Professional Documents

Culture Documents

F-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-Horizontal

Uploaded by

enrique.chavez0 ratings0% found this document useful (0 votes)

2 views7 pagesOriginal Title

F-CEM-021_CPTCH-012-19A-FCAW_AWS D1.1_PLANA-HORIZONTAL

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views7 pagesF-Cem-021 - Cptch-012-19a-Fcaw - Aws D1.1 - Plana-Horizontal

Uploaded by

enrique.chavezCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

CERTIFICATE OF CONFORMANCE

(AWS A5.20 D1.8 / FEMA 353)

ESAB SeAH Corporation

56, JEONGDONG-RO 62BEON-GIL, SEONGSAN-GU

CHANGWON-SI, GYEONGNAM, KOREA 641-120 Certificate No. : ESC-Seismic-16-1215 (Rev.0)

TEL: 82-55-289-8111, URL http://www.esab.co.kr Issued Date : December 15, 2016

Brand Name : Dual Shield 7100Ultra P/O No. :

Diameter : 1.2mm

AWS Classification : AWS A5.36 E71T1-C1A2-CS1-DH8 Weight : 10,800 kg

AWS A5.36 E71T1-M21A2-CS1-DH8 Lot Number : F103A6H400

EN ISO 17632-B T493T1-1M/CA-H10 Shielding Gas : 100%CO2

AWS A5.20 E71T-1C/T-9C Classification Testing

Shielding Gas : C1 (100%CO2)

Test Condition : As Welded

Typical Undiluted Weld Metal Analysis (wt%) Typical Mechanical Properties

C 0.04 Yield Strength, ksi (Mpa) 82 (563)

Mn 1.39 Tensile Strength, ksi (Mpa) 89 (616)

Si 0.57 Elongation(2"), % 28

S 0.005

P 0.011 Typical Charpy V-Notch Impact Properties, Ft.-lbs (Joule)

Cr 0.03

Ni 0.02 Testing Temperature

Mo 0.01 0℉ (-18℃) 82 (111)

V 0.02 -20℉ (-30℃) 63 (86)

Cu 0.01

AWS A5.20 "D" Designator Testing

Shielding Gas : C1 (100%CO2)

Test Condition : As Welded

Low Heat Input High Heat Input

Test Settings

Sielding Gas 100% CO2 100% CO2

Heat Input Range, KJ/in (KJ/mm) 25-32(1.0-1.3) 78-85(3.0-3.3)

Heat Input, KJ/in (KJ/mm) 27.6 (1.1) 78.9 (3.1)

Current, amps 240 205

Voltage, volts 27 24

Polarity DCEP DCEP

ESO, in (mm) 3/4 (16) 3/4 (16)

Weld Position 1G 3G

Pass / Layer, Sequence 1F,2S,2T,2Q 2F,2S

Preheat Temp. ℉ (℃) 70 (21) 300 (150)

Interpass Temp. ℉ (℃) 212 (100) 480 (250)

Travel Speed, in/min (㎝/min) 35.9 (14.1) 9.5 (3.7)

Typical Mechanical Properties

Testing Conditions As Welded As Welded

Yield Strength, ksi (Mpa) 84.0 (579) 67 (466)

Tensile Strength, ksi (Mpa) 90.9 (627) 79 (547)

Elongation(2"), % 28 33

Typical Charpy V-Notch Impact

Testing Conditions As Welded As Welded

Temperature, ℉ (℃) 70 (20) 70 (20)

Average : Ft-lbs (Joule) 105 (143) 122 (165)

Extended Exposure Results

Shielding Gas Test Conditions Exposure Time Current (amps) Voltage (Volts) Diffusible Hydrogen

100% CO2 80℉ at 80% humidity 6 days (144hrs) 230 27 4.1ml/100g

AWS D1.8/D1.8M:2005, Annex D requirement : < 16 ml/100g after 72hour exposure at 80℉, 80% humidity

The undersigned certifies that the product supplied will meet the applicable ESAB SeAH Corp.

AWS filler metal specification including supplemental "D"designator (if, applicable) Quality Management Team

when tested in accordance with those specifications. Young-Sook, Kim

The ESAB SeAH Corp. quality system is audited and certified by ABS, LR and ASME.

This product conform to AWS A5.20/A5.20M:2005 with supplemental "D"designator

and FMEA 353 requirement.

General Manager

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Durability For Working Life of 120 YearsDocument11 pagesDurability For Working Life of 120 YearsDEBASIS BARMANNo ratings yet

- 003 Bt5 Pre-Engineered BuildingDocument31 pages003 Bt5 Pre-Engineered BuildingNicole VerosilNo ratings yet

- A Practical Guide To Fibre Science (PDFDrive)Document311 pagesA Practical Guide To Fibre Science (PDFDrive)Ola SeragNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Piping Fabrication Installation Erection and Testing PDFDocument33 pagesPiping Fabrication Installation Erection and Testing PDFDeepak0% (1)

- A Flair For SpringDocument8 pagesA Flair For SpringMonica MazzoniNo ratings yet

- Textile ListDocument13 pagesTextile ListMohsin Yasin55% (11)

- BASF industrial+Metal+CoatingsDocument12 pagesBASF industrial+Metal+CoatingsMaria Eugenia CiveiraNo ratings yet

- 2 Inch OutputPCVDocument1 page2 Inch OutputPCVDuy Nguyễn VănNo ratings yet

- Guide For ASME AUDIT - 2018: Table - U3 Mandatory Appendix 43 UG-20 (F)Document1 pageGuide For ASME AUDIT - 2018: Table - U3 Mandatory Appendix 43 UG-20 (F)anon_673643629No ratings yet

- A Study of Acrylic Dispersions Used in The Treatment of PaintingsDocument12 pagesA Study of Acrylic Dispersions Used in The Treatment of PaintingsMilica Stojanov100% (1)

- ASTM C55 - 01aDocument3 pagesASTM C55 - 01aMarco Soto100% (3)

- HTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFDocument14 pagesHTRI Thermal Design Sheet of BEU Type Shell Tube Heat Exchanger PDFSivi NallamothuNo ratings yet

- Superarc LA-75: Conformances Key FeaturesDocument2 pagesSuperarc LA-75: Conformances Key Featuressattar12345No ratings yet

- RicisDocument1 pageRicisHariyono Rudi NovantoNo ratings yet

- PramonnoDocument1 pagePramonnoHariyono Rudi NovantoNo ratings yet

- ChocolatosDocument1 pageChocolatosHariyono Rudi NovantoNo ratings yet

- Poron 4701-30 Very SoftDocument2 pagesPoron 4701-30 Very SoftItzelMalagonVeraNo ratings yet

- Kapton HN Data SheetDocument5 pagesKapton HN Data Sheet谢朋亨No ratings yet

- Output Summary: SI UnitsDocument14 pagesOutput Summary: SI UnitsEduardoNo ratings yet

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- DPP AGRU Geosinteticos DataSheet-SmoothLiner-HighDensityDocument1 pageDPP AGRU Geosinteticos DataSheet-SmoothLiner-HighDensityArquimedes Juarez SaavedraNo ratings yet

- 01f Hyundai Supercored 71H Data Sheet 2022Document2 pages01f Hyundai Supercored 71H Data Sheet 2022DHANEESH VELLILAPULLINo ratings yet

- Hyundai Supercored 71HDocument9 pagesHyundai Supercored 71HPongwitt BoonayamaneeNo ratings yet

- Pipeliner 70S-G: Conformances Key FeaturesDocument2 pagesPipeliner 70S-G: Conformances Key FeaturesZanuardi YahyaNo ratings yet

- Output Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesDocument1 pageOutput Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesIdil FitriNo ratings yet

- Catalogue - 71-T8 (Rev06)Document7 pagesCatalogue - 71-T8 (Rev06)Suntech Testing Limited STLNo ratings yet

- Superarc L-59: Conformances Key FeaturesDocument2 pagesSuperarc L-59: Conformances Key FeaturesjustinNo ratings yet

- SF-71 en EngDocument2 pagesSF-71 en EngbvbarcNo ratings yet

- Datos Técnicos Del Compressor - L63B752DBLB 208-230V60Hz 200-220V50Hz 3Document1 pageDatos Técnicos Del Compressor - L63B752DBLB 208-230V60Hz 200-220V50Hz 3Julio César Samamé VegaNo ratings yet

- Q1 Lot Number: 15888757: Certificate of ConformanceDocument2 pagesQ1 Lot Number: 15888757: Certificate of ConformanceDesdeAquiHastaAllaNo ratings yet

- Shield Bright 309L-1Document1 pageShield Bright 309L-1adanmeneses1No ratings yet

- Jpf5-E-0022 - 17 08 22Document10 pagesJpf5-E-0022 - 17 08 22pradeep yadavNo ratings yet

- FabCO 811N1Document2 pagesFabCO 811N1Sleyda MunozNo ratings yet

- Fio Fluxado Mx-100tDocument1 pageFio Fluxado Mx-100tFilipe CordeiroNo ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- Bergquist Gap Pad Comparison TableDocument1 pageBergquist Gap Pad Comparison TableMaike SongNo ratings yet

- ESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root GapDocument1 pageESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root Gapalok987No ratings yet

- SC-71MSR: Hyundai Welding Co., LTDDocument7 pagesSC-71MSR: Hyundai Welding Co., LTDRaviTeja BhamidiNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- GL50AADocument2 pagesGL50AAأبو زينب المهندسNo ratings yet

- Polyethylene PE1000 - Natural & Blue: PAR Group LTD Technical Data SheetDocument2 pagesPolyethylene PE1000 - Natural & Blue: PAR Group LTD Technical Data SheetMaiquel Eduardo ErnNo ratings yet

- Material Datea 2.4602Document3 pagesMaterial Datea 2.4602Charwin XiaoNo ratings yet

- Properties of Commercially Pure Titanium and Titanium AlloysDocument27 pagesProperties of Commercially Pure Titanium and Titanium AlloysZhu DanielNo ratings yet

- SL20GDocument2 pagesSL20Gridho_48No ratings yet

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourNo ratings yet

- Verti-Cor 3XP - 1.2mm - Part 720919 - Lot 2001309066Document1 pageVerti-Cor 3XP - 1.2mm - Part 720919 - Lot 2001309066Brad MannNo ratings yet

- Certificado de Cumplimiento Alambre 0.062Document2 pagesCertificado de Cumplimiento Alambre 0.062gizaloNo ratings yet

- Q1 DisplayDocument1 pageQ1 DisplayOscar BasantesNo ratings yet

- Product Certification FabCo 811N1 Lot 01873Document1 pageProduct Certification FabCo 811N1 Lot 01873Sleyda MunozNo ratings yet

- Ricis 2Document1 pageRicis 2Hariyono Rudi NovantoNo ratings yet

- 3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetDocument30 pages3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetGiancarloRichardRivadeneyraMirandaNo ratings yet

- Datasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1Document3 pagesDatasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1bhuvandesignNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Heat Stable Reactor Heater 1.5 KG - HR (9.24 MM ID Tube)Document38 pagesHeat Stable Reactor Heater 1.5 KG - HR (9.24 MM ID Tube)Ravindra BarangeNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Aisi 4140Document3 pagesAisi 4140Patrícia CanazartNo ratings yet

- Calculation Economizer - PL ProjectDocument12 pagesCalculation Economizer - PL ProjectXuan Man NguyenNo ratings yet

- Ultracore 360 C71: Conformances Key FeaturesDocument3 pagesUltracore 360 C71: Conformances Key FeaturesYousab CreatorNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- See Runtime Message Report For Warning MessagesDocument1 pageSee Runtime Message Report For Warning MessagesAnonymous Q2hxfbghNo ratings yet

- Ultrason E 3010: Polyethersulfone (PESU)Document2 pagesUltrason E 3010: Polyethersulfone (PESU)AmirNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- San 310CTRDocument2 pagesSan 310CTRNguyễn Hồng NamNo ratings yet

- Common Mode Chokes Pwc0603St Series: PWC 0603 S T 900 SDocument8 pagesCommon Mode Chokes Pwc0603St Series: PWC 0603 S T 900 SscribdpinoNo ratings yet

- Campus QuestionsDocument11 pagesCampus Questionssumitha ganesanNo ratings yet

- Experiment 02 The Determination of A Chemical FormulaDocument7 pagesExperiment 02 The Determination of A Chemical FormulaAlexya Rosas0% (1)

- PIR CatalogueDocument12 pagesPIR CatalogueUmen AryanNo ratings yet

- CBSE Class 10 Chemistry Worksheet - Chemical Reactions and EquationsDocument3 pagesCBSE Class 10 Chemistry Worksheet - Chemical Reactions and EquationsLushila Minj100% (1)

- Final Report: Industrial Training (Construction of Flyover)Document16 pagesFinal Report: Industrial Training (Construction of Flyover)Abhishek kumar100% (1)

- Pot TaryDocument19 pagesPot TaryAjit NehulkarNo ratings yet

- Agar Extraction Process For Gracilaria CliftoniiDocument7 pagesAgar Extraction Process For Gracilaria CliftoniiAdaNo ratings yet

- Class Never Goes Out of Style: List PriceDocument6 pagesClass Never Goes Out of Style: List Pricekarthikmr85No ratings yet

- MCS SpacerDocument3 pagesMCS SpacerAquiles CarreraNo ratings yet

- AlloysDocument7 pagesAlloysRAKIB AL MAHDINo ratings yet

- 169-188 Ao WireDocument20 pages169-188 Ao Wirersgm yarsiNo ratings yet

- Fly AshDocument35 pagesFly Ashb ramachandraNo ratings yet

- Ufgs 03 42 13.00 10Document20 pagesUfgs 03 42 13.00 10jackcan501No ratings yet

- Unit Process 009Document15 pagesUnit Process 009Talha ImtiazNo ratings yet

- Sikabit® W-15: Product Data SheetDocument3 pagesSikabit® W-15: Product Data SheetWWNNo ratings yet

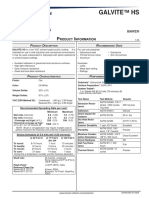

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- BS 4479-9-1990Document11 pagesBS 4479-9-1990윤규섭No ratings yet

- Proposal PDFDocument3 pagesProposal PDFওয়াহিদ মুরাদNo ratings yet

- Rate of Reaction 1 QPDocument11 pagesRate of Reaction 1 QPRobert EdwardsNo ratings yet

- Textile Industries in India-1-1Document3 pagesTextile Industries in India-1-1S Noor TaufeeqNo ratings yet