Professional Documents

Culture Documents

Heat Loss Examples

Heat Loss Examples

Uploaded by

selisen0 ratings0% found this document useful (0 votes)

27 views7 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views7 pagesHeat Loss Examples

Heat Loss Examples

Uploaded by

selisenCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

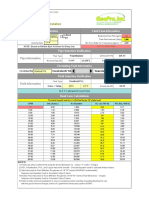

PREINSULATED PIPES FOR LOW TEMPERATURE UTILITIES FLEXIBLE

PIPE SYSTEMS M -PEX

‘made ace. Standard PN-EN 13941 (EN 13941) " Design and installation of preinsulated

bonded pipe systems for district heating" - Appendix D

MR-6/1-110 (180)

Output date:

flow ppsinetemp. tr 70,00 °C

reium pipeline temp. t= $0,00 °C

sollte. 10,00. °C

ipcin axis dpc (cuming ee eile) Z= 0,69 am

ouming om sil suriee)2= 0,60. m

‘Cred valu of depth 7, that he suficetansion aslee Roa thes sures

inca 20=

077m

Soi penetrtioncoeiceat 251.20 Wik.

for wet si om 1,5 Wink) 02 Wek), fordy sand abut. 1.0 Wik)

Cisingtbeexeral dame D> 0.1800 m

wall thickness ofeasingtubeg, 0.0030

Insulation extemal ameter y= 0,1740-m

‘Medium pipe diameter PEX—Ds= 0.1100 m

wall thickness of PEX nb_ 3, 0,0100 m

Distance in ight between casing tubes a 02000.

Distance hetvenpplsteases C= 0.3800 m.

‘cei of hamalcondciviy for PUR isaaton systems MPEX 2ie= 0,0245 Wink.

‘elisa of nal ends formeum pipe PEX weDINS2612 Hess 03800 WimK

‘fice of thermal conductivity oreaig UAE FELD Hygns 0,430 Wink.

(Qe- heat losses on flow pipeline

Q,- heat losses on return pipeline

vet ~1,)-U, x, -1,)

2,

H(t, 4) -Us x (ty 1)

Overall heat loss is:

ty tty

2

OQ, +O, =2x(U, -U,)x¢ -t)

adzie:

Uji Us - heat loss coefficient

tri t= temp.in flow and return pipeline

{+ undisturbed soil temp.at depth "2"

RAR + Rose + Ropy a R,

RFR Row + Roe wn

“Rh RFRA Ry + Rea) BE

‘The overall heat loss coefficient: 1

U,-U,=

where: R, +R, + Roex + Rez-tn + Ry

,~insulance of insulating material

Se

2 ay d,

Ryex -insulance of medium pipe PEX

1 D.

Ryge <5 InP

7 Dp (D,-2%8)

Ryexo- insulance of casing tube PE-LD

1 D,

tae

2tAe sp (D,- 2x8.)

Rypin=

R,- insulance ofthe soil

adzie: Zo = ZR, Ky

Ze Conese valve of dept 0 thet the src nso insane Ro

esol sure isinladed

0.0685 mKIW

Ry- insulance of heat exchange between flow and retum pipe

Heat loss of pipeline laying direetly in the ground

\ 740

140 2.9790 KW

2 x 31416 x 0,0245 0.1100" aot

Recah 1 tn 21800-90125 mk

Tx Side x oa “O.r7a0

1 1100.

ro 31416 x 0.3800 i 0,0900 Prat

. 1 2x _ 0770

Re 4 x 3146 «12000 NC 1.00 + 73800 = 01895 mK/W

1 4x 0700

Bs 2 x 31416 x 1,200 in 0,180 DS OATSC make

29790 + + +0376

re 2270+ 00125 + ost + 03766 See

( 03766 + 29790 + 00125 + 0,084) y=¢ 01895 yp

0.1898 :

( 0,3766 + 29790 + 00125 + 0.0840 -(_0,1895 y 00189 ‘Sia,

1

yeu. = 0.2746 Wink.

y 29790 + 0,0125 + 0.0840 + 0.1895 + 0.3766

Heat losses in flow pipeline:

02906 x( 70.00 = 1000) 139 x¢ $0,900 - 10,00 16,8000. Wim

Heat loses in ear pipetin:

Gr 0.206 x( 50,00 = 10,00 )- 159 x( 7000 - 10.00 10,6700 Wim

Heat loss in both pein

QFHOe= 274700 Wim

The overal het loss

01

OFrOr= 200 x( 0.2906 - ois yx(M2_ + 5AM Ig.99 274700 Wim

made ace. Standard PN-EN 1394+ Al (EN 13941:2009+A1:2010) " Design and

installation of preinsulated bonded pipe systems for district heating” ~ Appendix D

MR-6A-110(180)

‘ow pipeline emp. 70,00

tum ppsine emp. = 50,00

soiltem = 10,00

counting om vil surice == 0,60

Pipeline axis depth (counting rom sil surce)2= 0,69

‘Comected value of depth Z, so thatthe surface uaasiion insulance Ro atthe soil srfice is

incaded Ze=

o7T

Soil peneton oes 2s= 1,20

{or we om 15 Wn) to 2 WK) for diy sand about. 1.0 Wie)

0.1800

wat ihnes ofeasiag be B= 0,080

Inston exeraldamter Dx 0,740

Metin pipe dancer d= 951100

Disunc in ht ween casing tes a= 02000

Distance teewen pipe anes C= 0/3800

coctientofthamalcondusviy fr PUR inslstion 20,0245

Qe- heat losses on flow pipeline

(Q,- heat losses on return pipeline

Casing tbe exeraal diameter

Oy =U, x (ty -8,)- Uy X(t, -1,) @, =U, x(t, -#,)

Overall heat los:

tp +t,

O, +0) = 2x(U, -U,)x (“ht

where:

Ui U; - heat loss coefficient

trit;~ temp.in flow and return pipeline

1,- undisturbed soil tempat depth "2"

where:

R,- insulance of insulating material

R,-insulance of the soil

were: Zo =Z+R,xA,

°c

eG.

°C

Zo~ Conected valu of depth Z so that he surface rani insulance Rot the vil surfice included

R= 0.0683 mK/W

Ry- insulance of heat exchange between flow and return pipe

page 1

Heat loss of single pipeline laying directly in the ground

R: L In 0.1740 = 2.9790 mew

200 x 31416 x 00245 “0,110

1 4x oym

R In = 03770 mK/W

200 x 3416 x 12000 01800

ust

x Ih 100 +4— P] = 0.1899 mK/W

3,1416 x 1,2000 c y 0,38 ui

our aasiaaaania | aanioeaeiSHeE cg Wha,

TST BST FOI

03770 _+ 29790

J T 3 Wit

u (03770 + 2,9790 )*- 0,1899 Ozona Nae

gate win

( 03770 + 2,9790 y. 0,1899 *

rast ai Bt

Qe 030 x{ 7000 - 1000 = OM2 mI 5090 - 1000 J= 1726 wim

aie ae aie

Q- 030—-x{ $000 - 10,00 }- 002 x{ 70,00 - 10,00 }= 10,94 — Win

res at bs pel

et 28,2021 Wim

Ute gp wr

03770 + 2.9790 + 0,189

Overall heat loss

QQ 200 x¢ 030 = 002 xf AO +8000 a9) = 2820 Wim

wykonane wg normy PN-EN 15698-1 luty 2009 (EN-15698-1:2009), PN-EN 15698-1:2008

Rura MR-6/E2x50(160)

Temperatura ruroclagu zasllajacego T=] 10 [°C

Temperatura rurociagu zasilajacegoT>=| 50 [°C

Temperatura gruntuTy-| 10 [°C

Polowa odstgpu pomigdey Srodkami rar D| 0,03

‘Srednica rury ostonowe) D.| 0,16

Grubox? scianki rary oslonowe] z=] 0,003

‘Sredhica rury preewodowe) D yi] 0.05

Gruboxé scianki rary preewodowe) &5s| 0.0046

Grubose Seianki rary preewodowe) B5x| 0.0046

Oitaglosé pomigdey rarami preewodouymi s{ 0.0L

Promieh rary ostonowe) r | 0077

‘Srednica rary preewodowe) Dp 3] 0,05 _|m

Promien rary preewodowe) rs] 0,0204 [m

Promieh rury preewodowe) rs] 0.0204

reat

z

Preewodnosé pianki PURZ pu] 00245

Liniowy wspétezynmik przenikania ciepla (U) mozna opisaé w nastepujacy sposbb:

(T+ [W'm"*K"]

Tot)

2 J

Preewodnosé cieping ).py motna wyrazié nastepujqco:

T+r

-Ty [wen

eatiboony = AE * Ay *h, +

J

Pray tym,

Obliczenie wspétezynnika utraty ciepla

0.02090 _0,00000110_. 2

oe oe on ed

on)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ABCO Heat Exchanger CalculationsDocument1 pageABCO Heat Exchanger CalculationsselisenNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- CdA CalculatorDocument9 pagesCdA CalculatorselisenNo ratings yet

- Heat Transfer. Heat Loss From A Buried Oil Pipe. Mills Example 3.3Document34 pagesHeat Transfer. Heat Loss From A Buried Oil Pipe. Mills Example 3.3selisenNo ratings yet

- HVAC Heater Calculation SheetDocument1 pageHVAC Heater Calculation SheetselisenNo ratings yet

- Partially Full Pipe Calculation Tool: US UnitsDocument4 pagesPartially Full Pipe Calculation Tool: US UnitsselisenNo ratings yet

- Çeşitli Profil Ebat Ve AğırlıklarıDocument37 pagesÇeşitli Profil Ebat Ve AğırlıklarıselisenNo ratings yet

- Processes 09 00939 v2Document19 pagesProcesses 09 00939 v2selisenNo ratings yet

- The Theory Behind Heat TransferDocument7 pagesThe Theory Behind Heat TransferselisenNo ratings yet

- Heat Loss From PipeDocument11 pagesHeat Loss From Pipemlarakahan100% (1)

- 01 Heat Conduction Pipe CalculatorDocument10 pages01 Heat Conduction Pipe CalculatorselisenNo ratings yet

- Pipe Headloss Calculator: Pipe Selection Fluid Flow InformationDocument1 pagePipe Headloss Calculator: Pipe Selection Fluid Flow InformationselisenNo ratings yet

- Heat Transfer. Heat Loss From A Pipe in An Indoor LocationDocument29 pagesHeat Transfer. Heat Loss From A Pipe in An Indoor LocationselisenNo ratings yet

- Chapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument23 pagesChapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallselisenNo ratings yet

- Temperature Rise of Centrifugal Pumps at No Flow and Low FlowDocument3 pagesTemperature Rise of Centrifugal Pumps at No Flow and Low FlowselisenNo ratings yet

- Calculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesDocument5 pagesCalculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesselisenNo ratings yet

- Ts - en - 12845 - Sprinkler SistemiDocument129 pagesTs - en - 12845 - Sprinkler SistemiselisenNo ratings yet

- Lineer İnterpolasyon Ve GrafikDocument18 pagesLineer İnterpolasyon Ve GrafikselisenNo ratings yet

- Psikrometrik Hesap ProgramiDocument2 pagesPsikrometrik Hesap Programiselisen100% (1)

- Pompa Basınç KSB PDFDocument40 pagesPompa Basınç KSB PDFselisenNo ratings yet