Professional Documents

Culture Documents

Keyed Through Tenon Joints

Uploaded by

Jerry Zhang0 ratings0% found this document useful (0 votes)

12 views4 pagesOriginal Title

Keyed-Through-Tenon-Joints

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views4 pagesKeyed Through Tenon Joints

Uploaded by

Jerry ZhangCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Bulletin

No. 2016‐08

First Release: July 2016 Revised:

Prepared by: Daniel Hindman, P.E., Ph.D. & Jim DeStefano, P.E., AIA, F.SEI

Title: Keyed Through Tenon Joints

Introduction

Keyed Through Tenon (KTT) joints use a

protruding tenon secured by a series of

trapezoidal keys on the back side of the

mortise. KTT joints are commonly used

on timber Howe trusses to join the king

post to the bottom chord (Figure1) and

also commonly used in New World

Figure 1 Howe Truss

Dutch Barns to join the anchor beam to

the post (Figure 2).

Figure 1 Howe Truss

KTT joints are typically loaded in tension. An

advantage of KTT joints compared to pegged

joints is the elimination of tension perpendicular to

grain failure in the mortise because the keys are

placed on the back of the mortise causing

compression forces.

Currently, there is little guidance or design

literature for KTT joints. The purpose of this

technical bulletin is to explain recent work done to

quantify the strength of KTT joints.

Figure 2 Anchor Beam

TFEC 1 Tech Bulletin No. 2016‐08

Research

The research was conducted by Lance Shields as a part of

his Master’s thesis under the supervision of Professor

Daniel Hindman at Virginia Tech, Blacksburg, Virginia.

Test specimens were fabricated from Douglas Fir and

White Oak and tested to failure to identify potential failure

modes (Figure 3). Specimens with different tenon lengths

(4 inches and 11 inches) were tested, as well as specimens

with 1 key and 2 keys.

Test results indicated that proper detailing and

proportioning of KTT joints is crucial to their

structural performance. Some of the joints Figure 3 Test Setup

failed prematurely in a brittle fashion while

others demonstrated ductile behavior. It is desirable to

have structural joints exhibit ductility.

KTT joints with short tenons (4 inch projection)

tended to fail when the relish below the key

mortises sheared off. KTT joints with long tenons

(11 inch projection) did not exhibit this failure

mode.

Relish shear failures are a brittle failure mode and

should be avoided. It is crucial that tenons be long

enough to preclude this failure mode.

Figure 4 Relish Failure

Another brittle failure mode that was observed

was splitting of the tenon. Splitting was caused by

tensile stress perpendicular to the grain of the

tenon. This failure mode was only observed in

joints that contained a single key. KTT joints with

two keys did not exhibit splitting failures.

It is advisable to use two keys in KTT joints as a

precaution against a brittle splitting failure.

Figure 5 Tenon Split

TFEC 2 Tech Bulletin No. 2016‐08

KTT joints that did not experience brittle relish

shear or splitting failures behaved in a ductile

fashion. The key wedges first crushed at their

bearing surfaces and then progressed to a bending

failure. Even after the keys fractured in bending, the

joint continued to resist load, exhibiting ductile

behavior.

All of the joints tested had a single wedge for each

key. If opposing wedges are used for keys, it is

anticipated that the key bending resistance will be

Figure 6 Crushing and Bending of Key Wedges improved.

Detailing Guidelines

The following guidelines for

proportioning KTT joints is intended

to minimize the likelihood of a brittle

joint failure. The dimensions

indicated are minimum dimensions

and may need to be increased where

required by structural calculations.

The end distance at the key

mortise should not be less

than 10 inches.

A minimum of two keys,

each consisting of opposing

wedges.

Tenon thickness should be

not less than 2 inches.

Key mortise should be sized

to allow for seasoning of the

timbers and subsequent

tightening of keys.

Figure 7 KTT Joint Detail

TFEC 3 Tech Bulletin No. 2016‐08

Key wedges should be made from seasoned hardwood

with a specific gravity not less than that of the timber.

Seasoning effects must be considered. As the timbers

season and shrink, it is crucial that the key wedges be

tightened. Failure to do so could have dire consequences.

Figure 8 Key Wedge

Structural Design

In analyzing the structural capacity of a KTT joint loaded in tension, the following failure modes

should be evaluated.

Net tension strength of the tenon

Relish shear resistance of the tenon

Crushing strength of keys

Reference

Investigation of Trough Tenon Keys on the Tensile Strength of Mortise and Tenon Joints by

Lance Shields, Virginia Tech, Blacksburg, VA, June 10, 2011

Daniel Hindman, P.E., Ph.D. is an Associate Professor in the Department of Sustainable

Biomaterials at Virginia Tech, Blacksburg, VA

Jim DeStefano, P.E., AIA, F.SEI is president of DeStefano & Chamberlain, Inc., Fairfield, CT

TFEC 4 Tech Bulletin No. 2016‐08

You might also like

- Chapter 3a Riveted JointDocument20 pagesChapter 3a Riveted JointAdugna GosaNo ratings yet

- Structural TieDown StrapDocument4 pagesStructural TieDown StrapRaja RajanNo ratings yet

- Moment Connections in TimberDocument5 pagesMoment Connections in TimberrajeevNo ratings yet

- Effect of Bolt Pretension in Single Lap Bolted Joint IJERTV4IS010269Document4 pagesEffect of Bolt Pretension in Single Lap Bolted Joint IJERTV4IS010269ayush100% (1)

- Russell-Taylor Delta-Tibial Interlocking Nail TechniqueDocument30 pagesRussell-Taylor Delta-Tibial Interlocking Nail TechniquemikeydamanNo ratings yet

- Whether You Need To Ream Casing To Bottom, or Rotate During Cementing, MLT Rings Enable SuccessDocument4 pagesWhether You Need To Ream Casing To Bottom, or Rotate During Cementing, MLT Rings Enable SuccessSudish BhatNo ratings yet

- E-EMM 3122-8-Failure in Ferrous Metal (N)Document28 pagesE-EMM 3122-8-Failure in Ferrous Metal (N)KHAIRUL NASHRAN BIN ANUAR / UPMNo ratings yet

- The Mortise and Tenon Joint: Best Results Come Directly From Chisel and SawDocument6 pagesThe Mortise and Tenon Joint: Best Results Come Directly From Chisel and SawAdrian Cocis100% (1)

- Design of Permanent Joints RivetsDocument37 pagesDesign of Permanent Joints RivetsAmunyela FelistasNo ratings yet

- Bridge Plating PDFDocument4 pagesBridge Plating PDFKae 王珊婷 Wang100% (1)

- American Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsDocument32 pagesAmerican Institute of Timber Construction: AITC 104-2003 Typical Construction DetailsMohammad Humayun KabirNo ratings yet

- Failures in RivetDocument8 pagesFailures in RivetAtrayee MajumderNo ratings yet

- Theory of Structure: Post-Tensioned SlabsDocument18 pagesTheory of Structure: Post-Tensioned SlabsPuru VashisthNo ratings yet

- Locking Plate Techniques For Fracture Stability: Jay D. Ryan, DPMDocument5 pagesLocking Plate Techniques For Fracture Stability: Jay D. Ryan, DPMAnonymous kdBDppigENo ratings yet

- Machine Design-I and II Lecture NotesDocument37 pagesMachine Design-I and II Lecture NotesAzeem MohammadNo ratings yet

- Ch08 TCSu 2021 HandoutDocument33 pagesCh08 TCSu 2021 Handout林昱呈No ratings yet

- Rebar TyingDocument24 pagesRebar Tyingdeepak singhNo ratings yet

- Design of Steel Bolted ConnectionsDocument34 pagesDesign of Steel Bolted ConnectionsManjunath Tontanal0% (1)

- Design of Permanent Joints: Version 2 ME, IIT KharagpurDocument11 pagesDesign of Permanent Joints: Version 2 ME, IIT Kharagpurk.ramakrishnaNo ratings yet

- 27 Riveted Joints Types and UsesDocument11 pages27 Riveted Joints Types and UsesPRASAD326100% (1)

- Multiple Fragment Fracture Fixation TechniquesDocument8 pagesMultiple Fragment Fracture Fixation Techniqueskenny StefNo ratings yet

- fplrp382 PDFDocument26 pagesfplrp382 PDFWiryantoNo ratings yet

- Mech-V-Design of Machine Elements I U7 PDFDocument45 pagesMech-V-Design of Machine Elements I U7 PDFHaniya FathimaNo ratings yet

- 26-19 Y 24-20Document10 pages26-19 Y 24-20aur.lai.kaNo ratings yet

- Riveted Joints Types and UsesDocument11 pagesRiveted Joints Types and UsesAbdurrahman shuaibNo ratings yet

- Notches Notch Sensitivity and Applications in Fracture MechanicsDocument12 pagesNotches Notch Sensitivity and Applications in Fracture MechanicstahirNo ratings yet

- سمنر2Document58 pagesسمنر2123No ratings yet

- Managing Horizontal Forces in Stamping Dies-Part 2 - MetalForming Magazine ArticleDocument6 pagesManaging Horizontal Forces in Stamping Dies-Part 2 - MetalForming Magazine ArticleNaukowyDrpNo ratings yet

- Fulton-Trepanier-Dispelling The Myth About Unbonded PT BuildingsDocument7 pagesFulton-Trepanier-Dispelling The Myth About Unbonded PT BuildingsFabrini SousaNo ratings yet

- Structural BracingStrapDocument4 pagesStructural BracingStrapAlex ZecevicNo ratings yet

- 9 Failure PDFDocument19 pages9 Failure PDFRalph Ian CaingcoyNo ratings yet

- Rivets and Welded JointDocument37 pagesRivets and Welded JointJohn Kris San LuisNo ratings yet

- Stress Analysis of Riveted Lap JointDocument7 pagesStress Analysis of Riveted Lap JointMeck LotfiNo ratings yet

- Topic 2 Wood JointsDocument54 pagesTopic 2 Wood JointsMachalyn Chua100% (2)

- Turnout Operating Unit MK 2Document5 pagesTurnout Operating Unit MK 2Li XinNo ratings yet

- Nuts and Bolts: Threaded Fastener IssuesDocument11 pagesNuts and Bolts: Threaded Fastener IssuesPeterNo ratings yet

- FastenersDocument11 pagesFastenersvenkat mechNo ratings yet

- Keynote ToruTakeuchiDocument73 pagesKeynote ToruTakeuchit3487810interzetruNo ratings yet

- CH 08Document35 pagesCH 08rorychuang0803No ratings yet

- Newsletter 0911 PDFDocument80 pagesNewsletter 0911 PDFWilson MillanNo ratings yet

- Failure Modes of Bolt and Nut Assemblies Under Tensile LoadingDocument11 pagesFailure Modes of Bolt and Nut Assemblies Under Tensile LoadingclevercogNo ratings yet

- Chapt 08 2023-StudentDocument40 pagesChapt 08 2023-Student66011058No ratings yet

- Rite Up PDFDocument66 pagesRite Up PDFDayal SharanNo ratings yet

- 59 Why Nuts and Bolts Come Loose V1Document2 pages59 Why Nuts and Bolts Come Loose V1civicbladeNo ratings yet

- Author Manuscript: Microstructure and Thickness Effects On Impact Behavior and Separation Formation in X70 Pipeline SteelDocument20 pagesAuthor Manuscript: Microstructure and Thickness Effects On Impact Behavior and Separation Formation in X70 Pipeline Steelvijayaraman rajendranNo ratings yet

- Steel Structures Fasteners GuideDocument34 pagesSteel Structures Fasteners GuideEmreNo ratings yet

- Riveting Process Modeling and Simulating For DeforDocument9 pagesRiveting Process Modeling and Simulating For DeforDheeraj GundNo ratings yet

- Instruction Manual For Installing High-Strength Bolts: With Direct Tension Indicators (ASTM F959M) Metric Series EditionDocument24 pagesInstruction Manual For Installing High-Strength Bolts: With Direct Tension Indicators (ASTM F959M) Metric Series EditionHendri Arief SetyawanNo ratings yet

- Damaging: Permanent JointsDocument16 pagesDamaging: Permanent JointsKrishna MurthyNo ratings yet

- 05S2604AIDocument3 pages05S2604AIArto SillanpääNo ratings yet

- Con Eng f4sDocument13 pagesCon Eng f4scristian.rodriguezNo ratings yet

- Metallic Wires for Card Clothing ApplicationsDocument8 pagesMetallic Wires for Card Clothing ApplicationsVenkat PrasannaNo ratings yet

- Steel Connections: Pre Pare D by Rayan Mohamme DDocument13 pagesSteel Connections: Pre Pare D by Rayan Mohamme DFAHD ABDUL RAHMANNo ratings yet

- 9.nto Vol 09Document25 pages9.nto Vol 09Oualid HamdiNo ratings yet

- GN-Guideline-98 - Wall Bracing Tie-DownDocument1 pageGN-Guideline-98 - Wall Bracing Tie-Downsparta_avatarNo ratings yet

- ME 307 Machine Design I: Bolted Joint Design and AnalysisDocument24 pagesME 307 Machine Design I: Bolted Joint Design and Analysisfog900No ratings yet

- ME 307 Machine Design I: Bolted Joint StiffnessDocument24 pagesME 307 Machine Design I: Bolted Joint Stiffnessfog900No ratings yet

- The Running-In Process in Tribology: Proceeding of the 8th Leeds–Lyon Symposium on Tribology, Held in the Institute National des Science Appliquées de Lyon, France, 8–11 September 1981From EverandThe Running-In Process in Tribology: Proceeding of the 8th Leeds–Lyon Symposium on Tribology, Held in the Institute National des Science Appliquées de Lyon, France, 8–11 September 1981No ratings yet

- The Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaFrom EverandThe Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD M R TaplinNo ratings yet

- Juice Up Your Joinery: Artistic Tenons Pack Structural Power With Visual PunchDocument8 pagesJuice Up Your Joinery: Artistic Tenons Pack Structural Power With Visual PunchJerry ZhangNo ratings yet

- Develop Your Own Designs: A Step-By-Step Process Unlocks Your CreativityDocument6 pagesDevelop Your Own Designs: A Step-By-Step Process Unlocks Your CreativityJerry ZhangNo ratings yet

- Rules of Timber Joinery DesignDocument3 pagesRules of Timber Joinery DesignJerry ZhangNo ratings yet

- SpycywlfDocument195 pagesSpycywlfJerry ZhangNo ratings yet

- Design of Rounded Dovetail JointsDocument6 pagesDesign of Rounded Dovetail JointsJerry ZhangNo ratings yet

- In Pursuit of Traditional Japanese Amanita muscaria PicklesDocument82 pagesIn Pursuit of Traditional Japanese Amanita muscaria PicklesJerry ZhangNo ratings yet

- Mushoku Tensei - Jobless Reincarnation Volume-8Document217 pagesMushoku Tensei - Jobless Reincarnation Volume-8Pablo Alconz100% (1)

- Lecture 01Document61 pagesLecture 01Jerry ZhangNo ratings yet

- CS2Class7 DynProgrammingDocument3 pagesCS2Class7 DynProgrammingJerry ZhangNo ratings yet

- 31 Samss 001Document38 pages31 Samss 001nadeem shaikh100% (1)

- Steel - Ch5 - Beam-Column 1 - 0Document30 pagesSteel - Ch5 - Beam-Column 1 - 0Munther MohdNo ratings yet

- HW12-2021 - CLTD - SHG - CLF Rev02 - 428891754Document10 pagesHW12-2021 - CLTD - SHG - CLF Rev02 - 428891754Arslan GoharNo ratings yet

- Low Voltage Joints and Terminations PDFDocument24 pagesLow Voltage Joints and Terminations PDFElafanNo ratings yet

- Anti-Slip Tapes: Technical Data SheetDocument2 pagesAnti-Slip Tapes: Technical Data SheetSabuhi JafarliNo ratings yet

- 1684468-Helical SpringDocument219 pages1684468-Helical SpringzohebNo ratings yet

- Elevator & Conveying SystemsDocument2 pagesElevator & Conveying SystemssuhasNo ratings yet

- Zhou 2007Document9 pagesZhou 2007Francisco Luiz Perdigão NetoNo ratings yet

- Engineering Learning ModulesDocument158 pagesEngineering Learning Moduleskarthikraja21100% (2)

- S75 Catalog Eng PDFDocument8 pagesS75 Catalog Eng PDFsixtoNo ratings yet

- Electrical Schedule and WiringDocument1 pageElectrical Schedule and WiringJeremy BuelbaNo ratings yet

- TOP/05 is flexible friction material for brake padsDocument1 pageTOP/05 is flexible friction material for brake padsMarcos LópezNo ratings yet

- Method Statement Retaining WallDocument3 pagesMethod Statement Retaining Wallibrahim0% (1)

- 3 Point Bending Test Determines Glass Flexural PropertiesDocument4 pages3 Point Bending Test Determines Glass Flexural PropertiesFlynn GouldNo ratings yet

- Determination of Wall "U" ValueDocument1 pageDetermination of Wall "U" Value1985PolytechNo ratings yet

- VAroughneck EnglishDocument8 pagesVAroughneck Englishguitar_flyNo ratings yet

- Ergonomic Height-Adjustable Medical SinksDocument4 pagesErgonomic Height-Adjustable Medical SinksShaikh Emran HossainNo ratings yet

- Investigatory Project On Prep of CementDocument9 pagesInvestigatory Project On Prep of CementKrish JaiswalNo ratings yet

- Types of Brick BondsDocument8 pagesTypes of Brick BondsDheeraj ChauhanNo ratings yet

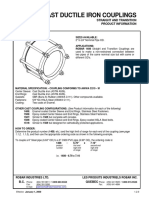

- P Robar 1408 Cast Ductile Iron CouplingsDocument1 pageP Robar 1408 Cast Ductile Iron CouplingsBrandon HoltenNo ratings yet

- Foundation Design MarkDocument20 pagesFoundation Design MarkJuliet Lobrino RozosNo ratings yet

- Kraloy - PVC Conduit FittingsDocument34 pagesKraloy - PVC Conduit FittingsEduardo ClavierNo ratings yet

- DAT11 - VISIT - Central - Structure of Skyscrapers - Teaching NotesDocument15 pagesDAT11 - VISIT - Central - Structure of Skyscrapers - Teaching Notesahtin618No ratings yet

- Thermal Engineering - K. K. Ramalingam PDFDocument107 pagesThermal Engineering - K. K. Ramalingam PDFsatya100% (1)

- Ppo PPSDocument22 pagesPpo PPSSirawit WitpathomwongNo ratings yet

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueDocument1 pageControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilNo ratings yet

- Part 5 Manufacturing 2023Document94 pagesPart 5 Manufacturing 2023Ilham AyuningNo ratings yet

- Defects in ToolDocument10 pagesDefects in ToolAhsan AliNo ratings yet

- HRSG & BOP Foundations TrainingDocument82 pagesHRSG & BOP Foundations Trainingsreenivasulu chenchugariNo ratings yet

- Piles DesignDocument12 pagesPiles Designn_sasanNo ratings yet