Professional Documents

Culture Documents

Tech Manual Permanent Cement Retainer and Bridge Plug - Latest

Uploaded by

Aadil HaroonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tech Manual Permanent Cement Retainer and Bridge Plug - Latest

Uploaded by

Aadil HaroonCopyright:

Available Formats

1 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Permanent Cement Retainer

Permanent Bridge Plug

Weatherford’s Permanent Cement Retainer (PCR) and Permanent Bridge Plug (PBP)

products are based on a modular, field-proven, drillable cast iron design that provides

versatility in a variety of applications.

The PCR may be set mechanically or by a wireline setting tool, with the top slips

interchangeable to allow this ability. The PCR converts to an ideal well test isolation valve

by replacing the bottom guide with a tail pipe adapter.

The PCR also converts to a Permanent Bridge Plug (PBP) by replacing the sleeve valve

with a solid plug.

The PBP is also a field-proven, modular cast iron drillable tool for various applications. As

with the PCR, changing the top slips enables this versatile bridge plug to be set

mechanically or with a wireline setting tool.

Applications

Cementing

Stimulation

Well abandonment

Temporary or permanent zone isolation

Features, Advantages, and Benefits

Cast iron drillable design

Simple, surface-controlled valve automatically closes when stinger is removed

Easily converts between mechanical or wireline set

Components rotationally locked for easy drill out

Converts to a PBP Bridge Plug

Temperature ratings to 400ºF available

Differential pressure rating to 10,000 psi through 8⅝ in. tools

Sets in casing grades up to P-110

Allows pressure-testing before squeeze

Valve protects sensitive zones in low-fluid wells

Convertibility reduces inventory requirements

Fast drill out saves rig time

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

2 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide

Note: Parts List (Bill of Materials) and Dimensional layouts are available through Windchill. Click on the Windchill link and

then input the product number in the Search window.

If you do not have access to Windchill, complete a User Authorization Request (UAR) asking for “Read Public” access to

the specific product line you need, e.g., Packers, Safety Valves, and Engineering will grant your request to enable your

use of the software program to access the Windchill files for the specific product line.

4½ in. Permanent Cement Retainer PCR 00171836

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.593 91.26

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

4½ in. Permanent Cement Retainer PCR 00230767

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.593 91.26

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Mechanical

4½ in. Permanent Cement Retainer PCR 00230835

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.593 91.26

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 204.44

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

3 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

4½ in. Permanent Cement Retainer PCR 00171142

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.593 91.26

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

4½ in. Permanent Cement Retainer PCR 00172138

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.593 91.26

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Wireline

4½ in. Permanent Cement Retainer PCR 00230859

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.593 91.26

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 204.44

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

4 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

4½ in. Permanent Bridge Plug PBP 00162426

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.594 91.29

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

4½ in. Permanent Bridge Plug PBP 00164149

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.594 91.29

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

4½ in. Permanent Bridge Plug PBP 00733946

Specification Imperial Metric

Casing Size (in.–mm) 4.500 114.30

Casing Weight (lbm/ft–k g/m) 9.5–15.1 14.14–22.47

Casing Minimum/Maximum ID (in.–mm) 3.826–4.090 97.18–103.89

Maximum OD (in.–mm) 3.594 91.29

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

5 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

5 in. Permanent Cement Retainer PCR 00164126

Specification Imperial Metric

Casing Size (in.–mm) 5.000 127.00

Casing Weight (lbm/ft–k g/m) 11.5–18.0 17.11–26.79

Casing Minimum/Maximum ID (in.–mm) 4.276–4.560 108.61–115.83

Maximum OD (in.–mm) 3.937 100.00

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

5 in. Permanent Cement Retainer PCR 00164119

Specification Imperial Metric

Casing Size (in.–mm) 5.000 127.00

Casing Weight (lbm/ft–k g/m) 11.5–18.0 17.11–26.79

Casing Minimum/Maximum ID (in.–mm) 4.276–4.560 108.61–115.83

Maximum OD (in.–mm) 3.937 100.00

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

5 in. Permanent Bridge Plug PBP 00164093

Specification Imperial Metric

Casing Size (in.–mm) 5.000 127.00

Casing Weight (lbm/ft–k g/m) 11.5–18.0 17.11–26.79

Casing Minimum/Maximum ID (in.–mm) 4.276–4.560 108.61–115.83

Maximum OD (in.–mm) 3.938 100.03

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

6 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

5 in. Permanent Bridge Plug PBP 00164171

Specification Imperial Metric

Casing Size (in.–mm) 5.000 127.00

Casing Weight (lbm/ft–k g/m) 11.5–18.0 17.11–26.79

Casing Minimum/Maximum ID (in.–mm) 4.276–4.560 108.61–115.83

Maximum OD (in.–mm) 3.938 100.03

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

5½ in. Permanent Cement Retainer PCR 00170743

Specification Imperial Metric

Casing Size (in.–mm) 5.500 139.70

Casing Weight (lbm/ft–k g/m) 15.5–23.0 23.07–34.23

Casing Minimum/Maximum ID (in.–mm) 4.670–4.950 118.62–125.73

Maximum OD (in.–mm) 4.32 109.73

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

5½ in. Permanent Cement Retainer PCR 00281258

Specification Imperial Metric

Casing Size (in.–mm) 5.500 139.70

Casing Weight (lbm/ft–k g/m) 15.5–23.0 23.07–34.23

Casing Minimum/Maximum ID (in.–mm) 4.670–4.950 118.62–125.73

Maximum OD (in.–mm) 4.32 109.73

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

7 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

5½ in. Permanent Cement Retainer PCR 00235104

Specification Imperial Metric

Casing Size (in.–mm) 5.500 139.70

Casing Weight (lbm/ft–k g/m) 15.5–23.0 23.07–34.23

Casing Minimum/Maximum ID (in.–mm) 4.670–4.950 118.62–125.73

Maximum OD (in.–mm) 4.32 109.73

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 204.44

Setting Mode Mechanical

5½ in. Permanent Cement Retainer PCR 00164780

Specification Imperial Metric

Casing Size (in.–mm) 5.500 139.70

Casing Weight (lbm/ft–k g/m) 15.5–23.0 23.07–34.23

Casing Minimum/Maximum ID (in.–mm) 4.670–4.950 118.62–125.73

Maximum OD (in.–mm) 4.32 109.73

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

5½ in. Permanent Cement Retainer PCR 00174913

Specification Imperial Metric

Casing Size (in.–mm) 5.500 139.70

Casing Weight (lbm/ft–k g/m) 15.5–23.0 23.07–34.23

Casing Minimum/Maximum ID (in.–mm) 4.670–4.950 118.62–125.73

Maximum OD (in.–mm) 4.32 109.73

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

8 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

5½ in. Permanent Cement Retainer PCR 00232552

Specification Imperial Metric

Casing Size (in.–mm) 5.500 139.70

Casing Weight (lbm/ft–k g/m) 15.5–23.0 23.07–34.23

Casing Minimum/Maximum ID (in.–mm) 4.670–4.950 118.62–125.73

Maximum OD (in.–mm) 4.32 109.73

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 204.44

Setting Mode Wireline

5½ in. Permanent Bridge Plug PBP 00154426

Specification Imperial Metric

Casing Size (in.–mm) 5.500 139.70

Casing Weight (lbm/ft–k g/m) 15.5–23.0 23.07–34.23

Casing Minimum/Maximum ID (in.–mm) 4.670–4.950 118.62–125.73

Maximum OD (in.–mm) 4.32 109.73

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

5½ in. Permanent Bridge Plug PBP 00170334

Specification Imperial Metric

Casing Size (in.–mm) 5.500 139.70

Casing Weight (lbm/ft–k g/m) 15.5–23.0 23.07–34.23

Casing Minimum/Maximum ID (in.–mm) 4.670–4.950 118.62–125.73

Maximum OD (in.–mm) 4.32 109.73

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

9 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

5¾ in. Permanent Cement Retainer PCR 00172245

Specification Imperial Metric

Casing Size (in.–mm) 5.750 146.05

Casing Weight (lbm/ft–k g/m) 14.0–25.2 20.83–37.50

Casing Minimum/Maximum ID (in.–mm) 4.890–5.290 124.21–134.37

Maximum OD (in.–mm) 4.700 119.38

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Mechanical

5¾ in. Permanent Cement Retainer PCR 00172246

Specification Imperial Metric

Casing Size (in.–mm) 5.750 146.05

Casing Weight (lbm/ft–k g/m) 14.0–25.2 20.83–37.50

Casing Minimum/Maximum ID (in.–mm) 4.890–5.290 124.21–134.37

Maximum OD (in.–mm) 4.700 119.38

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Wireline

6⅝ in. Permanent Cement Retainer PCR 00170431

Specification Imperial Metric

Casing Size (in.–mm) 6.625 168.28

Casing Weight (lbm/ft–k g/m) 17.0–34.0 25.30–50.60

Casing Minimum/Maximum ID (in.–mm) 5.575–6.135 141.61–155.83

Maximum OD (in.–mm) 5.375 136.53

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

10 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

6⅝ in. Permanent Cement Retainer PCR 00170412

Specification Imperial Metric

Casing Size (in.–mm) 6.625 168.28

Casing Weight (lbm/ft–k g/m) 17.0–34.0 25.30–50.60

Casing Minimum/Maximum ID (in.–mm) 5.575–6.135 141.61–155.83

Maximum OD (in.–mm) 5.375 136.53

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

6⅝ in. Permanent Bridge Plug PBP 00170206

Specification Imperial Metric

Casing Size (in.–mm) 6.625 168.28

Casing Weight (lbm/ft–k g/m) 17.0–34.0 25.30–50.60

Casing Minimum/Maximum ID (in.–mm) 5.575–6.135 141.61–155.83

Maximum OD (in.–mm) 5.375 136.53

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

6⅝ in. Permanent Bridge Plug PBP 00170719

Specification Imperial Metric

Casing Size (in.–mm) 6.625 168.28

Casing Weight (lbm/ft–k g/m) 17.0–34.0 25.30–50.60

Casing Minimum/Maximum ID (in.–mm) 5.575–6.135 141.61–155.83

Maximum OD (in.–mm) 5.375 136.53

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

11 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

7 in. Permanent Cement Retainer PCR 00154360

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.692 144.58

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

7 in. Permanent Cement Retainer PCR 00174823

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.692 144.58

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Mechanical

7 in. Permanent Cement Retainer PCR 00174818

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.692 144.58

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 204.44

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

12 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

7 in. Permanent Cement Retainer PCR 00171283

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.692 144.58

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

7 in. Permanent Cement Retainer PCR 00174786

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.692 144.58

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Wireline

7 in. Permanent Cement Retainer PCR 00290402

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.692 144.58

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 148.89

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

13 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

7 in. Permanent Bridge Plug PBP 00164671

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.693 144.60

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

7 in. Permanent Bridge Plug PBP 00175245

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.693 144.60

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Mechanical

7 in. Permanent Bridge Plug PBP 00164792

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.693 144.60

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

14 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

7 in. Permanent Bridge Plug PBP 00290548

Specification Imperial Metric

Casing Size (in.–mm) 7.000 177.80

Casing Weight (lbm/ft–k g/m) 20.0–38.0 29.76-56.55

Casing Minimum/Maximum ID (in.–mm) 5.920–6.456 150.37–163.98

Maximum OD (in.–mm) 5.693 144.60

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 204.44

Setting Mode Wireline

7⅝ in. Permanent Cement Retainer PCR 00165014

Specification Imperial Metric

Casing Size (in.–mm) 7.625 139.70

Casing Weight (lbm/ft–k g/m) 26.4–39.0 39.29–58.04

Casing Minimum/Maximum ID (in.–mm) 6.625–6.969 168.28–177.01

Maximum OD (in.–mm) 6.320 160.53

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

7⅝ in. Permanent Cement Retainer PCR 00174851

Specification Imperial Metric

Casing Size (in.–mm) 7.625 139.70

Casing Weight (lbm/ft–k g/m) 26.4–39.0 39.29–58.04

Casing Minimum/Maximum ID (in.–mm) 6.625–6.969 168.28–177.01

Maximum OD (in.–mm) 6.320 160.53

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

15 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

7⅝ in. Permanent Cement Retainer PCR 00174840

Specification Imperial Metric

Casing Size (in.–mm) 7.625 139.70

Casing Weight (lbm/ft–k g/m) 26.4–39.0 39.29–58.04

Casing Minimum/Maximum ID (in.–mm) 6.625–6.969 168.28–177.01

Maximum OD (in.–mm) 6.320 160.53

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 204.44

Setting Mode Mechanical

7⅝ in. Permanent Cement Retainer PCR 00174732

Specification Imperial Metric

Casing Size (in.–mm) 7.625 139.70

Casing Weight (lbm/ft–k g/m) 26.4–39.0 39.29–58.04

Casing Minimum/Maximum ID (in.–mm) 6.625–6.969 168.28–177.01

Maximum OD (in.–mm) 6.320 160.53

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

7⅝ in. Permanent Cement Retainer PCR 00232220

Specification Imperial Metric

Casing Size (in.–mm) 7.625 139.70

Casing Weight (lbm/ft–k g/m) 26.4–39.0 39.29–58.04

Casing Minimum/Maximum ID (in.–mm) 6.625–6.969 168.28–177.01

Maximum OD (in.–mm) 6.320 160.53

Material Cast Iron

Element Material and Durometer Nitrile 80

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 300 148.89

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

16 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

7⅝ in. Permanent Cement Retainer PCR 00754774

Specification Imperial Metric

Casing Size (in.–mm) 7.625 139.70

Casing Weight (lbm/ft–k g/m) 26.4–39.0 39.29–58.04

Casing Minimum/Maximum ID (in.–mm) 6.625–6.969 168.28–177.01

Maximum OD (in.–mm) 6.320 160.53

Material Cast Iron

Element Material and Durometer Nitrile 90

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 400 204.44

Setting Mode Wireline

7⅝ in. Permanent Bridge Plug PBP 00161441

Specification Imperial Metric

Casing Size (in.–mm) 7.625 139.70

Casing Weight (lbm/ft–k g/m) 26.4–39.0 39.29–58.04

Casing Minimum/Maximum ID (in.–mm) 6.625–6.969 168.28–177.01

Maximum OD (in.–mm) 6.320 160.53

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

7⅝ in. Permanent Bridge Plug PBP 00161628

Specification Imperial Metric

Casing Size (in.–mm) 7.625 139.70

Casing Weight (lbm/ft–k g/m) 26.4–39.0 39.29–58.04

Casing Minimum/Maximum ID (in.–mm) 6.625–6.969 168.28–177.01

Maximum OD (in.–mm) 6.320 160.53

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

17 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

8⅝ in. Permanent Cement Retainer PCR 00169910

Specification Imperial Metric

Casing Size (in.–mm) 8.625 219.08

Casing Weight (lbm/ft–k g/m) 24.0–49.0 35.72–72.92

Casing Minimum/Maximum ID (in.–mm) 7.511–8.097 190.78–205.66

Maximum OD (in.–mm) 7.125 180.98

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

8⅝ in. Permanent Cement Retainer PCR 00170422

Specification Imperial Metric

Casing Size (in.–mm) 8.625 219.08

Casing Weight (lbm/ft–k g/m) 24.0–49.0 35.72–72.92

Casing Minimum/Maximum ID (in.–mm) 7.511–8.097 190.78–205.66

Maximum OD (in.–mm) 7.125 180.98

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

8⅝ in. Permanent Bridge Plug PBP 00170864

Specification Imperial Metric

Casing Size (in.–mm) 8.625 219.08

Casing Weight (lbm/ft–k g/m) 24.0–49.0 35.72–72.92

Casing Minimum/Maximum ID (in.–mm) 7.511–8.097 190.78–205.66

Maximum OD (in.–mm) 7.125 180.98

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

18 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

8⅝ in. Permanent Bridge Plug PBP 00172642

Specification Imperial Metric

Casing Size (in.–mm) 8.625 219.08

Casing Weight (lbm/ft–k g/m) 24.0–49.0 35.72–72.92

Casing Minimum/Maximum ID (in.–mm) 7.511–8.097 190.78–205.66

Maximum OD (in.–mm) 7.125 180.98

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 10,000 689.48

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

9⅝ in. Permanent Cement Retainer PCR 00170961

Specification Imperial Metric

Casing Size (in.–mm) 9.625 244.48

Casing Weight (lbm/ft–k g/m) 36.0–61.1 53.57–90.93

Casing Minimum/Maximum ID (in.–mm) 8.375–8.921 212.73–226.59

Maximum OD (in.–mm) 8.125 206.38

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 5,000 344.74

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

9⅝ in. Permanent Cement Retainer PCR 00170122

Specification Imperial Metric

Casing Size (in.–mm) 9.625 244.48

Casing Weight (lbm/ft–k g/m) 36.0–61.1 53.57–90.93

Casing Minimum/Maximum ID (in.–mm) 8.375–8.921 212.73–226.59

Maximum OD (in.–mm) 8.125 206.38

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 5,000 344.74

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

19 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

9⅝ in. Permanent Bridge Plug PBP 00164980

Specification Imperial Metric

Casing Size (in.–mm) 9.625 244.48

Casing Weight (lbm/ft–k g/m) 36.0–61.1 53.57–90.93

Casing Minimum/Maximum ID (in.–mm) 8.375–8.921 212.73–226.59

Maximum OD (in.–mm) 8.125 206.38

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 5,000 344.74

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

9⅝ in. Permanent Bridge Plug PBP 00165204

Specification Imperial Metric

Casing Size (in.–mm) 9.625 244.48

Casing Weight (lbm/ft–k g/m) 36.0–61.1 53.57–90.93

Casing Minimum/Maximum ID (in.–mm) 8.375–8.921 212.73–226.59

Maximum OD (in.–mm) 8.125 206.38

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 5,000 344.74

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

10¾ in. Permanent Cement Retainer PCR 00170302

Specification Imperial Metric

Casing Size (in.–mm) 10.750 273.05

Casing Weight (lbm/ft–k g/m) 32.75–60.70 48.74–90.33

Casing Minimum/Maximum ID (in.–mm) 9.660–10.192 245.36–258.88

Maximum OD (in.–mm) 9.437 239.70

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 5,000 344.74

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

20 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

10¾ in. Permanent Cement Retainer PCR 00170263

Specification Imperial Metric

Casing Size (in.–mm) 10.750 273.05

Casing Weight (lbm/ft–k g/m) 32.75–60.70 48.74–90.33

Casing Minimum/Maximum ID (in.–mm) 9.660–10.192 245.36–258.88

Maximum OD (in.–mm) 9.437 239.70

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 5,000 344.74

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

10¾ in. Permanent Bridge Plug PBP 00172578

Specification Imperial Metric

Casing Size (in.–mm) 10.750 273.05

Casing Weight (lbm/ft–k g/m) 32.75–60.70 48.74–90.33

Casing Minimum/Maximum ID (in.–mm) 9.660–10.192 245.36–258.88

Maximum OD (in.–mm) 9.437 239.70

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 5,000 344.74

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

10¾ in. Permanent Bridge Plug PBP 00172484

Specification Imperial Metric

Casing Size (in.–mm) 10.750 273.05

Casing Weight (lbm/ft–k g/m) 32.75–60.70 48.74–90.33

Casing Minimum/Maximum ID (in.–mm) 9.660–10.192 245.36–258.88

Maximum OD (in.–mm) 9.437 239.70

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 5,000 344.74

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

21 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

11¾ in. Permanent Cement Retainer PCR 00164853

Specification Imperial Metric

Casing Size (in.–mm) 11.750 298.45

Casing Weight (lbm/ft–k g/m) 38.0–60.0 56.55–89.29

Casing Minimum/Maximum ID (in.–mm) 10.772–11.150 273.61–283.21

Maximum OD (in.–mm) 10.437 265.10

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 4,000 275.79

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

11¾ in. Permanent Cement Retainer PCR Heavy Weight 00175378

Specification Imperial Metric

Casing Size (in.–mm) 11.750 298.45

Casing Weight (lbm/ft–k g/m) 60.0–83.0 89.29–123.52

Casing Minimum/Maximum ID (in.–mm) 10.368–10.772 263.35–273.61

Maximum OD (in.–mm) 9.937 252.10

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 4,000 275.79

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

11¾ in. Permanent Cement Retainer PCR 00164854

Specification Imperial Metric

Casing Size (in.–mm) 11.750 298.45

Casing Weight (lbm/ft–k g/m) 38.0–60.0 56.55–89.29

Casing Minimum/Maximum ID (in.–mm) 10.772–11.150 273.61–283.21

Maximum OD (in.–mm) 10.437 265.10

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 4,000 275.79

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

22 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

11¾ in. Permanent Cement Retainer PCR Heavy Weight 00175207

Specification Imperial Metric

Casing Size (in.–mm) 11.750 298.45

Casing Weight (lbm/ft–k g/m) 60.0–83.0 89.29–123.52

Casing Minimum/Maximum ID (in.–mm) 10.368–10.772 263.35–273.61

Maximum OD (in.–mm) 9.937 252.10

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 4,000 275.79

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

11¾ in. Permanent Bridge Plug PBP 00174722

Specification Imperial Metric

Casing Size (in.–mm) 11.750 298.45

Casing Weight (lbm/ft–k g/m) 38.0–60.0 56.55–89.29

Casing Minimum/Maximum ID (in.–mm) 10.772–11.150 273.61–283.21

Maximum OD (in.–mm) 10.437 265.10

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 4,000 275.79

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

11¾ in. Permanent Bridge Plug PBP 00174688

Specification Imperial Metric

Casing Size (in.–mm) 11.750 298.45

Casing Weight (lbm/ft–k g/m) 38.0–60.0 56.55–89.29

Casing Minimum/Maximum ID (in.–mm) 10.772–11.150 273.61–283.21

Maximum OD (in.–mm) 10.437 265.10

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 4,000 275.79

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

23 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

13⅜ in. Permanent Cement Retainer PCR 00165224

Specification Imperial Metric

Casing Size (in.–mm) 13.375 339.73

Casing Weight (lbm/ft–k g/m) 48.0–72.0 71.43–107.15

Casing Minimum/Maximum ID (in.–mm) 12.347–12.715 313.61–322.96

Maximum OD (in.–mm) 12.000 304.80

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 3,000 206.84

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

13⅜ in. Permanent Cement Retainer PCR 00164943

Specification Imperial Metric

Casing Size (in.–mm) 13.375 339.73

Casing Weight (lbm/ft–k g/m) 48.0–72.0 71.43–107.15

Casing Minimum/Maximum ID (in.–mm) 12.347–12.715 313.61–322.96

Maximum OD (in.–mm) 12.000 304.80

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 3,000 206.84

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

13⅜ in. Permanent Bridge Plug PBP 00161279

Specification Imperial Metric

Casing Size (in.–mm) 13.375 339.73

Casing Weight (lbm/ft–k g/m) 48.0–72.0 71.43–107.15

Casing Minimum/Maximum ID (in.–mm) 12.347–12.715 313.61–322.96

Maximum OD (in.–mm) 12.000 304.80

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 3,000 206.84

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

24 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

13⅜ in. Permanent Bridge Plug PBP 00165033

Specification Imperial Metric

Casing Size (in.–mm) 13.375 339.73

Casing Weight (lbm/ft–k g/m) 48.0–72.0 71.43–107.15

Casing Minimum/Maximum ID (in.–mm) 12.347–12.715 313.61–322.96

Maximum OD (in.–mm) 12.000 304.80

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 3,000 206.84

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

16 in. Permanent Cement Retainer PCR 00175313

Specification Imperial Metric

Casing Size (in.–mm) 16.000 406.40

Casing Weight (lbm/ft–k g/m) 65.0–118.0 96.73–175.60

Casing Minimum/Maximum ID (in.–mm) 14.570–15.250 370.08–387.35

Maximum OD (in.–mm) 14.125 358.78

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 2,000 137.90

Temperature Rating (°F–°C) 200 93.33

Setting Mode Mechanical

16 in. Permanent Cement Retainer PCR 00807566

Specification Imperial Metric

Casing Size (in.–mm) 16.000 406.40

Casing Weight (lbm/ft–k g/m) 65.0–118.0 96.73–175.60

Casing Minimum/Maximum ID (in.–mm) 14.570–15.250 370.08–387.35

Maximum OD (in.–mm) 14.125 358.78

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 2,000 137.90

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

25 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

16 in. Permanent Bridge Plug PBP 00719038

Specification Imperial Metric

Casing Size (in.–mm) 16.000 406.40

Casing Weight (lbm/ft–k g/m) 65.0–118.0 96.73–175.60

Casing Minimum/Maximum ID (in.–mm) 14.570–15.250 370.08–387.35

Maximum OD (in.–mm) 14.125 358.78

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 2,000 137.90

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

18 in. Permanent Cement Retainer PCR 00175224

Specification Imperial Metric

Casing Size (in.–mm) 18.000 339.73

Casing Weight (lbm/ft–k g/m) 70.58–87.50 105.03–130.21

Casing Minimum/Maximum ID (in.–mm) 17.088–17.250 434.04–438.15

Maximum OD (in.–mm) 16.650 422.91

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 2,000 137.90

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

18⅝ in. Permanent Cement Retainer PCR 00172010

Specification Imperial Metric

Casing Size (in.–mm) 18.625 339.73

Casing Weight (lbm/ft–k g/m) 87.50–106.0 130.21–157.75

Casing Minimum/Maximum ID (in.–mm) 17.480–17.755 443.99–450.98

Maximum OD (in.–mm) 17.125 434.98

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 2,000 137.90

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

26 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Specification Guide – continued

20 in. Permanent Cement Retainer PCR 00175209

Specification Imperial Metric

Casing Size (in.–mm) 20.000 508.00

Casing Weight (lbm/ft–k g/m) 94.0–133.0 139.89–197.93

Casing Minimum/Maximum ID (in.–mm) 18.730–19.124 475.74–485.75

Maximum OD (in.–mm) 18.375 466.73

Material Cast Iron

Element Material and Durometer Nitrile 70

Pressure Rating (psi–bar) 2,000 137.90

Temperature Rating (°F–°C) 200 93.33

Setting Mode Wireline

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

27 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

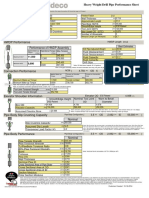

Illustrative Representations

Wireline Mechanical Wireline Mechanical

Set Set Set Set

Permanent

Cement

Retainers

Permanent

Bridge Plugs

Permanent

Cement

Retainers with

Tubing Adapters

4½–7⅝ in. 8⅝–20 in.

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

28 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

Table of Contents

Section Description Page

1 Purpose ................................................................................................................................... 30

2 Scope....................................................................................................................................... 30

3 Hazard Identification (HAZID) .................................................................................................. 30

4 Abbreviations, Acronym s, and Definitions .............................................................................. 32

5 Responsibilities ....................................................................................................................... 33

6 Maintenance, Preservation, and Storage ................................................................................. 33

7 Required Materials................................................................................................................... 33

8 Part List ................................................................................................................................... 33

9 Part List Illustration ................................................................................................................. 33

10 Pre-assembly checks............................................................................................................... 33

11 Assembly procedures .............................................................................................................. 39

12 Dimensional Data..................................................................................................................... 43

13 Dimensional Data Illustration ................................................................................................... 45

14 Pre-run Inspection ................................................................................................................... 46

15 Precautions and Handling ....................................................................................................... 46

16 General Running Operation ..................................................................................................... 47

17 Mounting PCR or PBP on the Mechanical Setting Tool MST.................................................... 47

18 Running Procedure .................................................................................................................. 48

19 Special Running Consideration ............................................................................................... 49

20 Running Sequence .................................................................................................................. 51

21 Setting Equipment Guide for Electric Line Set PCR or PBP ..................................................... 53

22 Operation ................................................................................................................................. 53

23 PCR and PBP Shear Stud Guide .............................................................................................. 53

24 Hydraulic Force s Acting on Cement Retainers ........................................................................ 54

25 Recommended Removal Techniques for Cement Retainers and Bridge Plugs ....................... 56

26 Conversion of Cement Retainer to a Bridge Plug .................................................................... 57

27 PCR Cement Retainer/PBP Bridge Plug Equipment Guide ...................................................... 58

28 Wireline Adapter Kit (WAK)...................................................................................................... 58

29 Slips Only ................................................................................................................................ 59

30 Wireline Adapter Kit Assembly ................................................................................................ 60

31 Parts Li sts – Wireline Adapter Kit ............................................................................................ 61

32 Dimensional Data – Wireline Adapter Kits ............................................................................... 66

33 PCR Tail Pipe Adapter ............................................................................................................. 69

34 Specification Guide – PCR Tail Pipe Guides............................................................................ 70

35 Dimensional Data – PCR Tail Pipe Guides ............................................................................... 71

36 SSA Stinger Seal Assembly ..................................................................................................... 72

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

29 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

37 Operation – Stinger Seal Assembly ......................................................................................... 72

38 Specification Guide ................................................................................................................. 73

39 Parts Li st – Stinger Sub Assembly .......................................................................................... 73

40 Assembly – Stinger Seal Assembly ......................................................................................... 74

41 Di sa ssembly – Stinger Seal Assembly..................................................................................... 74

42 Dimensional Data – Stinger Seal Assembly ............................................................................. 75

43 JSA Snap Out Stinger Assembly ............................................................................................. 76

44 Operation – JSA Snap Out Stinger Assembly .......................................................................... 76

45 Specification Guide – JSA Snap Out Stinger ........................................................................... 77

46 Parts Li sts – JS A Snap Out Stinger ......................................................................................... 78

47 Assembly – JS A Snap Out Stinger........................................................................................... 80

48 Di sa ssembly – JSA Snap Out Stinger ...................................................................................... 80

49 Dimensional Data – JSA Snap Out Stinger .............................................................................. 81

50 Training and Competency........................................................................................................ 82

51 Document Change Record ....................................................................................................... 83

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

30 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

1 Purpose

Weatherford work instructions are intended to clearly define the minimum requirements for the safe use of equipment

and to protect employees, materials, and the environment. This document also serves as a guide for complete

conformity to Weatherford quality policies. Every effort has been made to ensure the accuracy of this work instruction;

however, the specifications and requirements of the original equipment manufacturer (OEM) always supersede this

document and must be followed. This work instruction shall remain in effect unless otherwise approved, in writing, by a

member of Global Product Line Management.

2 Scope

The scope of this document covers the following equipment only: Permanent Cement Retainer (PCR) and Permanent

Bridge Plug (PBP) and their Accessories.

It has been prepared to aid employees of Weatherford International Inc., its agents, and affiliates, who through the

authorization of Weatherford International Inc., have been selected and trained to operate, test and maintain the

products specified here within.

3 Hazard Identification (HAZID)

Hazard Controls

MOTION Use mechanical aides to lift or request assistance from a

second person, prepare the w ork area first to avoid

Heavy, tubular equipment bending, stretching and tw isting when placing in the vice.

Ensure tubular equipment is secured at all times to avoid

rolling.

Controls

MECHANICAL Hazard

Hand/finger injuries: Metal shards, burrs, protrusions, and Wear suitable cut-resistant gloves; avoid passing hands

gouges may have very sharp edges across threads or surfaces where burrs may be present.

Hazard Controls

PRESSURE Ensure pressure testing is conducted in a

controlled/enclosed area, conduct low pressure test first

and increase pressure in increments.

Pressure testing/pressurized systems

Ensure the proper test caps are fitted and that

compressible fluid is purged.

Document pressure tests on a calibrated chart recorder.

NOISE Hazard Controls

Noise & Vibration Wear ear protection.

©2010-2020 Weatherford. All rights – proprietary and confidential – reserved.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or non-patentable, of Weatherford. Recipients agree that the document is

loaded with conf idential restrictions, and with the understanding that neither it, nor the information contained within, will be reproduced, used or disclosed in whole or in part for any purpose

except as may be specifically authorized in writing by Weatherford.

D001148109 (B.4) PMTD: Parra, Maria C 2020-10-22

31 of 84

Technical Manual – 4½–20 in. Permanent Cement Retainer PCR/

4½–13⅜ in. Permanent Bridge Plug PBP

Document Number Classification Document Level Revision Number Issue Date Prepared By Approval

GL-OCH-OEPS-L4-22 CONTROLLED L4 B 22 OCTOBER 2020 MEGHAN MCLEOD COMP TWIC

3.1 Hazard Identification Symbols

Job Hazard Analysis (JHA), an identification of specific hazards, shall be conducted prior to

assembly, repair, and maintenance to determine potential hazards which necessitate the

implementation of controls including personal protective equipment (PPE). Attend all appropriate

safety briefings and meetings.

Employees and sub-contractors, regardless of position or qualification, not only have the right, but

the obligation, to stop any work if conditions are deemed to be unsafe or a hazardous situation

arises.

Management of Change (MOC) applies to this work instruction; modification is prohibited without

authorization from the Global Product Line Manager (GPLM).

Symbols and Symbol Guidance

The f orce caused by attraction of all other masses to

Gravity/Falls the mass of the Earth. Examples – f alling object,

collapsing roof , and a body tripping or f alling

The change in position of objects or substances.

Examples – v ehicle, v essel, or equipment mov ement;

Motion/Movement f lowing water; wind; and body positioning when lif ting,

straining, or bending

The presence and f low of an electric charge.

Electricity Examples – Power lines, transf ormers, static charges,

lightning, energized equipment, wiring, and batteries

Energy applied by a liquid or gas that has been

compressed or is under a v acuum. Examples –

Pressure pressure piping, compressed cy linders, control lines,

v essels, tanks, hoses, and pneumatic and hy draulic

equipment

Including chemicals, radioactiv e materials, lithium

batteries, and explosiv es. The energy present in

chemicals that inherently , or through reaction, has the

potential to create a phy sical or health hazard to

Hazardous Substances people, equipment or the env ironment. Examples –

f lammable v apors, reactiv e hazards, carcinogens or

other toxic compounds, corrosiv es, py rophoric,

combustibles, oxy gen-def icient atmospheres, welding

f umes, and dusts

Sound is produced when a f orce causes an object or

substance to v ibrate and the energy is transf erred

through the substance in wav es. Examples –

Noise and Vibration equipment noise, impact noise, v ibration, high-

pressure release, and the impact of noise to

communication

The energy of the components of a mechanical

sy stem, i.e., rotation, vibration, or motion within an

Hazard identification should be a systematic Mechanical otherwise stationary piece of equipment or machinery .

process and the wheel is used to ensure that Examples – rotating equipment, compressed springs,

driv e belts, conv ey ors, and motors

the person(s) conducting the exercise has The measurement of dif f erences in thermal energy of

objects or the env ironment, which the human body

considered all categories, ensuring that the Temperature senses as either heat or cold. Examples – open f lame,

assessment is comprehensive. ignition sources, hot or cold surf aces, liquids or gases ,

steam, and f riction

Liv ing organisms that can present a hazard. Examples

Each of the categories is considered in turn – animals, bacteria, v iruses, insects, blood-borne

Biological pathogens, improperly handled f ood, and

and hazards related to the task/activity can be contaminated water

The impact of our surroundings. Examples – weather

identified. Environmental conditions, simultaneous operations, and conf ined

spaces

Critical to serv ice quality . Examples – critical