Professional Documents

Culture Documents

ABCO Heat Exchanger Calculations

Uploaded by

selisenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ABCO Heat Exchanger Calculations

Uploaded by

selisenCopyright:

Available Formats

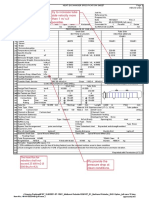

General Lay-Out

35.0

AXA Heat Exchangers

35.0

35.0

Transfer of Heat

26.0

Between Two Fluids - Liquid or Gaseous

1

°C

2

Fluid 1 - COLD Fluid 2 - HOT

Mass Flow kg/h 1041.1 310017

Specific Heat kJ/kgK 3.740 4.180

Temperature, inlet °C 26.0 35.0

Temperature, outlet °C 35.0 35.0

Capacity kW 9.7

Log. Mid. Temp. Diff. (MTD) K Err:502

Correction Factor - Counter/Cross Flow (CCCF)

The CCCF corrects the MTD value when the flow is not pure counter flow i.e. the two fluids move towards each

other, especially when the hot fluid outlet temperature is lower than the cold fluid outlet temperature. The CCCF

then becomes lower than 1,0.

Correction Factor (CCCF) 0.9

MTD Corrected K Err:502

What kind of heat exchanger do you have in mind ? 1 (see the explanation below)

Plate Type (1) Shell & Tube (2); Winded-up Tube Coil (3); Extented Surface / Fins (4); Others (5)

PLATE HEAT EXCHANGER - compact solution and the most economical type for liquid

Heat transfer coefficients each side - liquid up to 20.000 W/m²K, gas up to 500 W/m²K

Quite sensitive to high temperatures, high pressures, pressure variations. Not good for gas/air

Heat Transfer Coefficient (HTC)

The size of the Heat Transfer Coefficients (HTC) can be almost any value up to the limit above. It depends on the

velocity, flow profile, geometry of the heat exchanger and the proporties of the fluid (viscosity, heat conductivity and

specific heat). When considering the size of the Heat Transfer Coeffecient (HTC) it is important to use low values

as a worse-case. To be sure to find the right size of the AXA heat exchanger, and an acceptable pressure drop, the

HTC should be calculated (which is quite theoretical and extentive procedure). Putting in the HTC below is without

any responsibility for ABCO.

Heat Transfer Coefficient, Side 1 (alfa 1) W/m²K 10,000

Heat Transfer Coefficient, Side 2 (alfa 2) W/m²K 10,000

AB&CO is a Scandinavian company est. 1988

operating worldwide within innovative and cost Overall Heat Transmission Coefficient (k-value) W/m²K 755

efficient process heating, with focus on design

and manufacturing of smaller steam boilers,

thermal oil heaters and process air heaters.

Necessary Heat Surface (F') m² Err:502

Extra surface (general safety margin) % 15

Actual Heat Surface (F'') m² Err:502

Although you have chosen a specific AXA heat exchanger, you will get the three optional heat exchangers just for

your evaluation. Note that HTC should be considered for each option i.e. you need to make three print-outs.

Option 1: Plate Heat Exchanger (PHE) Overall Height/Width/Length : Err:502

Liquid (1) or Gas (2) Fluid 1: 1 Plate Width mm 1,438

Fluid 2: 1 Plate Height mm 2,689

Platestack Depth mm Err:502

Plate quantity pcs. Err:502

Extra heat Surface to achieve a moderate pressure drop : % 100

Very often the max. allowable pressure drop will determine the size of a PHE. Extra surface easily becomes 100 %.

Option 2 : Shell & Tube Heat Exchanger Overall Height/Width/Length : Err:502

Outer Diameter, Tube mm 18 Total tube length m Err:502

Wall Thickness, Tube mm 1.5 Tube pitch mm 23

Length each tube m 1.1 Number of tubes stk. Err:502

Distance tube-to-tube mm 5 Cross sect. area, Tube m² Err:502

Diameter, Shell mm Err:502

Length, Shell mm 1100

Option 3: Winded-up Tube Coil Overall Height/Width/Length : Err:502

Outer Diameter, Tube mm 18 Total tube length m Err:502

Wall Thickness, Tube mm 1.5 Number of windings pcs. Err:502

Number of coils in parallel stk. 1

Outside diameter mm 100 Core diameter (center volume) mm 64

Space between inner / outer coil mm 0.11 Total height of coil(s) mm Err:502

Distance between two windings mm 12

AB&CO - TT BOILERS A/S | Copenhagen, Denmark | T: +45 4817 7599 https://www.abco.dk

You might also like

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- General Lay-Out of AB&CO Heat ExchangersDocument1 pageGeneral Lay-Out of AB&CO Heat Exchangersfernando garza0% (1)

- Transfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersDocument1 pageTransfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat ExchangersMarco Ordoñez0% (1)

- Modification and Design of Finned Tube HDocument6 pagesModification and Design of Finned Tube Hbu biNo ratings yet

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- Heat Exchanger Design for BreweryDocument14 pagesHeat Exchanger Design for BreweryAnand BhiseNo ratings yet

- PASES, AIRE 448308 LB - HR REVaa1.SEGDocument1 pagePASES, AIRE 448308 LB - HR REVaa1.SEGTIPAZONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument35 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Heat Transfer Equipment Design and SelectionDocument72 pagesHeat Transfer Equipment Design and SelectionLouie GresulaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument37 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- CalcDocument1 pageCalcsebaversa0% (1)

- ChE 301 PartII Lecture IIIDocument64 pagesChE 301 PartII Lecture IIIMahmudur Rahman RiadNo ratings yet

- 12.1 Why Finned Tube Heat Exchangers?Document18 pages12.1 Why Finned Tube Heat Exchangers?hortalemosNo ratings yet

- Influence of Fan Setting Height On The Cooling Performance of A Plate-Fin-Type Heat Sink With MicroprocessorDocument9 pagesInfluence of Fan Setting Height On The Cooling Performance of A Plate-Fin-Type Heat Sink With Microprocessornadir boutalbiNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument31 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- HE Design, Esra Belhaj, 13.10.2020Document48 pagesHE Design, Esra Belhaj, 13.10.2020Esra BelhajNo ratings yet

- MSS SP 58Document1 pageMSS SP 58octa aldyNo ratings yet

- TAR Example For Hempatherm Vs CabothermDocument8 pagesTAR Example For Hempatherm Vs Cabotherm이선엽No ratings yet

- Spesifikasi AlatDocument5 pagesSpesifikasi AlatLisna RohmawatiNo ratings yet

- Reboiler DatasheetDocument6 pagesReboiler DatasheetMIHNo ratings yet

- Assignment T2 2020 PDFDocument1 pageAssignment T2 2020 PDFAnkitNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Ambient Heat Loss From A VesselDocument2 pagesAmbient Heat Loss From A VesselandersonNo ratings yet

- 1 Heat Exchanger VDFDocument26 pages1 Heat Exchanger VDFPablo TorresNo ratings yet

- Air Cooled Heat Exchanger Design Calculator (Estimation) : To ModifyDocument9 pagesAir Cooled Heat Exchanger Design Calculator (Estimation) : To ModifyBilal BhattiNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument29 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Coil Sizing for Batch Cooling and HeatingDocument8 pagesCoil Sizing for Batch Cooling and Heatingankur2061No ratings yet

- Aspen Exchanger Design for Miami CoolerDocument38 pagesAspen Exchanger Design for Miami CoolerCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument19 pagesShell and Tube Heat Exchanger DesignValium MorphineNo ratings yet

- ChE 301 PartII Lecture IVDocument45 pagesChE 301 PartII Lecture IVMahmudur Rahman RiadNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument66 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Review On Highly Integrated Solutions For Power Electronic Devices - Part 1Document15 pagesReview On Highly Integrated Solutions For Power Electronic Devices - Part 1Imtiaz AhmedNo ratings yet

- Heat Exchanger - z1 - Double PipeDocument26 pagesHeat Exchanger - z1 - Double PipeUğur ÖzçınarNo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- Heat Transfer and Pressure Drop Properties of High Viscoussolutions in Plate Heat Exchangers (2008)Document16 pagesHeat Transfer and Pressure Drop Properties of High Viscoussolutions in Plate Heat Exchangers (2008)Aman KumarNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- In-tube condensation performance evaluation criteriaDocument12 pagesIn-tube condensation performance evaluation criteriaFrancisco OppsNo ratings yet

- Electronic Cooling Solutions PDFDocument46 pagesElectronic Cooling Solutions PDFRashed KaiserNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateneelNo ratings yet

- EDMFMT391803A - Indoor Unit FXMQ-PVMDocument4 pagesEDMFMT391803A - Indoor Unit FXMQ-PVMsurya liemzNo ratings yet

- Zxme025e-Pfj R404aDocument5 pagesZxme025e-Pfj R404aMario UrsuNo ratings yet

- Design and Fabrication of Shell and Tube Heat ExchangerDocument10 pagesDesign and Fabrication of Shell and Tube Heat Exchangerहरिओम हरीNo ratings yet

- Individual Minor Equipment Design: Heat Exchanger (HX-101) : CHEN 4015: Chemical Engineering Design ProjectDocument29 pagesIndividual Minor Equipment Design: Heat Exchanger (HX-101) : CHEN 4015: Chemical Engineering Design ProjectrosieNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Steam Coil AnalysisDocument6 pagesSteam Coil AnalysisMyung Ho SynNo ratings yet

- Freeconvection RRH JeisDocument11 pagesFreeconvection RRH JeisОлег КучеренкоNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- AQ10T-BFM, 363PL 2335kWDocument2 pagesAQ10T-BFM, 363PL 2335kWLiviu ConstantinNo ratings yet

- Mughal Steel 600M3H MX25MDocument1 pageMughal Steel 600M3H MX25MIrfan AhmedNo ratings yet

- Heat Exchanger RatingDocument10 pagesHeat Exchanger RatinggabrieltravassosNo ratings yet

- Plate Heat ExchangersDocument7 pagesPlate Heat ExchangersBaneMarkovicNo ratings yet

- PHE01 M6M 102P 1600kWDocument1 pagePHE01 M6M 102P 1600kWtsoomoo tsolmonNo ratings yet

- Enhancement of Heat Transfer With Conical Hole Filament Insert in A Flow Through Circular TubeDocument4 pagesEnhancement of Heat Transfer With Conical Hole Filament Insert in A Flow Through Circular TubeMonis AbdulmananNo ratings yet

- Cross Flow Heat Exchanger SlidesDocument12 pagesCross Flow Heat Exchanger SlidesOmar AbdullahNo ratings yet

- Finned Tube Heat ExchangerDocument6 pagesFinned Tube Heat ExchangerShailesh DeshmukhNo ratings yet

- Aspen Exchanger DesignDocument30 pagesAspen Exchanger DesignCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- Gantt-Chart L2Document7 pagesGantt-Chart L2Elijah JaireNo ratings yet

- Gantt Chart LDocument8 pagesGantt Chart LAshok PuttaparthyNo ratings yet

- Cooling Tower. Application - TreybalDocument89 pagesCooling Tower. Application - TreybalPinak ProjectsNo ratings yet

- Snowkey Application HandbookDocument160 pagesSnowkey Application HandbookWalter J Naspirán CastañedaNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- CdA CalculatorDocument9 pagesCdA CalculatorselisenNo ratings yet

- Heat Exchanger Calculations: Inside Heat Trasfer CoefficientDocument4 pagesHeat Exchanger Calculations: Inside Heat Trasfer CoefficientBimal DeyNo ratings yet

- HVAC Heater Calculation SheetDocument1 pageHVAC Heater Calculation SheetselisenNo ratings yet

- Potable Water Expansion Tank Sizing ProgramDocument2 pagesPotable Water Expansion Tank Sizing ProgramChaosNo ratings yet

- The Theory Behind Heat TransferDocument7 pagesThe Theory Behind Heat TransferselisenNo ratings yet

- Temperature Rise of Centrifugal Pumps at No Flow and Low FlowDocument3 pagesTemperature Rise of Centrifugal Pumps at No Flow and Low FlowselisenNo ratings yet

- Partially Full Pipe Calculation Tool: US UnitsDocument4 pagesPartially Full Pipe Calculation Tool: US UnitsselisenNo ratings yet

- 02 - Heat ExchangersDocument88 pages02 - Heat ExchangersDana GuerreroNo ratings yet

- Heat loss and fluid temperature calculation for buried insulated and non-insulated oil pipelinesDocument34 pagesHeat loss and fluid temperature calculation for buried insulated and non-insulated oil pipelinesselisenNo ratings yet

- Viscosity Vs Temperature CalculatorDocument7 pagesViscosity Vs Temperature CalculatorRafael PerraciniNo ratings yet

- Processes 09 00939 v2Document19 pagesProcesses 09 00939 v2selisenNo ratings yet

- Insulation Thickness Heat Transfer Pipe CalculationsDocument2 pagesInsulation Thickness Heat Transfer Pipe Calculationsrajpal14667% (6)

- Heat Loss From PipeDocument11 pagesHeat Loss From Pipemlarakahan100% (1)

- 01 Heat Conduction Pipe CalculatorDocument10 pages01 Heat Conduction Pipe CalculatorselisenNo ratings yet

- Domestic Water Booster Pump CalculationsDocument25 pagesDomestic Water Booster Pump CalculationsuddinnadeemNo ratings yet

- Calculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesDocument5 pagesCalculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesselisenNo ratings yet

- Pipe Headloss Calculator: Pipe Selection Fluid Flow InformationDocument1 pagePipe Headloss Calculator: Pipe Selection Fluid Flow InformationselisenNo ratings yet

- Chapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument23 pagesChapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallselisenNo ratings yet

- Water Properties Calculation ToolDocument2 pagesWater Properties Calculation ToolselisenNo ratings yet

- Heat Transfer. Heat Loss From A Pipe in An Indoor LocationDocument29 pagesHeat Transfer. Heat Loss From A Pipe in An Indoor LocationselisenNo ratings yet

- Insulation Thickness Heat Transfer Pipe CalculationsDocument2 pagesInsulation Thickness Heat Transfer Pipe Calculationsrajpal14667% (6)

- Duct Elbow Area PDFDocument14 pagesDuct Elbow Area PDFSakthi.pNo ratings yet

- Sump Pit CalculationDocument4 pagesSump Pit CalculationEng Mahmoud Hamdy33% (3)

- 3 2 2 Chemsheets As Group 2 Physical PropertiesDocument5 pages3 2 2 Chemsheets As Group 2 Physical Propertieszasgher2No ratings yet

- Molecules: Eco-Friendly Synthesis of A New Class of Pyridinium-Based Ionic Liquids With Attractive Antimicrobial ActivityDocument14 pagesMolecules: Eco-Friendly Synthesis of A New Class of Pyridinium-Based Ionic Liquids With Attractive Antimicrobial ActivityBilal KazmiNo ratings yet

- Uop 291 - 76Document4 pagesUop 291 - 76Hasib YounisNo ratings yet

- Characteristics of Aromatic Compounds: Chemistry Molecule ConjugatedDocument4 pagesCharacteristics of Aromatic Compounds: Chemistry Molecule ConjugatedBobby RedianNo ratings yet

- Solubility EnhancementDocument15 pagesSolubility EnhancementJitendra YadavNo ratings yet

- 04 Moisture AnalysisDocument6 pages04 Moisture AnalysisMelati Aprilani100% (2)

- Thermodynamics Multiple Choice QuestionsDocument19 pagesThermodynamics Multiple Choice QuestionsJevan CalaqueNo ratings yet

- Mypchem Ch10answersDocument3 pagesMypchem Ch10answersPikunoShuousNo ratings yet

- Test-03 - MDCAT Test Series 2021 Phase-IIDocument5 pagesTest-03 - MDCAT Test Series 2021 Phase-IIFarzand e IslamNo ratings yet

- Process Dynamics and Control: By: Gemechu Bushu (AAU)Document32 pagesProcess Dynamics and Control: By: Gemechu Bushu (AAU)gebreslassie gereziherNo ratings yet

- Icho 15Document28 pagesIcho 15los sabiosNo ratings yet

- Guide To EWDocument2 pagesGuide To EWlb_BotsNo ratings yet

- Experimental Techniques in PhysicsDocument41 pagesExperimental Techniques in PhysicsTejinder SinghNo ratings yet

- Highlight Key ConceptsDocument6 pagesHighlight Key ConceptsJojo The wonderful0% (1)

- Effect of Fouling FactorDocument5 pagesEffect of Fouling FactorMehta Mehul100% (1)

- Chemistry 1C Syllabus Foothill College Fall 2010Document12 pagesChemistry 1C Syllabus Foothill College Fall 2010stlawryNo ratings yet

- Lab Manual Experiments Organic Chemistry Biology SectionDocument21 pagesLab Manual Experiments Organic Chemistry Biology SectionJulio PastreNo ratings yet

- 8.3 - Packed-Bed ReactorsDocument20 pages8.3 - Packed-Bed ReactorscarolinacmleiteNo ratings yet

- Aits 1718 FT III Jeea Paper 1Document21 pagesAits 1718 FT III Jeea Paper 1amuthan kannanNo ratings yet

- Reportsheet#6 - Properties and Purification of Water - Chem1103lDocument7 pagesReportsheet#6 - Properties and Purification of Water - Chem1103lMarielleCaindecNo ratings yet

- Inorganic Chemistry 2 Main Exam (3) and MemoDocument11 pagesInorganic Chemistry 2 Main Exam (3) and MemoKgasu MosaNo ratings yet

- ELIMINATOR® Liquid Line Filter Drier Types DCL and DML: Data SheetDocument16 pagesELIMINATOR® Liquid Line Filter Drier Types DCL and DML: Data SheetSouljah KhifferNo ratings yet

- Physics p1 2019Document3 pagesPhysics p1 2019taphesh48No ratings yet

- Questions Physical SciencesDocument6 pagesQuestions Physical SciencesJoseph Sebastian Dee100% (1)

- Laser DissertationDocument7 pagesLaser DissertationPayForAPaperCanada100% (1)

- Second-Order ReactionsDocument5 pagesSecond-Order ReactionsDorego TaofeeqNo ratings yet

- The Repair of Reinforced Concrete - John BroomfieldDocument4 pagesThe Repair of Reinforced Concrete - John BroomfieldJad LouisNo ratings yet

- Avogadro's LawDocument31 pagesAvogadro's LawMary joy100% (2)

- Mosfet Chapter - 2Document61 pagesMosfet Chapter - 2田佳生No ratings yet

- Eoy Final Exam Study GuideDocument14 pagesEoy Final Exam Study Guideapi-324757649No ratings yet