Professional Documents

Culture Documents

Transfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat Exchangers

Uploaded by

Marco OrdoñezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transfer of Heat Between Two Fluids - Liquid or Gaseous: General Lay-Out AXA Heat Exchangers

Uploaded by

Marco OrdoñezCopyright:

Available Formats

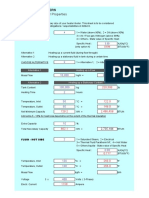

General Lay-Out

AXA Heat Exchangers 71.9

80.0

Transfer of Heat 75.0

Between Two Fluids - Liquid or Gaseous

10.0

1 °C

2

Fluid 1 Fluid 2

Mass Flow kg/h 1000 8000

Specific Heat kJ/kgK 4.000 4.000

Temperature, inlet °C 10.0 80.0

Temperature, outlet °C 75.0 71.9

Capacity kW 72.2

Log. Mid. Temp. Diff. (MTD) K 22.6

Correction Factor - Counter/Cross Flow (CCCF)

The CCCF corrects the MTD value when the flow is not pure counter flow i.e. the two fluids move towards each

other, especially when the hot fluid outlet temperature is lower than the cold fluid outlet temperature. The CCCF

then becomes lower than 1,0.

Correction Factor (CCCF) 0.9

MTD Corrected K 20.3

What kind of heat exchanger do you have in mind ? 1 (see the explanation below)

Plate Type (1) Shell & Tube (2); Winded-up Tube Coil (3); Extented Surface / Fins (4); Others (5)

PLATE HEAT EXCHANGER - compact solution and the most economical type for liquid

Heat transfer coefficients each side - liquid up to 20.000 W/m²K, gas up to 500 W/m²K

Quite sensitive to high temperatures, high pressures, pressure variations. Not good for gas/air

Heat Transfer Coefficient (HTC)

The size of the Heat Transfer Coefficients (HTC) can be almost any value up to the limit above. It depends on the

velocity, flow profile, geometry of the heat exchanger and the proporties of the fluid (viscosity, heat conductivity and

specific heat). When considering the size of the Heat Transfer Coeffecient (HTC) it is important to use low values

as a worse-case. To be sure to find the right size of the AXA heat exchanger, and an acceptable pressure drop, the

HTC should be calculated (which is quite theoretical and extentive procedure). Putting in the HTC below is without

any responsibility for ABCO.

Heat Transfer Coefficient, Side 1 (alfa 1) W/m²K 10,000

AB&CO is a Scandinavian company est. 1988

Heat Transfer Coefficient, Side 2 (alfa 2) W/m²K 10,000

operating worldwide within innovative and cost Overall Heat Transmission Coefficient (k-value) W/m²K 755

efficient process heating, with focus on design

and manufacturing of smaller steam boilers, Necessary Heat Surface (F') m² 4.7

thermal oil heaters and process air heaters.

Extra surface (general safety margin) % 15

Actual Heat Surface (F'') m² 5.4

Although you have chosen a specific AXA heat exchanger, you will get the three optional heat exchangers just for

your evaluation. Note that HTC should be considered for each option i.e. you need to make three print-outs.

Option 1: Plate Heat Exchanger (PHE) Overall Height/Width/Length : 0,7 / 0,3 / 0,3 m

Liquid (1) or Gas (2) Fluid 1: 1 Plate Width mm 315

Fluid 2: 1 Plate Height mm 667

Platestack Depth mm 216

Plate quantity pcs. 51

Extra heat Surface to achieve a moderate pressure drop : % 100

Very often the max. allowable pressure drop will determine the size of a PHE. Extra surface easily becomes 100 %.

Option 2 : Shell & Tube Heat Exchanger Overall Height/Width/Length : 0,5 / 0,4 / 1,4 m

Outer Diameter, Tube mm 18 Total tube length m 104.3

Wall Thickness, Tube mm 1.5 Tube pitch mm 23

Length each tube m 1.1 Number of tubes stk. 95

Distance tube-to-tube mm 5 Cross sect. area, Tube m² 0.0168

Diameter, Shell mm 314

Length, Shell mm 1100

Option 3: Winded-up Tube Coil Overall Height/Width/Length : 0,2 / 0,2 / 13,6 m

Outer Diameter, Tube mm 18 Total tube length m 104.3

Wall Thickness, Tube mm 1.5 Number of windings pcs. 405

Number of coils in parallel stk. 1

Outside diameter mm 100 Core diameter (center volume) mm 64

Space between inner / outer coil mm 0.11 Total height of coil(s) mm 12,151

Distance between two windings mm 12

AB&CO - TT BOILERS A/S | Copenhagen, Denmark | T: +45 4817 7599 https://www.abco.dk

You might also like

- Half Pipe Coil AgitatedDocument1 pageHalf Pipe Coil AgitatedNITINNo ratings yet

- Surface Condenser Thermal Analysis (100914)Document11 pagesSurface Condenser Thermal Analysis (100914)amlanfacebookNo ratings yet

- Sop For Fan SizingDocument3 pagesSop For Fan SizingHsein WangNo ratings yet

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocument6 pagesShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNo ratings yet

- Heat Exchanger Design and HT Coefficent Calculation From RC-6 BookDocument20 pagesHeat Exchanger Design and HT Coefficent Calculation From RC-6 BookJag KhadseNo ratings yet

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsDocument6 pagesShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemNo ratings yet

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- Boiler Efficiency Calculation MethodDocument2 pagesBoiler Efficiency Calculation MethodSomplak KudaNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- Combustion CalcsDocument8 pagesCombustion CalcsZhaqir HusseinNo ratings yet

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- Gas Conditioning System Specification Sheet: Process InformationDocument3 pagesGas Conditioning System Specification Sheet: Process InformationNITIN P SHAHNo ratings yet

- Condenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Document5 pagesCondenser Design: Calculation of LMTD: Hot Fluid (Cold Fluid (Difference (Lokesh EmandiNo ratings yet

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićNo ratings yet

- Mean Metal Temperature CalculationDocument28 pagesMean Metal Temperature CalculationAvijit DasguptaNo ratings yet

- Ejector Dry Air Equi CalcsDocument5 pagesEjector Dry Air Equi Calcsgagewang100% (1)

- REBOILER (RB-101) : Operating ConditionsDocument27 pagesREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiNo ratings yet

- Ist Stage Cooler Process and Mechanical DetailsDocument2 pagesIst Stage Cooler Process and Mechanical DetailsjnmanivannanNo ratings yet

- Air Cooler Design (Ujian)Document36 pagesAir Cooler Design (Ujian)Wahyu JatiNo ratings yet

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDocument2 pagesHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamNo ratings yet

- Heat Exchanger DesignDocument48 pagesHeat Exchanger DesignJose SotoNo ratings yet

- Condenser CalculatorDocument17 pagesCondenser CalculatorSaurav KumarNo ratings yet

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocument2 pagesBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1100% (1)

- Shell & Tube Condenser Design MethodDocument4 pagesShell & Tube Condenser Design MethodwestewrNo ratings yet

- P&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) FormulasDocument4 pagesP&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) Formulasjnmanivannan100% (1)

- Helical Super Heater DesignDocument13 pagesHelical Super Heater DesignG S DeshpandeNo ratings yet

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Shell and Tube VaporizerDocument17 pagesShell and Tube VaporizercontinentalflossNo ratings yet

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTNo ratings yet

- Adiabatic Flame Temperature CalculationDocument8 pagesAdiabatic Flame Temperature CalculationLuis VargasNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ParmarNo ratings yet

- Case 2 - Tank Heat LossDocument84 pagesCase 2 - Tank Heat Lossahmad santosoNo ratings yet

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 pagesHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeNo ratings yet

- Pipe Heat Transfer CalculationsDocument12 pagesPipe Heat Transfer CalculationsmansourotaibiNo ratings yet

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- HEAT EXCHANGER PERFORMANCE ANALYSISDocument6 pagesHEAT EXCHANGER PERFORMANCE ANALYSISJM Flores De SilvaNo ratings yet

- Heat Exchanger Design 1Document9 pagesHeat Exchanger Design 1Rajeev SaxenaNo ratings yet

- Technological Institute of The PhilippinesDocument25 pagesTechnological Institute of The PhilippinesJohn Leonard FazNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignrcalaforraNo ratings yet

- Air Exchanger TDDocument9 pagesAir Exchanger TDRajput PratiksinghNo ratings yet

- Final Design Values of PHE C-510 CoolersDocument4 pagesFinal Design Values of PHE C-510 CoolersRamji MishraNo ratings yet

- Heat Exchanger - Preliminary Data SheetDocument4 pagesHeat Exchanger - Preliminary Data SheetgksakthiNo ratings yet

- Properties by Correlation For Process SimulationDocument4 pagesProperties by Correlation For Process SimulationSuryakant RanderiNo ratings yet

- Design and Calculation AgitationDocument18 pagesDesign and Calculation AgitationGLENDA CASINONo ratings yet

- Shell & Tube Heat Exchanger Rating ProjectDocument20 pagesShell & Tube Heat Exchanger Rating ProjectFareeha HasanNo ratings yet

- A. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CDocument12 pagesA. Process Inputs Fluid Flow Rate (Kg/hr) Density (gm/cc) Sp.Heat (Kcal/kg.°C) λ (Kcal/kg) Inlet Temperature °CPrad1979100% (1)

- Calculating flow and heat transfer in a cement plant cyclone preheaterDocument5 pagesCalculating flow and heat transfer in a cement plant cyclone preheaterhmaza shakeelNo ratings yet

- Heat Exchanger Shell Id CalculationsDocument7 pagesHeat Exchanger Shell Id CalculationsmanojNo ratings yet

- Open TankDocument27 pagesOpen Tankhgagselim2012No ratings yet

- US Units Heat Exchanger Specification SheetDocument1 pageUS Units Heat Exchanger Specification SheetDwi PutraNo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiNo ratings yet

- Heat Exchanger DesignDocument37 pagesHeat Exchanger DesignAnurag IngleNo ratings yet

- General Lay-Out of AB&CO Heat ExchangersDocument1 pageGeneral Lay-Out of AB&CO Heat Exchangersfernando garza0% (1)

- ABCO Heat Exchanger CalculationsDocument1 pageABCO Heat Exchanger CalculationsselisenNo ratings yet

- Modification and Design of Finned Tube HDocument6 pagesModification and Design of Finned Tube Hbu biNo ratings yet

- Anexo 4 - Ficha Intercambiador de Calor de Placas 98.8 KW SWEPDocument2 pagesAnexo 4 - Ficha Intercambiador de Calor de Placas 98.8 KW SWEPSicologo CimeNo ratings yet

- CalcDocument1 pageCalcsebaversa0% (1)

- Heat Exchanger Calculation Sheet - 1Document10 pagesHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNo ratings yet

- Heat Transfer Equipment Design and SelectionDocument72 pagesHeat Transfer Equipment Design and SelectionLouie GresulaNo ratings yet

- Calculation of Boiler Properties: Ab&Co TT BoilersDocument2 pagesCalculation of Boiler Properties: Ab&Co TT BoilersMarco Ordoñez0% (1)

- Heat Balance Calculation Sheet - Part A: AB&CO Process HeatingDocument1 pageHeat Balance Calculation Sheet - Part A: AB&CO Process HeatingMarco Ordoñez0% (1)

- HorarioNovDic2020 2EGBDocument1 pageHorarioNovDic2020 2EGBMarco OrdoñezNo ratings yet

- Astm 1403Document4 pagesAstm 1403Marco OrdoñezNo ratings yet

- Astm D792Document6 pagesAstm D792Aabraham Samraj Ponmani100% (1)

- Astm 1403Document4 pagesAstm 1403Marco OrdoñezNo ratings yet

- Astm D792Document6 pagesAstm D792Aabraham Samraj Ponmani100% (1)

- Astm D792Document6 pagesAstm D792Aabraham Samraj Ponmani100% (1)

- Goulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Document40 pagesGoulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610sebasNo ratings yet

- Astm D792Document6 pagesAstm D792Aabraham Samraj Ponmani100% (1)

- Api CPRDocument7 pagesApi CPRMarco OrdoñezNo ratings yet

- Toda Radiacion CelgelDocument34 pagesToda Radiacion CelgelMarco OrdoñezNo ratings yet

- Goulds Model 3640: Between Bearings Two-Stage Pumps Designed To Meet The Demanding Process Pump Requirements of API-610Document7 pagesGoulds Model 3640: Between Bearings Two-Stage Pumps Designed To Meet The Demanding Process Pump Requirements of API-610Marco OrdoñezNo ratings yet

- Chalmers University of Technology Master S Thesis (After Correction)Document70 pagesChalmers University of Technology Master S Thesis (After Correction)Dani IrawanNo ratings yet

- Fundamentals of Steam Heating SystemsDocument8 pagesFundamentals of Steam Heating Systemsdelta_scopeNo ratings yet

- Line SizingDocument17 pagesLine SizingAllyssa Jane ErcillaNo ratings yet

- Gas Turbine Cooling Methods and Rotary Stall CFD AnalysisDocument2 pagesGas Turbine Cooling Methods and Rotary Stall CFD AnalysisChristopherGunawanNo ratings yet

- Ansys Fluid Dynamics Verification ManualDocument226 pagesAnsys Fluid Dynamics Verification ManualVinay Kusumanchi100% (2)

- Flow Measurements ReportDocument34 pagesFlow Measurements Reportapi-3714301No ratings yet

- z5040758 FAHAD Lowsalinitywaterflooding FINALDocument28 pagesz5040758 FAHAD Lowsalinitywaterflooding FINALAminNo ratings yet

- CalSpan Upset Recovery TrainingDocument2 pagesCalSpan Upset Recovery TrainingHighspeed FlyboyNo ratings yet

- Feasibility Analysis of Blending Hydrogen Into Natural Gas NetworksDocument54 pagesFeasibility Analysis of Blending Hydrogen Into Natural Gas NetworksMarcos Ridiley Alcântara CostaNo ratings yet

- Ontents: Sample Problems Practice ProblemsDocument51 pagesOntents: Sample Problems Practice ProblemsBijimol BinuNo ratings yet

- ME612 Computational Fluid Dynamics: Coarse GoalsDocument4 pagesME612 Computational Fluid Dynamics: Coarse GoalsMradul YadavNo ratings yet

- Homework 3 - Design of A Heat Exchanger For A 50mw Power StationDocument20 pagesHomework 3 - Design of A Heat Exchanger For A 50mw Power Stationapi-120516727No ratings yet

- Holy Angel University permeability and seepage activityDocument9 pagesHoly Angel University permeability and seepage activityJoshua DayritNo ratings yet

- 05 - Circuit DiagramsDocument82 pages05 - Circuit DiagramsJarrod DebonoNo ratings yet

- Co-Flow Jet (CFJ) Airfoils Practicality in Engineless AirplanesDocument25 pagesCo-Flow Jet (CFJ) Airfoils Practicality in Engineless Airplanesinam vfNo ratings yet

- Discharge 03Document39 pagesDischarge 03გიორგი არძენაძეNo ratings yet

- Finite Volume Method: An IntroductionDocument43 pagesFinite Volume Method: An IntroductionAsesh PramanikNo ratings yet

- Chapter 3 Pressurized Irrigation2 ZigyibelDocument28 pagesChapter 3 Pressurized Irrigation2 ZigyibelSolomon AdelaNo ratings yet

- OMNIDocument162 pagesOMNIsyed jeelani ahmedNo ratings yet

- FC50 2.5 Flume DatasheetDocument2 pagesFC50 2.5 Flume DatasheetNDH H775No ratings yet

- VTU Tribology Lesson PlanDocument3 pagesVTU Tribology Lesson Plankumar100% (1)

- AIAA Science and Technology Forum and Exposition AgendaDocument219 pagesAIAA Science and Technology Forum and Exposition AgendaJSANo ratings yet

- Thermodynamic energy equationDocument10 pagesThermodynamic energy equationJúlio Gabriel Queiroz dos SantosNo ratings yet

- EROSIVE BURNING OF COMPOSITE PROPELLANTS-King PDFDocument33 pagesEROSIVE BURNING OF COMPOSITE PROPELLANTS-King PDFedcrfv35No ratings yet

- Minor LossesDocument8 pagesMinor LossesshieferNo ratings yet

- Fluid Mechanics Lab ManualDocument46 pagesFluid Mechanics Lab ManualphrqdurhNo ratings yet

- Lecture Notes - Physics of SedimentationDocument88 pagesLecture Notes - Physics of Sedimentationsaptak1990No ratings yet

- CE-UG-2018 Spring FEB-JUN 2020 FLUID MECHANICS – II (CE- 251) COURSE OUTLINEDocument26 pagesCE-UG-2018 Spring FEB-JUN 2020 FLUID MECHANICS – II (CE- 251) COURSE OUTLINESalmanNo ratings yet

- Hydrodynamic Pressure Calculation For Sump: Bending Moment Diagram Hoop Tension DiagramDocument8 pagesHydrodynamic Pressure Calculation For Sump: Bending Moment Diagram Hoop Tension Diagramepe civilNo ratings yet

- CE Board Nov 2020 - Hydraulics - Set 12Document2 pagesCE Board Nov 2020 - Hydraulics - Set 12Justine Ejay MoscosaNo ratings yet