C Heat No. : F05377

Drawing No.: DU500049322 Rev B Ambient Temp : 30°C

Die No.: 1485 Hardness Range:- 285-341 HBW

Qty.: 40 Nos. Test Method : Brinell Hardness Test

Vendor Sr.No.: - Equipment Used: Deep Throat Hardness Tester

HT Load No.: N CX-239 QT CX-240 Sr No. 2015/01

Reference Standard: ASTM E10 Machine Make: FSA

Load Applied: 3000 Kgs Calibration Agency: SME Cal. Center

Type of Penetrator: Dia 10 mm Carbide Ball Certificate No.: SME/22/183

Std Block Details: SH-0001/22 (Hardness value - 300.4 HBW) Calibrated On: 14.01.2022

Entity Performing Test: WIF Sanaswadi Calibration Due On: 13.01.2023

Hardness

Q03006 Rev. AC / Q03009 Rev. X Date of Test :- 19 & 20.05.2022

Procedure :-

Precise Measuring Method of HBW Impression : Type B : Hand-Held Microscope with fixed measuring lines.

Sr. No. Hardness in HBW

40 Nos. 285-321 HBW

Test Performed By Reviewed By Approved By :

Atul Jedhe Satish Gadgil (Sr.Manager HT) Ajay Joshi (GM, MQC & HT)

F-HT-10 / Rev. 00 / 01-Apr-2016

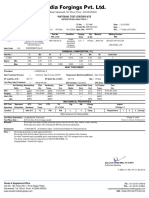

Certificate of Compliance

Customer : TechnipFMC TC No.: EC0231

Date: 06.06.2022

Die No. : 1485 Heat Code : MGG

PO No : 4500608712 Line Item No : 0010

Offer Qty. : 40 Nos.

Part No/ Rev : P565885 Rev C Drg No / Rev : DU500049322 Rev B

Part Name : TOP ENTRY BODY FORGING, Serial No. : -

CHECK VALVE, MAX TOP ENTRY, 3

15000 CWP AISI 4340 ALLOY STEEL

SPEC M25124

I. Material

A. Material Type : AISI 4340

B. Material Spec/ Rev. : As per Spec no : M25124 Rev No. A

C. Material Test Report No : Mill Heat No : F05377

II. Dimensional

A. AQL : AS PER QUALITY PLAN B. Sample Size : 8 Nos

III. Secondary Process : Heat Treatment

A. Process Name : Normalised

Heat Lot No. : CX-239 Process Spec : Q00025 Rev S

B. Process Name : QT DT

Heat Lot No. : CX-240 CX-242-B Process Spec : Q00025 Rev S

IV. NDE

A. Process Name : MPI

Certificate No : NA Process Spec : NA

A. Process Name : UT

Certificate No : NA Process Spec : NA

This is certified that subjected material is manufactured from material mentioned above &

verified by us as per written sample size & found conforming to requirements.

Sign with Stamp

Ajay Joshi (GM, MQC & HT)

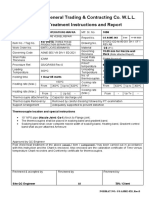

Mechanical Test Annexure

Die No.: 1485 Material Grade: AISI 4340

Heat No.: F05377 HT Lot No. : CX-240

Heat Code: MGG

TENSILE TEST

UTS YS Elg RA

QTC Test QTC Hardness after

Specimen Test Temp. NABL Lab Sample

Specimen H.T. 0.2 % Offset

Orientation (⁰C) Report No. No.

Location HBW

PSI PSI % %

L B-22-2429-P 145862 128474 20.70 62.33

0.5" Below HT

321 , 321 Ambient 1

Surface

T B-22-2430-P 145769 127663 20.00 54.77

285-341 Spec. Min. 130000.00 110000.00 16.00 35.00

IMPACT TEST

QTC Test

Specimen Requirement Test Temp. NABL Lab Sample

Specimen 1 2 3 Average

Orientation (⁰C) Report No. No.

Location

Avg. - 42 J Min

66 60 86 70.67

Single - 32 J Min

L LE - 0.38 mm Min B-22-2429-P 0.85 0.8 1.07 0.91

%Shear - Report 60 55 65 60.00

0.5" Below HT

-40°C 1

Surface Avg. - 28 J Min

50 50 52 50.67

Single - 18.7 J Min

T LE - Report B-22-2430-P 0.72 0.73 0.75 0.73

%Shear - Report 40 40 45 41.67

Ajay Joshi (GM, MQC & HT)

Authorised Signatory

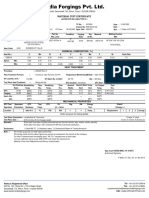

Mechanical Test Annexure

Die No.: 1485 Material Grade: AISI 4340

Heat No.: F05377 HT Lot No. : CX-240

Heat Code: MGG

TENSILE TEST

UTS YS Elg RA

QTC Test QTC Hardness after

Specimen Test Temp. NABL Lab Sample

Specimen H.T. 0.2 % Offset

Orientation (⁰C) Report No. No.

Location HBW

PSI PSI % %

L B-22-2536-P 146083 129002 20.24 60.99

0.5" Below HT

321 , 321 Ambient 2

Surface

T B-22-2537-P 146632 129794 18.48 60.54

285-341 Spec. Min. 130000.00 110000.00 16.00 35.00

IMPACT TEST

QTC Test

Specimen Requirement Test Temp. NABL Lab Sample

Specimen 1 2 3 Average

Orientation (⁰C) Report No. No.

Location

Avg. - 42 J Min

76 78 80 78.00

Single - 32 J Min

L LE - 0.38 mm Min B-22-2536-P 0.98 1 1.02 1.00

%Shear - Report 60 60 60 60.00

0.5" Below HT

-40°C 2

Surface Avg. - 28 J Min

66 66 60 64.00

Single - 18.7 J Min

T LE - Report B-22-2537-P 0.90 0.88 0.86 0.88

%Shear - Report 55 55 55 55.00

Ajay Joshi (GM, MQC & HT)

Authorised Signatory

You might also like

- Floors & Trench Drains A112.6.3 2001Document18 pagesFloors & Trench Drains A112.6.3 2001Anonymous G6ceYCzwt100% (1)

- HT 001Document1 pageHT 001Sam Raja100% (1)

- STK/WIF/20-21/283 Bar No.: QTC With DespatchDocument58 pagesSTK/WIF/20-21/283 Bar No.: QTC With DespatchDeepak HoleNo ratings yet

- General Structural / Construction Notes and Specifications: Wall Footing Details (Where Applicable)Document5 pagesGeneral Structural / Construction Notes and Specifications: Wall Footing Details (Where Applicable)anon_181338447No ratings yet

- Grade Slab DesignDocument6 pagesGrade Slab DesignMALAY MRIDHANo ratings yet

- AISI 4130 To API 6A Ed00Document2 pagesAISI 4130 To API 6A Ed00EDWIN M.PNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- Astm A350 LF2 PDFDocument1 pageAstm A350 LF2 PDFAna Raquel SantosNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5armin heidariNo ratings yet

- Importance of Facade TestingDocument10 pagesImportance of Facade Testingy2kareinNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Magotteaux Braunverfrb ENDOCDocument2 pagesMagotteaux Braunverfrb ENDOCSelwyn MunatsiNo ratings yet

- BS en 14620 Part 3Document24 pagesBS en 14620 Part 3ASHISH SHRIVASTAVANo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- 1485 - Ec0216Document6 pages1485 - Ec0216Deepak HoleNo ratings yet

- 1485 - Ec0231Document6 pages1485 - Ec0231Deepak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- HT 003Document1 pageHT 003Sam RajaNo ratings yet

- HT 002Document1 pageHT 002Sam RajaNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- MTC - A335 P22 Seamless PipeDocument1 pageMTC - A335 P22 Seamless PipeSri GangaNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- MTR - HT# 52154Document1 pageMTR - HT# 52154ColinNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Inspection Report - Motor+16701004051+KT - 12V1600G80SDocument1 pageInspection Report - Motor+16701004051+KT - 12V1600G80SChristopherNo ratings yet

- NE6188CZDocument9 pagesNE6188CZhobolghaniNo ratings yet

- 21app0808 MTR-14Document1 page21app0808 MTR-14gmendoza.logistica3No ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Material Test Report: Cert No: 697430Document1 pageMaterial Test Report: Cert No: 697430Abozar BilanNo ratings yet

- 1.VFB-150-2 Tr.316 90601-077 QRDocument1 page1.VFB-150-2 Tr.316 90601-077 QRSurya ManaluNo ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- 41 CR 4Document2 pages41 CR 4Jhon ChitNo ratings yet

- Page 3 Tsi MTC Plate (MTC - 249)Document2 pagesPage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Cricri CriNo ratings yet

- NST 3.1 PDFDocument1 pageNST 3.1 PDFPankaj RaneNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNo ratings yet

- LM72CZ V01Document8 pagesLM72CZ V01hobolghaniNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- KJ290CYDocument8 pagesKJ290CYhobolghaniNo ratings yet

- H151Document2 pagesH151KalpanaBansalNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 1485 - EC2169-signedDocument4 pages1485 - EC2169-signedDeepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- C To DDocument1 pageC To DDeepak HoleNo ratings yet

- 4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDocument3 pages4340/ BS EN10083 817M40, 140 KSI (965 MPA), FORGINGS AND BAR Stock, Restricted Use SubseaDeepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- Deepak Dattatray HoleDocument2 pagesDeepak Dattatray HoleDeepak HoleNo ratings yet

- Bar No 4002Document2 pagesBar No 4002Deepak HoleNo ratings yet

- F-HRA-05 On Job Training Record R04Document3 pagesF-HRA-05 On Job Training Record R04Deepak HoleNo ratings yet

- Htytdjhfjgk LJ K JKFTDRGBNDocument45 pagesHtytdjhfjgk LJ K JKFTDRGBNDeepak HoleNo ratings yet

- Repayment-Deepak As On Date 07.12.2022Document2 pagesRepayment-Deepak As On Date 07.12.2022Deepak HoleNo ratings yet

- Deviation Request - Raltech 10 10 2020Document1 pageDeviation Request - Raltech 10 10 2020Deepak HoleNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanDeepak HoleNo ratings yet

- Bar No - 5763: Test CertificateDocument2 pagesBar No - 5763: Test CertificateDeepak HoleNo ratings yet

- EleconDocument2 pagesEleconDeepak HoleNo ratings yet

- STK/WIF/1920/1691 Bar No.: C CR MN Mo Ni P S Si VDocument32 pagesSTK/WIF/1920/1691 Bar No.: C CR MN Mo Ni P S Si VDeepak HoleNo ratings yet

- Corrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDocument1 pageCorrective and Preventive Action (8D) Report: Cust. Complaint Serial Number Cust. Complaint Ref. No. & DateDeepak HoleNo ratings yet

- TEST PIECE STAMPING REPORT - Pole End Plate DAK MI Die. No. 4510-RestampDocument1 pageTEST PIECE STAMPING REPORT - Pole End Plate DAK MI Die. No. 4510-RestampDeepak HoleNo ratings yet

- Die No Product TP Req Alloy ProcessDocument2 pagesDie No Product TP Req Alloy ProcessDeepak HoleNo ratings yet

- FmatterDocument16 pagesFmatterMuhammad Azanuddin Abdul JalilNo ratings yet

- 03 Sheet Metal FormingDocument38 pages03 Sheet Metal FormingPanNo ratings yet

- CP 636 CatalogueDocument1 pageCP 636 CatalogueMohammed KabiruddinNo ratings yet

- Price-List Polycab Industrial Flexible CablesDocument4 pagesPrice-List Polycab Industrial Flexible CablessaurabhNo ratings yet

- Heat Treatment: Degarmo'S Materials and Processing in ManufacturingDocument38 pagesHeat Treatment: Degarmo'S Materials and Processing in ManufacturingGavin Raymond Briones100% (1)

- Extruders: Horizontal and Vertical Extruders For High-Performance and Fluoro MaterialsDocument2 pagesExtruders: Horizontal and Vertical Extruders For High-Performance and Fluoro MaterialsMuhammad Nur CahyadiNo ratings yet

- CTP Engine BearingsDocument4 pagesCTP Engine BearingsmkNo ratings yet

- MMTI Product Catalogue PDFDocument76 pagesMMTI Product Catalogue PDFThamara Cienfuegos MondragonNo ratings yet

- Guardian Roof BrochureDocument20 pagesGuardian Roof BrochureGuardian RoofsNo ratings yet

- Tononoka Steel and PipeDocument30 pagesTononoka Steel and PipeShreekant KeraiNo ratings yet

- 9M402 49Document23 pages9M402 49margamkiran20033No ratings yet

- Eds 07 3102 Secondary Substation Civil DesignDocument26 pagesEds 07 3102 Secondary Substation Civil DesignUmerfarooq TawriNo ratings yet

- Manufacturing Engineering I Chapter 1Document29 pagesManufacturing Engineering I Chapter 1Abiyot egataNo ratings yet

- 72010RathGibson WeldDecayTesting TechSheet Sfs PDFDocument6 pages72010RathGibson WeldDecayTesting TechSheet Sfs PDFWalter NoceNo ratings yet

- 19SE201 - Advanced Steel Design: M. Thiruvannamalai, AP/Civil, MSEC, SivakasiDocument16 pages19SE201 - Advanced Steel Design: M. Thiruvannamalai, AP/Civil, MSEC, SivakasiNagalakshmi SanthakumarNo ratings yet

- Mandi Gobindgarh Hazardous Waste Report NGT April2021Document7 pagesMandi Gobindgarh Hazardous Waste Report NGT April2021arbaz khanNo ratings yet

- Noise Control - Flooting FloorDocument24 pagesNoise Control - Flooting FloorPraveenKatkooriNo ratings yet

- HD 35-04 Provisions For The Use of Secondary and Recycled Materials (Nov 2004)Document16 pagesHD 35-04 Provisions For The Use of Secondary and Recycled Materials (Nov 2004)sandycastleNo ratings yet

- Buehler-Sum-Met Sample Preparation TechniqueDocument136 pagesBuehler-Sum-Met Sample Preparation TechniquesgarrabNo ratings yet

- Cadangan Membina Dan Menyiapkan Sebuah Rumah BangloDocument8 pagesCadangan Membina Dan Menyiapkan Sebuah Rumah Banglomemek gamingNo ratings yet

- Minerals Important To SocietyDocument20 pagesMinerals Important To SocietyDonna Claire AngusNo ratings yet

- 303 Gold: Special Maintenance QualitiesDocument3 pages303 Gold: Special Maintenance QualitiesLee Chong EeNo ratings yet

- GF Tower Construction PhotosDocument23 pagesGF Tower Construction PhotosAVENON MardocheeNo ratings yet

- Rev Itp 1Document32 pagesRev Itp 1aksinhadce2No ratings yet