Professional Documents

Culture Documents

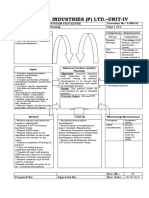

Overall Work Plan (Med - End - Filled) Products: Step 1 - Milling Process (MP)

Uploaded by

Mahmoud Lotfy0 ratings0% found this document useful (0 votes)

9 views6 pages1. The document outlines a 4-step quality control process for products: milling, mixing/finishing, before filling, and stored filled end products.

2. For each step, requirements are defined for sampling, procedures, testing, documentation, and release of products.

3. Key aspects addressed include sample sizes and identification labeling, specified tests at each step, use of notification forms and product validity forms, and recording results in log books. Adjustments are made as needed based on test results.

Original Description:

Original Title

QC Overall Work Plan 1-6-2020

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document outlines a 4-step quality control process for products: milling, mixing/finishing, before filling, and stored filled end products.

2. For each step, requirements are defined for sampling, procedures, testing, documentation, and release of products.

3. Key aspects addressed include sample sizes and identification labeling, specified tests at each step, use of notification forms and product validity forms, and recording results in log books. Adjustments are made as needed based on test results.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views6 pagesOverall Work Plan (Med - End - Filled) Products: Step 1 - Milling Process (MP)

Uploaded by

Mahmoud Lotfy1. The document outlines a 4-step quality control process for products: milling, mixing/finishing, before filling, and stored filled end products.

2. For each step, requirements are defined for sampling, procedures, testing, documentation, and release of products.

3. Key aspects addressed include sample sizes and identification labeling, specified tests at each step, use of notification forms and product validity forms, and recording results in log books. Adjustments are made as needed based on test results.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 6

Last update

Quality Control Mangement 15/2/2019

Overall Work Plan Updated on

1/6/2020

( Med - End - Filled ) Products

Step 1 -- Milling Process (MP)

Scope Products that contain :

1- Pigment 2- N.C 3- Aerosol

Sample One Sample Must apply the following

1- The sample weight is 150 g Mininmum for viscosity adjustment and 50 g Max on remill

2- Have identification Lable with Full data :

Name, Code, Batch Number, Date, Type, Number of sample, Sampler Signature

Procedure

1- Receiving sample according to the step requirements

2- Recording the sample data in the (Receiving Samples Log Book) Code:

3- Doing the following tests according to each product specification

3.1- Viscosity - if not accepted adjust by solvents and binders Code:

3.2- Fineness - if not accepted Remill Code:

3.3- Reduction (for colors Paste only) Code:

if Dark adjust by Binders - if light accept with Usage Recommendation (UR)

4- Reprocessing and Materials addition are Child Process Orders

4.1- Using Notification Form to adjust defected product Code:

5- Sending Notification copy signed and stamped by Q.C Chemist to the Production Engineer

to proceed adjusment and last steps are repeated

6- Record results for accepted product in Prodcut Validity Form (P.V.F)Code:

7- Sending P.V.F copy signed and stamped by Q.C Chemist to the Production Engineer

with UR Notes (if exist) to release or continue the product.

8- Recording Notifications and P.V.F on access record by Data entry

Document Code: 4M-QP001 1

Last update

Quality Control Mangement 15/2/2019

Overall Work Plan Updated on

1/6/2020

Step 2 -- Mixing or Finishing Process (FP)

Scope All Products Produced by Direct Mixing or After Milling

Sample 2 Samples Must apply the following

Sample (1) For Q.C Lab

1- The sample weight is 200 g Mininmum

2- Have identification Lable with Full data :

Name, Code, Batch Number, Date, Type, Number of sample, Sampler Signature

Sample (2) For Application Lab after Viscosity adjustment

1- The sample weight is 200 g Maximum

2- Have identification Lable with Full data :

Name, Code, Batch Number, Date, Type, Number of sample, Sampler Signature

Procedure

1- Receiving Sample (1) according to the step requirements

2- Recording the sample data in the (Q.C Receiving Samples Log Book)Code:

3- Doing Viscosity test according to each product Specification

if not accepted adjust it according to each Product Testing Work Plan

4- When Viscosity is accepted

4.1- Complete Testing according to each Product Testing Work Pla

4.2- Production Worker must take Sample (2) to application

5- Receiving Sample (2) according to the step requirements

6- Recording the sample data in the (App. Receiving Samples Log BookCode:

7- Apply the product according to each product Application Method

8- In case of any defect adjust according to each Product Testing Work Plan

8.1- Using Notification Form to adjust defected product Code:

9- Sending Notification copy signed and stamped by Q.C Chemist to the Production Engineer

to proceed adjusment and last steps are repeated

10- Record results for accepted product in Prodcut Validity Form (P.V.F) Code:

11- Sending P.V.F copy signed and stamped by Q.C Chemist to the Production Engineer

with UR (if exist) to release the product For Filling or Reprocessing.

12- Recording Notifications and P.V.F on access record by Data entry

Document Code: 4M-QP001 2

Last update

Quality Control Mangement 15/2/2019

Overall Work Plan Updated on

1/6/2020

Step 3 -- Before Filling

Scope 1- All Products Directly after Production

2- All Products after 8 Hrs from Production

Except Metallic Paints After 6 From Production

Sample 1 Sample Must apply the following

1- The sample weight is 200 g Mininmum after Filteration unit

2- Have identification Lable with Full data :

Name, Code, Batch Number, Date, Type, Number of sample, Sampler Signature

Procedure

1- Receiving Sample according to the step requirements

2- Recording the sample data in the (Q.C Receiving Samples Log Book)Code:

3- For Scope (1)

3.1- Doing Finness test by 150 Micron Film on glass

If not accepted then Refilter or higher filteration unit

4- For Scope (2)

4.1- Doing Viscosity test according to each product Specification

If not accepted adjust it according to each Product Testing Work Plan

4.2- Doing Masstone test For Metallic Paints Code:

If not accepted adjust it according to each Product Testing Work Plan

4.3- Doing Finness test by 150 Micron Film on glass

if not accepted then Refilter or higher filteration unit

5- Record results for accepted product in Prodcut Validity Form (P.V.F)Code:

6- Sending P.V.F copy signed and stamped by Q.C Chemist to the Production Engineer

with UR (if exist) to release the product For Filling or Reprocessing.

7- Recording Notifications and P.V.F on access record by Data entry

Document Code: 4M-QP001 3

Last update

Quality Control Mangement 15/2/2019

Overall Work Plan Updated on

1/6/2020

Step 4 -- Stored Filled End Product

Scope All Products stored for 3 Months

Sample 1 Sample Must apply the following

1- Random Sample form the Product Batch.

2- Have identification Lable with Full data :

Name, Code, Batch Number, Date, Type, Number of sample, Sampler Signature

Procedure

1- Receiving Sample according to the step requirements

2- Recording the sample data in the (Q.C Receiving Samples Log Book)Code:

3- Doing Full test according to each Product Specification

If not accepted check by another sample then direct the product Batch for reprocessin

4- Record results for accepted product in Prodcut Validity Form (P.V.F)Code:

5- Sending P.V.F copy signed and stamped by Q.C Chemist to the Production Engineer

with UR (if exist) to release the product For Filling or Reprocessing.

6- Recording Notifications and P.V.F on access record by Data entry

Document Code: 4M-QP001 4

Document Code: 4M-QP001 5

Document Code: 4M-QP001 6

You might also like

- 1.procedure For Incoming Material. Customer Products (6 Files Merged)Document16 pages1.procedure For Incoming Material. Customer Products (6 Files Merged)Valentine GaneshNo ratings yet

- QMS Audit Check SheetDocument7 pagesQMS Audit Check Sheetaboo2uNo ratings yet

- Process Performance Qualification ProtocolDocument7 pagesProcess Performance Qualification Protocolsandeep sharmaNo ratings yet

- Monitoring and Measurement of QmsDocument3 pagesMonitoring and Measurement of QmsamoNo ratings yet

- Inspection and Testing of ValveDocument5 pagesInspection and Testing of ValveCandy Kendee100% (2)

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionFrom EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Formel Q New Parts Integral QPN 2006Document22 pagesFormel Q New Parts Integral QPN 2006Aldo Arturo Lucero SampedroNo ratings yet

- PROCESS VALIDATION PROTOCOL ExampleDocument14 pagesPROCESS VALIDATION PROTOCOL ExampleNazia KabirNo ratings yet

- Ppap ClassDocument20 pagesPpap ClassrjzepfelNo ratings yet

- Blake PastoralDocument4 pagesBlake PastoralSanya AhmedNo ratings yet

- Procedure For Internal AuditingDocument4 pagesProcedure For Internal AuditingQuality Unit 1 Ajay Pandey67% (3)

- PM - 8.05 Product Monitoring and MeasuringDocument2 pagesPM - 8.05 Product Monitoring and MeasuringMangBedjoNo ratings yet

- Production Part Approval Process (Ppap)Document20 pagesProduction Part Approval Process (Ppap)Primoz Cermelj100% (1)

- SFT-ECAS - OP - 24c Factory Inspection Report (RoHS) Final Draft 21st Jan, 18Document15 pagesSFT-ECAS - OP - 24c Factory Inspection Report (RoHS) Final Draft 21st Jan, 18Duong N. KhoaNo ratings yet

- The Company'S Factory Production Control System (FPC) FPC 0: BackgroundDocument7 pagesThe Company'S Factory Production Control System (FPC) FPC 0: BackgroundSandy D. RockNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- Quality System Procedure For Change Point ControlDocument3 pagesQuality System Procedure For Change Point Controlrajesh sharmaNo ratings yet

- Decommissioning HSE PDFDocument105 pagesDecommissioning HSE PDFRafael Rocha100% (1)

- Process Validation For Solid Dosage FormsDocument4 pagesProcess Validation For Solid Dosage Formsnani7862012No ratings yet

- GMP Quality Assurance and Validation Procedures 2Document48 pagesGMP Quality Assurance and Validation Procedures 2gmpsop100% (4)

- 5M CHANGE ProcedureDocument8 pages5M CHANGE ProcedurePk Nimiwal100% (1)

- 1 Objective: Packaging Validation Packaging Line/packaging RoomDocument13 pages1 Objective: Packaging Validation Packaging Line/packaging RoomAngel CvetanovNo ratings yet

- Procedure For ProductionDocument7 pagesProcedure For ProductionSharif Khan100% (1)

- Tandard Perating Rocedure: TitleDocument5 pagesTandard Perating Rocedure: TitlevishalstjsNo ratings yet

- Lecture 11 - QAQCDocument36 pagesLecture 11 - QAQCTMTNo ratings yet

- Clinical Crown Lengthening in The Esthetic Zone2028Document12 pagesClinical Crown Lengthening in The Esthetic Zone2028AchyutSinhaNo ratings yet

- GP 12Document2 pagesGP 12Antonio Lara100% (8)

- QMS 055 SampleDocument8 pagesQMS 055 Samplebaluchakp100% (1)

- Risk Based Validation and Requalification of Processes EquipmentDocument33 pagesRisk Based Validation and Requalification of Processes EquipmentfenixseravgonNo ratings yet

- Supplier Audit: Instructions and Criteria For ScoreDocument7 pagesSupplier Audit: Instructions and Criteria For ScoreAmilaLakmalNo ratings yet

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- API 572 Practise QuestionDocument58 pagesAPI 572 Practise Questionbelonk_182100% (6)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- ISO/TS16949-Self Audit ChecklistDocument14 pagesISO/TS16949-Self Audit ChecklistBharathNo ratings yet

- Chopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureDocument5 pagesChopra Industries (P) Ltd.-Unit-Iv: Quality Management System ProcedureShankar ChowdhuryNo ratings yet

- Mostafa Mahmoud Soliman CV - March 2023Document5 pagesMostafa Mahmoud Soliman CV - March 2023Mustafa Mahmoud MatarNo ratings yet

- High Pressure Processing of Food - Principles, Technology and ApplicationsDocument758 pagesHigh Pressure Processing of Food - Principles, Technology and ApplicationsEduardo Estrada100% (1)

- Receiving Inspection ProcedureDocument2 pagesReceiving Inspection ProcedureErwin SantosoNo ratings yet

- Production Process and Product Release Procedure: 1 PurposeDocument7 pagesProduction Process and Product Release Procedure: 1 PurposeOmprakash ThakurNo ratings yet

- Structural Tanks and ComponentsDocument19 pagesStructural Tanks and ComponentsRodolfo Olate G.No ratings yet

- FsmsDocument9 pagesFsmsEngr Muhammad Asim IqbalNo ratings yet

- PV SDF 1 FdaDocument111 pagesPV SDF 1 FdaMelike EceoğluNo ratings yet

- 3 Growing in FaithDocument5 pages3 Growing in FaithJohnny PadernalNo ratings yet

- PPAPDocument4 pagesPPAPMattNo ratings yet

- Vendor Assessment - Self AssessmentDocument10 pagesVendor Assessment - Self Assessmentjennice18No ratings yet

- IFS GMP Check Guidance V1 EN FINALDocument8 pagesIFS GMP Check Guidance V1 EN FINALCristina Caetano de MatosNo ratings yet

- Global QCC Report-2015 PDFDocument84 pagesGlobal QCC Report-2015 PDFDave MustanieNo ratings yet

- Step 1 of 4Document7 pagesStep 1 of 4IdzhamReezaNo ratings yet

- QMP 8.2.4Document3 pagesQMP 8.2.4vernier11No ratings yet

- QualitysystemsDocument8 pagesQualitysystemsádfa caNo ratings yet

- 7-IF-QMS-07 Internal AuditDocument6 pages7-IF-QMS-07 Internal AuditGourav SainiNo ratings yet

- Cara ReportDocument25 pagesCara ReportSurendharNo ratings yet

- Prod-P01 ManufacturingDocument4 pagesProd-P01 ManufacturingRonald NyamurowaNo ratings yet

- Chapter 2. Additional EU Organic - 3Document14 pagesChapter 2. Additional EU Organic - 3Manuel MariñasNo ratings yet

- Summary Changes V4 Vs V5-0 GR enDocument8 pagesSummary Changes V4 Vs V5-0 GR ennmmartinsaNo ratings yet

- Working STNDDocument4 pagesWorking STNDvekas bhatiaNo ratings yet

- GSQMDocument48 pagesGSQMisolongNo ratings yet

- AV-OP-06 Manufacturing Iss 1Document4 pagesAV-OP-06 Manufacturing Iss 1Kevin DeLimaNo ratings yet

- GSB Procedure For CertificationDocument2 pagesGSB Procedure For Certificationsaisridhar99No ratings yet

- First & Last PieceDocument3 pagesFirst & Last PieceQuality VenusNo ratings yet

- PRC1003Document3 pagesPRC1003MohamedNo ratings yet

- ReportDocument4 pagesReportleav DaranyNo ratings yet

- MSP - MR - 03 Internal AuditDocument6 pagesMSP - MR - 03 Internal AuditsharanNo ratings yet

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersFrom EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersNo ratings yet

- ISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012From EverandISTQB Certified Tester Advanced Level Test Manager (CTAL-TM): Practice Questions Syllabus 2012No ratings yet

- 7 Quality PrinciplesDocument21 pages7 Quality PrinciplesMahmoud LotfyNo ratings yet

- Product Testing Work Plan: Single Color (Duco Paints - Metallic Paints)Document4 pagesProduct Testing Work Plan: Single Color (Duco Paints - Metallic Paints)Mahmoud LotfyNo ratings yet

- 4M Coatings ProfileDocument3 pages4M Coatings ProfileMahmoud LotfyNo ratings yet

- Nano ChemistryDocument17 pagesNano ChemistryMahmoud LotfyNo ratings yet

- Basic Information: Information Filled Out by StudentDocument14 pagesBasic Information: Information Filled Out by StudentMahmoud LotfyNo ratings yet

- Basic Information: Information Filled Out by Student: Nomenclature Rules of Metal ComplexesDocument15 pagesBasic Information: Information Filled Out by Student: Nomenclature Rules of Metal ComplexesMahmoud LotfyNo ratings yet

- Basic Information: Information Filled Out by StudentDocument14 pagesBasic Information: Information Filled Out by StudentMahmoud LotfyNo ratings yet

- Organic ConversionsDocument1 pageOrganic ConversionsMahmoud LotfyNo ratings yet

- Basic Information: Information Filled Out by StudentDocument13 pagesBasic Information: Information Filled Out by StudentMahmoud LotfyNo ratings yet

- 1st Term - Chapter One - 2nd Secondary - ChemistryDocument64 pages1st Term - Chapter One - 2nd Secondary - ChemistryMahmoud LotfyNo ratings yet

- A Research Presented ToDocument28 pagesA Research Presented ToAngeliePanerioGonzagaNo ratings yet

- ENG 110-Task 4 (Unintended Messages)Document2 pagesENG 110-Task 4 (Unintended Messages)Erika Noreen Dela RosaNo ratings yet

- Manuscript 1Document26 pagesManuscript 1Juan Paolo CapatiNo ratings yet

- DexaDocument36 pagesDexaVioleta Naghiu100% (1)

- Fpubh 10 1079779Document10 pagesFpubh 10 1079779Dona WirdaningsiNo ratings yet

- Victron Orion-Tr - Smart - DC-DC - Charger-Manual Non IsolatedDocument19 pagesVictron Orion-Tr - Smart - DC-DC - Charger-Manual Non IsolatedThomist AquinasNo ratings yet

- General Method For Cable Sizing - Electrical Installation GuideDocument10 pagesGeneral Method For Cable Sizing - Electrical Installation Guidebhaskar_dandapathakNo ratings yet

- DIABETES MELLITUS BensonDocument14 pagesDIABETES MELLITUS BensonNixon KeyaNo ratings yet

- Di SilvioDocument47 pagesDi SilviomaryroseengNo ratings yet

- Solar Grass Cutter MachDocument21 pagesSolar Grass Cutter MachAnonymous I13s99No ratings yet

- Define and State The Purpose of Therapeutic DietDocument10 pagesDefine and State The Purpose of Therapeutic DietKen GarciaNo ratings yet

- Yumiko@Document2 pagesYumiko@api-25886263No ratings yet

- Incorporating Developmental Screening and Surveillance of Young Children in Office PracticeDocument9 pagesIncorporating Developmental Screening and Surveillance of Young Children in Office PracticeakshayajainaNo ratings yet

- 1100 Buggy Service ManualDocument54 pages1100 Buggy Service Manualferran_alfonsoNo ratings yet

- 7-13-1996 Joel Nance MDDocument3 pages7-13-1996 Joel Nance MDAnother AnonymomsNo ratings yet

- X-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteDocument2 pagesX-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteAmr RagabNo ratings yet

- digiPHONENT UG enDocument44 pagesdigiPHONENT UG enIrving Javier Leal OrtizNo ratings yet

- Pulse Oximetry CircuitDocument19 pagesPulse Oximetry Circuitنواف الجهنيNo ratings yet

- Weather and ClimateDocument5 pagesWeather and ClimateprititjadhavnNo ratings yet

- Design of Sour Water Stripping System: February 2009Document23 pagesDesign of Sour Water Stripping System: February 2009mohsen ranjbarNo ratings yet

- Aqa Food Technology Coursework Mark SchemeDocument7 pagesAqa Food Technology Coursework Mark Schemeafjwdbaekycbaa100% (2)

- TableBookErrata PDFDocument4 pagesTableBookErrata PDFIbnuyusoff77No ratings yet

- Anthropocene Working Group PDFDocument6 pagesAnthropocene Working Group PDFRuth Stacy EmmanuelNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)