Professional Documents

Culture Documents

Member Asae: Chemigation Equipment Requirements Safety System Components: The Minimum Equipment

Uploaded by

MoqaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Member Asae: Chemigation Equipment Requirements Safety System Components: The Minimum Equipment

Uploaded by

MoqaCopyright:

Available Formats

Chemigation Via Sprinkler Irrigation:

Current Status and Future Development

E. Dale Threadgill

MEMBER

ASAE

ABSTRACT and trickle/drip irrigation systems can only be

successfully used for chemigation of soil applied

HIS article provides a summary of the current state

T of the art of chemical application through irrigation

systems. Chemigation of both soil and foliar applied

chemicals. Only sprinkler type irrigation systems will

accomodate both soil and foliar applied chemicals. Since

the current interest in chemigation centers around total

chemicals can be effective and is economical. Eighty-four

chemigation (i.e. the application of all types of

percent of the total chemigated area (4.6 million ha) in

chemicals), the discussion in this article will pertain only

the U.S. was chemigated with sprinkler systems in 1983

to sprinkler irrigation systems unless otherwise

with 43%, 61% and 3.5% of the sprinkler, trickle and

surface irrigated areas, respectively, being chemigated at specifically noted.

least once. Uniformity of chemical distribution is an essential

element of successful chemigation and is usually

proportional to the uniformity of water distribution by

INTRODUCTION

the irrigation system. The uniformity of application of

Chemigation can be defined as the application of a water and chemicals by a sprinkler irrigation system can

chemical (fertilizer, herbicide, insecticide, fungicide, be expressed as the coefficient of uniformity, CU (Pair,

nematicide, etc.) via an irrigation system by injecting the 1983). The CU for applications of water from properly

chemical into water flowing through the system. calibrated ground-based sprayers ranges from 50 to 92%

Although the term chemigation is relatively new, the (Bode et al., 1968) while aircraft normally obtain a CU of

concept of applying fertilizer in the form of animal about 70% (Yates, 1962). Most types of sprinkler

manure in irrigation water likely began soon after the use irrigation systems can be designed and operated to

of irrigation. The basic idea of applying commercial achieve CU's of 85% or more. However, many solid-set

fertilizer through a sprinkler irrigation system and periodic lateral move systems achieve CU's of only

(fertigation) was studied by Bryan and Thomas (1958) 70 to 75% while traveling gun type systems normally

more than 25 years ago. Advances in irrigation system achieve a CU of 80% or less under optimum conditions

and injection equipment design have stimulated research and most farmers obtain CU's of less than 70% with

which has resulted in the expansion of chemigation to these systems (Heermann and Kohl, 1980). A

include herbicides ( h e r b i g a t i o n ) , fungicides continuously moving lateral sprinkler system such as the

(fungigation), insecticides (insectigation) and center pivot normally achieves a CU of 90% when

nematicides (nemagation). Thus, chemigation now properly calibrated and operated (Pair, 1983). The

encompasses both soil and foliar applied chemicals. higher CU's of continuously moving lateral sprinkler

The rapid development of chemigation technology systems make them ideally suited for total chemigation.

coupled with the increasing interest in this technique by The operator must recognize and determine whether the

agricultural producers stimulated scientists to hold a lower uniformities of other types of sprinkler irrigation

National Symposium on Chemigation in 1981 and the systems are acceptable for chemigation.

2nd National Symposium on Chemigation in 1982. The

scheduling of a 3rd National Symposium on Chemigation Chemigation Equipment Requirements

in 1985 and the apparent rapid adoption of chemigation Safety system components: The minimum equipment

as a crop management practice makes it appropriate to required for chemigation is an irrigation system, an

summarize the current status and consider the future irrigation pumping station, a chemical injection pump

development of this technology. and a chemical reservoir. However, chemigation should

never be attempted with only this minimum equipment.

COMPONENTS OF CHEMIGATION SYSTEMS The installation and proper maintenance of safety

Adaptability of Irrigation Systems equipment to prevent backflow of chemicals into the

Application of chemicals by chemigation occurs only water source or backflow of water into the chemical

where the irrigation water is applied. Therefore, surface reservoir is essential. Liability and potential litigation

resulting from inadequate safety equipment or improper

use of chemigation must be recognized. Although most

Article was submitted for publication in December, 1984; reviewed

and approved for publication by the Soil and Water Div. of ASAE in states have not yet adopted legislation mandating

May, 1985. chemigation safety measures, several states do have

Project is supported by State and Hatch funds allocated to the specific legislation addressing this requirement (Georgia,

University of Georgia College of Agriculture Experiment Stations and 1981; Wisconsin, 1979; Florida, 1984) and most other

by grant funds from the Richard King Mellon Foundation.

The author is: E. DALE THREADGILL, Professor and Head,

states have ample legal basis for regulating chemigation

Agricultural Engineering Dept., University of Georgia, Coastal Plain and providing redress to parties who suffer injury or

Experiment Station, Tifton, GA. damage as a result of chemigation (Davis, 1981).

16 © 1985 American Society of Agricultural Engineers 0001-2351/85/0101-0016$02.00 APPLIED ENGINEERING in AGRICULTURE

Irrigation Pipe Line suction line of the chemical injection pump and

Anti-siphon Device Irrigation Pump interlocked with the power supply for the injection pump

to prevent flow in either direction when the injection

pump stops.

Additionally, a pressure switch in the chemical

injection line may be desirable. Electrically interlocking

this switch with the safety shutdown system for the

Check Valve irrigation system will provide automatic shutdown of the

Pressure Switch irrigation and chemigation systems if pressure is lost in

Discharge Line' the injection discharge line.

Injection Pump: A wide variety of injection pumps are

Suction Line

Strainer available including water, electric motor and engine

powered units. Both piston and diaphragm type pumps

Fig. 1—Safety devices and arrangement for chemigation through an are commonly used for injection into high pressure

engine powered irrigation system.

irrigation systems with the diaphragm type becoming

increasingly more popular. In some areas, a precision

Additionally EPA is currently developing label built water motor connected internally to a piston

requirements for the registration of pesticides for injector pump which operates on water power is used

application via chemigation (Gray, 1984). (Harrison, 1982). The injection pump should be accurate

The chemigation safety features recommended for within one-half to one percent, easily adjusted for

both internal combustion engine and electric motor different injection rates, and mechanically rugged with

powered irrigation pumping plants are described in the internal and external components being of

ASAE Engineering Practice EP409 (ASAE, 1983). These acceptably noncorrosive materials. Based upon eight

safety features are illustrated in Figs. 1 and 2 along with years of chemigation research by a team of scientists at

additional suggested devices which serve as back-up the University of Georgia's Coastal Plain Experiment

safety features when primary devices fail or for Station where both piston and diaphragm pumps from a

additional primary safety. These safety features are variety of manufacturers have been used, diaphragm

comprised of two safety systems - a backflow prevention pumps are the preferred design. Most diaphragm pumps

system and an interlocking injection system. The have the capability of handling a wide variety of chemical

normally recommended backflow prevention system formulations, are more easily constructed of

consists of a check valve in the irrigation mainline and a noncorrosive materials, are more durable, and lend

vacuum breaker arranged to keep chemical or a mixture themselves to design for easy adjustment of injection rate

of water and chemical from draining or siphoning back while the pump is operating.

into the water source. An additional back-up backflow The range of chemical application rates via

prevention system component is a low pressure activated chemigation ranges from 1.18 L/ha (1 pt/ac) for foliar

drain located between the anti-siphon device and the applied materials such as insecticides to more than 285

irrigation pump to drain into a storage reservoir any L/ha (30 gal/ac) for liquid fertilizer solutions such as

chemical which may slowly leak through the check valve. nitrogen (Stansell, 1981) and on up to 425 L/ha (45

The normally recommended interlocking injection gal/ac) for the application of suspension fertilizer

system consists of a check valve located in the chemical mixtures with slurry injection pumps. These rates

injection line and the interlocking of the power supplies applied with a 61 ha center pivot translate nominally to,

for the irrigation pump and the chemical injection respectively, 7 L/h, 1600 L/h and 2380 L/h as required

pump. The check valve prevents water from flowing into injection rates. An injection pump that is capable of

the chemical reservoir and overflowing water and accurate injection in the range of 7-2380 L/h (2-629 gph)

chemical onto the ground. Power supply interlocking is neither available nor practical. Thus, at least two

prevents the chemical injection pump from continuing to injection pumps, one with a low and one with a high

inject chemical into the mainline and potentially injection rate range, are required for systems used for

overflowing or backflowing when the irrigation system total chemigation. Three pumps may be necessary in

stops. An additional safety device for the interlocking some situations. Chemigation pumps having capabilities

system is a normally closed solenoid valve located in the within any desired range are generally available.

A survey of injection pumps indicates that available

Irrigation Pipe Line

pulsation rates range from 54 to 3500 pulses/min.

Electric Motor Preliminary research data have shown that the pulsation

and Pump rate of the injection pump can have a significant effect on

Anti-siphon Device

the efficacy of some insecticide formulations (Young and

Threadgill, 1984). Groselle et al. (1984) found that a

pulsation rate of 400 pulses/min produced significantly

smaller droplets of an oil-formulated insecticide in the

Check Valve mainline of an irrigation system model than were

Pressure Switch generated at higher (725 pulses/min) or lower (72

Discharge Line pulses/min) pulsation rates. However, these differences

were eliminated when the insecticide passed through a

single orifice impact sprinkler. Insufficient information

is currently available to serve as a criteria for pulsation

Fig. 2—Safety devices and arrangement for chemigation through an rate selection. Research to further define the effects of

electric motor powered irrigation system. pulsation rate is continuing.

Vol. l(l):June, 1985 17

previous section. Groselle et al. (1984) and Cochran et al.

(1984) have found that the sprinkler will generally reduce

the size of oil-insecticide droplets as compared to droplet

sizes found in the mainline flow. Smaller sprinkler

A. Straight Center B. Flush

orifices cause a greater reduction in oil-insecticide

droplet sizes than larger orifices.

The velocity of flow in an irrigation mainline decreases

with increasing distance from the point of chemical

injection which results in a decreasing potential for

C. Upstream D. Downstream entrainment and mixing of injected materials. While this

Flow % may be of negligible influence for water soluble

formulations of fertilizers (Fischbach, 1982), other

results suggest that the distribution uniformity of water

Fig. 3—Four injection port orientations. soluble herbicides may differ from the uniformity of the

irrigation water and that the distribution concentations

Chemical Reservoir: Criteria for selecting a chemical and uniformity of these herbicides can be substantially

reservoir for chemigation are similar to those used for different detween high and low pressure irrigation

selecting reservoirs for conventional chemical systems (Dowler et al., 1982a). Stone (1984) found that

applications. For insecticide applications at low rates, a the distribution of an oil-formulated insecticide from a

smaller reservoir may be desirable while some center pivot was less uniform (CU = 81%) than the

formulations of pesticides and plant nutrients may water (CU = 86%). Young (1984) notes that the efficacy

require a very large reservoir equipped for either of oil-formulated insecticides has been erratic and

mechanical or hydraulic agitation of the chemical. unacceptably low when applied via chemigation in a

Injection Port: The configuration of the injection port irrigation system having an initial mainline flow velocity

and its orientation in the main irrigation line have a of less than 82 m/min (4.5 ft/s). Velocity of flow may

significant effect on the droplet size distribution of oil- have a similar influence on suspension fertilizers and

formulated pesticides and can significantly affect their wettable powder pesticides. These results indicate that

efficacy. Fig. 3 illustrates four injection port orientations further study of the effects of flow velocity and other

that have been studied. In studies with oil-formulated irrigation system characteristics on chemical distribution

insecticides injected into a model of a center pivot system and efficacy is needed.

Groselle (1984) found that orientation C (Fig. 3)

produced significantly smaller oil-insecticide droplets in CHEMIGATION AS A PRODUCTION

the mainline of the irrigation system than did orientation MANAGEMENT TOOL

D. However, he noted that there were no differences in

the oil-insecticide droplet sizes between either of these Threadgill (1981) discussed the crop production

orientations after the material was emitted from a single management advantages available when chemigation is

orifice impact sprinkler. In a related study Young (1984) properly utilized. These advantages can be summarized

observed that injection of this oil-formulated insecticide as follows:

by orientation D is a small center pivot produced 1. Provides excellent uniformity of chemical

significantly better insect control than when orientation application.

C was used. Further research by Cochran et al. (1984) 2. Allows prescription application of chemicals.

illustrated that irrigation system pressure, injection port 3. Allows timely chemical application.

orientation and sprinkler characteristics definitely affect 4. Allows easy and effective chemical incorporation

the droplet size distribution of oil-formulated pesticides. and activation.

Further research is needed to definitively characterize 5. Reduces soil compaction.

the effects of these variables and the oil-pesticide fluid 6. Reduces mechanical damage to the crop.

properties on pesticide distribution and efficacy. The 7. Reduces operator hazards.

influence of these factors upon the efficacy of nonoil- 8. May reduce chemical requirements.

formulated chemicals has not yet been studied. 9. May reduce environmental contamination.

Experience by the research team at the Coastal Plain 10. Economical

Experiment Station has illustrated that simultaneous 11. Effective

injection of two or more chemicals is quite practical. Realization of these potential management advantages

However, incompatibility problems such as requires that the chemigation system be properly

precipitation, etc., which usually occur with tank designed and properly utilized. Proper calibration of the

mixtures of incompatible chemicals will also occur when chemical injection system is essential to achieve good

two or more incompatible chemicals, injected from results (Stansell, 1981).

separate injection pumps, are introduced into the

irrigation mainline through a common injection port. ECONOMICS OF CHEMIGATION

Under these circumstances, injection of each chemical The potential cost of a particular application via

through a separate injection port located at least 150 mm chemigation depends upon the need for supplemental

from any other injection port has solved the problem. water at the time of chemigation. For example,

Irrigation System Characteristics: Although limited application of some chemicals may be required at the

information is available, some effects of sprinkler design same time that the crop normally receives an irrigation

and flow velocity within the irrigation mainline upon while other chemical applications may be needed when

chemical distribution and efficacy have been observed. irrigation is not required by the crop. When chemigation

Some sprinkler design effects were discussed in a is coupled with a normal irrigation, the variable cost of

18 APPLIED ENGINEERING in AGRICULTURE

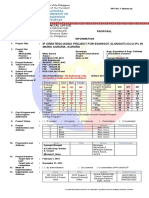

chemigation will only be the cost of operating the TABLE 1. COSTS ($/ha) OF A SINGLE CHEMIGATION AND

CONVENTIONAL APPLICATION OF CHEMICALS.

chemical injection system. For chemigation when

irrigation is not required, the variable chemigation cost Type of chemical Conventional * Chemigationf Water applied

would also include the cost of operating the irrigation Fertilizer $6.20 $13.06 1.0 cm

system. Herbicide 14.00$ 13.06 1.0 cm

Insecticide 5.60 9.84 0.3 cm

Also, the cost of chemigation will depend upon the Fungicide 5.60 9.84 0.3 cm

amount of water required for an efficacious application Nematicide 14.00$ 13.06 1.0 cm

of the particular chemical. For example, application of •Costs of aircraft and tractor sprayer assumed to be equal.

some fertilizers, nematicides and pre-emerge herbicides tBased upon operating cost of a 61 ha center pivot (fixed

cost of irrigation system charged against irrigation) plus

may require 1.0 to 1.5 cm of water for proper entire annual fixed cost of chemigation system.

incorporation or activation while most insecticides, $ Includes cost of mechanical incorporation.

fungicides and post-emerge herbicides will likely require

only 0.3 to 0.5 cm of water.

An additional factor in the economics of chemigation The costs in Table 1 show that use of a chemigation

is the capital or fixed cost of the chemigation system. The system for only one chemical application per year will

cost is quite variable depending upon the size and likely be cost effective for only those chemicals requiring

number of injection pumps and the type of components incorporation. However, the potential management

used in the safety system. Considering currently available advantages offered by chemigation can only be realized

components, a reasonable minimum system cost would through multiple annual chemigations. Table 2 presents

be $1,500 while the maximum cost could be $8,000 or cost comparisons of several multiple chemigation

more. Chemigation systems can either be fixed (devoted scenarios. It is evident from these comparisons that

to a single irrigation system) or mobile. Mobile units chemigation is very cost effective when a system is used

which include two chemical injection pumps, two storage two or more times annually with chemigation costs

tanks and all recommended safety features except those ranging from 34 to 60% of conventional costs.

installed in the irrigation mainline are presently available Chemigation cost savings generally increase as the

from several manufacturers at a cost of about $3,500. number of annual applications increases, depending

These mobile units can greatly reduce chemigation costs upon the annual combination of chemicals applied.

where an operator uses one unit with several irrigation

systems. EFFECTIVENESS OF CHEMIGATION

Considering that the purchase of an irrigation system The effectiveness of chemigation application of

is initially justified upon the need and benefits of fertilizers, herbicides, nematicides, fungicides,

irrigation alone, the capital or fixed cost of the irrigation insecticides, broad spectrum soil fumigants and plant

system can be amortized to irrigation usage alone. Thus, growth regulators has been intensively evaluated in

the fixed costs of only the chemigation system recent years. An interdisciplinary team of scientists at

components are charged to chemigation in the following the University of Georgia's Coastal Plain Experiment

analyses. Station has evaluated the effectiveness of chemigation for

Table 1 presents a comparison of costs for a single the past eight years on at least 22 different crops. A

chemigation or conventional (aircraft or tractor sprayer) major portion of the results of their studies can be found

application of various chemicals. Chemigation costs are in the annual reports of their research (Threadgill, 1980;

based upon a 61 ha center pivot capable of applying a Smittle, 1981; Dowler, 1982; and Young and Threadgill,

minimum water amount of 0.4 cm. The fixed cost of the 1984) plus the proceedings of the two national symposia

chemigation system is assumed to be $4,000 with a useful on chemigation (Young, 1981; and Young and Sumner,

life of 10 years. Assuming $2/ha annual maintenance 1982). Additional reports on the results of their research

costs, total fixed costs of this chemigation system would and that of other scientists can be found in the following

be $8.56/ha per year. Conventional chemical application references (Chalfant and Young, 1982: Crutchfield et

costs are based upon commercial aircraft and tractor al., 1977; Dowler, 1982; Dowler et al., 1982a, 1982b;

rates in the Southeast U.S. in 1984. Fischbach and Martin, 1975; Gascho and Hook, 1984;

TABLE 2. COSTS ($/ha) FOR MULTIPLE CHEMIGATION AND CONVENTIONAL

APPLICATIONS OF CHEMICALS.

1 2 3 4 5 6 7 8 9 10

Chemicals and IF 1F,1H 2F,1H 2F,1H 2F,1H 2F,1H 2F,1H 3F,1H 3F,2H 3F,2H

number applied* 11 lI,lFg 2I,lFg 41 41 4Fg 51

Chemigation

Fixed costf $ 8.56 $ 4.28 $ 2.85 $ 2.14 $ 1.71 $ 1.43 $ 1.22 $ 1.07 $ 0.95 $ 0.86

Variable cost$ $ 4.50 $ 9.00 13.50 14.78 16.06 17.34 18.62 23.12 27.62 28.90

Total cost 13.06 13.28 16.35 16.92 17.77 18.77 19.84 24.19 28.57 29.76

Conventional §

Total cost 6.20 20.20 26.40 32.00 37.60 43.20 48.80 55.00 69.00 74.60

Chemigation

savings - 6.86 6.92 10.05 15.08 19.83 24.43 28.96 30.81 40.43 44.84

*F = fertilizer, H = herbicide, I = insecticide, Fg = fungicide, numeral indicates number of applications of

particular type.

tAssumed $4,000 fixed cost of chemigation system plus $2/ha annual maintenance cost.

$ Based upon operating cost of a 61 ha center pivot.

§ Refer to Table 1 for individual values.

Vol. l(l):June, 1985 19

Gascho et al., 1984; Heikes, 1979; Johnson et al., 1982; formulations presents some incompletely analyzed

McMaster and Douglas, 1976; Ogg, 1980; Ogg et al., engineering problems regarding how materials are mixed

1983; Phatak et al., 1982; Raun, 1979; Smittle and and carried in the water, uniformity of application and

Johnson, 1982; Smith et al., 1973; Sumner and Phatak, possible residues in the irrigation system. Wettable

1982a, 1982b; Sumner et al., 1983; Threadgill, 1982; powder, water soluble and emulsified concentrate

Young, 1980; and Young et al., 1981). Rather than formulations of these foliar materials have given

summarize the results of all these studies herein, the inconsistent and erratic results in a wide range of tests.

reader is referred to these references for detailed Most efficacy evaluations have occurred using

information. Generally, these results have demonstrated currently recommended rates of the chemicals. Only

that chemigation is feasible and can be very effective recently have studies been initiated evaluating reduced

when the irrigation system and chemical injection system chemical rates and, in some cases, achieving the desired

are properly installed and operated and when the proper efficacy with reduced chemical rates appears promising.

chemical, chemical formulation and water application Determination of the appropriate quantity of water

rates are used. Chemical formulation appears to be (minimum and maximum) which can be used in

particularly important for applications where foliar chemigation has received considerable interest. In

retention of the chemical is required for efficacy (i.e. general, chemigation with materials that do not require

fungicides, insecticides and post-emergence herbicides). incorporation into the soil has been effective with water

For these foliar applications, the most consistent positive quantities ranging from 0.25 to 1.9 cm. Phytotoxicity

results have been obtained when the technical chemical caused by fertigation has not been reported even though

has been formulated in an oil without the addition of any a wide range of nutrient rates and formulations has been

emulsifier. However, chemigation with these applied.

TABLE 3. RESULTS OF CHEMIGATION SURVEY SUMMARIZED BY ASAE REGIONS FOR THE 35

REPORTING STATES (IN HECTARES), 1983.

ASAE Type of

region irrigation Type of chemigation

(states) system Irrigated Fertigated Herbigated Insectigated Fungigated Nemagated

Southeast Sprinkler 1,083,500 80,100 10,000 5,000 6,300 100

(GA, AL, FL, surface 727,900 100 100

KY, TN, SC, NC, trickle 62,800 1,600 400 600 200

VA, MS) Total 1,874,200 81,800 10,500 5,000 6,900 300

Southwest Sprinkler 1,268,500 378,800* 8,300 46,200 36,100 300

(TX, OK, LA, surface 3,679,500 80,900 2,000

AR) trickle 18,100 6,200

Total 4,966,100 385,000 89,200 48,200 36,100 300

Mid-Central Sprinkler 2,090,300 675,800 41,300 81,700

(KS, MO, NE, surface 2,792,000 202,400

IA) trickle 2,300

Total 4,884,600 878,200 41,300 81,700

Illinois-Wisconsin Sprinkler 224,600 14,600 2,400 120

(IL, WI

trickle

Total 224,600 14,600 2,400 120

Tri-State Sprinkler 56,700 24,300

(IN, MI, OH) surface 2,400 ZTJ1Z

trickle 40

Total 59,140 24,300

Rocky Mountain Sprinkler 518,500 147,400 22,300 19,400 16,400

(NM, CO, UT, WY) surface 2,671,700

trickle 650 200

Total 3,190,850 147,600 22,300 19,400 16,400

Pacific Sprinkler 858,600 721,200 3,000 900

(CA, NV, AZ, HI) surface 3,615,000 197,800 18,200 2,000 38,200

trickle 111,300 110,200

Total 4,584,900 1,029,200 21,200 2,000 39,100

Pacific Northwest Sprinkler 2,170,900 686,400 410,400 8,100 22,600 26,300

(WA, OR, ID, surface 2,049,500 6,100

MT, AK) trickle 3,900 2,000

Total 4,224,300 694,500 410,400 8,100 22,600 26,300

North Atlantic Sprinkler 53,700 10,100 40

(PA, WV, MD, NJ, surface

DE, CT, NY, VT, trickle 2,300 1,100 1,000

MA, NH, ME, RI) Total 56,000 11,200 40 1,000

North Central Sprinkler 202,400 121,400 1,200 400

(ND, SD, MN) surface

trickle

Total 202,400 121,400 1,200 400

*May include some surface and trickle system fertigated acreage.

20 APPLIED ENGINEERING in AGRICULTURE

CURRENT CHEMIGATED AREA irrigated area (35 states) represents 88% of the total U.S.

The management advantages, positive economics and trickle area. Therefore, the survey results provide an

effectiveness of chemigation coupled with the rapid estimate of the current status of chemigation in a high

development of research information on chemigation has percentage of the irrigated area of the U.S.

stimulated a very rapid increase in the degree of Eighty-four percent of the total area chemigated in

utilization of this crop production management tool 1983 was with sprinkler irrigation systems, 13% with

throughout the United States. A chemigation survey was surface systems and 3 % with trickle systems. While 43%

conducted to determine the current chemigated area in of the sprinkler irrigated area and 61% of the trickle

each state by submitting a survey instrument to irrigated area was chemigated at least one time in 1983,

Extension Agricultural Engineers in each of the 40 states only 3.5% of the surface irrigated area was chemigated.

which have an extension agricultural engineer with a Fertigation was the most widely used form of

major emphasis on irrigation (as identified in the 1982 chemigation, being practiced on 33.5% of the sprinkler

USDA Directory of State Extension Agricultural irrigated area and 60% of the trickle irrigated area but

Engineers). The information received from the 35 on only 0.3% of the surface irrigated area. Likewise,

responding states is summarized in Table 3. Chemigated herbigation was used on 5.8, 0.2 and 0.6%, insectigation

area was not identified as to the number of times a was used on 1.9, 0.0 and 0.003%, fungigation was used

particular type of chemical was applied on a particular on 1,0, 0.3, and 0.2% and nemagation was used on 0.3,

area. For example, a value of 3,000 ha fertigated could 0.6 and 0.0% of the sprinkler, trickle and surface

imply (a) 3,000 ha fertigated one time, (b) the same irrigated areas, respectively.

3,000 ha fertigated two or more times, or (c) 1,000 ha Although it is desirable to know the trend in the use of

each fertigated three times. Telephone discussions with a chemigation, there are no prior reported national level

few of the extension engineers who contributed data to compare with the results of this survey. However,

information for sprinkler type irrigation systems stated data from 1981 and 1982 Georgia surveys (Harrison,

that the listed herbigated and nemagated areas were only 1983) show that chemigated area in Georgia increased

treated one time while the listed areas for fertigated, 11% during one year. Based upon this Georgia data and

insectigated and fungigated crops were generally treated discussions with extension engineers in several reporting

more than one time. Therefore, it is appropriate to state states, I estimate the U.S. chemigated area and/or use

that the listed areas denote that chemigation was applied with sprinkler irrigation systems is expanding at an

to that number of hectares at least one time and more annual rate of 8 to 9%.

than once in many cases.

Data are summarized and reported by ASAE Regions. SUMMARY

Most states reported that the degree of accuracy of their Chemigation is an effective crop production

data on chemigated area is at best fair and in most cases management tool which is particularly well adapted to

merely an estimate. Very few states currently conduct a continuously moving lateral sprinkler type irrigation

survey of chemigated area. States from which survey data systems. Offering many management advantages, the

were not received or solicited are not identified in Table cost of multiple annual chemigations is generally 34 to

3. Irrigated area (Irrigation Journal, 1984) in the five 60% of the cost of applying those chemicals by a

states not responding plus the 10 states from which data conventional technique. Chemigation is very effective

were not solicited is as follows: (a) sprinkler - 832,600 ha, when the irrigation and chemigation system are properly

(b) surface - 96,000 ha and (c) trickle - 26,800 ha. installed and operated and when the proper chemical,

The results of the chemigation survey are summarized chemical formulation and water application rate are

in Table 4 for data received from the 35 reporting states. used. Effectiveness has been proven for both soil and

The total irrigated area (35 states) included in Table 4 foliar applied chemicals.

represents 98% of the total U.S. irrigated area (50 states) An adequate selection of commercially available

reported in Irrigation Journal (1984). Likewise, the total equipment is available for assembling a chemigation

sprinkler irrigated area (35 states) represents 98% of the system. Particular consideration must be given to safety

total U.S. sprinkler irrigated area and the total trickle devices to prevent backflow of chemicals into the water

TABLE 4. RESULTS OF CHEMIGATION SURVEY SUMMARIZED FOR THE 35 REPORTING

STATES (IN HECTARES), 1983.

Type of

irrigation Type of chemigation

system Irrigated Fertigated Herbigated Insectigated Fungigated Nemagated Total

Sprinkler 8,527,700 2,860,100 497,700 161,760 82,700 26,700 3,628,960

surface 15,538,000 406,400 99,200 4,000 38,200 547,800

trickle 201,390 121,300 400 600 1,200 123,500

Total 24,267,090 3,387,800 597,300 165,760 121,500 27,900 4,300,260

Chemigated

as percentage

of irrigated

total N/A 14.0 2.5 0.7 0.5 0.1 17.7

Sprinkler

chemigated as

percentage of

sprinkler

total N/A 33.5 5.8 1.9 1.0 0.3 N/A

Vol. l(l):June, 1985 21

source, into the chemical reservoir or onto the soil Georgia, Coastal Plain Experiment Station, Tifton, GA, 69 pp.

surface. Consideration and use of legislation or 12. Fischbach, P. E. 1982. Applying chemical through irrigation

systems-safety and environmental considerations. Proc. of 2nd

regulations requiring approved safety systems is National Symposium on Chemigation, University of Georgia, Tifton,

increasing at both state and national levels. GA, pp. 80-87.

Although considerable information about chemigation 13. Fischbach, P. E. and Alex Martin. 1975. Herbigation

has been developed in the past few years, research on -applying herbicide through sprinkler systems. ASAE Paper No.

75-1527. ASAE, St. Joseph, MI 49085.

many factors has barely begun while other factors are not 14. Florida. 1984. Antisyphon requirements for irrigation systems.

yet being addressed. Such factors as sprinkler design, Florida statutes, Rule 5E-2.30.

system pressure and flow velocity, injection port 15. Gascho, G. J. and J. E. Hook. 1984. Nitrogen management for

configuration and chemical formulation are known to irrigated corn grown on sand. Fer. Issues 1(1): 1-6.

have a significant effect on chemigation efficacy in 16. Gascho, G. J., J. E. Hook and G. A. Mitchell. 1984. Sprinkler-

applied and side-dressed nitrogen for irrigated corn grown on sand.

certain cases and are receiving further study while Agron. J. 76:77-81.

injection pump pulsation rate may be of less importance. 17. Georgia. 1981. Agriculture - rules, etc. regulating irrigation

Initial studies on efficacy of reduced rates of chemicals systems. Georgia General Assembly, House Bill No. 521.

applied via chemigation have provided promising results 18. Gray, Philip. 1984. Personal communication about "Pesticide

application through irrigation systems," unpublished draft of proposed

and information on maximum and minimum amounts of Environmental Protection Agency document.

water for chemigation is being developed but both water 19. Groselle, D. E. 1984. Droplet size of oil formulated insecticides

and chemical rates need a great deal of additional generated in irrigation water during chemigation. Unpublished M.S.

research. thesis, University of Georgia, Athens, GA.

A survey revealed that 84% of the total chemigated 20. Groselle, D. E., J. R. Stansell and J. R. Young. 1984. Particle

size variation of oil-formulated insecticides in chemigation. ASAE

area (4.30 million ha) in the U.S. is chemigated with Paper No. 84-2098, ASAE, St. Joseph, MI 49085.

sprinkler irrigation systems with 43% (3.63 million ha) 21. Harrison, D. S. 1982. Selection, operation, calibration and

of the sprinkler irrigated area and 61% (0.12 million ha) maintenance of chemigation equipment. Proc. of 2nd National

of the trickle irrigated area being chemigated at least one Symposium on Chemigation, University of Georgia, Tifton, GA. pp.

74-79.

time in 1983. Chemigation was practiced on only 3.5% of 22. Harrison, K. L. 1983. Irrigation survey, 1981 and 1982.

the surface irrigated area. Types of chemigation University of Georgia, Cooperative Extension Service, Tifton, GA.

arranged in order of decreasing use are fertigation, 23. Heermann, D. F. and R. A. Kohl. 1980. Fluid dynamics of

herbigation, insectigation, fungigation and nemagation. sprinkler systems, p. 583-618. In: M. E. Jensen (ed.) Design and

The use of chemigation with sprinkler irrigation operation of farm irrigation systems. ASAE Monograph No. 3, St.

Joseph, MI 49085.

systems is predicted to increase rapidly as current and 24. Heikes, P. E. 1979. Herbigation: Applying herbicides through

developing research programs generate more complete sprinkler systems. Weeds Today 10:7-9.

information about this rapidly developing technology. 25. Irrigation Journal. 1984. '83 irrigation survey. Irrigation

Journal 34(1).

26. Johnson, A. W., W. A. Rhode and W. C. Wright. 1982. Soil

References distribution of phenamiphos applied by overhead sprinkler irrigation to

1. ASAE. 1983. Safety devices for applying liquid chemicals control Meloidogyne incognita on vegetables. Plant Disease

through irrigation systems. Engineering Practice ASAE EP409, 66(6):489-491.

Agricultural Engineers Yearbook of Standards, Am. Soc. Agri. Engr., 27. McMaster, G. M. and D. R. Douglas. 1976. Fungicide

St. Joseph, MI, pp. 522-523. application through sprinkler irrigation systems. TRANSACTIONS of

2. Bode, L. E., M. E. Gebhart and C. L. Day. 1968. Spray- the ASAE 19(6):1041-1044.

deposit patterns and droplet sizes obtained from nozzles used for low- 28. Ogg, A. G., Jr. 1980. A sprinkler system for research on

volume applications. TRANSACTIONS of the ASAE ll(6):754-756, applying herbicides in irrigation water. Weed Sci. 28:201-203.

761. 29. Ogg, A. G., Jr., C. C. Dowler, A. R. Martin, A. H. Lange, and

3. Bryant, B. B. and E. L. Thomas, Jr. 1958. Distribution of P. E. Heikes. 1983. Application of herbicides through irrigation

fertilizer materials applied through sprinkler irrigation systems. systems. Extension Service, U.S. Dept. of Agric. Item AD-FO-2280, 8

Bulletin 598. University of Arkansas Agricultural Experiment Station, pp.

Fayetteville, AR, 12 pp. 30. Pair, C. H. (ed.). 1983. Irrigation, 5th ed. The Irrig. Assoc,

4. Chalfant, R. B. and J. R. Young. 1982. Chemigation, or Silver Spring, MD, 686 pp.

application of insecticide through overhead sprinkler irrigation 31. Phatak, S. C , D. R. Sumner, B. G. Mullinex, Jr. and N. C.

systems, to manage insect pests infesting vegetable and agronomic Glaze. 1982. Effect of metham sodium applied through overhead

crops. J. Econ. Entomol. 75:237-241. sprinkler irrigation system on soil pest control and growth and yield of

5. Cochran, D. L., E. D. Threadgill and J. R. Young. 1984. Use vegetable crops. Hort. Sci. 17:38. (Abstract)

of center pivot simulator for chemigation research. ASAE Paper No. 32. Raun, E. S. 1979. Pest management using center pivots. Irrig.

84-2099, ASAE, St. Joseph, MI 49085. Age May-June: 17-18.

6. Crutchfield, D. A., R. N. Clark, and A. F. Wiese. 1977. 33. Smith, D. T., R. C. Berner, and J. P. Walter. 1973. Nitralin

Deposition of atrazine and trifluralin with sprinkler irrigation. Proc. and trifluralin incorporation by rainfall and irrigation. Weed Res.

South. Weed Sci. Soc. 30:428. 13:359-366.

7. Davis, C. L. 1981. Liability considerations in chemigation. 34. Smittle, D. A. (ed.). 1981. Irrigated multiple-cropping

Proc. of National Symposium on Chemigation, University of Georgia, production systems: A summary of progress, 1977-1980. University of

Tifton, GA, pp. 113-119. Georgia, Coastal Plain Experiment Station, Tifton, GA. 46 pp.

8. Dowler, C. C. 1982. Activity of selected herbicides applied 35. Smittle, D. A. and A. W. Johnson. 1982. Effects of

postemergence through irrigation. Southern Weed Science Society management practices on Meloidogyne incognita and snap bean yield.

Proc. p. 397. (Abstract). J. of Nematol. 14:63-68.

9. Dowler, C. C , W. A. Rohde, L. E. Fetxer, D. E. Scott, Jr., T. 36. Stansell, J. R. 1981. Chemigation injectors: selection,

E. Sklany, and C. W. Swann. 1982a. The effect of sprinkler irrigation calibration and use. Proc. of National Symposium on Chemigation.

on herbicide efficacy in selected crops and distribution and penetration University of Georgia, Tifton, GA. pp. 103-108.

in some Coastal Plain soils. The Univ. of Georgia College of 37. Stone, K. C. 1984. Water and chemical distribution through a

Agriculture Research Bulletin 281. 27 pp. sprinkler irrigated plant canopy. Unpublished M.S. thesis, University

10. Dowler, C. C , E. D. Threadgill and J. R. Stansell. 1982b. of Georgia, Athens, GA.

Chemigation equipment and techniques for irrigation research. 38. Sumner, D. R. and S. C. Phatak. 1982a. Control of

American Society of Agronomy Abstracts, p. 51. Rhizoctonia solani and Pythium spp. with metham sodium applied

11. Dowler, C. C. (ed.). 1982. Irrigated multiple-cropping through sprinkler irrigation. Phytopathology 72:948. (Abstract).

production systems: A summary of progress, 1981. University of 39. Sumner, D. R. and S. C. Phatak. 1982b. Control of root

22 APPLIED ENGINEERING in AGRICULTURE

diseases of snapbean with soil fungicides and metham sodium applied 46. Young, J. R. 1980. Suppression of fall armyworm populations

through overhead irrigation. Report of Bean Imp. Coop, and Nat. Dry by incorporating insecticides into irrigation water. Fla. Entomol.

Bean Council Res. Conf. p. 61-62. Gainesville, FL. Jan. 5-7. 73:447-450.

40. Sumner, D. R., C. C. Dowler, A. W. Johnson, N. C. Glaze, S. 47. Young, J. R. (ed.). 1981. Proc. of National Symposium on

C. Phatak, R. B. Chalfant, and J. E. Epperson. 1983. Root diseases of Chemigation, University of Georgia, Tifton, GA. 126 pp.

cucumber in an irrigated multiple-cropping system with pest 48. Young, J. R., T. C. Kiesling, and J. R. Stansell. 1981.

management. Plant Disease 67:1071-1075. Insecticide application with sprinkler irrigation systems.

41. Threadgill, E. D. (ed.). 1980. Irrigated multiple-cropping TRANSACTIONS of the ASAE 24(1): 121-123.

production systems: A progress report, 1977-1979. University of 49. Young, J. R. and D. R. Sumner (ed.). 1982. Proc. of 2nd

Georgia, Coastal Plain Experiment Station, Tifton, GA. National Symposium on Chemigation. University of Georgia, Tifton,

42. Threadgill, E. D. 1981. Why chemigate? Proc. of National GA. 98 pp.

Symposium on Chemigation, University of Georgia, Tifton, GA. pp. 50. Young, J. R. and E. D. Threadgill (ed.). 1984. Irrigated

1-6. multiple-cropping production systems: A summary of progress, 1982.

43. Threadgill, E. D. 1982. Chemigation: New way to get crops to University of Georgia, Coastal Plain Experiment Station, Tifton, GA.

take their medicine. Ga. Agr. Rsch. 22(4): 16-17. 94 pp.

44. Wisconsin. 1979. Agriculture Admin. Code NR 112.15. 51. Young, J. R. 1984. Personal communications. Insect Biology

45. Yates, W. E. 1962. Spray pattern analysis and evaluation of Laboratory, Coastal Plain Experiment Station, Tifton, GA.

deposits from agricultural aircraft. TRANSACTIONS of the ASAE 52. Young, J. R. and E. D. Threadgill. 1984. Unpublished data.

5(l):49-53. Coastal Plain Experiment Station, Tifton, GA.

Emergency Stop Concept for Farm Machinery

(continued from page 15)

Shutting off the air supply is a simple way to provide shielding the cable and setting a minimum actuation

engine kill. Naturally aspirated engines can have air shut tension.

off at any point in the air intake without harmful effects. A first logical application of this concept would be on

On the other hand, if air is shut off on the suction side of stationary feed grinders, conveyors, etc. where people

a turbo-charged engine, some oil seal damage could must work near the operating machine.

occur. For this reason, air shut off of a turbo unit should

possibly be downstream of the pressure side. References

Carburetor equipped engines can best be starved for 1. Hammond, W. C , Bobby L. Tyson, and Furman W. Kay. 1983.

Emergency stop mechanism for farm machinery. ASAE Paper No.

air downstream from the carburetor to prevent flooding SER 83-102, ASAE, St. Joseph, MI 49085.

although flooding is a minor problem. 2. Sevart, J. B. and Bradley Klausmeyer. 1982. Emergency stop

Nuisance tripping from crops or brush is a factor to be devices for a g r i c u l t u r a l machinery. A G R I C U L T U R A L

considered. This would require properly locating and ENGINEERING 63(9):11-13 Steptember.

Vol. l(l):June, 1985 23

You might also like

- The Everyday DASH Diet Cookbook PDFDocument256 pagesThe Everyday DASH Diet Cookbook PDFgab20100% (1)

- Aquaponics: Growing Fish and Plants Together - Colorado AquaponicsDocument76 pagesAquaponics: Growing Fish and Plants Together - Colorado AquaponicsAquaponics94% (16)

- Chemical Injection MethodsDocument13 pagesChemical Injection MethodsIndra NainggolanNo ratings yet

- Chemical Injection MethodsDocument13 pagesChemical Injection MethodsCakTomNo ratings yet

- Irrigation SystemDocument7 pagesIrrigation System185412No ratings yet

- Jackson Vocational Interest Survey (JVIS) - Extended ReportDocument18 pagesJackson Vocational Interest Survey (JVIS) - Extended ReportRoxana ButnareanuNo ratings yet

- Hospital Waste Water TreatmentDocument5 pagesHospital Waste Water TreatmentNP100% (1)

- Agrarian Structure in Historical PerspectiveDocument11 pagesAgrarian Structure in Historical PerspectiveTado LehnsherrNo ratings yet

- 9 - Drip IrrigationDocument58 pages9 - Drip Irrigationgregorio roaNo ratings yet

- TLE Grade 8 ExaminationDocument2 pagesTLE Grade 8 ExaminationREdValeraBonilla100% (1)

- Fertigation and Irrigation Management Systems of Vertical Gardens and Green RoofsDocument21 pagesFertigation and Irrigation Management Systems of Vertical Gardens and Green RoofsAhmed NabilNo ratings yet

- Greenhouse Project - 5 AcresDocument17 pagesGreenhouse Project - 5 AcresJagtej Singh Anand100% (2)

- Drip Irrigation - Management and MaintenanceDocument3 pagesDrip Irrigation - Management and Maintenancepfdc GuwahatiNo ratings yet

- 577300-0 Irrigmgmtguide Chapter 09 With TitlepageDocument10 pages577300-0 Irrigmgmtguide Chapter 09 With TitlepageShephard KadairaNo ratings yet

- Contamination Control of Aircraft Hydraulic SystemDocument15 pagesContamination Control of Aircraft Hydraulic SystemDeenanathNo ratings yet

- Drip Irrigation Report 2Document20 pagesDrip Irrigation Report 2Siddharth DeshmukhNo ratings yet

- Automation in Irrigation - A Review: ArticleDocument18 pagesAutomation in Irrigation - A Review: ArticlePaulo Sérgio RodriguesNo ratings yet

- Analyzing Dynamic Spray Fan Pattern (SFP) Coverage With High Speed Imaging To Simulate Ground Coverage of A Pulse Width Modulated SprayerDocument13 pagesAnalyzing Dynamic Spray Fan Pattern (SFP) Coverage With High Speed Imaging To Simulate Ground Coverage of A Pulse Width Modulated Sprayerrobert.cesarNo ratings yet

- Precision Orchard Sprayer Based On Automatically Infrared Target Detecting and Electrostatic Spraying TechniquesDocument6 pagesPrecision Orchard Sprayer Based On Automatically Infrared Target Detecting and Electrostatic Spraying TechniquesRaghav JiNo ratings yet

- Diaconu Andreea enDocument4 pagesDiaconu Andreea enAndreea DiaconuNo ratings yet

- (Template) Sprinkler and Micro Irrigation Systems Manual - PROOF 21072020Document84 pages(Template) Sprinkler and Micro Irrigation Systems Manual - PROOF 21072020Lakum Ravi N.No ratings yet

- Rajab Omary, Et AlDocument16 pagesRajab Omary, Et AlAvijanNo ratings yet

- Classification of Wear State For A Positive Displacement Pump Using Deep Machine LearningDocument19 pagesClassification of Wear State For A Positive Displacement Pump Using Deep Machine LearningScience DirectNo ratings yet

- AE027Document3 pagesAE027faithtolentino0626No ratings yet

- Applied SciencesDocument22 pagesApplied SciencesGEORGE MYLONASNo ratings yet

- XCM 173Document17 pagesXCM 173api-26532647No ratings yet

- Fault DetectionDocument15 pagesFault DetectionTrian TeeNo ratings yet

- Design and Implementation of Solar Powered AutomatDocument9 pagesDesign and Implementation of Solar Powered Automatjefferyson06No ratings yet

- ACFrOgCABTRADw6S0x3TiETVxdMHOeul YDPOa85w-JuC5f9KDl hiMC05pWShhmFJ-RwTlMdUGpO20XscXIvbov8NIyX3rKgeNeYNdKOmlEuWou6oKv3IWfEzuyeVvXyrcPy9Fe98E53DX2X6unDocument90 pagesACFrOgCABTRADw6S0x3TiETVxdMHOeul YDPOa85w-JuC5f9KDl hiMC05pWShhmFJ-RwTlMdUGpO20XscXIvbov8NIyX3rKgeNeYNdKOmlEuWou6oKv3IWfEzuyeVvXyrcPy9Fe98E53DX2X6unAmos MutoroNo ratings yet

- Technical Publication: Improving Wastewater Treatment With Air Flow InstrumentationDocument4 pagesTechnical Publication: Improving Wastewater Treatment With Air Flow InstrumentationMariana PorrasNo ratings yet

- Definition:: Why To Use Flow Equalization TanksDocument4 pagesDefinition:: Why To Use Flow Equalization TanksJonah BasaNo ratings yet

- Chemical Induction UnitDocument6 pagesChemical Induction UnithanaNo ratings yet

- SECTION 9.20 Portable Transfer of Hazardous Liquids: P. A. NolteDocument5 pagesSECTION 9.20 Portable Transfer of Hazardous Liquids: P. A. NolteVladimir Balzary LapcevicNo ratings yet

- 577300-0 Irrigmgmtguide Chapter 06 With TitlepageDocument76 pages577300-0 Irrigmgmtguide Chapter 06 With TitlepageShephard KadairaNo ratings yet

- Field Evaluation of Emission Uniformity For Trickle Irrigation Systems (Case Study: Sattarkhan Irrigation Network)Document4 pagesField Evaluation of Emission Uniformity For Trickle Irrigation Systems (Case Study: Sattarkhan Irrigation Network)TI Journals PublishingNo ratings yet

- A F C A A: Utomatic LOW Ontrol FOR Erial PplicationsDocument8 pagesA F C A A: Utomatic LOW Ontrol FOR Erial PplicationsJavier EncaladaNo ratings yet

- Injector Equipment SelectionDocument11 pagesInjector Equipment SelectionTS WongNo ratings yet

- Processes: Hydrodynamics and Mass Transfer Analysis in Bioflow Bioreactor SystemsDocument21 pagesProcesses: Hydrodynamics and Mass Transfer Analysis in Bioflow Bioreactor SystemsSomesh MishraNo ratings yet

- May - June 2005 Irrigation Newsletter, Kings River Conservation District NewsletterDocument2 pagesMay - June 2005 Irrigation Newsletter, Kings River Conservation District NewsletterKings River Conservation DistrictNo ratings yet

- Nom 127 Ssai Calidad AguaDocument8 pagesNom 127 Ssai Calidad AguaGerad ValdezNo ratings yet

- Florida BLDG Code Appendix FDocument17 pagesFlorida BLDG Code Appendix FSarah GlennNo ratings yet

- Aplikasi Mikrokontroler Arduino Pada Sistem Irigasi Tetes UNTUK TANAMAN SAWI (Brassica Juncea)Document11 pagesAplikasi Mikrokontroler Arduino Pada Sistem Irigasi Tetes UNTUK TANAMAN SAWI (Brassica Juncea)Jackal LitNo ratings yet

- MF 2877Document2 pagesMF 2877siddhasivaNo ratings yet

- M4 Flow Equalization UODocument17 pagesM4 Flow Equalization UObella nur ryzky pertiwiNo ratings yet

- 1 Article Azojete Vol 4 1-15Document15 pages1 Article Azojete Vol 4 1-15Oyeniyi Samuel KehindeNo ratings yet

- Ijert Ijert: Aerobic Sequencing Batch Reactor For Wastewater Treatment: A ReviewDocument17 pagesIjert Ijert: Aerobic Sequencing Batch Reactor For Wastewater Treatment: A ReviewAmanda JacksonNo ratings yet

- Icees 2019 8719237Document4 pagesIcees 2019 8719237Sama AshleighNo ratings yet

- Flow ChemistryDocument3 pagesFlow ChemistryPranali GawliNo ratings yet

- Machinery EquipmentDocument19 pagesMachinery EquipmentDrew NeroNo ratings yet

- Hort Technology 251 Arduino Irrigation ControllerDocument10 pagesHort Technology 251 Arduino Irrigation Controlleradbo abdoNo ratings yet

- 116CH0120 RP ReportDocument12 pages116CH0120 RP ReportAscender ZeusNo ratings yet

- Anticipating Challenges With In-Building Disinfection For Control of Opportunistic PathogensDocument10 pagesAnticipating Challenges With In-Building Disinfection For Control of Opportunistic PathogensJackie ChanNo ratings yet

- Icst 1019Document3 pagesIcst 1019International Jpurnal Of Technical Research And ApplicationsNo ratings yet

- OWM NJ Aerobic Guidance 230928 155524Document15 pagesOWM NJ Aerobic Guidance 230928 155524Sadiya ParvinNo ratings yet

- Mobile Spray PumpDocument4 pagesMobile Spray PumpGaneshNo ratings yet

- Chemical Engineering Journal: Feilin Hao, Mingwei ShenDocument9 pagesChemical Engineering Journal: Feilin Hao, Mingwei ShenasadNo ratings yet

- Irrigation ReportDocument11 pagesIrrigation ReportHazael BoodhramNo ratings yet

- Effect of Sludge Recirculation On Removal of Antibiotics in Two-Stage Membrane Bioreactor (MBR) Treating Livestock WastewaterDocument13 pagesEffect of Sludge Recirculation On Removal of Antibiotics in Two-Stage Membrane Bioreactor (MBR) Treating Livestock WastewaterAlexandru-Adrian BrateiNo ratings yet

- Injection of Chemicals Into Irrigation Systems: Rates, Volumes, and Injection PeriodsDocument7 pagesInjection of Chemicals Into Irrigation Systems: Rates, Volumes, and Injection PeriodsaffanNo ratings yet

- Irjet V9i6485Document5 pagesIrjet V9i6485kzakari.1231No ratings yet

- The Fabrication of A Semi-Automated Fogponics System For Herb Growing in Urban Indoor GardeningDocument19 pagesThe Fabrication of A Semi-Automated Fogponics System For Herb Growing in Urban Indoor GardeningTyrone Adan FigueroaNo ratings yet

- Aeroponic Monitoring System For An Iot Based NFT Farm Using Web TechnologyDocument4 pagesAeroponic Monitoring System For An Iot Based NFT Farm Using Web Technologyfaqih devNo ratings yet

- Automated Hydraulic Pesticide SprayerDocument5 pagesAutomated Hydraulic Pesticide SprayerPatrick GarciaNo ratings yet

- Unit-4 AMRDocument27 pagesUnit-4 AMR1011NEERAJA SNo ratings yet

- Yodanis 2000Document24 pagesYodanis 2000MoqaNo ratings yet

- Schoch 2000Document22 pagesSchoch 2000MoqaNo ratings yet

- Sosa 2000Document14 pagesSosa 2000MoqaNo ratings yet

- Wagner Pacifici2001Document13 pagesWagner Pacifici2001MoqaNo ratings yet

- Vinitzky Seroussi2000Document19 pagesVinitzky Seroussi2000MoqaNo ratings yet

- Stainton 2000Document21 pagesStainton 2000MoqaNo ratings yet

- Walton 2000Document20 pagesWalton 2000MoqaNo ratings yet

- Sidorenko 2007Document6 pagesSidorenko 2007MoqaNo ratings yet

- Pollock 2000Document24 pagesPollock 2000MoqaNo ratings yet

- Stephanou 2000Document30 pagesStephanou 2000MoqaNo ratings yet

- Taylor 2000Document36 pagesTaylor 2000MoqaNo ratings yet

- Shekun 2007Document4 pagesShekun 2007MoqaNo ratings yet

- Vallentyne 2000Document30 pagesVallentyne 2000MoqaNo ratings yet

- Obtaining Nanostructural Materials by The Electroacoustic Spraying MethodDocument5 pagesObtaining Nanostructural Materials by The Electroacoustic Spraying MethodMoqaNo ratings yet

- Kabaldin 2008Document9 pagesKabaldin 2008MoqaNo ratings yet

- Kabaldin 2007Document6 pagesKabaldin 2007MoqaNo ratings yet

- Kabaldin 2007Document8 pagesKabaldin 2007MoqaNo ratings yet

- Calculating The Accuracy of The Turning of Smooth Shafts: V. G. Mal'tsevDocument2 pagesCalculating The Accuracy of The Turning of Smooth Shafts: V. G. Mal'tsevMoqaNo ratings yet

- Biryukov 2007Document5 pagesBiryukov 2007MoqaNo ratings yet

- Determining The Dynamic Parameters of The Structures of The Vibration Machines On An Elastic FoundationDocument4 pagesDetermining The Dynamic Parameters of The Structures of The Vibration Machines On An Elastic FoundationMoqaNo ratings yet

- System For Lubricating The Machine-Tool Spindle Assembly Rolling Bearings With Minimal Lubricant ConsumptionDocument11 pagesSystem For Lubricating The Machine-Tool Spindle Assembly Rolling Bearings With Minimal Lubricant ConsumptionMoqaNo ratings yet

- Kabaldin 2007Document5 pagesKabaldin 2007MoqaNo ratings yet

- Pneumatic Manipulators For Interrupting Converter-Slag Flow: V. V. TochilkinDocument3 pagesPneumatic Manipulators For Interrupting Converter-Slag Flow: V. V. TochilkinMoqaNo ratings yet

- Water-Cooled Cutter: V. I. Kotel'nikov, Sh. R. Abdullaev, and A. A. LarinDocument2 pagesWater-Cooled Cutter: V. I. Kotel'nikov, Sh. R. Abdullaev, and A. A. LarinMoqaNo ratings yet

- Disk Tool For Machining A Conical Screw Surface: N. A. Chemborisov, V. B. Stupko, and D. N. LarionovDocument3 pagesDisk Tool For Machining A Conical Screw Surface: N. A. Chemborisov, V. B. Stupko, and D. N. LarionovMoqaNo ratings yet

- Diamond Planing of Coated Cutting Tools: Ya. I. Barats and D. A. TikhonovDocument2 pagesDiamond Planing of Coated Cutting Tools: Ya. I. Barats and D. A. TikhonovMoqaNo ratings yet

- Faster and Better Broaching of Faceted Holes: Yu. N. SeleznevDocument2 pagesFaster and Better Broaching of Faceted Holes: Yu. N. SeleznevMoqaNo ratings yet

- Vibratory Contact Transducer For The Metric Module of Multipurpose Machine ToolsDocument3 pagesVibratory Contact Transducer For The Metric Module of Multipurpose Machine ToolsMoqaNo ratings yet

- General Principles of Comprehensive Technical System Reliability EvaluationDocument4 pagesGeneral Principles of Comprehensive Technical System Reliability EvaluationMoqaNo ratings yet

- Evaluating Machine-Part Loads by Eddy-Current Monitoring of Metallic CoatingsDocument2 pagesEvaluating Machine-Part Loads by Eddy-Current Monitoring of Metallic CoatingsMoqaNo ratings yet

- OO0619Document16 pagesOO0619Anonymous 9eadjPSJNgNo ratings yet

- Robinson Crusoe: Zooloretto The Dice GameDocument5 pagesRobinson Crusoe: Zooloretto The Dice GameMuneeb ArshadNo ratings yet

- The Crop Coefficient (K) Values of The Major Crops Grown Under Mediterranean ClimateDocument28 pagesThe Crop Coefficient (K) Values of The Major Crops Grown Under Mediterranean ClimateMahmoud A. SalemNo ratings yet

- Bio-Control Agents - Bioinsecticides and BioherbicidesDocument7 pagesBio-Control Agents - Bioinsecticides and BioherbicidesNurulAtikahAbdulAzizNo ratings yet

- Local CCET GuideDocument38 pagesLocal CCET GuideMPDC ValenciaNo ratings yet

- Exercises On Adverb ClausesDocument2 pagesExercises On Adverb ClausesMaldin SiskaNo ratings yet

- Pig's DNA From Wisdom PanelDocument11 pagesPig's DNA From Wisdom PanelNicholas FryeNo ratings yet

- Technology and Livelihood Education: (Agriculture and Fishery Arts)Document15 pagesTechnology and Livelihood Education: (Agriculture and Fishery Arts)Jessa PalaypayonNo ratings yet

- Analysis of The Great Lakes / St. Lawrence LowlandsDocument10 pagesAnalysis of The Great Lakes / St. Lawrence LowlandsfredrickNo ratings yet

- Discuss Man's Transition in Diets As This Country Has Progressed From From An Agricultural Economy To A Technological EconomyDocument2 pagesDiscuss Man's Transition in Diets As This Country Has Progressed From From An Agricultural Economy To A Technological Economyselenita2909No ratings yet

- IADDA IPCREATES PROJECT FOR EGONGOT ICCsIPs IN MARIA AURORA AURORA - FinalDocument10 pagesIADDA IPCREATES PROJECT FOR EGONGOT ICCsIPs IN MARIA AURORA AURORA - FinalNCIP AuroraNo ratings yet

- Ynspire Magazin-1-23 ENDocument48 pagesYnspire Magazin-1-23 ENmarconchinNo ratings yet

- Bengali Culinary Culture Till 12th CenturyDocument2 pagesBengali Culinary Culture Till 12th CenturySamir GanguliNo ratings yet

- List of Univ Engg CollegesDocument1 pageList of Univ Engg Collegessekgar g chowdhary100% (2)

- Environmental Ethics Position PaperDocument7 pagesEnvironmental Ethics Position Paperapi-215650967No ratings yet

- BOQ td17Document16 pagesBOQ td17Nitin Suyan PanchalNo ratings yet

- Food and Agricultural Import Regulations and Standards - Narrative - Beijing - China - Peoples Republic of - 12!12!2013Document63 pagesFood and Agricultural Import Regulations and Standards - Narrative - Beijing - China - Peoples Republic of - 12!12!2013Nguyen Thanh TrungNo ratings yet

- A Battle Royal Sparked: Weekend Storms Take Heavy TollDocument28 pagesA Battle Royal Sparked: Weekend Storms Take Heavy TollKristy ElliottNo ratings yet

- Shade Trees Reduce Building Energy Use and CO Emissions From Power PlantsDocument8 pagesShade Trees Reduce Building Energy Use and CO Emissions From Power PlantsEndah YulitaNo ratings yet

- Types of Ecosystem: Presented By, Priyanka Chowksey DaimsrDocument29 pagesTypes of Ecosystem: Presented By, Priyanka Chowksey DaimsrMahbubul Islam KoushickNo ratings yet

- Gelatin Pig Skin MarketDocument7 pagesGelatin Pig Skin MarketRofiqSunaryantoNo ratings yet

- BonsaiDocument8 pagesBonsaiAllanNo ratings yet

- Group3 AetasDocument24 pagesGroup3 Aetasmauvitz.alfoughreNo ratings yet

- Animal ProductionDocument7 pagesAnimal Productionrovic montefalcoNo ratings yet