Professional Documents

Culture Documents

Flanges General - Bolting Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud Bolts

Uploaded by

Hakan ŞahinoğluCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flanges General - Bolting Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud Bolts

Uploaded by

Hakan ŞahinoğluCopyright:

Available Formats

24.05.

2018 Flanges general - Bolt ng Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud Bolts

Flange Bolt-Up Bolt ng Torque Table 2

The torque tables are built on specific assumptions regarding bolt and nut factor. Before

using a given torque table, these assumptions should be verified to insure they are

appropriate for the specific application.

Even if all assumptions are appropriate, results may vary depending on actual conditions.

Many factors induce scatter in the results or increase the inherent variability in the bolting

process. These include variations in the nut factor; bolt, flange and nut condition; equipment

calibration and condition; perpendicularity of the bolt, nut and flange; etc.

The values in the tables are based on the equation:

T = Torque value, (ft-lbs)

F = Bolt pre-load, (lbs)

k = Nut Factor based on lubricant used

d = Nominal bolt diameter, (in.)

The nut factor is not the coefficient of friction.

It is an experimentally derived constant that includes the impact of friction.

ft-lbs to nm = 0.737562149277

nm to ft-lbs = 1.3558179

TABLE 2 / TORQUE FT-LBS - ASTM 193 GRADE B7 AND ASTM 193 GRADE

B16 STUD BOLTS

TORQUE FT-LBS

BOLT

DIA 30% Initial 70% 100% Final

Torque Torque Torque

1/2 17 39 55

9/16 24 55 80

5/8 33 77 110

3/4 59 137 195

7/8 93 217 310

1 140 325 465

1⅛ 205 480 685

1¼ 288 672 960

1⅜ 391 915 1305

1½ 518 1208 1725

http://www.wermac.org/flanges/flanges_bolt ng-torque-tables_table2.html 1/3

24.05.2018 Flanges general - Bolt ng Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud Bolts

19/16 588 1372 1960

1⅝ 668 1558 2225

1¾ 840 1960 2800

1⅞ 1044 2436 3480

2 1280 2985 4265

2¼ 1850 4315 6165

2½ 2565 5985 8550

2¾ 3121 7282 10400

3 4080 9520 13600

TABLE 2 / TORQUE FT-LBS - ASTM 193 GRADE B7 AND ASTM 193 GRADE

B16 STUD BOLTS

TABLE 2 / TORQUE NM - ASTM 193 GRADE B7 AND ASTM 193 GRADE B16

STUD BOLTS

TORQUE NM

BOLT

DIA 30% Initial 70% 100% Final

Torque Torque Torque

1/2 23 53 75

9/16 33 75 108

5/8 45 104 149

3/4 80 186 264

7/8 126 294 420

1 190 441 630

1⅛ 278 651 929

1¼ 390 911 1302

1⅜ 530 1241 1769

1½ 702 1638 2339

19/16 797 1860 2657

1⅝ 906 2112 3017

1¾ 1139 2657 3796

1⅞ 1415 3303 4718

2 1735 4047 5783

2¼ 2508 5850 8359

http://www.wermac.org/flanges/flanges_bolt ng-torque-tables_table2.html 2/3

24.05.2018 Flanges general - Bolt ng Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud Bolts

2½ 3478 8115 11592

2¾ 4232 9873 14101

3 5532 12907 18439

TABLE 2 / TORQUE NM - ASTM 193 GRADE B7 AND ASTM 193 GRADE B16

STUD BOLTS

Notes:

Bolting torque to develop 50% Bolt Yield Stress at Nut Factor, K=0.16

This Table is applicable to Never-Seize paste and Fel-Pro lubricant,

K=0.16.

The above Table is applicable only for ASTM A320 Grade L7, A193

Grade B7 and A193 Grade B16 Stud Bolts.

The torque values are approved for spiral wound graphite and PTFE

filled gaskets, graphite sheet gaskets GHE and GHR types, ring joint,

double jacketed and Camprofile gaskets with graphite and PTFE

lining.

The Final Torque Value accounts for 10% bolt relaxation.

This Table is not acceptable for PTFE coated Stud Bolts and nuts, for

these refer to Table 5.

http://www.wermac.org/flanges/flanges_bolt ng-torque-tables_table2.html 3/3

You might also like

- ASTM F1545 Plastic Lined Pipe 0803Document6 pagesASTM F1545 Plastic Lined Pipe 0803JabranYounasNo ratings yet

- Uk-Standard Asme Bladder AccumulatorDocument3 pagesUk-Standard Asme Bladder AccumulatorRamin SoadNo ratings yet

- Upa 150c Ing.Document7 pagesUpa 150c Ing.Alfredo HerreraNo ratings yet

- Torque para PrisionerosDocument3 pagesTorque para PrisionerosJulian Chia100% (1)

- TCE Babbitt 18391-2Document2 pagesTCE Babbitt 18391-2paulo cesar hernandez mijangosNo ratings yet

- Agitadores PlentyDocument16 pagesAgitadores Plentyrolando tapiaNo ratings yet

- Effect of Viscosity On PumpsDocument4 pagesEffect of Viscosity On PumpsChemkhiNo ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- Product Overview - LeuschDocument32 pagesProduct Overview - Leuschprihartono_diasNo ratings yet

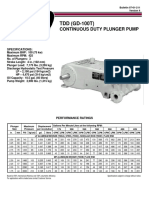

- Data Sheet TDD-GD100T PDFDocument2 pagesData Sheet TDD-GD100T PDFjhon peñaNo ratings yet

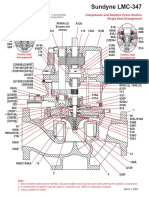

- Sundyne LMC-347: Compressor and Gearbox Cross Section Single Seal ArrangementDocument1 pageSundyne LMC-347: Compressor and Gearbox Cross Section Single Seal Arrangementmasoud67aNo ratings yet

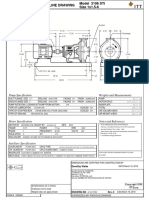

- Pump Specification Weights and Measurements: Dorothy WaiteDocument14 pagesPump Specification Weights and Measurements: Dorothy WaiteJuan Pablo SanchezNo ratings yet

- Screw SelectionDocument1 pageScrew Selectionamarr1No ratings yet

- Pressure Temperature Chart According To ASME B16.34 ASME B PV CodeDocument5 pagesPressure Temperature Chart According To ASME B16.34 ASME B PV CodeDwayne YiiNo ratings yet

- BFP ARC Valve FunctionDocument6 pagesBFP ARC Valve FunctionVenkat ShanNo ratings yet

- Horizontal & SuHorizontal & Sump Pumpmp PumpsDocument105 pagesHorizontal & SuHorizontal & Sump Pumpmp PumpsAnonymous dHLFEZuhBa50% (2)

- Report Vibrasi Plant CP-2Document13 pagesReport Vibrasi Plant CP-2hafiz_hayat_44190215No ratings yet

- Pump Tolerences PDFDocument10 pagesPump Tolerences PDFarunsyukumarNo ratings yet

- Installation, operation and maintenance manual for SJD-API ASSY w BRG 0909Document1 pageInstallation, operation and maintenance manual for SJD-API ASSY w BRG 0909dave fowlerNo ratings yet

- Single-Stage Steam TurbinesDocument8 pagesSingle-Stage Steam Turbinesfouzi gherNo ratings yet

- KS3-Steam Turbine Over Speed Trip SystemsDocument8 pagesKS3-Steam Turbine Over Speed Trip SystemsArul Kumaran Kothandapani100% (1)

- Equivalent Length of A Reducer - Google SearchDocument3 pagesEquivalent Length of A Reducer - Google SearchzoksiNo ratings yet

- Pages de ASME VIII - DIV.1 (2019) Table UW-12Document1 pagePages de ASME VIII - DIV.1 (2019) Table UW-12HamdiMallouli100% (1)

- Dinflo DFCSDocument2 pagesDinflo DFCSvictorharijantoNo ratings yet

- Multistage SpiroglideDocument4 pagesMultistage SpiroglidedestinyrestartNo ratings yet

- Install and maintain Check Rite wafer check valvesDocument18 pagesInstall and maintain Check Rite wafer check valvesRoman Arango Herrera0% (1)

- Pump ZM B PDFDocument12 pagesPump ZM B PDFRamon PachecoNo ratings yet

- Hydraulics CurriculumDocument8 pagesHydraulics CurriculumChris ChrisNo ratings yet

- Multistage Pump Disassembly GuideDocument24 pagesMultistage Pump Disassembly GuideHishamSayedNo ratings yet

- Elwood Parts and Service ManualDocument75 pagesElwood Parts and Service Manualdindin6666No ratings yet

- WS 3Document9 pagesWS 3Eddie SantillánNo ratings yet

- Tube and Pipe Material Comparison ChartDocument2 pagesTube and Pipe Material Comparison Chartvalli rajuNo ratings yet

- Royal Purple BarrierDocument14 pagesRoyal Purple BarrierAnonymous H3I29yjNo ratings yet

- Ball Valves - MethodDocument28 pagesBall Valves - Methodbloggerparthi100% (1)

- Compression Packing Selection Guide: Sealing Products For IndustryDocument13 pagesCompression Packing Selection Guide: Sealing Products For IndustryAdverNo ratings yet

- British o Ring Sizes Bs4518Document1 pageBritish o Ring Sizes Bs4518pmarteeneNo ratings yet

- Bidirectional Sealing Ball Valves in Power ApplicationsDocument3 pagesBidirectional Sealing Ball Valves in Power Applicationsxisefengchuang100% (1)

- Fan Calculation MooreDocument8 pagesFan Calculation MooreArjun GirishNo ratings yet

- Safety Data Sheet MSDS - Vanadium-Electrolyt-Lösung2014-10-20Document9 pagesSafety Data Sheet MSDS - Vanadium-Electrolyt-Lösung2014-10-20XaviAlonsoNo ratings yet

- Sedifilt Oil & Gas Brochure PDFDocument8 pagesSedifilt Oil & Gas Brochure PDFAalap DerasaryNo ratings yet

- KCDocument3 pagesKCSandheepKumarNo ratings yet

- H2S & Total Sulfur AnalyzersDocument16 pagesH2S & Total Sulfur AnalyzersBryan TungNo ratings yet

- Sa 193&sa 193M PDFDocument18 pagesSa 193&sa 193M PDFGabriel RodríguezNo ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Durco Plug Valve Dimensions PDFDocument28 pagesDurco Plug Valve Dimensions PDFjtai1983No ratings yet

- Manual 99 LDDocument20 pagesManual 99 LDCristianNo ratings yet

- Geg A: Bolt-Up Procedure For Flanged Connections 670.210Document9 pagesGeg A: Bolt-Up Procedure For Flanged Connections 670.210puwarin najaNo ratings yet

- ACHE Windmill DraftguardDocument5 pagesACHE Windmill DraftguardTIKSHALANo ratings yet

- Variables For Welding 11-3-2016 - 264B1DF6 PDFDocument2 pagesVariables For Welding 11-3-2016 - 264B1DF6 PDFSameh AminNo ratings yet

- EspeyDocument20 pagesEspeyGuillermo Esteban Diaz QuezadaNo ratings yet

- Hda Operational ManualDocument48 pagesHda Operational ManualDouglas DuarteNo ratings yet

- Metal Tapered Tube Plugs: Tube Plug Sizing ChartDocument1 pageMetal Tapered Tube Plugs: Tube Plug Sizing ChartRaghavanNo ratings yet

- BPCL CYLINDER MANUFACTURINGDocument34 pagesBPCL CYLINDER MANUFACTURINGVishalVaishNo ratings yet

- OPERATING & SERVICE MANUAL AZ-1-107-NL SERIES PUMPDocument16 pagesOPERATING & SERVICE MANUAL AZ-1-107-NL SERIES PUMPREZA ASGARINo ratings yet

- Flange Bolt-Up Bolting Torque Table 2 PDFDocument4 pagesFlange Bolt-Up Bolting Torque Table 2 PDFddarioxavier80No ratings yet

- جدول تورک فلنجDocument18 pagesجدول تورک فلنجAli AlizadehNo ratings yet

- Electrical Bolt Torque Values TablesDocument2 pagesElectrical Bolt Torque Values TablesOswaldo JavierNo ratings yet

- TABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedDocument3 pagesTABLE 100.12.1 Bolt-Torque Values For Electrical Connections US Standard Fasteners Heat-Treated Steel - Cadmium or Zinc PlatedKennedy VasconezNo ratings yet

- fc5200 SpecificationsDocument12 pagesfc5200 SpecificationsHakan ŞahinoğluNo ratings yet

- Jig B 35 July 2010 Soak TestDocument7 pagesJig B 35 July 2010 Soak Testtrao973483% (6)

- Bulletin 90 HingedPitLids May 20164Document2 pagesBulletin 90 HingedPitLids May 20164سید محمد حسن شریفیNo ratings yet

- JIG Bulletin - 84-EI-1560-Recommended-Practice-Dec-2015Document2 pagesJIG Bulletin - 84-EI-1560-Recommended-Practice-Dec-2015Hakan ŞahinoğluNo ratings yet

- Research On The Safety and Security Distance of Above-Ground Liquefied Gas Storage Tanks and DispensersDocument11 pagesResearch On The Safety and Security Distance of Above-Ground Liquefied Gas Storage Tanks and DispensersHakan ŞahinoğluNo ratings yet

- Smart H.265+: Smart Codec, Lower Bit Rate, Less StorageDocument12 pagesSmart H.265+: Smart Codec, Lower Bit Rate, Less StorageHakan ŞahinoğluNo ratings yet

- Combustible Dust and Gases HandlingDocument5 pagesCombustible Dust and Gases HandlingHakan ŞahinoğluNo ratings yet

- Combustible Dust and Gases HandlingDocument5 pagesCombustible Dust and Gases HandlingHakan ŞahinoğluNo ratings yet

- Libro de Mano de Recarga de Combustible AviacionDocument113 pagesLibro de Mano de Recarga de Combustible AviacionOzkhar AFNo ratings yet

- Reliable Perfection: First-Class Papers For Flexible Packaging SolutionsDocument8 pagesReliable Perfection: First-Class Papers For Flexible Packaging SolutionsHakan ŞahinoğluNo ratings yet

- Method Statement for New Petrol Filling Station DemolitionDocument15 pagesMethod Statement for New Petrol Filling Station DemolitionmuthunayakeNo ratings yet

- Handbook: For Sack Kraft Papers and Paper SacksDocument62 pagesHandbook: For Sack Kraft Papers and Paper SacksHakan ŞahinoğluNo ratings yet

- Pe100+ Quality Materials: Kiwa Gastec Certification B.VDocument2 pagesPe100+ Quality Materials: Kiwa Gastec Certification B.VHakan ŞahinoğluNo ratings yet

- Koc List Approved ContractorsDocument9 pagesKoc List Approved ContractorsAhmedNo ratings yet

- Mobilization Plan For The Y-12 9409-5 Tank Storage Facility 5 Rcra Closure Plan 2Document21 pagesMobilization Plan For The Y-12 9409-5 Tank Storage Facility 5 Rcra Closure Plan 2Hakan ŞahinoğluNo ratings yet

- Yantai Taihong Rubber Co rubber fender manufacturer history capabilitiesDocument40 pagesYantai Taihong Rubber Co rubber fender manufacturer history capabilitiesHakan ŞahinoğluNo ratings yet

- Notes On Convex Sets, Polytopes, Polyhedra, Combinatorial Topology, Voronoi Diagrams An Delaunay TriangulationsDocument193 pagesNotes On Convex Sets, Polytopes, Polyhedra, Combinatorial Topology, Voronoi Diagrams An Delaunay TriangulationsHakan ŞahinoğluNo ratings yet

- DIO - Final Form of UNINCORPORATED CONTRACT (Schedules) - REDACTED PDFDocument256 pagesDIO - Final Form of UNINCORPORATED CONTRACT (Schedules) - REDACTED PDFanisthabetNo ratings yet

- Yantai Taihong Rubber Co rubber fender manufacturer history capabilitiesDocument40 pagesYantai Taihong Rubber Co rubber fender manufacturer history capabilitiesHakan ŞahinoğluNo ratings yet

- AutoCAD® Plant 3D Spec and Catalog EditorDocument9 pagesAutoCAD® Plant 3D Spec and Catalog EditorHakan ŞahinoğluNo ratings yet

- RFD MD Update 20180504Document13 pagesRFD MD Update 20180504Hakan ŞahinoğluNo ratings yet

- P20 and P40 Operators Handbook Nov 2014Document16 pagesP20 and P40 Operators Handbook Nov 2014Hakan ŞahinoğluNo ratings yet

- Shoot - March 2015Document64 pagesShoot - March 2015Hakan ŞahinoğluNo ratings yet

- Soak Testing of Aviation Fuel Facilities and EquipmentDocument8 pagesSoak Testing of Aviation Fuel Facilities and EquipmentHakan Şahinoğlu100% (5)

- OTTAC HandbookDocument68 pagesOTTAC Handbookadinutza79No ratings yet

- MS Project For Construction Scheduler (Unreliable)Document29 pagesMS Project For Construction Scheduler (Unreliable)Teniozo_Mesdward100% (1)

- OTTAC HandbookDocument68 pagesOTTAC Handbookadinutza79No ratings yet

- Engineers Guide To Drinks - ColorDocument1 pageEngineers Guide To Drinks - ColorStuie444No ratings yet

- JCAMECH Volume 52 Issue 1 Pages 102-125Document24 pagesJCAMECH Volume 52 Issue 1 Pages 102-125Subodh KumarNo ratings yet

- Astm - D5528.6288Document13 pagesAstm - D5528.6288NeTiinho AndradeNo ratings yet

- Coanda Screen Design GuidanceDocument44 pagesCoanda Screen Design GuidanceEstefania Agudelo OrregoNo ratings yet

- Trsm1500en-Us 0517Document254 pagesTrsm1500en-Us 0517Keith McCann100% (1)

- OB-81 Lecture Notes Algebra, Trigonometry and FunctionsDocument23 pagesOB-81 Lecture Notes Algebra, Trigonometry and Functionssadam panhwarNo ratings yet

- Single-Phase PWM Rectifier Control for TractionDocument7 pagesSingle-Phase PWM Rectifier Control for Tractiondeepak_gupta_pritiNo ratings yet

- EMPUJE DE TIERRAS - Active Earth PressureDocument1 pageEMPUJE DE TIERRAS - Active Earth PressuremistakyNo ratings yet

- KASTO 206 (인장 및 압축 시험기) PDFDocument28 pagesKASTO 206 (인장 및 압축 시험기) PDFTJNo ratings yet

- 3D Modelling of Ground Surface Vibration Induced by Underground Train MovementDocument7 pages3D Modelling of Ground Surface Vibration Induced by Underground Train Movementkartho othoNo ratings yet

- Hyundai Heavy Industries - Engine Power Plant PDFDocument8 pagesHyundai Heavy Industries - Engine Power Plant PDFardian.sapartomoNo ratings yet

- MEMS Assignment On Crystal Structure of Silicon: R.Vijayaraghavan - 11MMT0002Document6 pagesMEMS Assignment On Crystal Structure of Silicon: R.Vijayaraghavan - 11MMT0002Vijayraghavan RameshNo ratings yet

- PCM400a (Dragged)Document1 pagePCM400a (Dragged)someone11111No ratings yet

- Astm D4751 - 04Document6 pagesAstm D4751 - 04nazrul islamNo ratings yet

- SP025 KMKT SET 1 (SOLUTION)Document11 pagesSP025 KMKT SET 1 (SOLUTION)naderaqistina23No ratings yet

- Basic Rotor Aerodynamics: 1D MomentumDocument6 pagesBasic Rotor Aerodynamics: 1D MomentumJagabar SathikNo ratings yet

- Pulsatile Oldroyd-B Blood Flow Dynamics in A Stenosed ArteryDocument9 pagesPulsatile Oldroyd-B Blood Flow Dynamics in A Stenosed ArteryJuana Valentina CamachoNo ratings yet

- Dictionary of Physical GeographyDocument626 pagesDictionary of Physical GeographyDiana Olarasu100% (3)

- ZnO Ethylene GlycolDocument12 pagesZnO Ethylene GlycolVipin NairNo ratings yet

- BADLEYS TRAPTESTER GeoTechLongDocument83 pagesBADLEYS TRAPTESTER GeoTechLongapi-27411749No ratings yet

- Soaring 7 2E EnrichmentExercises PDFDocument46 pagesSoaring 7 2E EnrichmentExercises PDFRicardo SantillanNo ratings yet

- Addressing Plugging Wear Spillage TransferchutesDocument43 pagesAddressing Plugging Wear Spillage Transferchutesmishra_1982No ratings yet

- Module 2 Thermochemistry - CalorimetryDocument34 pagesModule 2 Thermochemistry - CalorimetryBro KingNo ratings yet

- Ultimate Strength DesignDocument25 pagesUltimate Strength DesignBryle Steven Newton100% (2)

- Ulangkaji Bab 1-8 (Picked)Document4 pagesUlangkaji Bab 1-8 (Picked)Yokky KowNo ratings yet

- Low Thermal Conductivity Elastomeric InsulationDocument5 pagesLow Thermal Conductivity Elastomeric InsulationManuel MoranNo ratings yet

- Experiment 8: Determination of The Ratio of The Specific Heats of AIRDocument9 pagesExperiment 8: Determination of The Ratio of The Specific Heats of AIRwallace kitoNo ratings yet

- The Algebraic Geometry of Motions of Bar-And-Body FrameworksDocument32 pagesThe Algebraic Geometry of Motions of Bar-And-Body FrameworksGem KartikNo ratings yet

- A Few Problems: Nilava Metya June 11, 2020Document5 pagesA Few Problems: Nilava Metya June 11, 2020Noel BinuNo ratings yet

- Lighting TerminologiesDocument10 pagesLighting Terminologies200211555No ratings yet