Professional Documents

Culture Documents

1.1 The Benefits of Proper Air Pressure: Department of Automobile Engineering, SIT, Mangaluru, Valachil

Uploaded by

jovin jovin manojOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.1 The Benefits of Proper Air Pressure: Department of Automobile Engineering, SIT, Mangaluru, Valachil

Uploaded by

jovin jovin manojCopyright:

Available Formats

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

CHAPTER 1

INTRODUCTION

Tires are meticulously engineered and constructed to diver thousands of miles of reliable

service. However, for optimal benefit, they must be properly maintained with proper air

pressure, minimal wear, and so on. Proper Inflation Pressure is the most critical component in

tires upkeep.

• Correct vehicle loading

• Correct tire wear.

• Routine inspection

• Safe Driving Practices

• The state of the vehicle.

1.1 The Benefits of Proper Air Pressure

The optimal tire performance by using the proper air pressure. This means your tires will last

longer, save you money on gas, and help you avoid accidents. On your particular model car or

light truck, the "correct amount" of air is the pressure prescribed by the vehicle manufacturer,

which may be different on the front than the back tires. The tire placard (or sticker) mounted

to the vehicle door edge, door post, glove box door, or fuel door displays the correct air

pressure. If your vehicle lacks a placard, consult the owner's manual or the vehicle maker, tire

manufacturer, or your local dealer. For proper inflation, visit a local tire dealer. The maximum

vehicle load, cold tire air pressures, and tire size suggested by the vehicle manufacturer are all

listed on the tire placard. The consequences of not properly maintaining your tires might be

disastrous. most tire manufactures either provide a handbook or mould a safety warning

straight into the sidewall of the tire. This page displays a typical warning. As you can see, it

warns that tyre failure due to underinflation or overloading might result in catastrophic harm.

For correct inflation and loading, motorists is should refer to the vehicle owner's manual or

the tyre placard in the vehicle. Only specially trained individuals are permitted. tyres should

be mounted or demounted Improper or reckless mounting practises might cause a tyre and

wheel assembly to explode. Before mounting tyres, individuals must have the proper

equipment, training, and knowledge. When seating the beads, never exceed 40 psi. When

installing a tyre on a rim, always use a restraining device is and keep a safe distance from the

tire when inflating it. Remember that mounting and dismounting tyres and wheels should only

be done by trained specialists who are aware of the risks and have the necessary tools and

equipment. According to a study approximately 80% of the road are driven with one and more

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

tyre under inflated. Tyre losses air during normal driving (especially after hitting pot holes or

curbs) and seasonal changes in temperature.

Fig 1.1 Different tire inflated conditions

The vehicle can also lose one or two psi each month in winter and even more in the summer

and you can’t feel if the they are properly inflated just by looking at them. This is system

which is installed on the vehicle that enables the operator to adjust the inflation pressure of

individual tire of the vehicle.

This system has three general goals:

a) To Detect: If the air pressure in tyre has dropped (continuously check the air pressure in

each tyre)

b) To Notify: If there is any dropped in the air pressure in any tyre

c) To Inflate\Deflater: In case of over pressure or under pressure the tyre pressure is

maintained inflate the tyre to the required level if there is a drop in the tyre pressure and there

has to be an air supply as well as check wall that opens only when needed. It consists of

compressor which supplies air and air tank is used to stored air at constant pressure. This

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

pressurize air can be filled into tyres through flexible ducting with the help of rotary bearing.

The pressure condition is achieved by pressure gauges. The mode of transport in one of the

most important crieterion these days. The vehicle safety is thus essential. Accident is also

increasing at a quick pace. There are several factors which causes these accidents. The

improper inflation of tyres is one among them. Tyres lose air through normal driving

(especially after hitting pot holes or curbs). permeation and seasonal changes in temperature.

when tyres are under inflated the thread wear more quickly. under inflated tyres get damaged

quickly due to overheating as compared to properly inflated tyres The under inflation also

cause a small depreciation in the mileage as well. Above all the vehicle running with under

inflated tyres can cause accidents. Monitoring systems in such systems helps in monitoring

the tyre pressure constantly. The system which contains sensors feed the information to a

display panel which the driver can operate manually. The electronic unit control all the

information. The source taken from the vehicles of air is air braking system or from the

pneumatic systems. Thus, it helps in re-inflation of the tyres to proper pressure conditions

Under-inflated tyres increase rolling resistance, which can not only reduce fuel economy but

can also wear out tyres and reduce vehicle safety through poor handling Maintaining correct

tyre pressures and monitoring for uneven tyre wear (which can be caused by poor wheel

alignment) can help to ensure optimum vehicle performance. Central tire inflation (CT)

systems offer one solution to managing tire pressure, by automatically maintaining tire

pressures within a pre-determined range. commonly used in off-road vehicle applications CTI

systems are primarily installed for their safety benefit (e.g., reducing tyre blow-out) and

extending tire life.

1.2 Problem Identification

As we are aware that maintenance of correct tyre pressure is extremely important for the in

the

Enhancement of tire life. Due to drop in the pressure the tire goes underinflated and Reduces

fuel economy, quickest tire wear, not proper rolling, discomfort ride etc. So, to solve out all

these problems we make an automatic tire inflation system, which will Properly inflate tire

1.3 History

CTIS was first used in production on the American DUKW amphibious truck which was

introduced in 1942 The Czech heavy military 8x8 truck Tatra T813's central inflation and

deflation system was designed to maintain pressure even after multiple bullet punctures.

Military Tatra. trucks are equipped with CTIS as standard. From 1984, GM offered CTIS for

the Chevrolet Blazer and various pick-ups. Several trucks used by the US. military also have

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

CTIS (e.g., the HMMWV and its civilian counterpart, the Hummer H1). The feature is also

common in Soviet and Russian military trucks.

Fig 1.2 Tatra T813 prototype had CTIS already in 1960, it later

became standard for all Tatra military trucks

1.4 Design Objectives

The overall goal of our design project is to develop a system that will decrease tire wear

While improving fuel economy, performance and safety of a passenger vehicle through

Dynamically adjustable tire pressures. However, there are several key objectives that the

Team has targeted our design to meet, and these objectives include both design Characteristics

and business objectives.

1.5 Design Consideration

We used SOLIDWORKS software to design a three-dimensional model of the Frame. This

software allowed our team to visualize the design in 3-D space and reduce errors in

fabrication. The man criterion in Frame design was to achieve perfect balance between the

axle and frame, and compact dimension to achieve the required weight and torsional rigidity

criteria

Methodology

This project started with discussion with project guide about design. This discussion covering

project overview and throw out opinion that related about title and instruct to proposed a

certain design and concept before go up to next step. Then start to make and decide the best

idea about the title. Before that, literature review and research about title is the important point

to get the best idea. Then study and make a lot of investigation about conventional air filling

system This includes a study about concept of conventional air filling system, process to

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

fabricate, and material. These tasks have been done through study on the internet hooks, and

others information. After gather and collect all related information and obtain new idea and is

knowledge about the title, the project would continue with the design process. In this stage,

the knowledge. And idea should throw out in sketching process. After several design

sketched, the best design would be chosen among previous design so that we could carry on

designing process. Then the selected design would be transfer to engineering drawing using

CAD software in order to for analysis process. After that material preparation which is has

been confirm initially. Purpose of this process is to determine the suitable and follow the

product and design requirement. This process covering purchased material, measuring

material and cutting off based on requirement. Here, this process is important because the

material would determine whether our product in way to failure or otherwise. After all the

drawing and material preparation done the next process is a fabrication process. This process

based on dimension has been determined from drawing. During this process, all the

manufacturing process which is suitable could be used such as drilling process, thread using

lathe machine, welding process and cutting material using disc cutter. Analysis stage has been

implemented before fabrication stage. The evaluation is by considering the strength, portable,

durability, safety and others.

1.6 Organization of the Report

Chapter 1 INTRODUCTION presents the brief explanation about benefits of proper tire

pressure and basic information of tire pressure inflation

Chapter 2 LITERATURE REVIEW presents literature review for different types of tire

inflation system, it also includes defining the problem.

Chapter 3 OBJECTIVES AND METHODOLOGY illustrates the objectives and

methodology used for the project. It also contains theory and techniques about the system.

Chapter 4 DESIGN AND FABRICATION contains steps involved in the design of

experiments, selection of parameter and it also includes procedure used to fabricate the

system.

Chapter 5 RESULT AND DISCUSSION contains results and their explanation and

advantages, limitations and applications.

Chapter 6 CONCLUSION AND SCOPE FOR FUTURE WORK describes the conclusion

drawn from the result and also scope for future work.

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

CHAPTER-2

LITERATURE REVIEW

This Chapter gives the following studies made by some of authors in their research and gives

the history of the research

• RAM BANSAL, SHUBHAM SWAMI, ALIASGER KANCHWALA, MAZHAR

HUSSAIN [1], Research on ‘Automatic tire inflation system in dynamic condition’ is aimed

to establish a successful improvement overall fuel economy of vehicle along with the increase

of tire life and improved vehicle handling. The methodology of this project idea will work

based on placing a wireless pressure sensor fitted inside the wheel rim of each tire for sensing

the air pressure inside the tire continuously these sensors send signal continuously to the

TPMS (Tire Pressure Monitoring System) [2]. TPMS is presets the higher pressure and lower

pressure values. when under inflation occur in tire, the pressure sensors will send the signals

to TPMS and it will generate a buzzer sound which will give input to the ECU at the same

time. The ECU is programmed in such a manner of as soon as it will receive signal from

TPMS of either high or low pressure it will generate a current to actuate the compressor and

solenoid valve. An air compressed along with the air tank which will store the air at a preset

value of pressure in it. When ECU pass a signal to solenoid valve will allow to through air

tank via hosses. A rotary joint will keep between the knuckle and wheel hub to avoid tangling

of hosses in dynamic condition of wheels.

• LUKMAN MEDRIAVIN SILALAHI, MUDRIK ALAYDRUS, AGUS DENDI

ROCHENDI, MUHTHAR MUHTAR [3], Research on the paper ‘Design of Tire Pressure

Monitoring system using a Pressure Sensor Base’ is aimed for attaining stability,

maneuverability and fuel consumption of vehicle by giving an alert to the driver The

methodology of this project is a transmitter pressure sensor module will keep at the tire valve

and this sensor module will responsible for monitoring tire pressure. After that the pressure

in tire will send in to the receiver pressure sensor module through the Bluetooth system. The

transmission is carried out by the system is wireless, hence here using Bluetooth system. This

received data from the receiver pressure sensor module will process in microcontroller. The

processed data from the microcontroller will displayed on the LCD screen will inform the

user for this system needs the components like TPMS (Tire pressure monitoring system),

Bluetooth system, microcontroller system, transmitter pressure sensor module, receiver

pressure sensor module, etc. these pressure sensing modules will sense element of constant

area and respond to force applied will deflect the diaphragm inside the pressure transducer.

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

The deflection of the internal diaphragm is measured and converted into an electrical output.

These electrical signals transmit by Bluetooth system[4]

• A.V. WADMANE, P.S. PADURE [5], Review on ‘Automatic tire pressure controlling and

self-inflating system’ aimed that to maintain a mean pressure in a tire by controlling and self-

inflating by system for achieving satisfactory fuel efficiency, stability, increase life of the tires

and reduces the accidents In this paper, the methodology of the project is the system uses

portable compressor that will supply air to all four tires via hosses and rotary joint fixed

between the wheel spindle and wheel hub at each wheel [6]. The rotary joint effectively allow

air to be delivered to the required under inflated tire. This system acknowledges a essential

improvement in gas mileage, the wear reduction, and an increase in handling and tire

performance in diverse conditions. Components used in this system are compressor: which

pump air to the tank, air tank: air will store in certain pressure, pressure gauge: hints the

amount pressure in the tire and hosses supplies the air from tank to tire, rotary joint kept for

avoid tangling of hosses

. ALFONSO SILVA, JESÚS R. SÁNCHEZ, GERARDO E. GRANADOS, JUAN C.

TUDON-MARTINEZ, JORGE DE J. LOZOYA-SANTOS [7], Title of the paper is

Comparative Analysis in Indirect Tire pressure Monitoring systems in Vehicles. Aim of that

paper is Tire pressure Monitoring system are modules implemented in highly instrumented

vehicles to analyze t0he tire pressure condition at any time. When the vehicle is lack of this

instrumentation level, indirect TPMS can be used by considering the vehicle dynamics

behavior through conventional sensors. In this paper, two different approaches have been

studied to monitor indirectly the tire pressure condition in a vehicle. The first approach one is

based on the angular speeds of the four wheels by considering the vehicle load transfer, while

the second method is based on the vertical vehicle dynamics by using each corner as an

independent monitoring system. Both approaches have been compared in different simulation

scenarios in order to highlight their main advantages and drawbacks to consider for their

implement in a centralized control module, the data sent by the wireless pressure sensors is

analyzed, interpreted, and, if tire pressure is lower than a defined threshold, a warning signal

is transmitted directly to the car dashboard [8]

MARIUS TOMA, CRISTIAN, ANDREESCU, CORNELIA STAN [9], Title of the paper

is Influence of tire inflation pressure on the results of diagnosing brakes and suspension. Aim

of that paper is as noninvasive method of checking the status of a technical system, involves

the use of the so-called „diagnosis parameters”, which can be relatively easily measured,

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

without dismantling the respective system. A detailed diagnosis of a system of such

complexity will imply a large number of tests, some of which being of large amplitude. This

will lead to a low productivity of the diagnosis activity and to a long period of

immobilization of the vehicle which will affect also the productivity off the transport

activity. However, above all, it is important to retain that the braking system is one of the

most important systems of the vehicle in defining the level of the active safety.

Consequently, current regulations stipulate its inspection every 6 to 24 months, depending on

the vehicle type and its domain of utilization [10]. Considering all the above-mentioned

aspects, a global diagnosis, capable to correctly estimate the technical condition of the

braking system, is recommended. It should ensure a rapid and as simple as possible test of

which result should depend on the technical status of all the system components. The

parameters that meet all these requirements are the braking forces developed at each of the

vehicle wheels.

B. P. OMPRAKASH, T. SENTHIL KUMAR, “M.A.R.S - MECHANIZED AIR

REFILLING SYSTEM [11]: The aim of this study is to design and fabricate a system which

reduces human labor and time by eliminating the condition of driver to go to a gas station or

he has to attach a pump manually as physical connection of tyre and pump consumes more

time. Secondly, tire must not be under inflated nor over inflated i.e., pressure should be in

optimized level as under inflation causes wearing of tyre, consumption of more fuel and over

inflation causes explosion of tire [12]. It also gives better mileage and saves both money and

life. It also predicts about the puncture when there is continuous reduction of its set threshold

value. This system can be used in any type of tyre either tube or tubeless tires and the

permanent connection between valve and hoses which is only meant for tight connection

during rotation of tire; can be removed while changing a tyre by driver. The valve used with

tyre is one way valve so that inside air should not escape from it.

B. SZCZUCKA-LASOTA, T. WEGRZYN, B. LAZARZ, JA KAMINSKA [13], The aim

of study is to reducing the rubber waste of tire by TPMS, according to the regulation, tire

pressure in trucks should be checked and measured at least once every two weeks when the

tire is cold. As the literature data and the results of research conducted in various center

around the world. The article presents the newly developed remote monitoring of tire pressure

in the car fleet. The use of information from monitoring allows slowing down the tire wear

process. The article presents the results of tests of tire pressure and friction wear of the tread

made for the car fleet, the wear of monitored tires amounted to 7-13%, while the wear of

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

unmonitored tires reached even 70% [14]. The reduction of generated rubber waste will

amount to over 2000 tons less tire waste per year.

CHAPTER-3

OBJECTIVES AND METHODOLOGY

Objectives describe the precise result or outcome of the project where the person aims to

achieve within the stipulated time available and the resources

3.1 Problems derived from literature survey are as follows:

Underinflated tires overheat more quickly than properly inflated tires, which causes

damage to tires

Recurring underinflation of tire occurs even summer and winter seasons up to more

than 5 psi

Underinflation of tire causes unstable of vehicle and insecurity for the passengers,

leads to an accident

Recurring underinflation in tires reduces the tire’s lifespan, it would affect the

comfort of vehicle

3.2 Primary objective of the project

it is known that in an event of damaging of tire, it is a financial burden for the vehicle owner

and causes certain damages to vehicle. The main objective of this project is to increase the

lifespan of tires and also to reduce the damage to the vehicle. The secondary objectives are as

follows:

Maintains the required tire pressure: The function of the system is to maintain and

adjust the pressure in all the tires of the system according to varying loading and

driving conditions.

An automatic system: An automatic system further saves human energy and time in

filling the air in tires when they are in under inflated conditions.

Builds a low-cost system: the installation of such a system in vehicles is a low-cost

affair

Improves fuel efficiency and tire life: This system helps in less consumption of fuel

and also improves tire life by reducing chances of wear in tire

Safety for vehicle components: by attaining of proper tire pressure, system enhance

the safety for vehicle components like suspension, etc.

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

Improves driving comfort: system provides a good driving experience and travelling

comfort for the passengers

3.3 METHODOLOGY

Methodology gives the brief procedure of the project work or analysis of the known work.

the procedure is as shown

Literature survey

Defining

problem(s)

Design

Selection of material

Metal

cutting,

Fabrication

welding,

Forging,

Soldering

Experimental

testing

Result and

Discussion

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

CHAPTER-4

DESIGN AND FABRICATION

4.1 DESIGN CONCEPT

The use of computers in the creation, revision, analysis, and optimization of a design is

referred to as computer aided design, or CAD. Computers in engineering analysis such as

stress/strain, heat transfer, and flow analysis are referred to as CAE (Computer Aided

Engineering). CAD/CAE is claimed to have the greatest potential for significantly increasing

productivity since electricity. From concept to final product, CAD/CAE ensures quality.

Rather of bringing in quality control during the final inspection, it aids in the development of

a process that ensures quality throughout the product's life cycle. Prototypes can be

eliminated using CAD/CAE. Prototypes, on the other hand, were necessary to confirm rather

than anticipate performance and other qualities.

Fig 4.1 Two-dimensional CAD design of system

4.2 MODELING

A model is a representation of an object, a system, or an idea that differs from the entity

itself. Modeling is the process of creating a model, which is a representation of the

construction and operation of a certain system. A model is similar to the system it represents,

yet it is simpler. One of the goals of a model is to allow the analyst to predict the impact of

system modifications. On the one hand, a model should be a close representation of the real a

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

system, incorporating the majority of its key characteristics. However, it should not be so

complicated that understanding and experimenting with it is impossible. A good model is a

careful balance of realism and simplicity. Iteratively raising the complexity of a model is

recommended by simulation experts. Model validity is a key consideration in modelling.

Simulating the model under known input conditions and comparing model output to system

output are examples of model validation procedures. A mathematical model generated with

simulation software is, in general, a model meant for simulation research.

Software for modeling:

Solid works

Creo

CATIA

Unigraphics, etc.

4.3 CREO SOFTWARE

PTC's parametric, integrated 3D CAD/CAM/CAE solution, Creo Elements/Pro (previously

Pro/ENGINEER), is used by discrete manufacturers for mechanical engineering, design, and

manufacturing. Pro/ENGINEER was the first successful rule-based constraint (also known as

"parametric" or "variational") 3D CAD modelling system, developed by Dr. Samuel P.

Geisberg in the mid-1980s. The parametric modelling approach uses parameters, dimensions,

features, and relationships to record intended product behaviour and generate a recipe for

design automation and product development process optimization. Companies with a family-

based or platform-driven product strategy adopt this design approach. where a prescriptive

design strategy is critical to the design process' success by incorporating engineering

restrictions and relationships to swiftly optimize the design, or where the resulting geometry

is complicated or based on equations Creo Elements/Pro is a single, integrated, scalable

platform that combines design, analysis, and manufacturing capabilities. Solid modelling,

surfacing, rendering, data interoperability, routed systems design, simulation, tolerance

analysis, and NC and tooling design are all essential competencies. It, like other software, is

always being updated to add new features. The information below is intended to provide an

overview of the product's capabilities rather than particular data on its individual features.

Creo Elements/Pro is a CAD/CAM/CAE software package that competes with other similar

solutions currently on the market. Creo Elements/Pro is a parametric, feature-based Themo

Dellin-g architecture with powerful rule-based design capabilities that is integrated into a

single database strategy. The trapper parameter exemplifies how it allows in-depth control of

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

complex geometry. Engineering Design, Analysis, and Manufacturing are the three basic

headings that divide the product's capabilities.

4.4 ENGINEERING DESIGN

Creo Elements/Pro provides a set of tools for creating a full digital representation of the

product under development. There is also the ability to develop geometry for other integrated

design disciplines such as industrial and standard pipe work, as well as complete wire

definitions, in addition to the general geometry tools. Tools for collaborative development

are also available. A variety of concept design tools can be utilised in the downstream

engineering process to offer up-front Industrial Design concepts. These include everything

from idea sketches for industrial design to reverse engineering using point cloud data and

sophisticated free-form surface tools. Using CREO software, we generated a 3D model of

this project. The models are seen below.

Fig 4.2 front view of fabricated system

Fig 4.3 right view of fabricated system

Fig 4.4 Rear view of fabricated system

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

Fig 4.5 close angle view of fabricated system

4.5 FUNCTIONS OF THE COMPONENTS

The following are the primary components that are used in the design and manufacture of the

automatic tire pressure inflation system:

• Pressure sensor

• Indicator of pressure

• Bearing, with bearing cap

• Wheel Configuration

• Stand for frames

• Quick-coupling joint

• Valve solenoid

• AC motor

• Pulley

• A belt-driven system

• Compressor (DC)

• Battery

4.5.1 PRESSURE SWITCH

A pressure switch is a type of switch that closes an electrical contact when a specific fixed

pressure on its input is attained. The switch could be set up to make contact as the pressure

rises or falls. Another form of pressure switch measures mechanical force; for example,

pressure-sensitive mats are used to open commercial building doors automatically. A capsule,

bellows, Bourdon tube, diaphragm, or piston element deforms or displaces proportionately to

the applied. pressure in a pressure switch for sensing fluid pressure. The resulting motion is

delivered to a set of switch contacts, either directly or by amplifying levers. Because the

pressure may fluctuate, because contacts should operate fast, an over-center device, such as a

small snap-action switch, is utilised to ensure speedy contact activity. Mercury switches set

on a Bourdon tube are one type of sensitive pressure switch. By shifting the contacts or

modifying the tension in a counterbalance spring, the pressure switch can be adjusted. A

calibrated scale and pointer on industrial pressure switches may be used to display the

switch's set point. Small variations in pressure do not change the state of the contacts

in a pressure switch's differential range around its set point. The difference can be adjusted in

some varieties. A pressure switch's pressure-sensing element can be configured to respond to

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

the difference between two pressures. When the difference is considerable, such switches are

useful, for example, to detect a clogged filter in a water supply system. The switches must be

built to respond only to the difference, not to changes in the common mode pressure. The

pressure switch's contacts can be rated anywhere from a few tenths of an amp to roughly 15

amps, with smaller values found on more sensitive switches. A pressure switch is typically

used to drive a relay or other control device, although certain models can also control tiny

electric motors or other loads directly. Because the switch's core components They must be

chosen to balance strength and life expectancy against compatibility with process fluids when

they are exposed to the process fluid. Rubber diaphragms, for example, are frequently used in

contact with water, but would quickly disintegrate if employed in a system with mineral oil.

Enclosures are used on switches designed for use in hazardous regions containing flammable

gas to prevent an arc at the contacts from igniting the surrounding gas. Weatherproof,

corrosion-resistant, or submersible switch enclosures may be necessary. An electronic

pressure switch consists of a pressure transducer (strain gauge, capacitive element, or other)

and an internal circuit that compares the measured pressure to a predetermined set point. In

comparison to a mechanical switch, such devices may give better repeatability, accuracy, and

precision.

4.5.2 PRESSURE GAUGE

Many ways for measuring pressure and vacuum have been developed. Pressure gauges and

vacuum gauges are instruments used to measure pressure. A manometer is a pressure

measurement equipment that is usually confined to monitoring pressures near atmospheric

values. The term manometer is frequently used to refer to liquid column hydrostatic

instruments in particular. A vacuum gauge is used to measure the pressure in a vacuum,

which is separated into two types: high vacuum and low vacuum (and sometimes ultra-high

vacuum). Many of the techniques used to test vacuums have a pressure range that overlaps.

As a result, by combining multiple various types of gauges, it is possible to constantly

measure system pressure from 10 mbar to 1011 mbar.

4.5.3 BEARING WITH BEARING CAP

Because hammering the bearings could produce cracks, they are pressed smoothly into the

shafts. The bearing is constructed of steel, while the bearing cap is made of mild steel.

Construction and types of ball bearings

An inner ring, an outer ring, the balls, and the cage or separator are the four sections of a ball

bearing. The balls run in curvilinear grooves in the rings to improve the contact surface and

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

allow higher loads to be transported. Because the groove's radius is slightly bigger than the

ball's radius, a small amount of radial play is required. As a result, the bearing may

compensate for minor angular misalignment between the assembled shaft and mounting. The

divider It maintains the balls equally spaced and keeps them from colliding on the sides

where their relative velocities are highest. Ball bearings come in many different types and

sizes. Extra light, light, medium, and heavy single-row radial bearings are available. for each

bore, as illustrated in Fig. 1-3(a), (b), and (c).

Fig 4.6 100 Series 200 Series 300 Series Axial Thrust Angular Contact Self-

Aligning Bearing

400 represents the heavy series of bearings. Most, but not all, manufacturers utilise a

numbering scheme in which the bore in millimeters is calculated by multiplying the final two

digits by 5. The series number is indicated by the third digit from the right. Bearing 307, for

example, denotes a medium-series bearing with a 35-mm bore. Refer to the manufacturer’s

details for any additional digits that may be present in a bearing’s catalogue number. Deep

groove bearings and bearings with two rows of balls are listed by some manufacturers. See

the particular pages dedicated to Quality Bearings & Components (QBC) bearing

designations. A significant amount of axial thrust can be carried by the radial bearing. When

the load is totally directed along the axis, however, the thrust type of bearing should be

utilised. Both radial and axial loads will be handled by the angular contact bearing. Large

quantities of angular misalignment will be handled by the self-aligning ball bearing. The use

of rings with deep grooves can help to boost radial capacity or A double-row radial bearing

is used. Radial bearings are classified into two groups based on how they are assembled. The

maximum, or filling-notch type, and the Conrad, or non-filling-notch type, are the two types.

The balls in the Conrad bearing are positioned between the rings as indicated in the divider is

then riveted in place and they are evenly spaced.

4.5.4 ARRANGEMENT OF WHEEL

The frame support holds the simple wheel and braking setup. The pneumatic cylinder piston

is positioned near the brake drum. Wheel is attached by a pulley and it is connected by to the

motor which has a small pulley in the ratio of 10:1 respectively.

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

4.5.5 FRAME

Mild steel is used to construct the frame stand. The above-mentioned components are

arranged in this frame stand in a proper manner. The stand holds the remaining components

that make the project a huge success. Once all of the components have been mounted and

installed, the project's effectiveness can be seen.

4.5.6 QUICK JOINT COUPLING

Fig4.7 Quick joint coupling

A coupling (or coupler) is a very short piece of pipe or tube having a socket at one or both

ends that allows two pipes or tubes to be joined, welded, brazed, or soldered (copper, brass,

etc.) together in piping or plumbing. A short length of pipe with two female National pipe

threads (NPT) (a coupler is a double female while a nipple is a double male in North

American parlance) or two male or female British standard pipe threads can also be used. If

the coupling's two ends are not the same (e.g., one BSP threaded and one NPT threaded), The

device is then known as an adaptor. One simple socket and one threaded socket is another

option. Another option is to switch from 3/4" NPT to 1/2" NPT. The words decreasing

coupling or reducer are used when the two ends employ the same connection method but are

of different sizes.

4.5.7 SOLENOID VALVE

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

Fig4.3 Solenoid valve

Directional control valves regulate the flow of air and are used to control the start, stop, and

direction of the flow. Directional valves are classified as two-way, three-way, four way, or

multi way depending on how many pathways the air is allowed to go. The number of

regulated connections of the valve, inlet connections to the compressed air supply, and the

varying number of ways the air consumer receives the outlet connection, while the

atmosphere receives the exhaust connection. Cut off valve or solenoid valve is a solenoid

control valve that is used to alter the flow direction. The electronic control unit that is

mounted to the dash pad controls the solenoid cut off valve. The flow direction is controlled

by a separate solenoid valve in our project. One controls the flow of oil from the oil tank to

the hydraulic cylinder. The oil from the hydraulic cylinder is returned to the reservoir via

another one. One of the most significant components of a pneumatic system is the directional

valve. This valve, also known as a DCV, is used to alter the direction of air flow in a

pneumatic system. The internal moveable elements of the directional valve change position

to do this. This valve was chosen for its speed and ability to reduce manual labor, as well as

for its ability to convert the machine into an automatic machine through the use of a solenoid

valve. A solenoid is a device that turns electrical energy into force and motion in a straight

line. These are also utilized to control a mechanical system that controls the valve

mechanism. Solenoids can be either push or pull. The plunger of a push type solenoid is

pushed when the solenoid is electrically energized. When a pull type solenoid is energized,

the plunger is drawn back. The pieces of the solenoid should be named so that they can be

identified while making repairs, performing service work, or installing them.

Fig 4.4 5/2 Solenoid

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

The solenoid valve has 5 openings. This ensures easy exhausting of 5/2 valve. The spool of

the 5/2 valve slide inside the main bore according to spool position; the ports get connected

and disconnected. The working principle is as follows.

Position-1

When the spool is actuated towards outer direction port ‘P’ gets connected to ‘B’ and ‘S’

remains closed while ‘A’ gets connected to ‘R’.

Position-2

When the spool is pushed in the inner direction port ‘P’ and ‘A’ gets connected to each other

and ‘B’ to ‘S’ while port ‘R’ remains closed.

4.5.8 AC MOTOR

It is discovered to drive the roller shaft attached to the frame structure's end. A huge pulley is

found around the free end of the shaft of the motor, around which the belt passes. The motor's

other specifications are mentioned in the machine's design section. A single-phase motor can

only produce an alternating field since it only has one alternating current source: one that

pulls in one direction at first, then the other as the polarity of the field shifts. Because there

would be no moment on a squirrel-cage rotor in this field, it would simply jitter. However, if

pushed in one way, it will spin. The most significant difference between single-phase AC

motors is how they start the rotor in a specific direction so that the alternating field produces

rotary motion in the desired direction. A device that introduces a phase-shifted magnetic field

on one side of the rotor is commonly used to accomplish this. The performance curves of the

four major types of single-phase AC motors are shown in the diagram. They're outlined

below.

Fig 4.5 single-phase AC motor curves

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

4.5.8.1 Split-Phase Motor

Fig 4.6 Split-phase motor

The split phase motor has two independent windings wound in the stator that allow it to start.

Both windings are separated from one another. Only one winding is utilised for starting, and it

is wound with a smaller wire diameter and higher electrical resistance than the main windings.

This temporal delay, combined with the physical placement of the initial winding, causes the

field to appear to rotate from the rotor's perspective. The motor starts because of the apparent

rotation. When the motor reaches about 75% of rated speed, a centrifugal switch is used to

disconnect the starting winding. The motor then operates according to standard induction

motor principles.

4.5.8.2 Capacitor-Start Motors

Fig 4.7 Capacitor-start motor

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

The largest single grouping of general-purpose single-phase motors is capacitor start motors.

These motors come in a variety of sizes, from fractional to 3HP.configuration of the windings

and centrifugal switch is quite similar to that of a split phase motor. The key distinction is

that the first winding does not need to be very strong. A specific capacitor is used in series

with the beginning winding in the case of a capacitor start motor. The presence of this

capacitor causes a minor delay in the magnetization of the beginning and running poles. As a

result, there is the appearance of a spinning field. When the motor reaches its maximum

speed, The motor continues to run in typical induction motor mode once the starting switch

opens. This reasonably cost motor has high starting torque, ranging from 225 to 400 percent

of full load torque. Conveyors, air compressors, and refrigeration compressors are all

examples of loads that require a capacitor start motor. It's also used in many applications

where strong starting torque isn't required because of its overall attractive qualities. The

bulbous protrusion on the frame where the starting capacitor is positioned is generally enough

to identify a capacitor start motor.

4.5.9 PULLEY

Fig 4.8 Pulley

A pulley is a wheel mounted on an axle or shaft that supports the movement and direction

change of a cable or belt around its circle. Pulleys are used to lift loads, apply forces, and

convey electricity in a number of ways. The assembly of wheel, axle, and supporting shell is

referred to as a "block" in nautical contexts. A pulley, also known as a sheave or drum, may

have a groove running around its circle between two flanges. A rope, cable, belt, or other

drive element can be used in a pulley system. or a chain that runs inside the groove over the

pulley. The pulley is one of six simple mechanisms used to hoist weights, according to Hero

of Alexandria. Pulleys are joined together to form a block and tackle, which provides

mechanical advantage for applying huge forces. Pulleys are also used to carry power from one

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

rotating shaft to another as part of belt and chain drives. A belt and pulley system has two or

more pulleys that are connected by a belt. Mechanical power, torque, and speed can now be

communicated between axles. A mechanical advantage is realized when the pulleys have

different diameters The mechanical advantage of a belt drive is similar to that of a chain

drive; however, unlike gears and sprockets, the mechanical advantage of a belt sheave is

approximated by the ratio of the pitch diameter of the sheaves only. A drum-style pulley,

which lacks a groove or flanges, is frequently slightly convex to keep the flat belt centered.

The crowned pulley is another name for it. This sort of pulley, which was historically

commonly employed on industrial line shafts, is still used to drive the rotating brush in

upright vacuum cleaners, belt sanders, and bandsaws. The diameters of pulleys, like the

diameters of gears and, consequently, their number of teeth, determine a gear ratio, and hence

the speed increases or reductions and mechanical advantage that they can offer. Cone pulleys

and step pulleys (which work on the same principle but are usually applied to flat belt and V

belt versions, respectively) are a way to provide multiple drive ratios in a belt-and-pulley

system that can be shifted as needed, similar to how a transmission does with a shiftable gear

train. The most typical way drill presses deliver a range of spindle speeds is by V belt step

pulleys.

4.5.10 BELT DRIVE

Fig4.9 Belt drive

A belt is a flexible material loop that connects two or more spinning shafts that are usually

parallel mechanically. Belts can be used to create motion, carry electricity effectively, and

track relative movement. The shafts do not have to be parallel, and belts are wrapped around

pulleys with a twist between them. The belt can drive the pulleys usually in one direction

(the same if the shafts are parallel) or it can be crossed, reversing the direction of the driven

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

shaft in a two-pulley system (the opposite direction to the driver if on parallel shafts). As a

source of motion, a conveyor belt can be used to continuously move a cargo between two

location The carrying medium of a belt conveyor system is a conveyor belt (often shortened

to belt conveyor). Conveyor systems are available in a wide range of designs and sizes. In a

belt conveyor system, an endless loop of carrying medium—the conveyor belt—rotates

around two or more pulleys (also known as drums). One or both of the motorized pulleys

move the belt and the material on the belt forward. The powered pulley is the drive pulley,

while the unpowered pulley is the idler pulley. Belt conveyors are classified into two groups:

Bulk material handling and general material handling (such as moving boxes around a plant)

(such as transporting enormous amounts of resources and agricultural goods such as grain,

salt, coal, ore, sand, and overburden).

4.5.11 COMPRESSOR (DC):

A compressor delivers high-pressure compressed air. It moves ahead thanks to an electric

motor. The cylinder's inlet is supplied with air by the compressor. An air compressor, as the

name implies, compresses and increases the pressure of air. The air compressor extracts air

from the surrounding environment, compresses it, and transfers it under high pressure to a

storage vessel. It can then be transferred by pipeline to a site that requires compressed air.

Because air compression requires some manual labor, the compressor must be driven by a

prime mover. Compressed air is utilised in industry for a range of purposes, including

pneumatic drills, rivets, paint spraying, and supercharging internal combustion engines.

Elevators, rams, pumps, and a variety of other equipment are all controlled by it.

Compressed air is sucked to produce air ballast in blast furnaces and Bessemer converters.

Batteries are used to store extra solar energy that has been converted into electrical energy in

remote systems. Only isolated sunlight loads are exempt, such as irrigation pumps or

drinking water storage. In fact, for devices with a power output of less than a kilowatt.

Batteries appear to be the only technically and economically practical storage solution.

Because both the PV system and the batteries have large capital expenses. The total system

must be optimized in terms of available energy and local demand patterns. To be

economically effective, solar energy storage requires a battery with a precise set of

characteristics We utilis lead acid batteries to store electrical energy from solar panels for

street lighting, and more information about lead acid cells may be found below

4.5.12 LEAD-ACID WET CELL

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

The lead-acid cell is the most widely employed kind when high load currents are required. A

dilute solution of sulfuric acid (H2SO4) serves as the electrolyte. The load current to the

starter motor of an automobile, for example, is normally 200 to 400A when using battery

power to start the engine. Although a single lead-acid cell provides a nominal output of 2.1

volts, lead-acid cells are frequently used in series combinations of three for a 6-volt battery

and six for a 12-volt battery. A secondary cell or store cell that may be recharged is a lead

acid cell. As long as the cell is in good physical condition, the charge and discharge cycle

can be repeated several times to restore the output voltage condition. Heat from high charge

and discharge currents, on the other hand, reduces the useful life of an automotive battery to

3 to 5 years. The lead-acid kind of secondary cell has the highest output voltage of the four

varieties, allowing for less cells for a given battery voltage.

Fig 4.10 Lead acid battery

4.5.11.1 CONSTRUCTION

The positive and negative electrodes in a lead-acid battery are made up of a series of plates

welded to a connecting strap. The plates are submerged in an electrolyte made up of eight

parts water and three parts concentrated sulfuric acid. Each plate is made up of a lead-

antimony alloy grid or framework. The active material, lead oxide, may be pasted onto the

grid thanks to this design. A forming charge creates the positive and negative electrodes

during cell manufacturing. The active ingredient in the positive plate is converted to lead

peroxide (PbO2) during the manufacturing process. A spongy lead serves as the negative

electrode (Pb). The majority of automobile batteries are sent dry from the manufacturer. The

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

electrolyte is added during installation, and the battery is subsequently charged from the

plates. In normal operation, maintenance-free batteries require little or no water. Except for a

pressure vent, certain varieties are completely sealed, with no way to introduce water. The

components of a battery are depicted in the diagram.

4.5.11.2 CHEMICAL ACTION

Hydrogen and sulphate ions combine to form sulfuric acid. Lead peroxide from the positive

electrode reacts with hydrogen ions to generate water, and with sulphate ions to form lead

sulphate when the cell discharges. He sulphate is produced by combining lead on the

negative plate with sulphate ions. As a result of the discharge, more water is produced,

diluting the electrolyte and forming lead sulphate on the plates. As the discharge proceeds,

sulphate fills the grids' pores, slowing acid circulation in the active material. The powder

seen on the exterior terminals of aged batteries is lead sulphate. Charging is required when

the combination of a weak electrolyte and sulfation on the plate reduces the battery's output.

On The external D.C. source reverses the current in the battery during charging. Chemical

processes are reversed when ions move in the electrolyte in the opposite direction. The

positive plate's lead sulphates react with water and sulphate ions to produce lead peroxide

and sulfuric acid. By adding sulfuric acid, this activity re-forms the positive plates and

strengthens the electrolyte.

Fig 4.11 Chemical reaction in batteries

While reforming lead on the negative plate to react with hydrogen ions; this also forms

currents can restore the cell to full output, with lead peroxide on the positive plates, spongy

lead on the negative plate, and the required concentration of sulfuric acid in the electrolyte.

The lead-acid cell's chemical formula is

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

Charge

Pb + PbO₂ + 2H₂SO₄ 2pbSO₄ + 2H₂O

Discharge

4.6 WORKING PRINCIPLE

Switch on the ac motor for the dynamic rotation of the tire, ac motor is connected to the

tire by a belt drive

The primary hose is connected to the coupling which is connected to the pressure gauge

The solenoid valve inlet is supplied with D.C compressed air. This project's power source

is a battery.

A pressure switch is positioned in the air flow tube and is used to measure tyre pressure.

The pressure switch reading determines the needed tyre pressure.

The current pressure is sensed by this pressure switch, and the output signal is sent to the

solenoid valve. The pressure switch activates the solenoid valve if the tyre pressure

falls below the previously set valve.

The pressurized air is now delivered to the tyre via a rapid release link, which allows the

wheel to freely rotate.

When the required pressure is reached, the pressure switch deactivates the solenoid

valve, allowing the tyre pressure to remain constant. The human component in this

automated system is minimal.

4.7 DESIGN CALCULATION

4.7.1 Design of belt

L=Π ( r₁ + r₂ ) 2 l + ( r₁ - r₂ )²

l

Where,

r₁=Radius of driving pulley

=63 / 2

r₂=Radius of followers

=200 / 2

l=Distance between two pulley

=135 mm

∴L=Π(31.5 + 100) + 2 x (135) + (31.5 – 100)²

=413.12 + (135 x 2) + 4692

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

L=5375 mm

4.7.2 Power transmitted by belt drive

d=Diameter of the drive pulley in mm

n=Speed of the drive pulley in rpm.

r=Velocity of the belt in m/sec

V=Π d n

60

=Π x 63 x 1440

1000

V=4.75 m/sec.

4.7.3 Maximum tension in the belt

T=Maximum stress X Cross section Area of the belt

=f x b x t

[f=2 N/mm²]

=2 x 10 x 12

T =240 N

4.7.4 Design of ball bearing

Bearing No. 6404

Outer Diameter of Bearing (D) = 47 mm

Thickness of Bearing (B) = 14 mm

Inner Diameter of the Bearing (d) =20 mm

r₁=Corner radii on shaft and housing

r₁=1 (From design data book)

Maximum Speed=14,000 rpm (From design data book)

Mean Diameter (dm) = (D + d) / 2

= (47 + 20) / 2

dm=33.5 mm

4.7.5 Speeds in pulleys

Measured Specifications:

N1/N2 =D2/D1

Where,

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

N1 =Input speed to the Motor = 1440 rpm

N2 =Output speed from the pulley-2

D2 =Diameter of the pulley-2 = 200mm

D1 =Diameter of the Motor pulley=63mm

∴ N2 =(D1/D2) x N1

=( 63 / 200) x 1440= 453.6 rpm

This speed is equal to the small Sprocket speed = 453.6 Rpm

The speed of the huller shaft (N4) = (D3/D4) x N3

Where,

N4 ---- Speed of the rolling huller Shaft

N3 ---- Speed of the Small sprocket = Speed of Pulley – 2 = 453.6 rpm

D3 ---- Diameter of Small sprocket = 61 mm

D4 ---- Diameter of Big sprocket = 183 mm

So the speed of the rolling huller shaft = (61/183) * 453.6

= 151.2 Rpm

CHAPTER-5

RESULTS AND DISCUSSION

5.1 FABRICATED SYSTEM RESULT

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

Proper tire pressure thus always helps to improve the tire life, attains greater braking

efficiency, improved ride quality and cargo safety due to reductions in the vehicle vibrations,

improved vehicle mobility due to the increase in traction when the tire pressures are lowered.

When the required pressure in the tire is reached, the buzzer will indicate it to the driver and

the solenoid valve will shut off the air supply to the tire Thus on implementing the tire

pressure inflation system to the vehicle, the system will help the driver to regulate and

maintain proper pressure inside the tires. the development of tire pressure inflation system

has proven that the users inflate their tires more frequently at home over the weekends and

found to be as an easier application towards sustaining correct tire pressure at all times. Its

ability to relief excessive air from over inflated tire is also fully utilized as hooking up

automatic tire pressure inflation system to the value without any other devices are taken as an

advantage. The tire pressure inflation system is working with satisfactory condition.

5.2 COMPARISON BETWEEN MANUAL AND AUTOMATIC TIRE

PRESSURE INFLATION SYSTEM

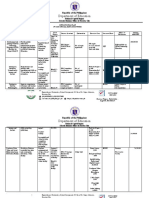

Table 5.2.1 comparison between manual and automatic tire pressure inflation system

parameter Manual system Automatic system

Man power more less

Chance of tire wear more less

Time consumption more less

Maintenance of tire Comparatively Need

inflation more less

Effectiveness less more

5.3 ADVANTAGES

Because they are designed to be used at their prescribed pressure, having under-inflated tyres

poses numerous risks. Underinflation can cause higher tyre wall deformation by concentrating

the weight on the tread shoulders, reducing the amount of surface contact the tyre has with

the road. This has a lot of ramifications.

• Increased tread wear, which increases the risk of aquaplaning in the wet; poorer handling

characteristics and vehicle control.

• Increased stopping distances

• Increased risk of tyre delamination, which could result in a rapid tyre failure.

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

• Less tyre blowouts since tyres are always at the optimum inflation level.

• Lower maintenance costs and increase productivity.

• Lessen human effort, Increase the efficiency of the vehicle.

• Increase the tyre's lifespan

• Prevents fatalities and accidents.

5.3 DISADVANTAGES

• The project is expensive.

• Regular maintenance is required.

• There must be a separate gas tank fitted.

5.4 APPLICATIONS

These types of automatic tyre pressure inflation systems can be used in a variety of fields,

including

• Application for automobiles.

• Automobile Manufacturing Industry

• This is a two-wheeler application.

• Applications for all four-wheelers.

CHAPTER-6

CONCLUSION & FUTURE SCOPE

6.1 CONCLUSION

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

This project work has given us a fantastic opportunity to put our limited knowledge to good

use. While working on this project, we received a lot of practical experience with planning,

purchasing, assembling, and machining. We believe that project work is an effective means

of bridging the gap between institutions and industries. We are pleased that we were able to

effectively finish the work within the time constraints. The design and fabrication of an

automatic tire pressure inflation system is performing admirably. We can appreciate the

challenges of maintaining tolerances and quality. We have performed to the best of our

ability and skill, making the most of the available resources. Let us add a couple more

sentences to our project conclusion statements. about our work on the impression project as a

result, we invented an "automatic tire pressure inflation in automobile," which helps to

automatically inflate the tyre whenever necessary, reducing human work. They can be

customised and developed according to the applications by employing various techniques.

6.2 SCOPE FOR FUTURE WORK

Michelin is working with several other companies to develop an active pressure Management

system called TIPM (Tyre Intelligent Pressure Management), due to be Available sometime

in 2005. This system has a compressor that automatically adjusts the Pressure in each tyre

while the vehicle is in operation to compensate for leaks and slow Leak punctures. The driver

will be able to adjust the pressure depending on the desired Driving mode: comfort, sporty,

all-terrain or over-obstacle. There are at least two other Systems in the early development

stages that are oriented toward the consumer market the Entire system and the Cycloid Air

Pump system. The entire self-inflating system uses at Valve that pulls in air from the

atmosphere. It then pumps the air into the under-inflated Tyre using a peristaltic-pump action.

The goal is to constantly maintain a specific Pressure

COST ESTIMATION

Various cost involved in design and fabrication of the modified bumper system are shown in

the figure below. Most if not all the material used for the project work are obtained from

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

scrab. Also, much altercation is taking during fabrication to arrive at the final design. Cost

will be optimized during production since the rework and iteration are eliminated.

Table showing Expenditure detail

Sl. No. PARTS Qty. Amount (Rs)

1 Motor 1 1800

2 Pulley 2 500

3 Belt 1 450

4 Wheel 1 950

5 Frame 1 2300

6 Bearing with bearing cap 2 450

7 Pressure gauge 1 300

8 Solenoid valve 1 850

9 Hose Req. amount 750

10 Pressure switch 1 1200

11 D.C Compressor 1 1800

12 Battery 1 1150

Total cost 12850/-

REFERENCES

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

[01]. Ram Bansal, Shubham Swami, Aliasgerkanchwala and Mazharhussain, “automatic

tire inflation system in dynamic condition” international journal of automobile

engineering, research and development, Vol 8, issue 1, jun 2018 ISSN (P):2277-4785

[02]. Indrajeet singh, department of mech engineering, R. S. R. Rungta college of

engineering & technology bhilai “to study on implementation of tire inflation system

for automotive vehicles.” International journal of innovative research in science,

engineering and technology, Vol 5, issue 4 (An ISO 3297:2007 certified organization),

April 2016

[03]. Lukman Medriavin Silalahi, Mudrik Alaydrus, Agus Dendi Rochendi, Muhthar

Muhtar, “design of tire pressure monitoring system using a pressure sensor base”

Department of electrical engineering, universitas mercu buana, vol 23, No 1 february

2019

[04]. Alexander Varghese, “Influence of Tire Inflation Pressure on Fuel Consumption,

Vehicle Handling and Ride Quality Modelling and Simulation”. Vol.1 page 250-283 .

ISSN:1987-3453, march 2013

[05]. A.V. WADMANE, P.S. PADURE, “Automatic tire pressure controlling and self-

inflating system: A review” ISOR journal of mechanical and civil engineering, vol 1

ISSN:2320-334, January 2005

[06]. Bhupendra Pratap singh, Hari Shankar Sahu, Raunak Chauhan, Novel Kumar sahu,

To study on Implementation of Tire inflation system for automative vehicles. Volume

5, page 212-236 Number April 2016

[07]. Alfonso Silva, Jesús R. Sánchez, Gerardo E. Granados, Juan C. Tudon-Martinez,

Jorge De J. Lozoya-Santos, “Comparative Analysis in Indirect Tire Pressure

Monitoring Systems in Vehicle” IFAC Paper online 52 may 2019

[08]. Fogel Strom, K.A “Tire pressure monitoring system with permanent tire

identification” US Patent 7348,878. June 2008

[09]. Marius Toma, Cristian, Andreescu, Cornelia Stan, “Influence of tire inflation pressure

on the results of diagnosing brakes and suspension” international conference

interdisciplinarity in engineering, INTER-ENG 2017, October 2017

[10]. P. Buekenhoudt, study on “new suspension test method” implemented in Belgium,

GOCA from Belgium, April 2012,

[11]. B. P. Omprakash, T. Senthil Kumar, “M.A.R.S - Mechanized Air Refilling System”

Vol.2 page 323-350.ISSN:1737-2231 July 2014

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

[12]. H. soni, P. Golar and A. Kherde, “Design of automatic tire inflation system”.

industrial science, Vol 1(4), ISSN: 2347-5420 march 2014

[13]. B. Szczucka-Lasota, T. Wegrzyn, B. Lazarz, Ja Kaminska, “Tire pressure remote

monitoring system reducing the rubber waste” international conference

interdisciplinarity in engineering, INTER-ENG 2017, October 2017

[14]. Andreescu MC, Stan C “influence of tire inflation pressure on the results of

diagnosing brakes and suspension.” international conference interdisciplinarity in

engineering, INTER-ENG 2017, October 2017, Tirgu-Mures, Romania

BIBLIOGRAPHY

PRAKASH S T, is an Assistant Professor in the Department of

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

Automobile Engineering, Srinivas Institute of Technology,

Mangaluru. He has published an overall of three papers namely,

“Power Generation by Utilizing Repulsions of Permanent

Magnet for Small Scale Applications”, “Effect of Graphite on

Tribological behaviour of PTFE Composites” and “Development

in Research work of Compressed air powered Engine by

increasing it efficiency”.

MOHAMMED FARIS M, currently pursuing his Bachelor’s

Degree in Automobile Engineering (VIII semester) in Srinivas

Institute of Technology, Mangalore. He was represented the

collage in various activities in and around the region. He is the

part of EV camp conducted in the collage. He is a studious student

in academics

JOVIN MANOJ, currently pursuing his Bachelor’s Degree in

Automobile Engineering (VIII semester) in Srinivas Institute of

Technology, Mangalore. He is the part of EV camp conducted in

the collage. He is a studious student in academics

JINCE JAMES, currently pursuing his Bachelor’s Degree in

Automobile Engineering (VIII semester) in Srinivas Institute of

Technology, Mangalore. He is an active sportsman. . He is the

part of EV camp conducted in the collage

VIBHU SREEDEEP, currently pursuing his Bachelor’s Degree

in Automobile Engineering (VIII semester) in Srinivas Institute of

Technology, Mangalore. . He is the part of EV camp conducted in

the collage

PAPER PRESENTED AND PUBLISHED

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

Presented and published a paper at an International Conference (RTIMES-2022) on “Design

and Fabrication of automatic tire pressure inflation system” hosted by Srinivas institute of

technology, mangaluru, Karnataka in association

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

DESIGN AND FABRICATION OF AUTOMATIC TIRE PRESSURE 2021-2022

INFLATION SYSTEM

Department of Automobile Engineering, SIT, Mangaluru, valachil Page 1

You might also like

- .Auto Tyre Pressure Inflation SystemDocument8 pages.Auto Tyre Pressure Inflation SystemboestinNo ratings yet

- .Auto Tyre Pressure Inflation SystemDocument20 pages.Auto Tyre Pressure Inflation SystemSRL MECHNo ratings yet

- Self Inflating TireDocument12 pagesSelf Inflating TirevndhilmechNo ratings yet

- Running Head: Central Automatic Tire Inflation System 1Document56 pagesRunning Head: Central Automatic Tire Inflation System 1Tonny MutaiNo ratings yet

- Automatic Tyre Pressure Inflation System: SynopsisDocument5 pagesAutomatic Tyre Pressure Inflation System: SynopsisTechky ManiacsNo ratings yet

- Automatically Tyre PressureDocument18 pagesAutomatically Tyre PressureMujeeb RahmanNo ratings yet

- Automatic Tyre Inflation SystemDocument32 pagesAutomatic Tyre Inflation SystemSanjana Singh50% (2)

- Tire Pressure Inflation SystemDocument8 pagesTire Pressure Inflation SystemijrdtNo ratings yet

- Automatic Tyre Inflation SystemDocument53 pagesAutomatic Tyre Inflation SystemMayur Salunke100% (1)

- Tyre PDFDocument5 pagesTyre PDFARULKUMARSUBRAMANIANNo ratings yet

- Automatic Tyre Pressure Inflation SystemDocument35 pagesAutomatic Tyre Pressure Inflation SystemmujeebNo ratings yet

- Final ReportDocument30 pagesFinal ReportSatish HSNo ratings yet

- Tyre Pressure Monitoring SystemDocument7 pagesTyre Pressure Monitoring SystemSrinivasa M Gowda SeenaNo ratings yet

- Continental In-Tire Sensors Read Tread DepthDocument6 pagesContinental In-Tire Sensors Read Tread DepthDaniel D' Jesús NiñoNo ratings yet

- Sensor Technology PresentationDocument14 pagesSensor Technology PresentationAaryan MoreNo ratings yet

- Automatic Tyre Inflation System in Dynamic Condition: Ram Bansal, Shubham Swami, Aliasgerkanchwala & MazharhussainDocument10 pagesAutomatic Tyre Inflation System in Dynamic Condition: Ram Bansal, Shubham Swami, Aliasgerkanchwala & MazharhussainTJPRC PublicationsNo ratings yet

- TIRE QuestionsDocument7 pagesTIRE QuestionsHemantkumar TungNo ratings yet

- Tyre Pressure Inflation SystemDocument37 pagesTyre Pressure Inflation SystemANAND KRISHNANNo ratings yet

- Automatic Tyre Inflation SystemDocument61 pagesAutomatic Tyre Inflation SystemFikhriMaulanaSetiakuSatuHatiNo ratings yet

- Remote Tire Monitoring Integrated with Mine ManagementDocument8 pagesRemote Tire Monitoring Integrated with Mine ManagementRotax_KidNo ratings yet

- Self-Inflating Tires Seminar Advanced TopicsDocument1 pageSelf-Inflating Tires Seminar Advanced TopicsSurya md4MC19ME154No ratings yet

- Tire Self Inflation SystemDocument12 pagesTire Self Inflation Systemgillanis multimediaNo ratings yet

- Braking System Mathematical ModelingDocument14 pagesBraking System Mathematical ModelingAvadhut kulkarniNo ratings yet

- Guide To Tyre Management On Heavy VehiclesDocument16 pagesGuide To Tyre Management On Heavy VehicleskabarridakuNo ratings yet

- Wireless Advance Tire Pressure Monitoring SystemDocument11 pagesWireless Advance Tire Pressure Monitoring Systemgauravkumar bhandari0% (1)

- Maintenance Booklet 2008 Light Trucks: M-Class, GL-Class, R-Class (Except AMG and Diesel Models)Document71 pagesMaintenance Booklet 2008 Light Trucks: M-Class, GL-Class, R-Class (Except AMG and Diesel Models)Xinyu CaiNo ratings yet

- Applications Drive Tire StrategiesDocument4 pagesApplications Drive Tire StrategiesJehuty88No ratings yet

- Automotive Safety Systems (Mee1041) : Tyre Pressure Monitoring System (TPMS)Document13 pagesAutomotive Safety Systems (Mee1041) : Tyre Pressure Monitoring System (TPMS)karthikNo ratings yet

- Be Tirewise:: Save Money at The Pump, Increase Efficiency, and Protect Your SafetyDocument6 pagesBe Tirewise:: Save Money at The Pump, Increase Efficiency, and Protect Your SafetyDominic MNo ratings yet

- Ontario Air Brake Handbook (2019)Document38 pagesOntario Air Brake Handbook (2019)Alex Baranyai100% (1)

- Breakdowns and Incidents: DVSA Safe Driving for Life SeriesFrom EverandBreakdowns and Incidents: DVSA Safe Driving for Life SeriesNo ratings yet

- Osprey: Accurate Tire Wear Measurement Using Automobile RadarDocument1 pageOsprey: Accurate Tire Wear Measurement Using Automobile RadarMohcin LaidiNo ratings yet

- Automatic tire pressure system ensures safetyDocument5 pagesAutomatic tire pressure system ensures safetybadaboyNo ratings yet

- Via VisionDocument8 pagesVia VisionTiagoAlbarranNo ratings yet

- Katalog TechnicznyDocument52 pagesKatalog TechnicznydareksoNo ratings yet

- Commercial Vehicle Tires Technical Data Book ContinentalDocument61 pagesCommercial Vehicle Tires Technical Data Book ContinentalRăzvan MărgăritNo ratings yet

- OS 01 Optimisation of Effective-TATATechnologiesDocument8 pagesOS 01 Optimisation of Effective-TATATechnologiesNagaArjunNo ratings yet

- ADocument36 pagesAsaad bin sadaqatNo ratings yet

- Aerodynamic Aspects of A Formula Student Race CarDocument8 pagesAerodynamic Aspects of A Formula Student Race CarVyssionNo ratings yet

- Automotive Wheel Alignment System: by Michael Danek Isaac KousariDocument26 pagesAutomotive Wheel Alignment System: by Michael Danek Isaac KousariSandra MarkivNo ratings yet

- Southeast: Crumb Rubber Processing in The Twenty - First CenturyDocument10 pagesSoutheast: Crumb Rubber Processing in The Twenty - First CenturyBarış KalebekNo ratings yet

- Sem1 Pnumatic Bumper ReportDocument33 pagesSem1 Pnumatic Bumper Reportdhanshri kolekarNo ratings yet

- Seminar Report Sheet MetalDocument30 pagesSeminar Report Sheet Metalrajverma200233No ratings yet

- Self Inflating Tire System: University of The East Caloocan Campus College of Engineering Mechanical EngineeringDocument5 pagesSelf Inflating Tire System: University of The East Caloocan Campus College of Engineering Mechanical EngineeringXylester Kenn FabreNo ratings yet

- High Performance Brake DiscDocument59 pagesHigh Performance Brake DiscbrindharajasekarNo ratings yet

- American Society For Quality: AdvertisementDocument12 pagesAmerican Society For Quality: AdvertisementshmzzhNo ratings yet

- Tire Guide: Product OverviewDocument22 pagesTire Guide: Product OverviewAbdulAziz AlGhamdiNo ratings yet

- Modern Automotive EnginesDocument24 pagesModern Automotive EnginesAbhishek ShettyNo ratings yet

- Automatic Tyre Pressure Inflation System For AutomobileDocument6 pagesAutomatic Tyre Pressure Inflation System For Automobileshreesha ikurNo ratings yet