Professional Documents

Culture Documents

The Digital Twin Paradigm For Future NASA and U.S. Air Force Vehicles

Uploaded by

nakibosmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Digital Twin Paradigm For Future NASA and U.S. Air Force Vehicles

Uploaded by

nakibosmanCopyright:

Available Formats

53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference<BR>20th AI AIAA 2012-1818

23 - 26 April 2012, Honolulu, Hawaii

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

The Digital Twin Paradigm for

Future NASA and U.S. Air Force Vehicles

E. H. Glaessgen*

Durability and Damage Tolerance Branch

NASA Langley Research Center, Hampton, Virginia, 23681

D.S. Stargel†

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

Aerospace, Chemical, and Material Sciences

Air Force Office of Scientific Research, Arlington VA, 22203

Future generations of NASA and U.S. Air Force vehicles will require lighter mass while being

subjected to higher loads and more extreme service conditions over longer time periods than the

present generation. Current approaches for certification, fleet management and sustainment are

largely based on statistical distributions of material properties, heuristic design philosophies,

physical testing and assumed similitude between testing and operational conditions and will likely be

unable to address these extreme requirements. To address the shortcomings of conventional

approaches, a fundamental paradigm shift is needed. This paradigm shift, the Digital Twin,

integrates ultra-high fidelity simulation with the vehicle’s on-board integrated vehicle health

management system, maintenance history and all available historical and fleet data to mirror the life

of its flying twin and enable unprecedented levels of safety and reliability.

Introduction

Existing methodologies for vehicle certification, fleet management and sustainment are largely

based on similitude and a heuristic understanding of the effects of operational and anomalous

conditions on the structural health, safety and performance of a vehicle. A common

manifestation of similitude and heuristics is in the form of the “factors-of-safety” used during

design and certification. So-called factors-of-safety are rooted in a heuristic legacy wherein a

factor of, say, 1.5 or 2.0 has “always” been sufficient to account for a particular class of

unknown unknowns (e.g., loads, material properties). Often, the history and pedigree of such

factors is uncertain.

Additionally, compounding of factors-of-safety is pervasive and may lead to unnecessarily heavy

structures and reduced performance without necessarily improving the actual safety of the

vehicle or the probability of mission success. Even current probabilistic or reliability

methodologies are inadequate because they are based on assumed similitude between the

circumstances in which the underlying statistics were obtained and the environment in which the

vehicle operates. When similitude is violated, probabilistic methods break down as readily as

those based on factors-of-safety. Although statistical assessments are important, they must be

part of an overall best-physics approach that is relevant to each individual vehicle.

*Assistant Branch Head. Associate Fellow AIAA

†Program Manager. Senior Member AIAA

1

This material is declared a work of the U.S. Government and American

is not subject Institute

to copyrightof Aeronautics

protection and States.

in the United Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

Similitude is so commonplace in the current engineering process that it is often invisible to the

engineers who invoke it. A ubiquitous example can be found in engineering design and analysis

where computer codes (including commercial finite element codes) are used to “predict” failures.

Such codes are of limited “predictive” capability because, in a general sense, they only produce

responses that have previously been observed experimentally and then programmed for future

assessment. For example, to account for a phenomenon such as the interaction between

environment and structural damage, the issue must have been foreseen, specific experiments

must have been performed and their results must have been incorporated within the models.

Further, since different environments, or even different degrees of environment, have differing

synergies with damage, the specific environments that will be encountered by the vehicle must

have been considered during the design process. Otherwise, “worst case” scenarios must be used

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

to ensure the health and safety of the vehicle; albeit at the expense of weight and performance.

Another common manifestation of similitude and heuristics is in the form of inspection intervals

and schedules used for fleet management and sustainment. Inspection schedules are typically

determined from experience with similar vehicles that have performed similar missions. Often,

inspection is performed based on experience with the fleet leader, the vehicle in the fleet that

experienced the most flights or the worst degradation. If, for example, unacceptable degradation

of a component was found during an inspection of the fleet leader, it may be decided that all

vehicles of that class be inspected immediately regardless of the specific history of each vehicle.

These issues are amplified when new designs or operating conditions are considered. Unlike the

methods used to insure safety and reliability of existing vehicles that have a clear and well-

understood legacy, many future vehicles will have little direct precedent to follow, and in some

cases (e.g., long duration space missions) the vehicle may be impossible to inspect and maintain

in the conventional sense. Thus, the ability to fully understand degradation and anomalous

events and foresee previously unknown unknowns may represent the difference between mission

success and mission failure.

The Digital Twin* paradigm is a long-term vision aimed at addressing these and other

shortcomings of current practices for certification, fleet management and sustainment. This

paper focuses on a discussion of the requirements for, development of and application of the

Digital Twin. The paper is composed of the following sections: conventional approaches for

certification and sustainment; the concept of a Digital Twin and its applications, including

certification and sustainment, vehicle health and mission management, and in-situ forensics;

identification of near-term opportunities for implementing elements of the Digital Twin

paradigm; a brief discussion of the advantages of the Digital Twin; its potential influence on

National goals; and a brief summary and references.

Conventional Approaches

Much of the philosophy and many of the guidelines used for certification, fleet management and

sustainment of NASA and U.S. Air Force vehicles can be found in government and professional

society standards and handbooks. A small sampling of requirements for structures, materials and

non-destructive evaluation (NDE) is shown in Table 1. These documents include expansive

*Originally conceived by the

Defense Sciences Office at DARPA 2

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

discussions of structural design and test, including factors-of-safety; fracture control; materials

and processing; NDE; effects of specific environments; detailed analysis of failure modes; and

standards for numerical models and analysis. Many of the documents used by NASA and the

U.S. Air Force are developed in-house, while others are derived from technical societies such as

the American Institute of Aeronautics and Astronautics (AIAA) and the American Society of

Mechanical Engineers (ASME). These documents are rooted in decades-old experience with

laboratory tests, protoflight tests and flight histories. In this section, some of the conventional

approaches to certification, fleet management and sustainment will be illustrated through the

discussion of examples taken from several of the documents, including: NASA-STD-5001A,

NASA-STD-5019 and NASA-HDBK-5010.

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

The criteria for determination of factors-of-safety for both deterministic and probabilistic

analyses are discussed in several of the standards listed in Table 1, including NASA-STD-

5001A1 that specifically addresses spaceflight hardware.

As discussed in the standard, the

accepted practice for “verification” of launch vehicles is “the prototype approach in which a

separate, dedicated test structure, identical to the flight structure, is tested to demonstrate that the

design meets the factor-of-safety requirements.” An alternative to the prototype approach is “the

protoflight approach wherein the flight structure is tested to levels somewhat above limit stress

(or load) but below yield strength.” The latter approach requires a factor-of-safety for yield that

is higher than the factor-of-safety used for prototype testing. “No test” options are also allowed

for metallic structures; however, according to the standard “projects which propose to use the

‘no-test’ approach generally must use larger factors of safety.” In all of these cases,

“verification” depends on the ability to perform laboratory tests on a “dedicated test structure

[that is] identical to the flight structure.” Additionally, the loading, boundary conditions,

environment must also be representative of flight conditions.

Table 1: Sample of Publicly Available Standards and Handbooks

3

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

The minimum design and test factors-of-safety for metallic and composite structures outlined in

NASA-STD-5001A1 are given in Tables 2 and 3. These factors vary widely depending on

circumstance and can be as large as 2.0 depending on the material and local structural

configuration. Because of the apparent scatter in material response under cyclic and creep

loading, the corresponding factors are even larger. According to NASA-STD-5001A1, a service

life factor of 4.0 is applied to “spaceflight structures made of well-characterized materials and

with sufficient load cycle data that accounts for all in-service environments,” while for

“structures made of materials that are not well characterized or those that may have complex

failure modes, such as composite structures, an additional factor and testing may be required by

the assigned Technical Authority at the responsible NASA Center.”

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

Table 2: Minimum Design and Test Factors for Metallic Structures1

1

Table 3: Minimum Design and Test Factors for Composite/Bonded Structures

Fracture critical hardware requires the additional imposition of damage tolerance requirements

(see, for example, NASA-STD-50192). Here, specific requirements, exceptions and

methodologies for assessing metallic and composite pressure vessels, rotating machinery,

structural components and other fracture critical hardware are discussed. The application of

continuum fracture mechanics analyses, including NASGRO fatigue crack growth analysis (see

JSC 22267B6), is the foundation of much of the codified fracture control methodology.

An extreme case of codified conservatism is discussed in NASA-HDBK-501010, where separate

conservatisms for crack size, applied loads, material properties, and analysis are discussed for

4

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

“known cracks” in fracture critical hardware. Known cracks in fracture critical hardware require

special treatment wherein upper bounds for crack size estimate accounting for “any possible non-

detected adjacent cracks and/or crack tip extensions” are required, as shown in Figure 1. Here,

the crack size assumed for analysis (2cA) is a combination of the NDE-detected crack dimensions

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

Figure 1: Imposed Conservatism for Detected Cracks (Adapted from Reference 10).

(2cD) and an adjustment based on the NDE detection capability (2cN).

Additionally, worst-case limit loads for the mission must be used to compute the far field stress

state at the location of the detected crack. Typically, these loads are used in conjunction with an

assumed fatigue spectrum. As an example, one of the many loading spectra developed by NASA

Goddard Space Flight Center for the analysis of payloads during launch and landing of the Space

Shuttle (STS) is shown in Table 4. The table shows the number of cycles during launch and

landing and the percentage of the total limit stress to be applied during each of these cycles.

Here, total limit stress is defined as the sum of the stresses due to low frequency, random and

acoustic loading.

Table 4: Launch and Landing Spectrum for STS Payloads10

5

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

The handbook requires analysts to use material properties corresponding to the lower bound of

fracture toughness and the upper bound of fatigue crack growth rate (da/dN vs. ΔK) as shown in

Figure 2. Upper bounds of fatigue crack growth rate curves are either visually estimated or

statistically estimated as being three standard deviations above the mean values. Finally,

analyses of known flaws must show that the component has a service life factor of four and a

safety factor of 1.5 against fracture.

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

Figure 2: Crack Growth Rate for Detected Cracks10

The codified practices that are advocated and mandated by these many standards and handbooks

have been carefully developed over several decades and have certainly stood the test of time.

They are invaluable tools for use by the present-day engineer for assessment of vehicle structure.

However, they tend to be reactive rather than proactive and are often based on heuristic

experience, worst-case scenarios and fleet leaders rather than on the specific material, structural

configuration and usage of an individual vehicle. Moreover, they may not be sufficient to

address the future extreme requirements of some future NASA and U.S. Air Force vehicles.

The Digital Twin

Concept

Future generations of aerospace vehicles will require lighter mass while being subjected to

higher loads and more extreme service conditions over longer time periods than the present

generation of vehicles. As a result, demands on structural materials will be greatly increased and

structural margins will necessarily be decreased. Since extreme thermal, mechanical, and

acoustical loadings may be impossible to reproduce in a laboratory at anything more than the

component scale, the identification and quantification of limit states via computational

simulation is needed.

6

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

Because the vehicles are likely to encounter conditions that cannot be foreseen, revolutionary

approaches to verification and validation of the models, simulations and systems must also be

developed. Additionally, the ability to modify and evaluate the consequences of modification to

mission parameters in near-real time will be required. Moreover, the consequences of failure

during a long-duration space mission, where the vehicle is far from home, will almost certainly

be catastrophic.

Future generations of vehicles will rely on increasingly complex, heterogeneous and

multifunctional material forms with increasingly complex failure modes. Thus, the extensive

legacy of historical flight information incorporated in the various standards and handbooks that

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

were based on decades of aircraft and spacecraft design experience, will likely be insufficient to

either certify future extreme vehicles or to guarantee mission success. Additionally, the

extensive physical testing that provided the confidence needed to assure the success of previous

missions has become increasingly expensive to perform. Thus, a complete and fundamental

understanding of physical processes related to degradation at the material, structural and system

level and throughout the vehicle’s life-cycle is needed to move beyond the past decades of

empirical and heuristic design rules that result in inefficiencies and unquantifiable reliability.

Complex missions, particularly those where external support is difficult or impossible, will

necessitate complete real-time management of complex materials, structures and systems that

will ultimately lead to “self-aware” vehicles. The numerous resulting engineering challenges

will necessitate a shift from current empirical-based standard engineering practice to an

additional emphasis on cradle-to-grave sustainment and reliability that will include (1) new

multidisciplinary physics-based methods to ensure robust certification, and (2) new

multidisciplinary methodolgies to ensure life-cycle sustainability. If various best-physics (i.e.,

the most accurate, physically realistic and robust) models can be integrated with one another and

with on-board sensor suites, they will form a basis for certification of vehicles by simulation and

for real-time, continuous, health management of those vehicles during their missions. They will

form the foundation of a Digital Twin15-18.

A Digital Twin is an integrated multiphysics, multiscale, probabilistic simulation of an as-built

vehicle or system that uses the best available physical models, sensor updates, fleet history, etc.,

to mirror the life of its corresponding flying twin. The Digital Twin is ultra-realistic and may

consider one or more important and interdependent vehicle systems, including airframe,

propulsion and energy storage, life support, avionics, thermal protection, etc. The extreme

requirements of the Digital Twin motivate the integration of design of materials and

revolutionary approaches for material processing. Manufacturing anomalies that may affect the

vehicle are also explicitly considered, evaluated and monitored. In addition to the backbone of

high-fidelity physical models of the as-built structure, the Digital Twin integrates sensor data

from the vehicle’s on-board integrated vehicle health management (IVHM) system, maintenance

history and all available historical and fleet data obtained using data mining and text mining.

By combining all of this information, the Digital Twin continuously forecasts the health of the

vehicle or system, the remaining useful life and the probability of mission success. The Digital

Twin can also predict system response to safety critical events and uncover previously unknown

7

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

issues before they become critical by comparing predicted and actual responses. Finally, the

systems on board the Digital Twin are capable of mitigating damage or degradation by activating

self-healing mechanisms or by recommending changes in mission profile to decrease loadings

thereby increasing both the life span and the probability of mission success.

Attributes

A graphical representation of some of the attributes of a Digital Twin is shown in Figure 3. The

narrative of the figure proceeds by column from the left-top pane to the right-bottom pane, as

follows:

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

Figure 3: Graphical Representation of the Digital Twin Paradigm.

Left Top Pane

The Digital Twin incorporates precise models of the as-built configuration of a vehicle or component,

including material microstructure, defects, fabrication anomalies, etc. Determination of these parameters

requires characterization at multiple length scales in the range from less than a micron to meters. Once this

precise “baseline” is determined, the ultra-high fidelity physical models can be used to predict future states

of the vehicle. The montage illustrates the wide range of material types, physical length scales and

structural configurations that may be considered by the Digital Twin. From upper left to lower right are:

failed fibers in a fiber-reinforced composite material, a finite element model of a space vehicle, a specimen

undergoing arc-jet testing, the BSTRA (ball strut tie rod assembly) joint in the Space Shuttle Orbiter main

8

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

engine feedline flowliner, the microstructure of an advanced alloy containing a fatigue crack, a carbon

nanotube and a friction stir-welded aluminum skin-stiffened panel.

Left Middle Pane

The Digital Twin relies heavily on its on-board IVHM system to continuously monitor aerodynamic,

thermal, inertial and other loading in addition to measures of degradation in vehicle health and

performance. The montage illustrates representative IVHM systems and system outputs. From left to right

are: a measured strain field near a fatigue crack, a cyclic loading spectrum, an IVHM fiber optic strain

sensing system and a computer tomography image of delaminations (blue squares) in a laminated

composite material.

Left Bottom Pane

The backbone of the Digital Twin is a suite of ultra-high fidelity physical models of the vehicle and its

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

systems and structures of interest. These may include models of one or more important and interdependent

vehicle systems, including airframe, propulsion and energy storage, life support, avionics, thermal

protection, etc. The montage illustrates the wide range of physical phenomena, models and modeling

outputs that may be included in the Digital Twin. From upper left to lower right are: an illustration of an

atom modeled in a quantum mechanics or molecular dynamics simulation, a three-dimensional finite

element simulation of deformation and fracture in an aluminum alloy, a hypothetical computational fluid

dynamics simulation of a vehicle during atmospheric re-entry, prediction of the number of cycles needed to

nucleate a fatigue crack (Nnuc), a finite element simulation of mode shapes in the Space Shuttle Orbiter

main engine feedline flowliner, a multi-scale model of crack growth, and a simple model of radiation

transport through boron-nitride nanotubes as a neutron shielding material.

Center Top Pane

The Digital Twin uses its on-board IVHM system to update the physics-based models with sensor data and

produce continuously refined predictions of vehicle health and probability of mission success. It can also

perform option and impact investigation to answer questions regarding the impact of changes to mission

profile on all future conditions of the vehicle. The figure shows Bayesian updates of the probability of

failure as a function of time wherein sensor data is incorporated to increase accuracy and decrease

uncertainty in the predictions.

Center Pane

Each Digital Twin is uniquely developed for a particular vehicle and may be employed to “fly” future

missions during the design and certification process, continuously assess health during flight, perform in-

situ forensics of the effect of potential or real hazards and virtually evaluate the effect of potential changes

to the mission. A hypothetical vehicle is shown in the figure.

Center Bottom Pane

The Digital Twin integrates fleet data, maintenance reports and other historical information via data mining

and text mining to further inform simulations of the vehicle. The figure shows a notional representation of

the computational and data processing capabilities of the Digital Twin as represented by the PLEIADES

supercomputer at NASA Ames Research Center, a model of the human brain and streams of text and data

supporting the Digital Twin.

Right Top Pane

The Digital Twin is enabling to virtual digital certification and sustainment by replacing past decades of

empirically based design rules that result in structural inefficiencies and unquantifiable reliability with

ultra-high fidelity simulations, sensor systems and data that are immediately relevant to each unique

vehicle. The figure shows several of the many existing standards and handbooks that may be replaced by

the Digital Twin.

Right Middle Pane

The Digital Twin mirrors the actual flight of the flying twin by using sensor updates to continuously assess

vehicle health including determining remaining life of structural components and systems, estimating

probability of mission success and evaluating in-situ repair (self-healing), in-flight mitigation or load

9

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

alleviation strategies and other mission modifications. The effects of modifications of mission parameters

are evaluated and previously unforeseen consequences are evaluated. The figure shows estimates of

remaining useful life (RUL) as a function of the number of load cycles.

Right Bottom Pane

The Digital Twin also uses its assessment of historical norms, fabrication/manufacturing reports and

maintenance data (where available) combined with Bayesian updates to high-fidelity models to perform in-

situ forensics, including anomaly detection/diagnosis and fault tree analysis. The figure shows a schematic

of a fault tree associated with the hypothetical failure of a sensor.

Identification of Near-Term Opportunities

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

Many of the technologies critical for the Digital Twin are currently being developed under

related visions for multi-scale and multi-physics modeling, structural health management, high-

performance computing and others. Unlike those individual visions, the vision for the Digital

Twin integrates the broad range of technologies with a singular focus. However, such an

ambitious concept is unlikely to attain maturity for many decades, so a series of intermediate

steps is required. Among these steps is the Air Force Research Laboratory (AFRL) Digital

Twin: Spiral 117, a plan to integrate existing state-of-the-art technologies, benchmark current

capabilities and identify gaps using components from an existing U.S. Air Force vehicle,

specifically, the F-15, as a testbed. Another approach, being considered by NASA, is to focus on

a small highly critical non-redundant component such as a microelectromechanical system

(MEMS) that has characteristic length scales accessible with only the highest fidelity simulation

methods and health management tools available. By exercising such ultra-high fidelity

approaches on flight hardware, the shortcomings of the existing state-of-the-art in multiscale

modeling, in-situ experimentation and material state awareness will be highlighted.

Advantages Over Conventional Approaches

As a virtual instantiation of a flying vehicle, the Digital Twin is expected to be able to experience

every event that its flying twin experiences. Because of its ability to mirror the life of a specific

vehicle in an as-built state, the Digital Twin will necessarily revolutionize certification, fleet

management and sustainment. It will also decrease system weight by reducing reliance on

statistical distributions of material properties, heuristic design philosophies, physical testing and

assumed similitude between testing and operational conditions. Once the vehicle is launched,

the Digital Twin will increase the reliability of the flying vehicle because of its ability to

continuously monitor and mitigate degradation and anomalous events. Additionally, it will

enable mission managers to make knowledgeable decisions regarding the consequences of

possible in-flight changes to a vehicle’s mission.

Influence on National Goals

Although the Digital Twin represents a revolution in the paradigms used for certification, fleet

management and sustainment in support of extreme flight missions, it has the ability to influence

other National priorities and goals. In addition to its prominence in the recently-published

10

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

roadmaps of NASA’s Office of Chief Technologist (OCT)15-16 and plans of the Air Force

Research Laboratory17-18, the Digital Twin paradigm can provide focus to the recent advocacy of

the National Science Foundation (NSF) and the National Research Council (NRC) in the areas of

Simulation Based Engineering Science (SBES)19, Integrated Computational Materials

Engineering (ICME)20 and Materials State Awareness21.

Many of the concepts discussed in the NSF’s recommendations for SBES are pervasive

throughout the themes of the Digital Twin, including, multiscale modeling of materials, dynamic

simulation of sensors, and verification and validation. Because the vehicles needed for future

extreme missions are unlikely to be developed using existing material forms, the design and

development of new enabling (e.g., multifunctional, nanostructured, ultra-durable) materials is

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

required and is well aligned with the NRC’s ICME roadmap. Additionally, an understanding of

the exact state of the structure of the vehicle or its systems, including the existence of defects at

the microstructural and, possibly, the atomistic scale, is required as a baseline for ultra-high

fidelity simulations. The ability to assess the evolution of defects is a critical element within the

Digital Twin’s on-board IVHM system and is well aligned with the NRC’s advocacy for

developments in Materials State Awareness.

Figure 4 is taken from the executive summary of the NASA OCT roadmap for technology area

12 (TA 12)16 and proposes a broad spectrum of future NASA technologies that can be focused by

the Digital Twin. The headings in the ellipses within Figure 4 represent the numbers and titles of

various sections in the OCT TA 12 roadmap where the technologies are discussed.

Potential spin-offs from the development of the Digital Twin span the breadth of the Nation’s

industrial and manufacturing sectors, infrastructure and development of nanotechnology. By

replacing conventional engineering practices with an understanding of the degradation of an

individual vehicle or vehicle system, the paradigm of the Digital Twin will impact the way that

physical items ranging from micro-devices to civil infrastructure are developed, certified and

maintained.

11

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

16

Figure 4: Integration of Technologies within a Digital Twin

Summary

Future generations of aerospace vehicles will require lighter mass while being subjected to

higher loads and more extreme service conditions over longer time periods than the present

generation of vehicles. As a result, demands on structural materials will be greatly increased and

structural margins will necessarily be decreased. Additionally, the requirements placed on other

systems and subsystems will be greater than those previously experienced even though demands

for long-term reliability will increase. Because extreme thermal, mechanical, and acoustical

loadings may be impossible to reproduce in a laboratory at anything more than the component

scale, the identification and quantification of limit states via computational simulation is needed.

Additionally, the vehicles are likely to encounter conditions that cannot be foreseen. Thus, the

ability to modify and evaluate the modification of mission parameters in near-real time will be

required.

Current approaches to certification, fleet management and sustainment of NASA and U.S. Air

Force vehicles are largely based on statistical distributions of material properties, heuristic

design philosophies, physical testing and assumed similitude between testing and operational

conditions and will likely be unable to address future extreme requirements. Some of the current

approaches to certification, fleet management and sustainment were illustrated through the

12

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

discussion of examples taken from several documents, including: NASA-STD-5001A, NASA-

STD-5019 and NASA-HDBK-5010.

To address the shortcomings of conventional approaches, the paradigm of a Digital Twin was

presented. The Digital Twin is an integrated multiphysics, multiscale, probabilistic simulation of

an as-built vehicle or system that uses the best available physical models, sensor updates, fleet

history, etc., to mirror the life of its corresponding flying twin. The Digital Twin is ultra-realistic

and may consider one or more important and interdependent vehicle systems. The Digital Twin

integrates sensor data from the vehicle’s on-board IVHM system, maintenance history and all

available historical and fleet data. By combining this information, the Digital Twin continuously

forecasts the health of the vehicle or system, the remaining useful life and the probability of

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

mission success. The systems on board the Digital Twin are also capable of mitigating damage

or degradation by activating self-healing mechanisms or by recommending changes in mission

profile to decrease loadings thereby increasing both the life span and the probability of mission

success.

Near-term opportunities for early development of the Digital Twin paradigm at AFRL and

NASA were discussed and include the integration of various existing state-of-the-art

technologies, benchmarking of current capabilities and identification of gaps using critical flight

components as testbeds. Advantages of the Digital Twin, its potential influence on far reaching

NASA, U.S. Air Force goals and broader National goals were also discussed.

References

1

Anon., “Structural Design and Test Factors of Safety for Spaceflight Hardware,” NASA-STD-

5001A, August 2008.

2

Anon., “Fracture Control Requirements for Spaceflight Hardware,” NASA-STD-5019, January

2008.

3

Anon., “Standard Materials and Process Requirements for Spacecraft,” NASA-STD-6016, July

2008.

4

Anon., “Non-Destructive Evaluation Requirements for Fracture Control Programs,” NASA-

STD-5009, April 2008.

5

Anon., “Guidelines for the Selection of Metallic Materials for Stress Corrosion Cracking

Resistance in Sodium Chloride Environments,” MSFC-STD-3029, May 2000.

6

Anon., “Fatigue Crack Growth Computer Program NASGRO,” Version 3.0, JSC 22267B,

November 2001.

7

Anon., “Strength and Life Assessment Requirements for Liquid Fueled Space Propulsion

System Engines,” NASA-STD-5012, June 2006.

8

Anon., “Standard for Models and Simulations,” NASA-STD-7009, July 2008.

9

Anon., “Fracture Control Requirements for Payloads Using the Space Shuttle,” NASA-STD-

5003, October 1996.

13

American Institute of Aeronautics and Astronautics

Paper for the 53rd Structures, Structural Dynamics, and Materials Conference:

Special Session on the Digital Twin

10

Anon., “Fracture Control Implementation Handbook for Payloads, Experiments, and Similar

Hardware,” NASA-STD-5010, May 2005.

11

Anon., “Fracture Control Requirements, Nondestructive for Aircraft and Missile Materials and

Parts,” Mil-HDBK-6870A, August 2001.

12

Anon., “Metallic Materials Properties Development and Standardization,” DOT/FAA/AR-

MMPDS-03, 2007.

13

Anon., “Space Systems – Composite Overwrapped Pressure Vessels,” ANSI/AIAA S-081,

December 2000.

14

Anon., “Rules for Construction of Pressure Vessels,” ASME Boiler and Pressure Vessel Code,

Downloaded by CARLETON UNIVERSITY LIBRARY on November 28, 2014 | http://arc.aiaa.org | DOI: 10.2514/6.2012-1818

Section VIII, September 2004.

15

Shafto, M., Conroy, M., Doyle, R., Glaessgen, E., Kemp, C., LeMoigne, J. and Wang, L.,

“Technology Area 11: Modeling, Simulation, Information Technology and Processing

Roadmap,” NASA Office of Chief Technologist, November, 2010.

16

Piascik, R., Vickers, J., Lowry, D., Scotti, S., Stewart, J. and Calomino, A., “Technology Area

12: Materials, Structures, Mechanical Systems, and Manufacturing Roadmap,” NASA Office of

Chief Technologist, November, 2010.

17

Kobryn, P.A. and Tuegel, E.J., “Condition-based Maintenance Plus Structural Integrity

(CBM+SI) & the Airframe Digital Twin,” USAF Air Force Research Laboratory, 88ABW-

201101428, March 2011.

18

Tuegel, E.J., Ingraffea, A.R., Eason, T.J. and Spottswood, S.M., “Reengineering Aircraft

Structural Life Prediction Using a Digital Twin,” International Journal of Aerospace

Engineering, doi:10.1155/2011/154798, 2011.

19

Anon., “Simulation-Based Engineering Science: Revolutionizing Engineering Science through

Simulation,” National Science Foundation, May 2006.

20

Anon., “Integrated Computational Materials Engineering: A Transformational Discipline for

Improved Competitiveness and National Security,” National Research Council, ISBN: 0-309-

12000-4, 2008.

21

Anon., “Proceedings of a Workshop on Materials State Awareness,” National Research

Council, ISBN: 0-309-12166-3, 2008.

14

American Institute of Aeronautics and Astronautics

You might also like

- Electronics Reliability and Measurement Technology: Nondestructive EvaluationFrom EverandElectronics Reliability and Measurement Technology: Nondestructive EvaluationNo ratings yet

- Digital Twin Paradigm for Future NASA and USAF VehiclesDocument14 pagesDigital Twin Paradigm for Future NASA and USAF VehiclesANDERSON ROMERO FLOREZNo ratings yet

- Experimental Wind Tunnel Investigtionof Propeller Wing Interactional AerodynamicsDocument21 pagesExperimental Wind Tunnel Investigtionof Propeller Wing Interactional AerodynamicsSBNo ratings yet

- Jurnal 19Document24 pagesJurnal 19fikri aryantoNo ratings yet

- Case Studies in Initial Sizing For Hybrid-Electric General Aviation AircraftDocument22 pagesCase Studies in Initial Sizing For Hybrid-Electric General Aviation AircraftIkeaMonsterNo ratings yet

- Scaling Laws For Radial Clearance and Support Structure Stiffness of Radial Foil BearingsDocument8 pagesScaling Laws For Radial Clearance and Support Structure Stiffness of Radial Foil BearingswataruNo ratings yet

- Roueche Et Al 2024 Performance of Hurricane Resistant Housing During The 2022 Arabi Louisiana TornadoDocument18 pagesRoueche Et Al 2024 Performance of Hurricane Resistant Housing During The 2022 Arabi Louisiana TornadoGUSTAVO ANDRÉS NIÑO BAUTISTANo ratings yet

- E-Analysis of High-Rise Buildings Subjected To Win PDFDocument16 pagesE-Analysis of High-Rise Buildings Subjected To Win PDFKassemDeebNo ratings yet

- Water RocketDocument2 pagesWater Rocketrupaliaher417No ratings yet

- Dihel Et Al 2023 Classifying Aircraft Using Velocity Data With Support Vector Machines and Likelihood Ratio TestsDocument14 pagesDihel Et Al 2023 Classifying Aircraft Using Velocity Data With Support Vector Machines and Likelihood Ratio Testsae21s043No ratings yet

- HCV SuspensionDocument9 pagesHCV SuspensionAnirudh PanickerNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Ali Alnedawi, Riyadh Al-Ameri, Kali Prasad NepalDocument12 pagesJournal of Rock Mechanics and Geotechnical Engineering: Ali Alnedawi, Riyadh Al-Ameri, Kali Prasad NepalYasser FarhanNo ratings yet

- Artificial Neural Network Models for Airport Rigid Pavement Top-Down Critical Stress Predictions Sensitivity EvaluationDocument13 pagesArtificial Neural Network Models for Airport Rigid Pavement Top-Down Critical Stress Predictions Sensitivity EvaluationLucas Cavalcante de AlmeidaNo ratings yet

- Synergistic Smart Morphing Aileron: Aero-Structural Performance AnalysisDocument14 pagesSynergistic Smart Morphing Aileron: Aero-Structural Performance Analysisfelip987No ratings yet

- Mars Science Laboratory Parachute Development Test Program OnuferDocument16 pagesMars Science Laboratory Parachute Development Test Program Onufer黄星No ratings yet

- Kapania Et Al 2012 Optimal Design of Unitized Panels With Curvilinear StiffenersDocument30 pagesKapania Et Al 2012 Optimal Design of Unitized Panels With Curvilinear Stiffeners785902070No ratings yet

- Systematic Literature Review and Mapping of The Prediction of Pile CapacitiesDocument12 pagesSystematic Literature Review and Mapping of The Prediction of Pile CapacitiesCaio Augusto Lemke CostaNo ratings yet

- H Robust Control Design For The Nasa Airstar Flight Test VehicleDocument14 pagesH Robust Control Design For The Nasa Airstar Flight Test Vehicleoni_centNo ratings yet

- Gerard 1962Document6 pagesGerard 1962obaidullah.dsuNo ratings yet

- Assessment of Simulated Wind Data Requirements For Wind Integration StudiesDocument8 pagesAssessment of Simulated Wind Data Requirements For Wind Integration Studiesyeprem82No ratings yet

- Aerodynamic Design Considerations For Tiltrotor Wing Extensions and WingletsDocument12 pagesAerodynamic Design Considerations For Tiltrotor Wing Extensions and WingletsYonghui XUNo ratings yet

- Weietal Nonlinearaeroelasticityof SUGARTBWDocument23 pagesWeietal Nonlinearaeroelasticityof SUGARTBWMossNo ratings yet

- Sensitivity of Seismic Response and Fragility To PDocument10 pagesSensitivity of Seismic Response and Fragility To Pahmad nafek august fouzyNo ratings yet

- Dynamic Failure Analysisof Ship Energy SystemsDocument11 pagesDynamic Failure Analysisof Ship Energy SystemsDAN CHAMZNo ratings yet

- Finite Element Analysis of Composite Laminate using ANSYSDocument9 pagesFinite Element Analysis of Composite Laminate using ANSYSKP HARISANKARNo ratings yet

- IMECE2018-88027: Aerodynamics Analysis For Optimization The Design of A Baja Sae ChassisDocument10 pagesIMECE2018-88027: Aerodynamics Analysis For Optimization The Design of A Baja Sae ChassisLIBETH ANDREA HERNANDEZ FRANCONo ratings yet

- Development of A Sizing and Analysis Tool For Electrohydrostatic and Electromechanical Actuators For The More Electric AircraftDocument17 pagesDevelopment of A Sizing and Analysis Tool For Electrohydrostatic and Electromechanical Actuators For The More Electric Aircraftjacob leeNo ratings yet

- Soybean Breeding Suitable To Rice Based PDFDocument37 pagesSoybean Breeding Suitable To Rice Based PDFGarten ZergNo ratings yet

- Extreme Load Estimation For Wind Turbines: Issues and Opportunities For Improved PracticeDocument12 pagesExtreme Load Estimation For Wind Turbines: Issues and Opportunities For Improved Practiceenc313169No ratings yet

- Comparative Analysis of Energy Storage Devices for Wind PowerDocument12 pagesComparative Analysis of Energy Storage Devices for Wind PowerRaihan NurNo ratings yet

- Supersonic Business Jet Conceptual Design in A Multidisciplinary Design Analysis Optimization EnvironmentDocument21 pagesSupersonic Business Jet Conceptual Design in A Multidisciplinary Design Analysis Optimization Environmenthemant gahnoliaNo ratings yet

- Supersonic Business Jet Conceptual Design in A Multidisciplinary Design Analysis Optimization EnvironmentDocument21 pagesSupersonic Business Jet Conceptual Design in A Multidisciplinary Design Analysis Optimization Environmenthemant gahnoliaNo ratings yet

- Rspa 2020 0079Document23 pagesRspa 2020 0079Nebiyu TenayeNo ratings yet

- Design, Construction, and Flight Testing of The World's Fastest Micro-Scale QuadcopterDocument15 pagesDesign, Construction, and Flight Testing of The World's Fastest Micro-Scale QuadcoptergrafpapNo ratings yet

- Evaluating The Effectiveness of A Guided Projectile: Georgia Institute of Technology/GTRI/ATAS, Atlanta, GA 30332-0844Document25 pagesEvaluating The Effectiveness of A Guided Projectile: Georgia Institute of Technology/GTRI/ATAS, Atlanta, GA 30332-0844oso5755No ratings yet

- Batool, A., VandenBerge, D.R., and Brandon, T.L. (2015). Practical application of blanket theory and the finite-element method to levee unDocument10 pagesBatool, A., VandenBerge, D.R., and Brandon, T.L. (2015). Practical application of blanket theory and the finite-element method to levee un万少震No ratings yet

- Editor'S Note: Thank You Johanna and Jackie Structural Safety and ReliabilityDocument3 pagesEditor'S Note: Thank You Johanna and Jackie Structural Safety and ReliabilityMladen MilicevicNo ratings yet

- Structural supply chain complexityDocument36 pagesStructural supply chain complexityfoenemNo ratings yet

- Gonzaga 2021 IOP Conf. Ser. Mater. Sci. Eng. 1109 012023Document8 pagesGonzaga 2021 IOP Conf. Ser. Mater. Sci. Eng. 1109 012023Fernando BatistaNo ratings yet

- Assessing Measures to Reduce Energy Losses in Distribution SystemsDocument10 pagesAssessing Measures to Reduce Energy Losses in Distribution SystemsYahaya FatawuNo ratings yet

- Applied Ocean Research: Reza Yousefi, Rouzbeh Shafaghat, Mostafa ShakeriDocument9 pagesApplied Ocean Research: Reza Yousefi, Rouzbeh Shafaghat, Mostafa ShakeriMaciej ReichelNo ratings yet

- Effect of Elevational and Member Damage On Jacket StrengthDocument8 pagesEffect of Elevational and Member Damage On Jacket StrengthKirolos AwadNo ratings yet

- 2023 Validation of FAA-Proposed Airport Pavement Serviceability Level Index ComponentsDocument13 pages2023 Validation of FAA-Proposed Airport Pavement Serviceability Level Index Componentsgandhara11No ratings yet

- Tailoring Network Properties of Castor Oil-Based Binder Through Factorial DesignDocument10 pagesTailoring Network Properties of Castor Oil-Based Binder Through Factorial DesignBernard ShamNo ratings yet

- WisconsinUNV CS 012716 Letter WebDocument2 pagesWisconsinUNV CS 012716 Letter WebADITYA DEVOLNo ratings yet

- Aeroelastic Tailoring for Aircraft PerformanceDocument13 pagesAeroelastic Tailoring for Aircraft Performancervramkumar78No ratings yet

- gruppofratturaojs,+numero_55_art_06Document12 pagesgruppofratturaojs,+numero_55_art_06Ezgi PelitNo ratings yet

- Bhatia 2003Document9 pagesBhatia 2003Burak ÇınarNo ratings yet

- Determination of Environmental Load Factors For ISO 19902 Code in Offshore Malaysia Using FORM Structural Reliability MethodDocument14 pagesDetermination of Environmental Load Factors For ISO 19902 Code in Offshore Malaysia Using FORM Structural Reliability MethodBesim QelajNo ratings yet

- Corle 2022Document12 pagesCorle 2022Yonghui XUNo ratings yet

- Empirical - Methods - Vs - Time - Series - Models BakkenDocument29 pagesEmpirical - Methods - Vs - Time - Series - Models BakkenColin JordanNo ratings yet

- 2015 Elasto RayDocument61 pages2015 Elasto RayRamesh SelvarajNo ratings yet

- A Robust CFD Methodology For Physically Realistic and Economically Feasible Results in Racing - Part II Intake CowlDocument27 pagesA Robust CFD Methodology For Physically Realistic and Economically Feasible Results in Racing - Part II Intake CowlAllan Bruno RosaNo ratings yet

- 2018EATS Review of DEP Hyun D. 6.2018 4998Document21 pages2018EATS Review of DEP Hyun D. 6.2018 4998IsamarMM01No ratings yet

- Simulation: Terminology For Model CredibilityDocument3 pagesSimulation: Terminology For Model CredibilityHectorNo ratings yet

- (211113) Tabulasi Cawangan SyarikatDocument24 pages(211113) Tabulasi Cawangan SyarikatMohd AnuarNo ratings yet

- Wang2017 ReliabilityDocument20 pagesWang2017 Reliabilityhemal4379No ratings yet

- C - Efficient and Robust Shell Design of Space Launcher Vehicle Structures - FRIEDRICH RUESS SCHRÖDERDocument19 pagesC - Efficient and Robust Shell Design of Space Launcher Vehicle Structures - FRIEDRICH RUESS SCHRÖDERJean DujardinNo ratings yet

- Integrated PowerModeling For A Solar-Powered, Computationally-Intensive Unmanned AircraftvDocument21 pagesIntegrated PowerModeling For A Solar-Powered, Computationally-Intensive Unmanned Aircraftv이재국No ratings yet

- Aiaaaviation2017 DLRF6Document23 pagesAiaaaviation2017 DLRF6Mohd AnuarNo ratings yet

- Everything You Need To Know About Scientific PublishingDocument11 pagesEverything You Need To Know About Scientific PublishingnakibosmanNo ratings yet

- Accessing Google Classroom - Student View: Click The + Sign To Join A ClassDocument1 pageAccessing Google Classroom - Student View: Click The + Sign To Join A ClassnakibosmanNo ratings yet

- Renewable Ethanol For Beverage and Industrial Uses: A Versatile and High Quality ProductDocument2 pagesRenewable Ethanol For Beverage and Industrial Uses: A Versatile and High Quality ProductnakibosmanNo ratings yet

- E-Return Filing Sowftware E Env Ii WBQG: (BZZB GKVD U Lvjvi C×WZ)Document10 pagesE-Return Filing Sowftware E Env Ii WBQG: (BZZB GKVD U Lvjvi C×WZ)nakibosmanNo ratings yet

- Pharmaceutical Applications of Isopropyl Alcohol. I. As A Solvent in Pharmaceutical ManufacturingDocument6 pagesPharmaceutical Applications of Isopropyl Alcohol. I. As A Solvent in Pharmaceutical ManufacturingnakibosmanNo ratings yet

- Transworld Mercantile Corporation: For Simplified It Solutions!Document6 pagesTransworld Mercantile Corporation: For Simplified It Solutions!nakibosmanNo ratings yet

- 40768-Article Text-143534-1-10-20190327Document3 pages40768-Article Text-143534-1-10-20190327nakibosmanNo ratings yet

- Bangabandhu Sheikh Mujib Industrial CityDocument150 pagesBangabandhu Sheikh Mujib Industrial CitynakibosmanNo ratings yet

- Daily Productivity ListDocument1 pageDaily Productivity ListnakibosmanNo ratings yet

- Masud Rana - Beduin Konya PDFDocument100 pagesMasud Rana - Beduin Konya PDFzakaria200811060No ratings yet

- Yamaha MT-125 OMDocument96 pagesYamaha MT-125 OMnakibosmanNo ratings yet

- National Blockchain Strategy - BangladeshDocument49 pagesNational Blockchain Strategy - BangladeshnakibosmanNo ratings yet

- Argumenta 22 Talia Morag The Tracking Dogma in The Philosophy of EmotionDocument21 pagesArgumenta 22 Talia Morag The Tracking Dogma in The Philosophy of EmotionnakibosmanNo ratings yet

- CA - Rnip Process Map English PDFDocument1 pageCA - Rnip Process Map English PDFnakibosmanNo ratings yet

- Dui NumberDocument201 pagesDui NumbernakibosmanNo ratings yet

- Khepa NortokDocument98 pagesKhepa NortoknakibosmanNo ratings yet

- A Study On SME Banking System and Procedure of BRAC Bank LimitedDocument82 pagesA Study On SME Banking System and Procedure of BRAC Bank LimitedShowkatul IslamNo ratings yet

- Vet Pathol-2004-Nusbaum-453 PDFDocument1 pageVet Pathol-2004-Nusbaum-453 PDFnakibosmanNo ratings yet

- SRO164 Law 2016 26 Customs Passenger (NonTourist) Baggage (Import) Rules 2016AmendedInJune2017Document10 pagesSRO164 Law 2016 26 Customs Passenger (NonTourist) Baggage (Import) Rules 2016AmendedInJune2017ferdous98No ratings yet

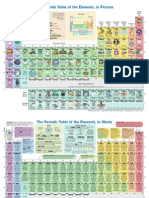

- The Periodic Table of Elements, in PicturesDocument2 pagesThe Periodic Table of Elements, in Picturesrustyy88100% (1)

- APPL Company ProfileDocument26 pagesAPPL Company ProfilenakibosmanNo ratings yet

- Argumenta 22 Talia Morag The Tracking Dogma in The Philosophy of EmotionDocument21 pagesArgumenta 22 Talia Morag The Tracking Dogma in The Philosophy of EmotionnakibosmanNo ratings yet

- Microbiology Lab BookDocument83 pagesMicrobiology Lab BookLavina D'costa100% (6)

- Significance of Marketing Activities in Garments Industry - A Case Study of BangladeshDocument10 pagesSignificance of Marketing Activities in Garments Industry - A Case Study of BangladeshnakibosmanNo ratings yet

- BatDocument14 pagesBatnakibosmanNo ratings yet

- Rules of BusinessDocument36 pagesRules of BusinessnakibosmanNo ratings yet

- SubwayDocument6 pagesSubwaySteven ChewNo ratings yet

- A Comprehensive StudyDocument10 pagesA Comprehensive StudynakibosmanNo ratings yet

- Indian RailwaysDocument19 pagesIndian RailwaysnakibosmanNo ratings yet

- Smart Ports Web Version PDFDocument58 pagesSmart Ports Web Version PDFvelisbarNo ratings yet

- Team: Sherlok: Akash SagarDocument8 pagesTeam: Sherlok: Akash SagarkartikNo ratings yet

- Digital Thread Formulation for Data-Driven Engineering DesignDocument38 pagesDigital Thread Formulation for Data-Driven Engineering Designsivaa hzNo ratings yet

- Trango Tech Digitalization Construction Report (Final)Document27 pagesTrango Tech Digitalization Construction Report (Final)Bilal KhanNo ratings yet

- Tech Trends Exec SummaryDocument18 pagesTech Trends Exec Summaryjuan pablo a dalmassoNo ratings yet

- Digital Twins Revolutionize Shipbuilding: White PaperDocument8 pagesDigital Twins Revolutionize Shipbuilding: White PapervimalrajpmNo ratings yet

- Digital Twin Technology - 2022 - VohraDocument265 pagesDigital Twin Technology - 2022 - Vohralolpoll771No ratings yet

- 998-22735626 - Software Tools - GMA - BrochureDocument20 pages998-22735626 - Software Tools - GMA - Brochureabderraoufdob2No ratings yet

- Computer Vision White PaperDocument16 pagesComputer Vision White PaperGustavo MontañoNo ratings yet

- Digital Twin Point of ViewDocument5 pagesDigital Twin Point of Viewmaximusala83No ratings yet

- Data Management in Industry 4.0: State of The Art and Open ChallengesDocument43 pagesData Management in Industry 4.0: State of The Art and Open ChallengesEng Tennyson SigaukeNo ratings yet

- Omniverse Enterprise 5 Steps Digital Twins EbookDocument11 pagesOmniverse Enterprise 5 Steps Digital Twins EbookDávid AnnamNo ratings yet

- AI in Smart Energy Systems Lecture 2 NotesDocument13 pagesAI in Smart Energy Systems Lecture 2 NotesKashif SubhanNo ratings yet

- Digital Twins - A Survey On Enabling Technologies, Challenges, Trends and Future Prospects - Compressed PDFDocument40 pagesDigital Twins - A Survey On Enabling Technologies, Challenges, Trends and Future Prospects - Compressed PDFKelner XavierNo ratings yet

- Cooperative Federated Learning and Model Update Verification in Blockchain Empowered Digital Twin Edge NetworksDocument14 pagesCooperative Federated Learning and Model Update Verification in Blockchain Empowered Digital Twin Edge NetworksStephen BrowserNo ratings yet

- YearinInfrastructure2018 DL PDFDocument332 pagesYearinInfrastructure2018 DL PDFLovepreet singhNo ratings yet

- GE APM Ged-Enterprise-WhitepaperDocument9 pagesGE APM Ged-Enterprise-WhitepaperThereNo ratings yet

- BK-IT26 Sensor Tech (Brochure) 10Document6 pagesBK-IT26 Sensor Tech (Brochure) 10zackyat7976No ratings yet

- DigiGuide Value Case.v4Document35 pagesDigiGuide Value Case.v4sunx62No ratings yet

- Digital Twin TechnologyDocument273 pagesDigital Twin TechnologySyntha100% (4)

- Construction 4.0Document43 pagesConstruction 4.0Hamda GhaffarNo ratings yet

- Motion Control NC63 Complete English 2022 08Document80 pagesMotion Control NC63 Complete English 2022 08vinodNo ratings yet

- Next Generation Digital TwinDocument11 pagesNext Generation Digital TwinDanielleBarretoBlancoNo ratings yet

- Maximize Asset Performance with SAP Intelligent Asset ManagementDocument31 pagesMaximize Asset Performance with SAP Intelligent Asset Managementpraveen RapetiNo ratings yet

- Digital Twins The Art of The Possible in Product Development and Beyond VFDocument6 pagesDigital Twins The Art of The Possible in Product Development and Beyond VFvinaytoshNo ratings yet

- Data Visualization in Internet of Things: Tools, Methodologies, and ChallengesDocument11 pagesData Visualization in Internet of Things: Tools, Methodologies, and Challengessusheela bhatNo ratings yet

- Living in The It EraDocument15 pagesLiving in The It EraTantan Whoot100% (1)

- Roles of Artificial Intelligence in Construction Engineering and Management - A Critical Review and Future TrendsDocument21 pagesRoles of Artificial Intelligence in Construction Engineering and Management - A Critical Review and Future TrendsSung Woo ShinNo ratings yet

- Virtual Product Development Matter ForDocument1 pageVirtual Product Development Matter ForLEENA KUJUR 21221022No ratings yet

- Ir 4 NotesDocument9 pagesIr 4 NotesNadrah HassanNo ratings yet