Professional Documents

Culture Documents

Certified Material Test Report

Uploaded by

Nabilah HusnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certified Material Test Report

Uploaded by

Nabilah HusnaCopyright:

Available Formats

1801 Theurer Blvd. Winona MN 55987 Tel.

844-265-2658 Fax 507-494-9664

3939 W 56th St. Indianapolis IN 46254 Tel. 317-216-1189 Fax 317-280-2500

15009 Lee Road Houston, Texas 77032 Tel.713-460-4381 Fax.713-996-7342

Certified Material Test Report

Certificate Number: B36945-11 Date Issued: March 15, 2024

Customer Name: CIMARRON ENERGY INC. Customer Part Number: N/A

Sold To: CIOK Customer P.O.: N/A

Description: FTASS'Y 1" 8 tpi 6-3/4"/UNC-2A Marking: N/A

Finish: CLEAR ZINC Cardinal Part Number: 10502717

Quantity Shipped

Material: SWRCH45K; 45K; B7 Production Lot Quantity: 24/24

SPECIFICATION / GRADE: ASTM A194/A194M-23; ASME SA194/SA194M-23 Grade 2H

SURFACE QUALITY: In accordance with ASTM F788/F788M-20ᵋ¹ PASS

COATING: CLEAR ZINC PASS

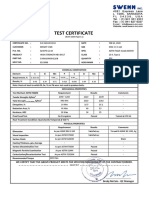

CHEMISTRY – Heat Number: J12200213

Heat Composition (WT% Heat Analysis)

Element: C Mn P S Si

Minimum: 0.40 - - - -

Maximum: - 1.00 0.040 0.050 0.40

Result: 0.45 0.70 0.011 0.005 0.18

MACROETCH (if required): ASTM E381-22; S2, R2, C2

*¹ Heat Treat Method: Tempering Temp. 520 ºC

Attribute Test Method Sample Size Requirement Result Acceptance

Hardness ASTM A370-2023 2 24-35 HRC 30-32 HRC PASS

Proof Load ASTM A962/A962M-23 2 Min: 106,000 lbf 106,000 lbf PASS

ZP Thickness ASTM B568(98)-2021 22 ASTM F1941-16/min.3 µm 6.3-7.5 µm PASS

ASTM F1941-16/6H no

Salt Spray Test ASTM B117-2019 15 PASS PASS

white rust, 24H no red rust

Decarburization ASTM F2328-17(2022) 1 - PASS PASS

Hardness after 24H at 540 ºC ASTM A194-2023 1 Min: 89 HRB 93-95 HRB PASS

Page 1 of 4 November 1, 2023

This template was printed on March 15, 2024. Printed template are uncontrolled. Please check the document access location for the current revision:

\\Netapp02\hub_iso_doc$\CORP\Material Certification\COC's

1801 Theurer Blvd. Winona MN 55987 Tel. 844-265-2658 Fax 507-494-9664

3939 W 56th St. Indianapolis IN 46254 Tel. 317-216-1189 Fax 317-280-2500

15009 Lee Road Houston, Texas 77032 Tel.713-460-4381 Fax.713-996-7342

SPECIFICATION / GRADE: ASTM A194/A194M-23; ASME SA194/SA194M-23 Grade 2H

SURFACE QUALITY: In accordance with ASTM F788/F788M-20ᵋ¹ PASS

COATING: CLEAR ZINC PASS

CHEMISTRY – Heat Number: G190000668

Heat Composition (WT% Heat Analysis)

Element: C Mn P S Si

Minimum: 0.40 - - - -

Maximum: - 1.00 0.040 0.050 0.40

Result: 0.45 0.66 0.011 0.005 0.22

MACROETCH (if required): ASTM E381-22; S2, R2, C3

*¹ Heat Treat Method: Quench at830℃ about 90 minutes, Tempering at550℃ about 120 minutes

Attribute Test Method Sample Size Requirement Result Acceptance

Hardness after Treatment PASS

ASTM A370-2023 1 Min: 89 HRB 92-94 HRB

(540 ºC 24Hour)

Hardness ASTM A370-2023 4 24-35 HRC 29-32 HRC PASS

Proof Load ASTM A962/A962M-23 3 Min: 106,000 lbf 106,0002 lbf PASS

Decarburization ASTM F2328-17(2022) 4 HV2≥HV1‐30 PASS PASS

Page 2 of 4 November 1, 2023

This template was printed on March 15, 2024. Printed template are uncontrolled. Please check the document access location for the current revision:

\\Netapp02\hub_iso_doc$\CORP\Material Certification\COC's

1801 Theurer Blvd. Winona MN 55987 Tel. 844-265-2658 Fax 507-494-9664

3939 W 56th St. Indianapolis IN 46254 Tel. 317-216-1189 Fax 317-280-2500

15009 Lee Road Houston, Texas 77032 Tel.713-460-4381 Fax.713-996-7342

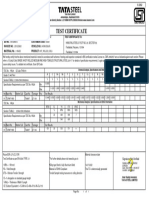

SPECIFICATION / GRADE: ASTM A193/A193M-23; ASME SA193/SA193M-23 B7

SURFACE QUALITY: In accordance with ASTM F788/F788M-20ᵋ¹ PASS

COATING: CLEAR ZINC PASS

CHEMISTRY – Heat Number: 18B704211

Heat Composition (WT% Heat Analysis)

Element: C Mn P S Si Cr Mo

Minimum: 0.38 0.75 - - 0.15 0.80 0.15

Maximum: 0.48 1.00 0.035 0.040 0.35 1.10 0.25

Result: 0.40 0.87 0.012 0.004 0.20 0.91 0.22

MACROETCH (if required): ASTM E381-22; S2, R2,C2

*¹ Heat Treat Method: Tempering Temp. 645 ºC, Quenching Temp. 860 ºC

Attribute Test Method Sample Size Requirement Result Acceptance

Hardness - 1 Max: 35 HRC 30 HRC PASS

Reduction of Area - 1 Min: 50 % 52 % PASS

Elongation (4D) - 1 Min: 16 % 17 % PASS

Yield (.2% Offset) - 1 Min: 105,000 PSI 116,000 PSI PASS

Tensile Strength - 1 Min: 125,000 PSI 134,000 PSI PASS

Decarburization ASTM F2328-17(2022) 2 HV(1)-HV(2) ≤ 30HV PASS PASS

Carburization ASTM F2328-17(2022) 2 HV(3) ≤ HV(1)+30 PASS PASS

Page 3 of 4 November 1, 2023

This template was printed on March 15, 2024. Printed template are uncontrolled. Please check the document access location for the current revision:

\\Netapp02\hub_iso_doc$\CORP\Material Certification\COC's

1801 Theurer Blvd. Winona MN 55987 Tel. 844-265-2658 Fax 507-494-9664

3939 W 56th St. Indianapolis IN 46254 Tel. 317-216-1189 Fax 317-280-2500

15009 Lee Road Houston, Texas 77032 Tel.713-460-4381 Fax.713-996-7342

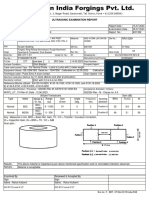

DIMENSIONAL INSPECTION: Per Cardinal Internal Inspection Plan

Sample

Dimension Data (1)

Size Min

Overall Length: 6-3/4" 1 6.7830

Thread Major: 0.998 / 0.983 1 0.9840

Thread Pitch: 0.9168 / 0.91 1 0.9130

Thread Minor: 0.8627 / 0.8288 1 0.8420

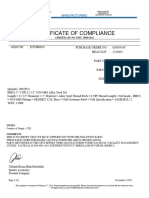

Compliancy Statement:

Cardinal Fastener hereby declares that the products supplied as represented in this test report are in compliance with the requirements of

the order as referenced above.

Comments:

Country of Origin: CHINA

*¹The Heat Treat Method Was Provided Based on Supplier’s’ Per Supplier Material Test Report.

Nabilah Husna Binti Hasbullah

Quality Assurance

Cardinal Fastener

This certified test report shall not be reproduced except in full, without the written approval of Cardinal Fastener. Any deviations or discrepancies that are

detected, or any departures from documented policies or procedures will be noted in the comment/notes section. We certify that the data reported above is a true

representation of the information provided and this test report conforms to DIN EN 10204 3.1. Parts mentioned in this test report were manufactured within

Fastenal’s quality management system. Fastenal is ISO 9001:2015 certified with TUV Rheinland of North America.

Page 4 of 4 November 1, 2023

This template was printed on March 15, 2024. Printed template are uncontrolled. Please check the document access location for the current revision:

\\Netapp02\hub_iso_doc$\CORP\Material Certification\COC's

You might also like

- Certified Material Test ReportDocument4 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- Certification As Per en 10204 3.1: Chemical Composition %Document2 pagesCertification As Per en 10204 3.1: Chemical Composition %BHUSHANNo ratings yet

- MTC - Oufo (Argentina) - 16Document1 pageMTC - Oufo (Argentina) - 16Aceros DessolNo ratings yet

- Certificado EsparragosDocument8 pagesCertificado EsparragosJesus CondoriNo ratings yet

- D72307 TC2 PDFDocument2 pagesD72307 TC2 PDFshivdas bichukaleNo ratings yet

- Certificate: Parker Hannifin Instrumentation (Changzhou) Co., LTDDocument3 pagesCertificate: Parker Hannifin Instrumentation (Changzhou) Co., LTDgroupj.sr.servicesNo ratings yet

- TC No 1201 StudDocument2 pagesTC No 1201 StudGaurav100% (1)

- Mechanical Properties: Chemical CompositionDocument1 pageMechanical Properties: Chemical CompositionHERSON FARID BUENO PIÑEROSNo ratings yet

- Inspection Certificate Acc, To/ En-35 22.1.2: Technical Requirements: ASME B-16.20 ANSI B16.5 Heat N°Document3 pagesInspection Certificate Acc, To/ En-35 22.1.2: Technical Requirements: ASME B-16.20 ANSI B16.5 Heat N°Raul Esteban Jaimes GalvisNo ratings yet

- Reporte Element T 47Document3 pagesReporte Element T 47Edson AragaNo ratings yet

- MTC - 2046Document1 pageMTC - 2046tameem.p2023No ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- AMBICA 40mm Rod SS316L MTCDocument2 pagesAMBICA 40mm Rod SS316L MTCmetalexinNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)Document1 pageNingbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)GLORIA MONSALVE SALAZARNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- Analysis Report: Min Max Method Analysis Units ResultDocument1 pageAnalysis Report: Min Max Method Analysis Units ResultRodolfo de la TorreNo ratings yet

- Varilla 1 1 - 4 A193 B7Document1 pageVarilla 1 1 - 4 A193 B7CarlosEduardoMorenoManceraNo ratings yet

- Material Test Report: Cse. Chiang Sung Enterprise Co., LTDDocument3 pagesMaterial Test Report: Cse. Chiang Sung Enterprise Co., LTDChethan Nagaraju KumbarNo ratings yet

- AMBICA 36mm Rod SS316L MTCDocument2 pagesAMBICA 36mm Rod SS316L MTCmetalexinNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)Document1 pageNingbo Dongxin High-Strength Nut Co.,Ltd: TEST CERTIFICATE (EN 10204.3.1)GLORIA MONSALVE SALAZARNo ratings yet

- Esparrago Astm 193 B7 1.1.4 - 7 X 3.60 Mt.Document1 pageEsparrago Astm 193 B7 1.1.4 - 7 X 3.60 Mt.Cristian Xavier Avendaño BelloNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- VARILLADocument1 pageVARILLAB. styllshNo ratings yet

- Sample MTC For Anchor BoltDocument1 pageSample MTC For Anchor BoltSALMAN PARVEZ ROKADIANo ratings yet

- 4130wog0913 - Rev14Document3 pages4130wog0913 - Rev14Quality controller100% (1)

- Test Certificate: (BS EN 10204 Type 3.1)Document1 pageTest Certificate: (BS EN 10204 Type 3.1)Sachin NambiarNo ratings yet

- Certif Tu inDocument18 pagesCertif Tu inSri GangaNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- Tubacex 10Document2 pagesTubacex 10Akash SinhaNo ratings yet

- BLQ Iiw T1 1018Document3 pagesBLQ Iiw T1 1018contacto.techndtNo ratings yet

- PTC-110 Pc-Bolt M27 L 2400 FR FTP 23887Document2 pagesPTC-110 Pc-Bolt M27 L 2400 FR FTP 23887mh hNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- 694Document1 page694Mauricio Ramirez100% (1)

- Metallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoDocument1 pageMetallurgical Test Report: NAS Mexico SA de CV Privada Andres Guajardo No. 360 Apodaca, N.L., C.P. 66600 MexicoEmigdio MartinezNo ratings yet

- Heat No S13Document1 pageHeat No S13Siddharth ParmarNo ratings yet

- 041101Document1 page041101Carolina MolfinoNo ratings yet

- CR-050219-B-35 # Swba10m24x60b # S14211-01-19Document1 pageCR-050219-B-35 # Swba10m24x60b # S14211-01-19qc_531040655No ratings yet

- GR 70 32MMDocument1 pageGR 70 32MMquality nakodaNo ratings yet

- Page 2 Tsi MTC 150x4 (MTC - 247)Document2 pagesPage 2 Tsi MTC 150x4 (MTC - 247)trayojam.rilNo ratings yet

- 90mm 316l Peeled and PolishedDocument1 page90mm 316l Peeled and PolishedB.M Industrial WorksNo ratings yet

- Page 2 of 6: Test Certificate No. 0000052877Document1 pagePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- ASTM A106 Data SheetDocument4 pagesASTM A106 Data Sheetmarcelomaster88No ratings yet

- Page 1 of 6: Test Certificate No. 0000052877Document6 pagesPage 1 of 6: Test Certificate No. 0000052877panduranganraghurama78% (9)

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Inspection Report: Setcore Arabia Petroleum ServiceDocument1 pageInspection Report: Setcore Arabia Petroleum ServiceMahmoud SalahNo ratings yet

- Perno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Document1 pagePerno GR2 Unc HDG 5-8 X 1 1-2 (Tkr+hy7129220)Naomi Mascco VilchezNo ratings yet

- Material Test & Inspection CertificateDocument1 pageMaterial Test & Inspection CertificateKato Megumi ChanNo ratings yet

- 10MMDocument1 page10MMStructures ProductionNo ratings yet

- Test Report Date ULR:-TC677119000007759P Name of Customer & Add. M/s Real Forge & FittingDocument14 pagesTest Report Date ULR:-TC677119000007759P Name of Customer & Add. M/s Real Forge & FittingAnurag YadavNo ratings yet

- Banjo Beam - MTC 3.5 MM E 46Document1 pageBanjo Beam - MTC 3.5 MM E 46Rajhans PressingNo ratings yet

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- A105 (VF863)Document1 pageA105 (VF863)Suli HartoNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Certificate of ComplianceDocument7 pagesCertificate of ComplianceNabilah HusnaNo ratings yet

- Certified Material Test ReportDocument2 pagesCertified Material Test ReportNabilah HusnaNo ratings yet

- Wa0007.Document10 pagesWa0007.Maz Izman BudimanNo ratings yet

- Toit A93518-1Document1 pageToit A93518-1Nabilah HusnaNo ratings yet

- Gator Laser SpecificationDocument9 pagesGator Laser SpecificationJaNo ratings yet

- Extracted Pages From General Chemistry, 6th Ed - BradyDocument9 pagesExtracted Pages From General Chemistry, 6th Ed - BradyAdi NugrahaNo ratings yet

- 16olorunfemietal2021 OlayinkaDocument35 pages16olorunfemietal2021 OlayinkaAjibade FaroukNo ratings yet

- 02 - PHY01 - Course Outcome 1Document66 pages02 - PHY01 - Course Outcome 1John Paul PaguiaNo ratings yet

- A. Tools and Techniques in Cytology (PDFDrive)Document12 pagesA. Tools and Techniques in Cytology (PDFDrive)Leonardo MuñozNo ratings yet

- Questions & Answers - ET Level 1Document4 pagesQuestions & Answers - ET Level 1Jawad MunirNo ratings yet

- BFT Catalogue 2012 SMDocument199 pagesBFT Catalogue 2012 SMnoufalmindster0% (1)

- MK Ji RB Evm HVM XVKV: GWM Q Avm Z N E Mevb KDocument4 pagesMK Ji RB Evm HVM XVKV: GWM Q Avm Z N E Mevb KPathokNo ratings yet

- Renasys™ Ez Plus: Smith&nephewDocument21 pagesRenasys™ Ez Plus: Smith&nephewBlanca Haydée Mesías Inostroza100% (1)

- Rotary Actuators, NAMUR Interface VDI - VDE 3845 & ISO 5211 (ATEX Certified) Series ARPDocument8 pagesRotary Actuators, NAMUR Interface VDI - VDE 3845 & ISO 5211 (ATEX Certified) Series ARPJhonata CavalcanteNo ratings yet

- Fluid3a Trawneh PDFDocument39 pagesFluid3a Trawneh PDFWesam abo HalimehNo ratings yet

- System1 Plots - Machinery-Diagnostic - Part1Document16 pagesSystem1 Plots - Machinery-Diagnostic - Part1Thyagaraju PalisettyNo ratings yet

- 1atoms Molecules and StoichiometryDocument95 pages1atoms Molecules and StoichiometryNurfarhah JohariNo ratings yet

- Modality and SyllabusDocument3 pagesModality and Syllabusuthso royNo ratings yet

- Introduction To Fluid Mechanics and Properties of FluidsDocument27 pagesIntroduction To Fluid Mechanics and Properties of FluidsAyumi QuiomNo ratings yet

- Vectors and 3D Geometry For Jee Advanced 3Rd Edition G Tewani All ChapterDocument47 pagesVectors and 3D Geometry For Jee Advanced 3Rd Edition G Tewani All Chapterwade.escamilla468100% (4)

- Trans3004 HX Rev2Document12 pagesTrans3004 HX Rev2Glacier RamkissoonNo ratings yet

- TVP Case Studies - Industrial Process HeatDocument6 pagesTVP Case Studies - Industrial Process HeatRahul SharmaNo ratings yet

- Bucket Elevator Calculation Rev 1Document8 pagesBucket Elevator Calculation Rev 1Irfan AhmedNo ratings yet

- Chemistry 9th Edition Zumdahl Test BankDocument25 pagesChemistry 9th Edition Zumdahl Test BankCarolineAvilaijke100% (55)

- Q4 Science 9 - Module 1Document23 pagesQ4 Science 9 - Module 1Danilo Saliog67% (6)

- Chapter-7 Shear DesignDocument14 pagesChapter-7 Shear DesignAngelo RosNo ratings yet

- Assigning R and SDocument12 pagesAssigning R and SApurba Sarker ApuNo ratings yet

- CPC 100 User Manual ENUDocument77 pagesCPC 100 User Manual ENUJose Ramirez TorresNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768wawan100% (1)

- Investigation On Mechanical Properties of Wire Arc Additive Manufacturing (Waam) of 316L Stainless Steel Using Fem Simulation and ExperimentDocument10 pagesInvestigation On Mechanical Properties of Wire Arc Additive Manufacturing (Waam) of 316L Stainless Steel Using Fem Simulation and ExperimentMohd AymanNo ratings yet

- Exam1 ProblemsDocument2 pagesExam1 ProblemsYonda KeduaNo ratings yet

- Iec 60038Document4 pagesIec 60038ZAHID IQBALNo ratings yet

- M.Tech 1st Sem Machine Degine SyllabusDocument12 pagesM.Tech 1st Sem Machine Degine SyllabusHOD Department of Mechanical EngineeringNo ratings yet

- Termoformadora de Bandeja SunWell M1370L-HTPF PainelDocument40 pagesTermoformadora de Bandeja SunWell M1370L-HTPF PainelGleicianeLimaGomesNo ratings yet