Professional Documents

Culture Documents

DENSOLEN R - AS50 Product Information PR00131517

Uploaded by

mokbelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DENSOLEN R - AS50 Product Information PR00131517

Uploaded by

mokbelCopyright:

Available Formats

For operating temperatures up to

+50 °C (+122° F).

Fulfills EN 12068-B50 and DIN 30672-B50.

Fulfills class B 50 in accordance with EN

12068, already with one wrapping with

50% overlapping.

Fulfills ISO 21809-3, Type 12A-1.

Extremely cost efficient and easy

application.

Especially qualified for the requirements

of the water pipe construction.

For a century now, DENSO Group Germany has been representing experience, quality and reliability for corrosion prevention and sealing

technology. The success of the internationally leading corporation is based on the development of the "DENSO-Tape", which was already

patented in 1927 as the first product worldwide for the passive corrosion prevention of pipelines. Since then, the DENSO Group Germany has

been establishing and guaranteeing the highest quality standards with technically trend-setting products. Research, development and

production take place exclusively in Germany. Our employees continuously implement safe and individual solutions in a personal cooperation

with the customer.

DENSOLEN ®-AS50 is a cold applied oxygen and it is resistant against soil carrier materials with butyl rubber

single tape system for outstanding bacteria and soil electrolytes. adhesive on both sides.

corrosion prevention of metal pipes

DENSOLEN ®-AS50 is compatible with Due to its intermediate layer,

with outstanding economic and

factory coatings made from PE, PP, DENSOLEN ®-AS50 features an out-

qualitative properties.

FBE, PU and bitumen. standing connection between adhe-

Due to the innovative formula, the sive and carrier film.

The system DENSOLEN ® -AS50

tapes grow completely together in

consists of: DENSOLEN ®-AS50 fulfills the interna-

the overlapping area and create a

DENSOLEN ®-HT Primer tional standards DIN 30672, EN

long-lasting hose-type coating.

A solvent containing prime coat in 12068, ASTM and .

DENSOLEN ®-AS50 significantly accordance with EN 12068 and

exceeds the requirements of the DIN 30672 for corrosion prevention

stress class B 50 in accordance with with DENSOLEN ® tapes. Please refer

EN 12068 and DIN 30672, using only to the separate product information Approved by: Butyl rubber adhesive

(co-ex.)

one wrapping process with 50% of the DENSOLEN ®-HT Primer. PE carrier material

overlap. DENSOLEN ®-AS50

PE butyl rubber (co-ex.)

The DENSOLEN ®-AS50 is basically im- A real co-extruded 3-ply plastic tape Butyl rubber adhesive

permeable against water vapor and made from stabilized polyethylene

DENSOLEN -AS50

Property Unit Typical value Test method

Carrier film color - black -

Butyl adhesive color inside - grey -

Butyl adhesive color outside - black, blue -

Total thickness mm ≥ 1.1

Carrier film thickness app. mm ≥ 0.6 ISO 4591

Inside adhesive layer thickness app. mm ≥ 0.5 ASTM D1000

Outside adhesive layer thickness app. mm ≥ 0.08

Elongation at break % ≥ 550 DIN 30672

Tape strength +23°C (+73°F) N / cm ≥ 95 EN 12068

Dielectric strength kV / mm ≥40 DIN 53481

+23°C (+73°F) DIN 53495

Water absorption % ≤ 0.1 / ≤ 0.4

1 day / 30 days ASTM D570

-46±4 (-50.8±7.2) DIN 53372

Brittleness temperature °C (°F)

-58±4 (-72.4±7.2) GOST 10354

DENSOLEN ®-AS50 with DENSOLEN ®-HT Primer

Required Test

Property Unit Typical value

value method

Specific electrical insulation resistance Ohm m 2 ≥ 1010 ≥ 108 EN 12068

15 DIN 53482

Contact resistance Ohm cm ≥ 10 Not stated

ASTM D257

+23°C (+73°F) +50°C (+122°F)

Peel resistance ≥ 30 ≥ 2,5 ≥4 ≥ 0,4 EN 12068

N / cm

metal/prime coat/tape (Claa ASTM

≥ 33 ≥ 2.5 Not

(Class stated

D1000

Peel resistance layer to layer +23°C (+73°F) +50°C (+122°F) C)

N / cm EN 12068

AS50 / AS50 ≥ 30 ≥4 ≥8 ≥2

Indentation resistance - residual layer +50°C (+122°F)

thickness at stamp load (10 N/mm² mm EN 12068

≥ 0.8 > 0,6

Stamp-diameter 5.65 mm)

Impact resistance J ≥ 10 ≥8 EN 12068

Cathodic disbondment resistance mm ≤6 Not stated ASTM G8

Lap shear strength +23°C (+73°F)

on steel N / cm2 ≥ 15 5 EN 12068

on factory coating ≥ 15 5

DENSOLEN® tapes can be easily applied manually. The processing with the original DENSOMAT® wrapping devices is even more effi-

cient. For DENSOLEN® tapes with widths of > 50 mm, we recommend the use of the DENSOMAT® wrapping device to guarantee an

excellent processing quality.

Content per box

Core

Width Tape length Tape area App.

diameter 2 Number of Total tape Total tape

(mm) (m) per roll (m ) weight

(mm) rolls area (m²) length (m)

(kg)

30 10 0.3 18 5.4 180 9.5

50 10 0.5 12 6 120 9.5

41

100 10 1.0 6 6 60 8

DENSOLEN®-AS50

150 10 1.5 6 9 180 12

100 50 5 3 15 150 18.5

78

150 50 7.5 2 15 100 18.5

Additional lengths and widths are available on request.

®

When stored in its original, unopened packaging, DENSOLEN -AS50 can be stored for at least 60 months after the manufacturing date.

Storage temperature: ≤ +50°C (+122°F)

Store in a dry location and do not rest anything against the front of the product.

DENSO GmbH Our product information, application recommendations and other

printed publications provide advice to the best of our knowledge and

Only our general terms and conditions of sale, which you will find at

www.denso-group.com, apply. This is a translation from the original

Felderstrasse 24 | 51371 Leverkusen | Germany indicate our level of knowledge at the time of printing. The content is German product information. In case of any discrepancy or any dispute

not legally binding. Therefore, no liability is assumed for incorrect and arising on the interpretation, the German text of the respective German

Phone: +49 214 2602-0 | info@denso-group.com missing advice. The applicator is obliged to check the suitability and product information, which is available at www.denso-group.com, shall

www.denso-group.com possibility of application for the intended purpose. Unless otherwise be decisive. The legal relationship shall be governed by German law.

specified, all of the brands named are trademarks of DENSO, at least 10.2020

registered in Germany, which are protected by law.

You might also like

- Densolen - System AS39P / R20HT: Product InformationDocument2 pagesDensolen - System AS39P / R20HT: Product InformationCarlos PazNo ratings yet

- Densoplast - Tape: Product InformationDocument2 pagesDensoplast - Tape: Product InformationAnant RubadeNo ratings yet

- Passive Corrosion Prevention For Flanges and Valves: Product InformationDocument3 pagesPassive Corrosion Prevention For Flanges and Valves: Product InformationAnant RubadeNo ratings yet

- Denso PVC Self-Adhesive Tape 200: Composition ApplicationDocument1 pageDenso PVC Self-Adhesive Tape 200: Composition ApplicationAloka KarunarathneNo ratings yet

- Protect Buried Pipes with Eco-Friendly ECOTAPE SystemDocument2 pagesProtect Buried Pipes with Eco-Friendly ECOTAPE SystemTeguh SilaNo ratings yet

- Catalog of Products Pini Si ClipsuriDocument60 pagesCatalog of Products Pini Si ClipsuriamaliabohusNo ratings yet

- MasterFlame JS 110 TdsDocument2 pagesMasterFlame JS 110 TdsmohamedNo ratings yet

- Etha FoamDocument4 pagesEtha Foaml561926No ratings yet

- Aladin Stripe: Resilient Soundproofing ProfileDocument6 pagesAladin Stripe: Resilient Soundproofing ProfileMarina MelentiNo ratings yet

- PDS of PE Melt STICKDocument1 pagePDS of PE Melt STICKMecon LtdNo ratings yet

- Domostyl Customized Mouldings en 11072012Document2 pagesDomostyl Customized Mouldings en 11072012vasistaicuNo ratings yet

- DEPROTEC R - PUR Product Information PR00218808-1Document2 pagesDEPROTEC R - PUR Product Information PR00218808-1pedro davilaNo ratings yet

- Wavin AS SWR Data SheetDocument2 pagesWavin AS SWR Data Sheetvinayak abhaleNo ratings yet

- Riblene FC 30Document2 pagesRiblene FC 30Josevi Jiménez MerinoNo ratings yet

- Sika Sealtape BDocument4 pagesSika Sealtape BHandi JuliamsyahNo ratings yet

- Corro-Coat PE Series 50 TDSDocument3 pagesCorro-Coat PE Series 50 TDSBiju_PottayilNo ratings yet

- Ad222 Transfer Pet White Top S8030 BG42WHDocument6 pagesAd222 Transfer Pet White Top S8030 BG42WHArmanFauziNo ratings yet

- Elastocoat C 6335-101Document4 pagesElastocoat C 6335-101Cristina AndronescuNo ratings yet

- Compare technical specifications of AGTEX fabric rangesDocument8 pagesCompare technical specifications of AGTEX fabric rangesBudhi KurniawanNo ratings yet

- Exact 8201Document2 pagesExact 8201Kashif MuhammadNo ratings yet

- Primer HT 03 eDocument2 pagesPrimer HT 03 eishaquesoomroNo ratings yet

- Molykote G-2003Document2 pagesMolykote G-2003Luz Angela GuerreroNo ratings yet

- Low Density Polyethylene Resin: Physical Properties (Based On Pellets and Press-Molded Sheet)Document1 pageLow Density Polyethylene Resin: Physical Properties (Based On Pellets and Press-Molded Sheet)Akram.yishakNo ratings yet

- Asia polymer-EV302Document1 pageAsia polymer-EV302ShahryarNo ratings yet

- 3X-TDS-R4D-ECHT-technical Note PDFDocument2 pages3X-TDS-R4D-ECHT-technical Note PDF今夕何夕No ratings yet

- Polydek: Elastomeric, Single Component Water-Based Waterproofing MembraneDocument4 pagesPolydek: Elastomeric, Single Component Water-Based Waterproofing MembraneprasadNo ratings yet

- DOWSIL™ 7092 High Green Strength Adhesive and Sealant: Features & BenefitsDocument4 pagesDOWSIL™ 7092 High Green Strength Adhesive and Sealant: Features & BenefitsDicky PratamaNo ratings yet

- C Series Carrier Tape MaterialDocument1 pageC Series Carrier Tape MaterialQuýNguyễnNo ratings yet

- Baytron CoatingguideDocument12 pagesBaytron Coatingguideislamfarag2No ratings yet

- 62 0918 Dowsil 993 Structural GlazingDocument4 pages62 0918 Dowsil 993 Structural GlazingJozsef LukaNo ratings yet

- Certoplast 514 TD EnglischDocument1 pageCertoplast 514 TD Englischgutman98No ratings yet

- basell 2427hDocument2 pagesbasell 2427hchaitanyaNo ratings yet

- CANUSA E Primer PDFDocument2 pagesCANUSA E Primer PDFZainudin100% (1)

- Corro-Coat PE Series 50: Technical Data SheetDocument3 pagesCorro-Coat PE Series 50: Technical Data SheetBiju_PottayilNo ratings yet

- General Purpose Corrosion Control Tape: ApplicationsDocument1 pageGeneral Purpose Corrosion Control Tape: ApplicationsGabriela CanaviriNo ratings yet

- WEIDMANN TapesDocument2 pagesWEIDMANN TapesSunil GurubaxaniNo ratings yet

- Densyl Mastic: Composition PrimerDocument2 pagesDensyl Mastic: Composition PrimerAloka KarunarathneNo ratings yet

- Elastic Foam Insulation for Windows & DoorsDocument2 pagesElastic Foam Insulation for Windows & Doorsemre sönmezNo ratings yet

- Wineo 300 - Technical DatasheetDocument1 pageWineo 300 - Technical DatasheetDaniel MorgadoNo ratings yet

- Adhesive CumDocument2 pagesAdhesive CumMokka SamaiyalNo ratings yet

- PIR Dämmung - ENDocument2 pagesPIR Dämmung - ENBorisNo ratings yet

- A Material Properties B Calculation Guide C Connection Technology D Installation Guide E Standards and ApprovalsDocument85 pagesA Material Properties B Calculation Guide C Connection Technology D Installation Guide E Standards and ApprovalsPedro PossoNo ratings yet

- ECOTAPE Data Sheet 2ply System BGD KGDocument2 pagesECOTAPE Data Sheet 2ply System BGD KGTeguh SilaNo ratings yet

- Thermosolo GS: Description and Scope of ApplicationDocument2 pagesThermosolo GS: Description and Scope of ApplicationCatalin FilipNo ratings yet

- Adekit A 140Document3 pagesAdekit A 140José Antonio CuberoNo ratings yet

- Deesa Pipe Gasket Catal - 230310 - 121140Document10 pagesDeesa Pipe Gasket Catal - 230310 - 121140Pietro MachadoNo ratings yet

- Product Data Sheet: Akzonobel Powder CoatingsDocument2 pagesProduct Data Sheet: Akzonobel Powder CoatingsigorciNo ratings yet

- TDS Fosroc Nitofoam 45 India PDFDocument2 pagesTDS Fosroc Nitofoam 45 India PDFTarun KumarNo ratings yet

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepeNo ratings yet

- Bitumen Board Insulation Joint FillerDocument2 pagesBitumen Board Insulation Joint FilleraahtagoNo ratings yet

- TDS Pe 002 Uf1810t 03Document2 pagesTDS Pe 002 Uf1810t 03qc jrpNo ratings yet

- Ds 5600 LD enDocument2 pagesDs 5600 LD enMarek KamenickyNo ratings yet

- Technical Data Sheet: Tape 1 PEDocument1 pageTechnical Data Sheet: Tape 1 PEJxyz QwNo ratings yet

- Tds Ottoseal A 205-67-50gbDocument4 pagesTds Ottoseal A 205-67-50gbGalih MedanNo ratings yet

- TPV-Medical High Bonding GradesDocument13 pagesTPV-Medical High Bonding GradesAlex DimitriouNo ratings yet

- Document 4Document1 pageDocument 4leoNo ratings yet

- EC Tech Report High Performance Polyurethanes: PDFFrom EverandEC Tech Report High Performance Polyurethanes: PDFVincentz Network GmbH & Co. KGNo ratings yet

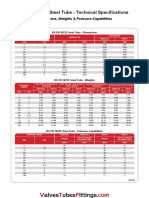

- Bs En10255 Steel Tube Technical Specifications Weight Dimensions Pressure 10255Document1 pageBs En10255 Steel Tube Technical Specifications Weight Dimensions Pressure 10255mokbelNo ratings yet

- Avk 555 202 DS131114Document2 pagesAvk 555 202 DS131114mokbelNo ratings yet

- Igem-G-4 Edition 2 g4Document49 pagesIgem-G-4 Edition 2 g4mokbelNo ratings yet

- BS en 88-1 2007 (Governors Up To 500mbar)Document32 pagesBS en 88-1 2007 (Governors Up To 500mbar)mokbelNo ratings yet

- Avk 555-301-302-V8-0713Document2 pagesAvk 555-301-302-V8-0713mokbelNo ratings yet

- Introduction and Scope IGEM-G-5 Edition 2Document14 pagesIntroduction and Scope IGEM-G-5 Edition 2sbansalNo ratings yet

- Area Classification GuideDocument42 pagesArea Classification Guideowenh796100% (4)

- 299H Series Pressure Reducing RegulatorsDocument32 pages299H Series Pressure Reducing RegulatorsmokbelNo ratings yet

- IGEM - G - 1 - Edition 2Document58 pagesIGEM - G - 1 - Edition 2mokbelNo ratings yet

- Ansi Aga B109 1 2000Document43 pagesAnsi Aga B109 1 2000dilor19100% (1)

- AWT Catalogue Books - 20mm - 180mmDocument76 pagesAWT Catalogue Books - 20mm - 180mmVin KenNo ratings yet

- Marketing Plan For RestaurantDocument28 pagesMarketing Plan For RestaurantAlpeshkumarNo ratings yet

- Marketing Plan TemplateDocument51 pagesMarketing Plan TemplateNurhayati Muhamad NorNo ratings yet

- Fusion Global PE Product Offer V4 Low ResDocument182 pagesFusion Global PE Product Offer V4 Low ResmokbelNo ratings yet

- APP Carbon Grade Chart v6Document1 pageAPP Carbon Grade Chart v6Tashrif YusufNo ratings yet

- Ansi Aga B109 1 2000Document43 pagesAnsi Aga B109 1 2000dilor19100% (1)

- H107en 201906 r4 Elcor Elcorplus 20200903 Red1Document228 pagesH107en 201906 r4 Elcor Elcorplus 20200903 Red1mokbelNo ratings yet

- Operations Management XYZ Co. For Alkyd Resin Student # Module #Document40 pagesOperations Management XYZ Co. For Alkyd Resin Student # Module #mokbelNo ratings yet

- Marketing PlanDocument7 pagesMarketing PlanHusain AttariNo ratings yet

- Marketing PlanDocument11 pagesMarketing PlanMritunjay KumarNo ratings yet

- 6 - 20140920verification of Accuracy of Domestic Gas Flow MeterDocument59 pages6 - 20140920verification of Accuracy of Domestic Gas Flow MetermokbelNo ratings yet

- Sample Statement of PurposeDocument3 pagesSample Statement of Purposepandeyinfy100% (1)

- OIML R 31 Diaphragm Gas MetersDocument28 pagesOIML R 31 Diaphragm Gas MetersAhmed HusseinNo ratings yet

- MBA Recommendation Letter Example - OdtDocument1 pageMBA Recommendation Letter Example - OdtmokbelNo ratings yet

- HR Manager Recommendation for Employee Pursuing MBA at HarvardDocument1 pageHR Manager Recommendation for Employee Pursuing MBA at Harvardmokbel100% (1)

- Improve Operations Management at XYZ Tea CompanyDocument5 pagesImprove Operations Management at XYZ Tea Companymokbel0% (2)

- MBA Application Recommendation LetterDocument1 pageMBA Application Recommendation LettermokbelNo ratings yet

- Executive Mba Recommendation Letter Sample - OdtDocument1 pageExecutive Mba Recommendation Letter Sample - Odtmokbel100% (1)

- Sample Mba Recommendation Letter From Employer - OdtDocument1 pageSample Mba Recommendation Letter From Employer - OdtmokbelNo ratings yet

- German Work BoxDocument8 pagesGerman Work BoxJuan Ricardo Castaño S100% (3)

- Schedule Stock TakingDocument14 pagesSchedule Stock TakingBangun PrasetyoNo ratings yet

- SKS Scope Mount InstructionsDocument4 pagesSKS Scope Mount Instructions王欢No ratings yet

- 4 - Technical Newsletter - Trimming MethodsDocument3 pages4 - Technical Newsletter - Trimming MethodsTaha TlijaniNo ratings yet

- 國產材製成直交集成板之防火性能初探Document11 pages國產材製成直交集成板之防火性能初探陳湘婕No ratings yet

- Use of Pyroxenite in Place of DolomiteDocument4 pagesUse of Pyroxenite in Place of DolomiteDhirender KapoorNo ratings yet

- Antarol FJ 601 - Technical Data SheetDocument1 pageAntarol FJ 601 - Technical Data SheetCARMEN LINARESNo ratings yet

- Various Polishing TechnicsDocument5 pagesVarious Polishing TechnicsAdrian AguileraNo ratings yet

- A Dozen Ways To Build A BoxDocument5 pagesA Dozen Ways To Build A BoxGustavo Cornejo100% (3)

- Qap For Jib CraneDocument2 pagesQap For Jib CraneSuaib VCSNo ratings yet

- ME6311 Manufacturing Technology Lab IDocument44 pagesME6311 Manufacturing Technology Lab Irahul dNo ratings yet

- Permanent Mold CastingDocument3 pagesPermanent Mold CastingNirav patelNo ratings yet

- Oxyfuel Cutting - Process and Fuel GasesDocument6 pagesOxyfuel Cutting - Process and Fuel Gasesunknown8787No ratings yet

- Fastener and material designations for roof panel penetrationsDocument1 pageFastener and material designations for roof panel penetrationsAhmed Saber NassarNo ratings yet

- Side Pocket Mandral PDFDocument27 pagesSide Pocket Mandral PDFwajihhasnainNo ratings yet

- Tds Uniqflow 488u enDocument1 pageTds Uniqflow 488u enm daneshpourNo ratings yet

- File D85ess 2Document2 pagesFile D85ess 2andi yusufNo ratings yet

- Manufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Document2 pagesManufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Madduri HemantNo ratings yet

- Valmet Take-Off DeviceDocument2 pagesValmet Take-Off DevicenotengofffNo ratings yet

- Fabrication Guidelines Rogers RO4830 High-Frequency LaminatesDocument5 pagesFabrication Guidelines Rogers RO4830 High-Frequency LaminatesjackNo ratings yet

- ASTM A738 Grade B: General Product DescriptionDocument2 pagesASTM A738 Grade B: General Product DescriptionhealgoseNo ratings yet

- PROMAPAINT®-E For Beams and Columns ProtectionDocument4 pagesPROMAPAINT®-E For Beams and Columns Protectionromvos8469No ratings yet

- Foolproof Crosscut Sleds: Innovative Technique Guarantees Perfect ResultsDocument6 pagesFoolproof Crosscut Sleds: Innovative Technique Guarantees Perfect ResultsRJ BevyNo ratings yet

- Soundness Test On Cement by Le - Chatelier MethodDocument4 pagesSoundness Test On Cement by Le - Chatelier MethodShahrukh NiazNo ratings yet

- Bending TestDocument15 pagesBending Testاوس محمد رؤوف لؤيNo ratings yet

- Hole Saw Speed Chart Bulletin 194Document2 pagesHole Saw Speed Chart Bulletin 194Muhammad IshaqNo ratings yet

- Sheetmetal FundamentalsDocument81 pagesSheetmetal Fundamentalsramkishore_87100% (1)

- Sky Pipes Fittings Price ListDocument4 pagesSky Pipes Fittings Price ListRatheesh KumarNo ratings yet

- Astm F899Document6 pagesAstm F899Gustavo SuarezNo ratings yet

- Velosit SL 501: Economic Self Leveling UnderlaymentDocument4 pagesVelosit SL 501: Economic Self Leveling UnderlaymentZammar ShahidNo ratings yet