Professional Documents

Culture Documents

Boiler 101: What Is A Boiler?

Uploaded by

Samuel Acuña JimenezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boiler 101: What Is A Boiler?

Uploaded by

Samuel Acuña JimenezCopyright:

Available Formats

Boiler 101

What is a Boiler?

A pressure vessel that provides a heat transfer surface (generally a set of

tubes) between the combustion products and the water. A boiler is usually

integrated into a system with many components.

Why use a Boiler?

Boilers are used to produce steam. The generation part of a steam system

uses a boiler to add energy to a feedwater supply to generate steam. The

energy is released from the combustion of fossil fuels or from process waste

heat.

Where are Boilers Used?

Anywhere you are creating heat and/or steam, you will probably find a boiler. ABMA members produce large

boilers for the commercial, industrial, utility sector and more. Boiler systems are used to create pulp & paper,

generate electricity and process foods. The complexity significantly increases as you increase the size and need

for greater performance of the boiler system.

What are the major components of the Boiler System?

The boiler itself is a main component of a generation system that also includes the fuel supply, combustion air

system, feedwater system, and exhaust gases venting system. ABMA members also manufacture the following

components.

Burner

Controls

Deaerator

Economizer

Fan

Heat Exchanger

Instrumentation

Stoker

Tubes

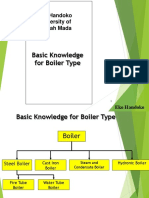

What are the basic types of Boilers?

There are two basic types of boilers: firetube and watertube. The fundamental difference between these boiler

types is which side of the boiler tubes contain the combustion gases or the boiler water/steam.

Firetube Boiler

In firetube boilers, the combustion gases pass inside boiler tubes, and heat is transferred to water between the

tubes and the outer shell. Today, larger firetube boilers are over 1,500 boiler horsepower (about 50,000 pounds

per hour. Firetube boilers are often characterized by their number of passes, referring to the number of times the

combustion (or flue) gases flow the length of the pressure vessel as they transfer heat to the water. The

turnaround zones can be either dryback or waterback. In dryback designs, the turnaround area is refractory-

lined. In waterback designs, this turnaround zone is water-cooled, eliminating the need for the refractory lining.

Watertube Boiler

In watertube boilers, boiler water passes through the tubes while the exhaust gases remain in the shell side,

passing over the tube surfaces. Because tubes can typically withstand higher internal pressure than the large

chamber shell in a firetube, watertube boilers are used where high steam pressures (3,000 psi, sometimes

higher) are required. Watertube boilers are also capable of high efficiencies and can generate saturated or

superheated steam. In fact, the ability of watertube boilers to generate superheated steam makes these boilers

particularly attractive in applications that require dry, high-pressure, high energy steam, including steam turbine

power generation. The performance characteristics of watertube boilers make them highly favorable in process

industries, including chemical manufacturing, pulp and paper manufacturing, and refining. Although firetube

boilers account for the majority of boiler sales in terms of units, watertube boilers account for the majority of

boiler capacity.

Waste Heat Recovery Boiler (WHRB)

These boilers may be either firetube or watertube design and use heat that would otherwise be discarded to

generate steam. Typical sources of heat for WHRBs include exhaust gases or high-temperature products from

an external manufacturing process in refineries and chemical manufacturing facilities, or combustion of a waste

fuel in the boiler furnace.

Heat Recovery Steam Generators (HRSGs)

HRSGs transfer energy from the exhaust of a gas turbine to an unfired or supplementary fired heat-recovery

steam generator to produce steam. Exhaust gases leave the gas turbine at temperatures of 1,000°F (538°C) or

higher and can represent more than 75% of the total fuel energy input. This energy can be recovered by passing

the gases through a heat exchanger (steam generator) to produce hot water or steam for process needs.

You might also like

- Design Calculations of a 20/26 MVA Power TransformerDocument148 pagesDesign Calculations of a 20/26 MVA Power Transformerعمر محمود100% (6)

- Boilers PDFDocument28 pagesBoilers PDFThulasi RamNo ratings yet

- Control Valve SizingDocument4 pagesControl Valve SizingMehfuz AnsariNo ratings yet

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewNo ratings yet

- Report in Steam Generators: Schematic Diagram of A Boiler SystemDocument18 pagesReport in Steam Generators: Schematic Diagram of A Boiler SystemZa YonNo ratings yet

- Type of BoilersDocument10 pagesType of BoilersZaheer Ahmad Raza100% (1)

- Boiler Report PDFDocument34 pagesBoiler Report PDFAditya Aggarwal83% (52)

- TEMA Heat Exchangers LPLDocument101 pagesTEMA Heat Exchangers LPLmasoodism100% (1)

- 2.1. Marine Boilers PDFDocument48 pages2.1. Marine Boilers PDFBasong San67% (3)

- Draft BS en 16883 Conservation of Cultural Heritage Guidelines For Improving Energy Performance of Historic BuildingsDocument35 pagesDraft BS en 16883 Conservation of Cultural Heritage Guidelines For Improving Energy Performance of Historic BuildingsbampintoNo ratings yet

- Introduction To Boiler: Fire Tube BoilersDocument34 pagesIntroduction To Boiler: Fire Tube BoilersSandhya NaveenNo ratings yet

- Fans in Thermal Power PlantsDocument3 pagesFans in Thermal Power PlantsMuhammad Nadeem RazaNo ratings yet

- DPIIT Recognized Startups List-21102019 PDFDocument706 pagesDPIIT Recognized Startups List-21102019 PDFWael Alzbier WaelNo ratings yet

- Equipment Design - BOILERSDocument24 pagesEquipment Design - BOILERSEmyu ClaridadNo ratings yet

- BoilerDocument90 pagesBoilerMargaret DaughertyNo ratings yet

- Lecture 7 - Steam Generators: Mechanics of Steam BoilersDocument7 pagesLecture 7 - Steam Generators: Mechanics of Steam BoilersIjazzzAliNo ratings yet

- Physical Study of A Steam Generating UnitDocument13 pagesPhysical Study of A Steam Generating Unitashier dave calulot80% (5)

- Failures of BoilersDocument7 pagesFailures of BoilersTeuku Rizal El SilencioNo ratings yet

- ArmstrongDocument6 pagesArmstrongJorge Herrera100% (1)

- TransducerDocument70 pagesTransducersmcoolguy68100% (1)

- Boiler ReportDocument15 pagesBoiler Reportshridhar sutarNo ratings yet

- Introduction To BoilersDocument16 pagesIntroduction To BoilersZiauddin ChawdhryNo ratings yet

- Water-Tube Boilers - International Site For Spirax SarcoDocument7 pagesWater-Tube Boilers - International Site For Spirax SarcotahirNo ratings yet

- Boilers NotesDocument16 pagesBoilers Notesjust randomNo ratings yet

- 9what Is A Boiler?Document59 pages9what Is A Boiler?Ali MuradNo ratings yet

- Boiler Structure and Principle (English)Document28 pagesBoiler Structure and Principle (English)Engr ImranNo ratings yet

- Lecture 7 - Steam GeneratorsDocument6 pagesLecture 7 - Steam GeneratorsHussain Abbas100% (1)

- NLB 225Document2 pagesNLB 225Sergio Roberto Cabrera BurgosNo ratings yet

- L&T ManualDocument60 pagesL&T ManualDineshNo ratings yet

- HW 2 - Hydropower - Iman AnsoriDocument3 pagesHW 2 - Hydropower - Iman Ansori1412091090100% (1)

- Steam System Basics PDFDocument67 pagesSteam System Basics PDFEduardo Miranda100% (1)

- Solar Panel Monitoring System Using IOTDocument6 pagesSolar Panel Monitoring System Using IOTIJRASETPublicationsNo ratings yet

- DR Ashok SDocument137 pagesDR Ashok SRama KrishnaNo ratings yet

- Boiler TypesDocument9 pagesBoiler TypesSharif Muhammad HossainNo ratings yet

- Steam Heat Energy Water Psi Kpa: Water-Tube Boiler Fossil Fuel-Fired Boilers Heat Recovery Boilers Heat Recovery BoilersDocument4 pagesSteam Heat Energy Water Psi Kpa: Water-Tube Boiler Fossil Fuel-Fired Boilers Heat Recovery Boilers Heat Recovery BoilersMarsNo ratings yet

- Food Process Engineering Lab 3. BOILER OPERATIONDocument22 pagesFood Process Engineering Lab 3. BOILER OPERATIONMuhyiddin Noor AfandiNo ratings yet

- Industrial Steam Boiler: ObjectiveDocument6 pagesIndustrial Steam Boiler: ObjectiveM. Hassan HaidderNo ratings yet

- #Lecture 3 - Steam GeneratorsDocument22 pages#Lecture 3 - Steam Generatorsmohamed EldesokyNo ratings yet

- Boiler Thermo AssignmentDocument6 pagesBoiler Thermo AssignmentBassam0% (2)

- General Boiler InfoDocument14 pagesGeneral Boiler InfoHossam KhalilNo ratings yet

- Heat GeneratorDocument6 pagesHeat GeneratorZac Ryan CasteloNo ratings yet

- Steam System Basics: Watertube BoilersDocument4 pagesSteam System Basics: Watertube BoilersNaNo ratings yet

- Boiler 101: What Is A Boiler?Document1 pageBoiler 101: What Is A Boiler?badNo ratings yet

- Assignment-Ali RazaDocument12 pagesAssignment-Ali RazaahsanNo ratings yet

- Boiler IntroductionDocument17 pagesBoiler IntroductionDavid SilalahiNo ratings yet

- 1 Boiler Horse Power Is About 42Document9 pages1 Boiler Horse Power Is About 42Faaz Al WahabNo ratings yet

- Basic Parts of A BoilerDocument9 pagesBasic Parts of A Boilermessi107No ratings yet

- Tugas Util (Boiler)Document4 pagesTugas Util (Boiler)AkhmadSumarnoNo ratings yet

- MODULE 1-Steam Generating Unit and Its AuxiliariesDocument23 pagesMODULE 1-Steam Generating Unit and Its Auxiliarieskoko blueNo ratings yet

- Chapter Two Steam Power PlantDocument42 pagesChapter Two Steam Power PlantPercy Aduviri FloresNo ratings yet

- Literature ReviewDocument20 pagesLiterature ReviewSunny ChauhanNo ratings yet

- Types of BoilersDocument9 pagesTypes of BoilersAhmad CheemaNo ratings yet

- BoilersDocument3 pagesBoilersatikulNo ratings yet

- Power Plant Engineering (SMEX1016) 2 PDFDocument28 pagesPower Plant Engineering (SMEX1016) 2 PDFshyam sundarNo ratings yet

- Coal-Based Electricity ProductionDocument11 pagesCoal-Based Electricity ProductionkirannainwalNo ratings yet

- Thermal Power Plants: Assignment No 1 Boilers 17-MS-PT-PE (T) - 20 Muneeb Ur Rehman KhanDocument8 pagesThermal Power Plants: Assignment No 1 Boilers 17-MS-PT-PE (T) - 20 Muneeb Ur Rehman KhanSuper SiangohanNo ratings yet

- What is a Boiler and its UsesDocument1 pageWhat is a Boiler and its UsesJr BolloNo ratings yet

- Boilers, Furnaces and Heat Exchangers: Vardelli Shanthan MT21HPE001Document7 pagesBoilers, Furnaces and Heat Exchangers: Vardelli Shanthan MT21HPE001Shanthan VardelliNo ratings yet

- Industrial Steam ProcessDocument1 pageIndustrial Steam ProcessPryce YurongNo ratings yet

- Textbooktraining Mat Boiler ThfluidheatersDocument44 pagesTextbooktraining Mat Boiler ThfluidheatersFirdausNo ratings yet

- How steam boilers work and their applicationsDocument8 pagesHow steam boilers work and their applicationsmobile legend practiceNo ratings yet

- Boilers: Espiritu, Christopher James Managuit, John Jeruel Querubin, Russel JohnDocument43 pagesBoilers: Espiritu, Christopher James Managuit, John Jeruel Querubin, Russel JohnRussel John Morillo Querubin100% (1)

- ATD Unit-4 NotesDocument44 pagesATD Unit-4 NotesSanjay KatreddyNo ratings yet

- Boiler:: Working Principle of A BoilerDocument22 pagesBoiler:: Working Principle of A BoilerZeshan AbdullahNo ratings yet

- Open Feedwater Heaters Closed Feedwater HeatersDocument22 pagesOpen Feedwater Heaters Closed Feedwater HeatersM.Thirunavukkarasu100% (1)

- Report on Reducing Boiler Pressure at Chevron PlantDocument25 pagesReport on Reducing Boiler Pressure at Chevron PlantMeer UmarNo ratings yet

- 255177555-Project-ReportDocument79 pages255177555-Project-ReportVenkyNo ratings yet

- Boiler Steam Generation Distribution 1712008851Document37 pagesBoiler Steam Generation Distribution 1712008851sukhvinderNo ratings yet

- Everything you need to know about boilersDocument36 pagesEverything you need to know about boilerssaikumarvavillaNo ratings yet

- Boiler Cont.Document9 pagesBoiler Cont.adnan mukhtarNo ratings yet

- Steam Power PlantsDocument18 pagesSteam Power Plantscan canNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Structure of the Atom ExplainedDocument24 pagesStructure of the Atom ExplainedKunalNo ratings yet

- Home Power Magazine - Issue 027 - 1992-02-03 PDFDocument100 pagesHome Power Magazine - Issue 027 - 1992-02-03 PDFwienslaw5804No ratings yet

- The Bowdoin Orient - Vol. 147, No. 22 - April 20, 2018Document16 pagesThe Bowdoin Orient - Vol. 147, No. 22 - April 20, 2018bowdoinorientNo ratings yet

- Microgrid Controller 600 en LR (Dic2013)Document16 pagesMicrogrid Controller 600 en LR (Dic2013)riki187100% (1)

- BattleTech Scenario Pack - The Black ThornsDocument74 pagesBattleTech Scenario Pack - The Black Thornskr0skr0No ratings yet

- CPG 0Document20 pagesCPG 0muhdshafiq12No ratings yet

- Bioethanol Production From Breadnut (Artocarpus Camansi) ProposalDocument46 pagesBioethanol Production From Breadnut (Artocarpus Camansi) ProposalIvan ArcenaNo ratings yet

- What Does 2Document3 pagesWhat Does 2api-235464896No ratings yet

- Adsorption Gas Treatment Plant - Design Information: Spec. NumberDocument5 pagesAdsorption Gas Treatment Plant - Design Information: Spec. NumberabhmarsNo ratings yet

- MMU-AP0124HP-E - EVAPORADORA TOSHIBA - Cópia PDFDocument1 pageMMU-AP0124HP-E - EVAPORADORA TOSHIBA - Cópia PDFCelso BrasilNo ratings yet

- Geothermal Energy NCESDocument71 pagesGeothermal Energy NCESAdarsh ShuklaNo ratings yet

- Titan 130 Gas Turbine Generator PackageDocument1 pageTitan 130 Gas Turbine Generator Packagegilen30No ratings yet

- Cursor 013 Te1 315kwm eDocument6 pagesCursor 013 Te1 315kwm ellovar100% (1)

- ENV130.0001, Renewable Energy Sources, Wang, Chunzeng Fall 2012 PDFDocument4 pagesENV130.0001, Renewable Energy Sources, Wang, Chunzeng Fall 2012 PDF0307aliNo ratings yet

- Module-2 Energy Systems & AnalysisDocument46 pagesModule-2 Energy Systems & Analysisrushi C SNo ratings yet

- Section VI DDocument88 pagesSection VI DAnonymous 7ZYHilDNo ratings yet

- En TH01!11!2004 Power Factor CorrectionDocument12 pagesEn TH01!11!2004 Power Factor CorrectionSirish SabbellaNo ratings yet