Professional Documents

Culture Documents

Automated Drawing Machine: International Journal of Research

Uploaded by

Abhijeet Narayanbhai VareOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Automated Drawing Machine: International Journal of Research

Uploaded by

Abhijeet Narayanbhai VareCopyright:

Available Formats

International Journal of Research e-ISSN: 2348-6848

p-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 05 Issue 07

March 2018

Automated Drawing Machine

Dr. M.Ashokrajkumar, Venkattaramanan.C, Vignesh.M , Vignesh.G , Vijay.M

ABSTRACT:

Our Project is to Design automated drawing automated drawing machine in universities

machine with using Arduino unoAT328P and laboratories, a cheap and less complex

design is an absolute need. The parts used

and CNC shield, it is capable to design

for the plotter in our project are easily

machine mechanical parts and 2d design. available at a very low price and spare parts

This Paper is help to fabrication of are also used. The construction is very

automated drawing Machine. In this simple and robust.

machine only G codes are used to command COMPONENTS USED:

or instructions. G codes are language, by • Aluminum frame

using this person Told computer control

• Arduino Uno 328 p

machine tool. The CNC machine is design

given 3d objects in 2d paper. We have also • Stepper motor

used automated drawing Machine for 3d • Servomotor

Printing.

ALUMINUM FRAME:

Keywords: CNC Shield, Arduino Board,

Arduino Drivers, G Codes

INTRODUCTION:

A Plotter is a special type of printer that uses

a pen to draw images on solid surfaces. In

CNC, microprocessor is used which is

capable of processing logical instructions Aluminium and its alloys are vital to

interfaced with a computer. The logical the aerospace industry and important

instructions are provided by using a in transportation and building industries,

computer in the form of code or text or such as building facades and window frame.

image which is then transformed into a The oxides and sulphates are the most useful

machine language by microprocessor to be compounds of aluminium. Despite its

executed by the machine. Aautomated prevalence in the environment, no known

drawing machine is a 3D controlled 2D form of uses aluminium salts metabolically,

plotting machines which uses a pen to draw but aluminium is well tolerated by plants

text or image on any given solid surface. It and animals.Because of these salts'

can be used for the purposes such as PCB abundance, the potential for a biological

Design, logo design, etc. This project is rolefor them is of continuing interest, and

based on automated drawing machine. With studies continue.

the increasing demand for the use of

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1637

International Journal of Research e-ISSN: 2348-6848

p-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 05 Issue 07

March 2018

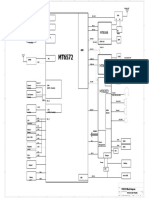

ARDUINO UNO 328P:

The Arduino Uno is a small microcontroller

board based on the ATmega328P which

offers control of stepper and servo motors

through motor drivers. The Arduino Uno

may dump with G codes manually or which

generated through Inscape software. The

controller converts G codes and send the

machine readable instructions to all the

components in the sketcher.

Stepper can be converted digital pulse in to a

movement of pen with respect to axis X, Y,

Z direction. A stepper motor is a brushless

motor that divides a full rotation into a

number of equal steps, the stepper motor is

known by its property to convert a number

of impulses into a defined increment in the

. shaft position. Each pulses move the shaft

through a fixed angle. We have used 3

SERVOMOTOR: stepper motors with lead screw. Motor

A servo motor shown in figure 4 is used for output will be in the form of rotation of lead

the movement of sketching pen in up and screw with respect to X, Y, Z Axis. Input

down inz direction. This will help the CNC current supplied is 12 volts through SMPS.

2D sketcher to point the pen in A4 sheet and

DESIGN PROCEDURE

withdrawingit from the sheet to stop

drawing. The basic idea for the design of mini CNC

machine can be understand from the work

which deals with the development of a

prototype CNC machine, controlled by a PC

interfaced with low cost embedded

microcontroller and LABVIEW. The

proposed mini CNC 2D sketcher needsthree

axes movements of a sketching unit which

comprises a sketching pen or pencil. These

movements in X and Y axis can be obtained

by two stepper motor for precise control

over sketching pen for building drawing.

The up and down movement of sketching

pen in Z axis direction can be controlled by

STEPPER MOTOR: a servo motor. While printing or drawing,

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1638

International Journal of Research e-ISSN: 2348-6848

p-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 05 Issue 07

March 2018

the proper synchronization of all the three • Then the controller outputs

axes through stepper motors and servo commands to motor and accessories

motor is most exigent task. These that can repetitively

movements can be achieved through the G And extremely accurately cut, design or

Code which can be programmed manually draw.

or generated through software like Inkscape

.The proposed mini CNC 2D sketcher has MINI CNC 2D SKETCHER:

the option of dumping the G Codes into the In the development of the proposed CNC 2D

microcontroller by any one method. An open sketcher shown in figure 7 is intended for all

source graphics editing software, Inkscape the basic functions of CNC machine like

can be used create or edit vector graphics automatic, precise, and consistent motion

such as simple sketch, rough line diagrams, control.The automatic sketch pen movement

logos and difficult paintings. This software for building drawing or sketch is obtained

converts the loaded image into G codes for by processing G code through the

the required 2D diagram in to Gerber file microcontroller.The three axes pen

which consist of required G code program to movements can be precisely.

be dumped into the microcontroller. The Automatically positioned along their lengths

other major advantage of using this software of travel by a servo motor and two stepper

is that the created rough sketch can be motors.The motor drivers are used to

further manipulated with due process the machine language obtained from

transformations, such as moving, rotating, Microcontroller and in turn run the motors

scaling and skewing as per the need of a in clockwise or anticlockwise directions so

customer who needs a building drawing. The as to achieve the desired pen movement.

outlook of a Inscape software. An A4 sheet is clamped or pasted using

cello tape at the edges of the proposed CNC

2D sketcher table. Then the program in the

form G code can be dumped manually or

through the generation from Inscape

software corresponds to the desired building

plan, elevation and other views. Once the G

code is dumped into the microcontroller

ATmega328P, it process and send the

instructions to respective components so as

to achieve the desired building drawing.

WORKING:

• Controlled by G-code.

• These are number values and co-

ordinates

• G-Code is generated by the computer

software

• Then G code is uploaded on the

Microcontroller of the CNC

machine.

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1639

International Journal of Research e-ISSN: 2348-6848

p-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 05 Issue 07

March 2018

stop and paused by click action on

computer. By using this we have make

Difficult and Complex Design in paper. This

is small machine which is easily

Transportable and Assembled everywhere

on Requirement of it. Bed Size of this

machine is 50X50mm. Stepper Motor will

be run on in this criteria of bed size. If we

have increase the size or length of lead

screw, it will be free to make big size of

design in paper. We have used G codes to

giving command. G-codes are language to

give the command to the machine to move

LIMITATION: right, left or up and down. On the successful

The machine runs in a slow pace and work of this machine we have some change

generates excess heat which causes the heat on it and make it commercial used and

sink to be heated quickly. A slight error may applying tools for cutting, grinding of soft

remain on the image file after it has been material etc.

plotted due to one side of the Y-axis fixed to

the moving mechanism and the other end is REFERENCE:

free to move. The Z-axis is not very rigid so

.[1] madekar, kajal j., et al. "automatic mini

it causes slight vibration.

cnc machine for pcb drawing and drilling."

FUTURE SCOPE: (2016). [2] linggarjati, jimmy, and

The pen of the machine can be replaced by a rindahedwig. "manually interchangeable

laser to make it work like a laser engraving heads of homemade computer numerical

or cutting machine. Engraving machine can control (cnc) machine." internetworking

be used on wood. The pen can also be indonesia journal 1.1 (2013). [3] m.r. wright,

replaced with a powerful drill so that it can d.e. platts, d.b. french, g. traicoff,

be used for both milling and drilling m.a.dupont, andg.a. head,“cnc control

purposes. The servo can be replaced with a systempatents,” us patent 545393, sep

stepper motor and the pen with a 3-D pen to 26,1995.

make it a 3-D printer which can print objects [4] torjus spilling “self-improving cnc

with dimensions. By extrapolation of the milling machine” university of oslo (2014)

axes, the working area of the machine can be [5] neje200mw mini diy laser engraving

extended keeping the algorithm unaltered. machine cnc laser printer

[6] Industrialsuppliesonline.net/craftsman-

cnc-router [7]

CONCLUSION: geocities.ws/industrialmarketplace/cnc-

In this paper we have used concept of low machines [8]

arduino.cc/en/Main/ArduinoBoardUno[9]

cost automated drawing machine, which is

en.wikipedia.org/wiki/ATmega328 [10] dual

easily control with computer and suddenly

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1640

International Journal of Research e-ISSN: 2348-6848

p-ISSN: 2348-795X

Available at https://edupediapublications.org/journals

Volume 05 Issue 07

March 2018

full-bridge driver. multiwatt15. ordering Interval in CNC Machines. International

numbers : l298n (multiwatt vert.) l298hn Journal of Mechanical Engineering and

[7] Sherring da Rocha Jr., P.A., Souza, Technology, 8(3), 2017, pp. 77–88.

R.D.S. and Emilia de Lima Tostes, M. [10] Mufaddal A. Saifee and Dr. Usha S.

Prototype CNC Mehta. Design and Implementation of

machine design, Journal of Energy and FPGA Based

Power Engineering, 6, 2012, pp. 1884– G Code Compatible CNC Lathe Controller.

1890. International Journal of Electronics and

[8] A. Sai Kumar, M. Ganesh and G Communication Engineering & Technology,

HimaBindu, Application of CNC Milling in 7(1), 2016, pp. 75-86

Manufacturing Turbine Blades. International [11] Anil Kumar, A., Sai Krishna, K., Sai

Journal of Civil Engineering and Reddy, R.B.G. and Shakti Prasad, V. CNC

Technology, 8(5), 2017, pp. 801–808. Machine

[9] M. Karthick, M. Sundarraj and T. Raja, for Drawing, B.Tech. Project Report, MLR

Design and Control of ATC for Shorter Institute of Technology, 2017.pp. 801–808.

Time

Available online: https://edupediapublications.org/journals/index.php/IJR/ P a g e | 1641

You might also like

- CNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopFrom EverandCNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopRating: 5 out of 5 stars5/5 (3)

- CNC Drilling Machine For Printed Circuit BoardDocument4 pagesCNC Drilling Machine For Printed Circuit BoardEditor IJTSRDNo ratings yet

- North - Data Mining For The Masses 2nd Edition - 2016Document312 pagesNorth - Data Mining For The Masses 2nd Edition - 2016ArtsulNo ratings yet

- Machine Report FinnalDocument6 pagesMachine Report FinnalRana FaisalNo ratings yet

- Procedure-Part-A - Structural Works - PDFDocument58 pagesProcedure-Part-A - Structural Works - PDFquiron2014No ratings yet

- Section 6 QuizDocument33 pagesSection 6 QuizImas Rohayati100% (2)

- Project Synopsis CNC Laser EngraverDocument11 pagesProject Synopsis CNC Laser EngraverNgangom Maximus100% (1)

- 2018 - Modern Design and Implementation of XY Plotter PDFDocument4 pages2018 - Modern Design and Implementation of XY Plotter PDFSachin ShindeNo ratings yet

- CNCDocument25 pagesCNCakashNo ratings yet

- BS 6349-2Document64 pagesBS 6349-2medianna100% (6)

- Multi-Purpose CNC Ink Plotter Using ArduinoDocument8 pagesMulti-Purpose CNC Ink Plotter Using ArduinoIJRASETPublicationsNo ratings yet

- Mini CNC Plotter and Laser EngraverDocument3 pagesMini CNC Plotter and Laser EngraverEditor IJTSRDNo ratings yet

- Full PPT CNC Plotter MCDocument33 pagesFull PPT CNC Plotter MCDishant PatelNo ratings yet

- Design and Development of CNC Writing and Drawing MachineDocument6 pagesDesign and Development of CNC Writing and Drawing MachineVIVA-TECH IJRINo ratings yet

- Pen PlotterDocument24 pagesPen PlotterMridul SethiNo ratings yet

- CNC Drilling Machine For Printed Circuit Board: Need To Cite This Paper? Want More Papers Like This?Document5 pagesCNC Drilling Machine For Printed Circuit Board: Need To Cite This Paper? Want More Papers Like This?Fauzan Ammar PutraNo ratings yet

- Major Project ReferenceDocument5 pagesMajor Project Referenceshiva sai donthulaNo ratings yet

- CNC Plotter MachineDocument34 pagesCNC Plotter MachineDishant PatelNo ratings yet

- Mini CNC Plotter Using Spare Parts IJERTCONV5IS23019Document5 pagesMini CNC Plotter Using Spare Parts IJERTCONV5IS23019Ali Mustafa AllafiNo ratings yet

- Arduino Based Cost Effective CNC Plotter MachineDocument4 pagesArduino Based Cost Effective CNC Plotter Machinegamezeunice49No ratings yet

- CNC PlotterDocument3 pagesCNC PlottervipulNo ratings yet

- 1.1 Objectives: Mini CNC PlotterDocument42 pages1.1 Objectives: Mini CNC Plotteryashwanth M V100% (1)

- 45 1514966110 - 03-01-2018 PDFDocument3 pages45 1514966110 - 03-01-2018 PDFEditor IJRITCCNo ratings yet

- Design and Implementation of Low-Cost 2D Plotter Computer Numeric Control (CNC) MachineDocument3 pagesDesign and Implementation of Low-Cost 2D Plotter Computer Numeric Control (CNC) Machinehasan alsarrafNo ratings yet

- Design and Fabrication of Polar Cnc-2D-PrinterDocument25 pagesDesign and Fabrication of Polar Cnc-2D-PrinterLovely AtchuthNo ratings yet

- 9 May2019Document4 pages9 May2019Jay Prakash Narayan VermaNo ratings yet

- Principales Teorias Comercio InternaconalDocument9 pagesPrincipales Teorias Comercio InternaconalTito HerreraNo ratings yet

- Writing CNC Machine 15ME55PDocument16 pagesWriting CNC Machine 15ME55Parun mNo ratings yet

- Mini CNC Plotter: Rathod Harsh P. (156020311042) Chauhan Umang R. (156020311019)Document24 pagesMini CNC Plotter: Rathod Harsh P. (156020311042) Chauhan Umang R. (156020311019)Harsh RathodNo ratings yet

- CNC Based Pen Using Arduino: Mayur U. Ladhe and Dr. D. V. RojatkarDocument3 pagesCNC Based Pen Using Arduino: Mayur U. Ladhe and Dr. D. V. Rojatkarandri enggopNo ratings yet

- Automatic PCB Track Design MachineDocument5 pagesAutomatic PCB Track Design MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 2d CNC Pen Plotter Machine FINAL PDFDocument49 pages2d CNC Pen Plotter Machine FINAL PDFVrajesh ShahNo ratings yet

- Design and Fabrication of 3-Axis CNC Milling Machine: AbstractDocument5 pagesDesign and Fabrication of 3-Axis CNC Milling Machine: AbstractMohammedsaleemNo ratings yet

- G-Code Controlled 2D Robotic Plotter: December 2017Document4 pagesG-Code Controlled 2D Robotic Plotter: December 2017hasan alsarrafNo ratings yet

- Edited PPT SahuDocument13 pagesEdited PPT SahuNites PorwalNo ratings yet

- Documentation CNC Drawing MachineDocument16 pagesDocumentation CNC Drawing MachineWilson Walas LlanqmNo ratings yet

- 0904 1083Document4 pages0904 1083andri enggopNo ratings yet

- Document 5Document4 pagesDocument 5ismail balaNo ratings yet

- 3D Printed Mini CNC Machine: Introduction! Introduction!Document7 pages3D Printed Mini CNC Machine: Introduction! Introduction!Santiago Luis GomezNo ratings yet

- Chapter 1 Introduction 1 1 IntroductionDocument34 pagesChapter 1 Introduction 1 1 IntroductionBeet LalNo ratings yet

- Fabrication of Three Axis CNC Milling MachineDocument4 pagesFabrication of Three Axis CNC Milling MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sarkar 2020 IOP Conf. Ser. Mater. Sci. Eng. 810 012066Document10 pagesSarkar 2020 IOP Conf. Ser. Mater. Sci. Eng. 810 012066Fahru ZainiNo ratings yet

- CNC PlotterDocument12 pagesCNC PlotterYussuf SherifNo ratings yet

- 3 Axis Drawing Machine PDFDocument5 pages3 Axis Drawing Machine PDFDhanar Tri AtmajaNo ratings yet

- CNC by SourabhDocument7 pagesCNC by SourabhsaurabhNo ratings yet

- Drawing Robot: Keyur Jain, Akash Nair, Prof. Shikha SinghDocument5 pagesDrawing Robot: Keyur Jain, Akash Nair, Prof. Shikha Singhhasan alsarrafNo ratings yet

- Automatic Mini CNC Plotter MachineDocument3 pagesAutomatic Mini CNC Plotter MachineVinayaga ProjectinstituteNo ratings yet

- A Project Report On CNC Machine: ComponentsDocument2 pagesA Project Report On CNC Machine: ComponentsksiojiohyuiNo ratings yet

- Mini Project (Synopsis)Document23 pagesMini Project (Synopsis)Akshar MishraNo ratings yet

- CNCMachine Based Laser Engraver With Arduino UNODocument10 pagesCNCMachine Based Laser Engraver With Arduino UNOSteve JobNo ratings yet

- 102 Laser Engraving MachineDocument15 pages102 Laser Engraving MachineChaitanya ghewareNo ratings yet

- Research Paper On SCARA DRAW-BOTDocument5 pagesResearch Paper On SCARA DRAW-BOTAshok GaikwadNo ratings yet

- A Real Time Novel Technique For Controlling CNC SystemDocument9 pagesA Real Time Novel Technique For Controlling CNC SystemakashlogicNo ratings yet

- Prototipe Mesin CNC 2D Berbasis Arduino UnoDocument10 pagesPrototipe Mesin CNC 2D Berbasis Arduino Unoandri enggopNo ratings yet

- Prev Q & A Cadcam Unit IDocument13 pagesPrev Q & A Cadcam Unit IJyothi GadiNo ratings yet

- Iot Based Smart 3D PrinterDocument11 pagesIot Based Smart 3D PrinterAbrar Ahmed100% (1)

- Automatic Mini CNC Machine For PCB Drawing and DrillingDocument5 pagesAutomatic Mini CNC Machine For PCB Drawing and DrillingSaifulla ShariffNo ratings yet

- Arduino Controlled CNC Printing Circuit MachineDocument7 pagesArduino Controlled CNC Printing Circuit MachineEditor IJTSRDNo ratings yet

- Ijser: Arduino Controlled Automatic Paper Stamping MachineDocument3 pagesIjser: Arduino Controlled Automatic Paper Stamping MachineStefan SmarandacheNo ratings yet

- Fifth Annual Electrical Engineering ExhibitionDocument6 pagesFifth Annual Electrical Engineering Exhibitionshafee001No ratings yet

- Ijramt V4 I2 17Document5 pagesIjramt V4 I2 17naeemudheenm45No ratings yet

- Operating CNC and Laser Machine Everywhere Using IoTDocument5 pagesOperating CNC and Laser Machine Everywhere Using IoTEditor IJTSRDNo ratings yet

- Stepper Motor Set UpDocument3 pagesStepper Motor Set UpChockalingam ʀᴏʙᴏᴛɪᴄsNo ratings yet

- User Manual - Goal Setting - FY2022-23 - Employee's Guide (002) - CompressedDocument19 pagesUser Manual - Goal Setting - FY2022-23 - Employee's Guide (002) - CompressedAbhijeet Narayanbhai VareNo ratings yet

- Operation and Instruction Manual: 7. Technical Characteristics of The MeterDocument4 pagesOperation and Instruction Manual: 7. Technical Characteristics of The MeterAbhijeet Narayanbhai VareNo ratings yet

- Covid Made People Realise You Need Your Own House - Gautam Singhania, CMD Raymond 2022-06-10 15 - 25 - 13Document5 pagesCovid Made People Realise You Need Your Own House - Gautam Singhania, CMD Raymond 2022-06-10 15 - 25 - 13Abhijeet Narayanbhai VareNo ratings yet

- Wool Processing: Fibre To Fabric: DR Barry HarrowfieldDocument18 pagesWool Processing: Fibre To Fabric: DR Barry HarrowfieldAbhijeet Narayanbhai VareNo ratings yet

- A Primer On Power Factor CorrectionDocument8 pagesA Primer On Power Factor CorrectionRAMESHRMGNo ratings yet

- Users GuideDocument220 pagesUsers GuideRicardo PequenoNo ratings yet

- Aus Gov JobsDocument541 pagesAus Gov JobsdodosawNo ratings yet

- M - Meriva Movil CEIBA II 2.3.0.0Document91 pagesM - Meriva Movil CEIBA II 2.3.0.0Jorge0195No ratings yet

- Debug 1214Document6 pagesDebug 1214hakim_chem14No ratings yet

- E1c P6722-02 - SCHDocument13 pagesE1c P6722-02 - SCHRiza VirsadaNo ratings yet

- Com - Upgadata.up7723 LogcatDocument4 pagesCom - Upgadata.up7723 Logcatxiaowangww0No ratings yet

- 07smspa cmENaDocument88 pages07smspa cmENamaheshNo ratings yet

- Baan Query Tool 2.7: User Guide - Baan LNDocument28 pagesBaan Query Tool 2.7: User Guide - Baan LNmoughabatNo ratings yet

- Mototrbo Xir P3688 Portable Radio: You'Re Simply More EfficientDocument4 pagesMototrbo Xir P3688 Portable Radio: You'Re Simply More EfficientIndra GunawanNo ratings yet

- I. Basic of Javascript Q1. Introduction To JAVASCRIPT?Document58 pagesI. Basic of Javascript Q1. Introduction To JAVASCRIPT?Prashant Sharma100% (1)

- Class XII Boolean Algebra: + B) .C. (A+B) (X' +Z) + ( (Y' +Z) - (X' +y) ) ' 1Document3 pagesClass XII Boolean Algebra: + B) .C. (A+B) (X' +Z) + ( (Y' +Z) - (X' +y) ) ' 1Srijan JaiswalNo ratings yet

- Limesurvey Manual For Instructors EDocument24 pagesLimesurvey Manual For Instructors EramiusNo ratings yet

- Sas 21Document2 pagesSas 21Sistine Rose LabajoNo ratings yet

- Aveva System Platform,: Formerly WonderwareDocument6 pagesAveva System Platform,: Formerly WonderwareArturNo ratings yet

- Spectrum and Signal Analys - Pulsed RF (Agilent)Document29 pagesSpectrum and Signal Analys - Pulsed RF (Agilent)Wesley GeorgeNo ratings yet

- M750 Service ManualDocument78 pagesM750 Service ManualcciprainNo ratings yet

- QRCP 2018 Data SheetDocument2 pagesQRCP 2018 Data SheetbeimanalfredoNo ratings yet

- Net - How To Connect Access Database in C# - Stack OverflowDocument4 pagesNet - How To Connect Access Database in C# - Stack OverflowSebastianNo ratings yet

- COMP4660-8420 Assignment2Document3 pagesCOMP4660-8420 Assignment2390942959No ratings yet

- Machine Drawing Problem SheetDocument1 pageMachine Drawing Problem SheetDeepak Gupta VlogsNo ratings yet

- (QC) 169+8 - Jordan 4 Oreo - WTG - PandaBuy RrepbudgetsneakersDocument1 page(QC) 169+8 - Jordan 4 Oreo - WTG - PandaBuy RrepbudgetsneakersReflexxxNo ratings yet

- Go TS7909Document7 pagesGo TS7909Pakalapati Naveen ChowdaryNo ratings yet

- IBRA Full Membership Form Inscribable - 01-2020Document2 pagesIBRA Full Membership Form Inscribable - 01-2020Vijay KumarNo ratings yet

- Berhanemeskel Reda PDF Anti Communism Far Left PoliticsDocument1 pageBerhanemeskel Reda PDF Anti Communism Far Left PoliticsAlula AbrahaNo ratings yet

- DxdiagDocument37 pagesDxdiagMarcoias MarcaasNo ratings yet