Professional Documents

Culture Documents

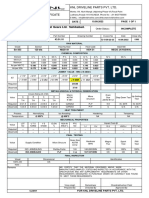

Certificate of Analysis & Testing: P.O. No. P.O. Date

Uploaded by

Fundary Shop0 ratings0% found this document useful (0 votes)

24 views1 pageThis certificate analyzes a heat of steel for torque supports. Chemical analysis shows the steel meets specifications for grade Fe540B. Mechanical tests show the steel meets or exceeds requirements for yield strength, tensile strength, and elongation. Impact toughness tests at room temperature and -20°C meet the minimum requirements. A bend test showed no cracks, meeting specifications. The certificate concludes the steel meets IS:8500-1991 Grade Fe540B standards.

Original Description:

Original Title

TC IS 8500

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis certificate analyzes a heat of steel for torque supports. Chemical analysis shows the steel meets specifications for grade Fe540B. Mechanical tests show the steel meets or exceeds requirements for yield strength, tensile strength, and elongation. Impact toughness tests at room temperature and -20°C meet the minimum requirements. A bend test showed no cracks, meeting specifications. The certificate concludes the steel meets IS:8500-1991 Grade Fe540B standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views1 pageCertificate of Analysis & Testing: P.O. No. P.O. Date

Uploaded by

Fundary ShopThis certificate analyzes a heat of steel for torque supports. Chemical analysis shows the steel meets specifications for grade Fe540B. Mechanical tests show the steel meets or exceeds requirements for yield strength, tensile strength, and elongation. Impact toughness tests at room temperature and -20°C meet the minimum requirements. A bend test showed no cracks, meeting specifications. The certificate concludes the steel meets IS:8500-1991 Grade Fe540B standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

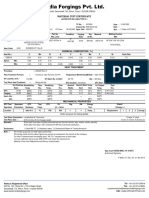

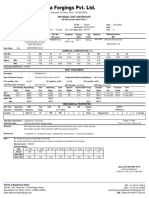

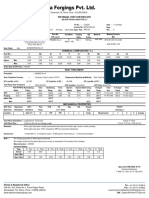

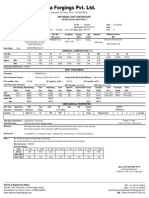

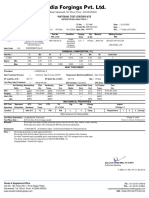

Our Lab Code No. KMRIPL/20/01/DMW/TR.

S/04 Date 30-Jan-2020

CERTIFICATE OF ANALYSIS & TESTING

Issued to : ETD/GZB Order Ref.

NORTHERN RAILWAY P.O. No. 19190972105803

GAZIABAD P.O. Date 20/9/2019

Heat No. Item Description Drawing No. Quantity

19-12-41 TORQUE SUPPORT FOR (WAG-9/WAG-7) 1209-01-218-003 44 Nos.

Sample: Test Bar

Chemical Analysis Report

Specification IS:8500 : 1991 Grade Fe540B Test Method Spectro

%C %Mn %Si %S %P %Cr %Mo %V %Ni %Cu Carbon Equivalent

Specified (Max) (Max) (Max) (Max) (Max) CE (Max)

0.20 1.60 0.45 0.045 0.045 0.44

Actual 0.19 1.10 0.37 0.011 0.026 0.14 0.03 0.001 0.12 0.01 0.4162

Mechanical Prooperties

Parameters Required Specification Actual Test Method

Yield Strength (Min) 380 MPa IS:8500-1991 393 MPa IS 1608 :2005

Tensile Strength (Min) 540 MPa Grade Fe540B 550 MPa IS 1608 :2005

Elongation % (Min) 20% 29.20% IS 1608 :2005

5.65 𝑆𝑜

Charpy- V notch, At Room At At Room At IS 1757-1988

Impact Toughness, Temp (−)𝟐𝟎℃ Temp (−)20℃

Joules, Min, 50 J 25 J 122 J 54 J

118 J 56 J

120 J 58 J

(Average of 3 Values) Avg. 120 J Avg. 56 J

Impact Test Temperature : Room Temperatre 25C ± 2C and (−)20℃

Bend 3t (t= Thickness of In bend sample no cracks were observed

IS 1599 : 1985

(Internal Diameter) the test piece), on the outer surface.

Angle of bend 180

Remarks : The above Chemical & Physical properties conform to IS:8500-1991 Grade Fe540B

Our Foundry is approved by RDSO Lucknow as a Class -A as per IS 12117

FOR KHARAGPUR METAL REFORMING INDUSTRIES PVT. LTD

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- 1485 - Ec0231Document6 pages1485 - Ec0231Deepak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1485 - Ec0216Document6 pages1485 - Ec0216Deepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1485 - Ec0234Document5 pages1485 - Ec0234Deepak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- ESPARRAGO A-193 B7 3l4-10 X 3660Document1 pageESPARRAGO A-193 B7 3l4-10 X 3660Incoservspa cl100% (1)

- F-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-HorizontalDocument7 pagesF-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-Horizontalenrique.chavezNo ratings yet

- Wpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetDocument2 pagesWpbf4054Imnep Pibiflex 4054 Im Nero: Technical Data SheetankitNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- MS Sheets MTCDocument6 pagesMS Sheets MTCAmit Kumar OjhaNo ratings yet

- Verti-Cor 3XP - 1.2mm - Part 720919 - Lot 2001309066Document1 pageVerti-Cor 3XP - 1.2mm - Part 720919 - Lot 2001309066Brad MannNo ratings yet

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 21app0808 MTR-14Document1 page21app0808 MTR-14gmendoza.logistica3No ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Abistir 7120Document2 pagesAbistir 7120Phung LucNo ratings yet

- 40nicrmo7-3: Steel GradeDocument3 pages40nicrmo7-3: Steel GradeGanesh K CNo ratings yet

- 43-Utm Load Cell Tensile Calibration CartificateDocument1 page43-Utm Load Cell Tensile Calibration CartificateCustomer SupportNo ratings yet

- Type 1 BricksDocument20 pagesType 1 Bricksprachi410No ratings yet

- Ict 1 Furan 17 5 23Document1 pageIct 1 Furan 17 5 23Boddu ThirupathiNo ratings yet

- GL50AADocument2 pagesGL50AAأبو زينب المهندسNo ratings yet

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesNo ratings yet

- Ningbo Brightfast Co.,Ltd: Certificate of Quality En10204 3.1Document1 pageNingbo Brightfast Co.,Ltd: Certificate of Quality En10204 3.1amicikicikNo ratings yet

- OT37137F 14/09/2011 07:02:20 A.M. - Pass - Pass Pass: Motor ID Time Temp Resist Megohm Da/Pi DC SurgeDocument10 pagesOT37137F 14/09/2011 07:02:20 A.M. - Pass - Pass Pass: Motor ID Time Temp Resist Megohm Da/Pi DC SurgeMyM Bobinados Ind. SoporTecnicoNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Electrical Test Report - 10MVA TransformerDocument15 pagesElectrical Test Report - 10MVA TransformerJherie CeeNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- 4 Chip Built in RGBW Smd5050Document5 pages4 Chip Built in RGBW Smd5050ZmecleuPeBatzNo ratings yet

- Special Steels A320 L43: American Standards AstmDocument1 pageSpecial Steels A320 L43: American Standards Astmsamirfun2006No ratings yet

- AbcDocument2 pagesAbcsurendarNo ratings yet

- Barra Astm A193 Grado B7 1Document1 pageBarra Astm A193 Grado B7 1Patrocinio Parra GalindoNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- TLP181 Datasheet en 20170512Document9 pagesTLP181 Datasheet en 20170512FranklinNo ratings yet

- Steel Grade: Material Data SheetDocument5 pagesSteel Grade: Material Data SheetNaveen HlNo ratings yet

- Zhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Document1 pageZhengbang Super Alloy Ltd.: BS EN 10204.3.1/产品质量证明Sales HBS SolutionsNo ratings yet

- DatasheetDocument6 pagesDatasheetTop Techno Lab CompanyNo ratings yet

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- RF 28 (19060041)Document1 pageRF 28 (19060041)Fundary ShopNo ratings yet

- Application To Atomic Energy Regulatory Board (Aerb) For Safety Status ReportDocument4 pagesApplication To Atomic Energy Regulatory Board (Aerb) For Safety Status ReportFundary ShopNo ratings yet

- Parameter 1:60 1:120 1:240 1:480: Sample Type:SerumDocument15 pagesParameter 1:60 1:120 1:240 1:480: Sample Type:SerumFundary ShopNo ratings yet

- GE Oil & Gas India Private Limited: BakerhughesDocument3 pagesGE Oil & Gas India Private Limited: BakerhughesFundary ShopNo ratings yet

- Baker Hughes, A GE Company Inspection Technologies BVBADocument1 pageBaker Hughes, A GE Company Inspection Technologies BVBAFundary ShopNo ratings yet

- Annex-1: Test Procedures For Different Types of 'Igred'Document3 pagesAnnex-1: Test Procedures For Different Types of 'Igred'Fundary ShopNo ratings yet

- Nabl 165Document12 pagesNabl 165Fundary ShopNo ratings yet

- Institute Number:: Intimation of Discrepancy DateDocument2 pagesInstitute Number:: Intimation of Discrepancy DateFundary ShopNo ratings yet

- Nabl 500 PDFDocument124 pagesNabl 500 PDFFundary ShopNo ratings yet

- CH 14 Waves and SoundDocument2 pagesCH 14 Waves and SoundMelindaNo ratings yet

- Additive Manufacturing of Steels: A Review of Achievements and ChallengesDocument44 pagesAdditive Manufacturing of Steels: A Review of Achievements and ChallengesExp KNo ratings yet

- NORSOK S-001 Fire IntegrityDocument4 pagesNORSOK S-001 Fire IntegrityAle BrambiNo ratings yet

- Lab 12 - Molar Volume of A GasDocument6 pagesLab 12 - Molar Volume of A GasAnonymous WI0nbsNo ratings yet

- 00 IntroductionDocument2 pages00 IntroductionRK MEHTANo ratings yet

- Manual 26260: Governing Fundamentals and Power ManagementDocument76 pagesManual 26260: Governing Fundamentals and Power Managementmarius_1959No ratings yet

- 7 EFv NPBL RS9 BV 6 J 37 Ux LTZgiqa R6 E6 R 1 C Osu TRC XDocument18 pages7 EFv NPBL RS9 BV 6 J 37 Ux LTZgiqa R6 E6 R 1 C Osu TRC XAbhishekNo ratings yet

- Glo Sikaplan WP WT TapesDocument8 pagesGlo Sikaplan WP WT Tapesahmedmido14No ratings yet

- Drying ExamplesDocument6 pagesDrying ExamplesIsabelNo ratings yet

- 9.1 - The First Condition For Equilibrium - PhysicsDocument3 pages9.1 - The First Condition For Equilibrium - PhysicsSghdhNo ratings yet

- Ultimate Lateral Load of Slope-Stabilising Piles: Géotechnique Letters September 2017Document9 pagesUltimate Lateral Load of Slope-Stabilising Piles: Géotechnique Letters September 2017ValerioNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- Measurement of Density and Viscosity of Dodecane and Decane With A Piezoelectric Tuning Fork Over 298-448 K and 0.1-137.9 MpaDocument7 pagesMeasurement of Density and Viscosity of Dodecane and Decane With A Piezoelectric Tuning Fork Over 298-448 K and 0.1-137.9 MpaCristian Esteban ArangoNo ratings yet

- Types of Sound SensorsDocument2 pagesTypes of Sound Sensorsfasdasd123No ratings yet

- Mechanics Question Paper MAKAUTDocument8 pagesMechanics Question Paper MAKAUTArka BanerjeeNo ratings yet

- Nptel R and C Lecture Notes Lec35Document43 pagesNptel R and C Lecture Notes Lec35Kart01No ratings yet

- Makrolon For Optical Data StorageDocument10 pagesMakrolon For Optical Data Storagefriedman2013No ratings yet

- Chapter 9 - Frame Analysis (New)Document56 pagesChapter 9 - Frame Analysis (New)sorento91050% (2)

- Fundamentals of Steam System Design - I-PDocument236 pagesFundamentals of Steam System Design - I-PJesus Andres SuarezNo ratings yet

- Instrumentation Interview QuestionsDocument72 pagesInstrumentation Interview QuestionsGowtham An94% (18)

- L-1 Bituminous Mix DesignDocument86 pagesL-1 Bituminous Mix DesignrajibchattarajNo ratings yet

- The Layers of The EarthDocument34 pagesThe Layers of The Earthmyrrdane100% (1)

- Petroleum Engineering Handbook Vol 4 - Production Operations EngineeringsDocument1 pagePetroleum Engineering Handbook Vol 4 - Production Operations EngineeringsDawud PrionggodoNo ratings yet

- Che F211 1069 20230809113326Document3 pagesChe F211 1069 20230809113326ArchNo ratings yet

- Acoustic Design of AuditoriumDocument12 pagesAcoustic Design of AuditoriumNur Fateha100% (2)

- PTFE 25% Carbon FilledDocument1 pagePTFE 25% Carbon FilledIan Putra Adita WibisanaNo ratings yet

- Work Power Energy PDFDocument28 pagesWork Power Energy PDFShabbir KhanNo ratings yet

- Surveying by Jaspal SirDocument57 pagesSurveying by Jaspal SirLimpidNo ratings yet

- Resina - TDS - 10200005 - EN - EN-WEICON-F2Document2 pagesResina - TDS - 10200005 - EN - EN-WEICON-F2kakonauta1No ratings yet

- Optimizing Windows For Enhancing Daylighting Performance and Energy SavingDocument8 pagesOptimizing Windows For Enhancing Daylighting Performance and Energy Savingyanot leiNo ratings yet