Professional Documents

Culture Documents

SNB Viscosifier For Do

Uploaded by

Mas SusiloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SNB Viscosifier For Do

Uploaded by

Mas SusiloCopyright:

Available Formats

TotalFinaElf E& P WIRE LINE, SNUBBING, WORKSHOP

STANDING INSTRUCTIONS NO. 05 - 0121

PAGE 1/8

REVISION 0

Indonésie VISCOSIFIER FOR DIESEL OIL DATE 05/1989

Document Information

Cover Page

Location

Area

Document Type STANDING INSTRUCTIONS

Document Number 05 – 0121

Revision 0

Description Line 1 VISCOSIFIER FOR DIESEL OIL

Description Line 2

Date 07/06/02

Total Pages 8

K S/………. Visa : KS/………… Visa :

TotalFinaElf E& P WIRE LINE, SNUBBING, WORKSHOP

STANDING INSTRUCTIONS NO. 05 - 0121

PAGE 2/8

REVISION 0

Indonésie VISCOSIFIER FOR DIESEL OIL DATE 05/1989

APPLICATIONS :

Sand washing, diesel Hivis pills, oil base carrier fluid for gravel pack sand and facturation.

COMPOSITION AND DATE :

For 1000 US GAL of diesel oil :

- 12 LBS J 602 PH control

- 10 US GAL J 601 Activator

- 10 US GAL J 421 Gelling agent

Viscosity obtained is 135 cps in down hole condition at 1500 m. The viscosity curve is

about linear. If quantities cut by half, viscosity is about half.

Increase in the same way.

MIXING PROCEDURE :

1. Mix J 601 and J 602 together.

2. Pour this mixture into the diesel oil to viscosity, then mix.

3. Add J 421 stir thoroughly.

Notes :

1. A gel breaker can be used if needed, check with Dowell Schlumberger for composition

and adjustment of viscosity needed.

2. Crude oil can be viscosity, depending on the composition.

K S/………. Visa : KS/………… Visa :

TotalFinaElf E& P WIRE LINE, SNUBBING, WORKSHOP

STANDING INSTRUCTIONS NO. 05 - 0121

PAGE 3/8

REVISION 0

Indonésie VISCOSIFIER FOR DIESEL OIL DATE 05/1989

P.T. Dowell Schlumberger Indonesia

BALIKPAPAN LABORATORY REPORT

REPORT NUMBER :

BRI / 89 / 092

SUBJECT : Viscosity of YF “GO”

CUSTOMER : TOTALFINAELF E & P INDONESIE

FIELD : Handil

WELL : -

RIG : -

REQUESTED BY : T. Dornoy

L A R No. : memo

PREPARED BY : DATE : 03/06/89

S. Ma’arif

REVIEWED BY : DATE : 03/06/89

T. Dornoy

DISTRIBUTION : - LRI

- ASL

This job design is based on valuable know-how developed by or for DS The submission of this job design by DS and any use thereof client is based on the

understanding that : (1) the client will use this design solely for evaluation and will make on commercial or other use thereof except for evaluation without

first obtaining prior written approval from DS and (2) the client will not communicate any information regarding this job design to any third party and (3)

the job design being based on engineering theory and as there are many well conditions which are uncertain unknown and not subject to our control DS

does not and cannot warrant the accuracy or correctness of the recommendations stipulated in the job design.

K S/………. Visa : KS/………… Visa :

TotalFinaElf E& P WIRE LINE, SNUBBING, WORKSHOP

STANDING INSTRUCTIONS NO. 05 - 0121

PAGE 4/8

REVISION 0

Indonésie VISCOSIFIER FOR DIESEL OIL DATE 05/1989

BRI/89/092 Page : 02

Information requested :

Rheology

Summary :

Test temperature : 80° F, 150° F, and 170° F.

YF “GO” composition :

980 gal diesel oil

+ 10 gal J421 (J292)

+ 12 gal J601 (J366)

+ 10 gal J602 (J353)

Result :

Rheology (R1, B1, F1) Calculated Visc.

At 170 sec.

At 80 °F = 110 : 95 : 85 : 49 : 45 255 cps

At 150 °F = 85 : 79 : 71 : 21 : 15 213 cps

At 170 ° F = 55 : 50 : 40 : 9 : 6 120 cps

Mixing Procedure :

1. Mix J601 and J602 until J601 fully dissolved

2. Mix J421 and mixture of J601 & J602 into calculated amount of diesel oil

simultaneously.

3. Keep stirring until gel occurred.

K S/………. Visa : KS/………… Visa :

TotalFinaElf E& P WIRE LINE, SNUBBING, WORKSHOP

STANDING INSTRUCTIONS NO. 05 - 0121

PAGE 5/8

REVISION 0

Indonésie VISCOSIFIER FOR DIESEL OIL DATE 05/1989

P.T. Dowell Schlumberger Indonesia

BALIKPAPAN LABORATORY REPORT

REPORT NUMBER :

BRI / 89 / 089

SUBJECT : Breaking time test

CUSTOMER : TOTALFINAELF E & P INDONESIE

FIELD : Bekapai

WELL : BB.8 / BA.10

RIG : -

REQUESTED BY : T. Dornoy for P. Pineau

L A R No. : memo

PREPARED BY : DATE : 30/05/89

S. Ma’arif

REVIEWED BY : DATE : 30/05/89

T. Dornoy

DISTRIBUTION : - LRI

- ASL

This job design is based on valuable know-how developed by or for DS The submission of this job design by DS and any use thereof client is based on the

understanding that : (1) the client will use this design solely for evaluation and will make on commercial or other use thereof except for evaluation without

first obtaining prior written approval from DS and (2) the client will not communicate any information regarding this job design to any third party and (3)

the job design being based on engineering theory and as there are many well conditions which are uncertain unknown and not subject to our control DS

does not and cannot warrant the accuracy or correctness of the recommendations stipulated in the job design.

K S/………. Visa : KS/………… Visa :

TotalFinaElf E& P WIRE LINE, SNUBBING, WORKSHOP

STANDING INSTRUCTIONS NO. 05 - 0121

PAGE 6/8

REVISION 0

Indonésie VISCOSIFIER FOR DIESEL OIL DATE 05/1989

BRI/89/099 Page : 02

Information requested :

Gel breaking time

Summary :

Depth : 1610 m – 1615 m, BHST = 180° F

Gel Concentration at 1000 gal :

991 gal fresh water

+ 2.0 gal D47

+ 250 lbs. J285

+ 90 lbs. J164

+ 2 gal W35

+ 5 gal F75

+ 0.50 lbs. J218

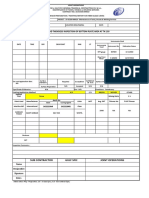

Test Results :

________________________________________________________________________________________

Descriptions Rheology ( RI, BI, FI) App. Viscosity Percentage

At 100 rpm, cps to original

Rpm: 300 200 100 6 3

________________________________________________________________________________________

After mixing (80 F) 179 162 128 46 28 384 -

After 1 hr at 180 F 91 71 48 9 4 144 38 %

After 2 hr at 180 F 45 33 20 4 4 60 16 %

________________________________________________________________________________________

Viscosity is considered 100% break if the viscosity dropped 10% to the or original viscosity.

Note :

- Another test was run as above system without using of J218 (breaker)

After 4 hours curing time at 180 F viscosity dropper 47% (180 cps) to original viscosity.

And viscosity dropped 18% (69 cps) after 17 hours curing time at 180°F.

- At this temperature (180 F), W35 has been reduced from 5 gal/1000 gal to 2 gal/1000 gal to adjust PH solution and

reach a stable solution at these temperature ranges.

K S/………. Visa : KS/………… Visa :

TotalFinaElf E& P WIRE LINE, SNUBBING, WORKSHOP

STANDING INSTRUCTIONS NO. 05 - 0121

PAGE 7/8

REVISION 0

Indonésie VISCOSIFIER FOR DIESEL OIL DATE 05/1989

PT. DOWELL SCHLUMBER INDONESIA Inter Office Correspondence

To : TPT ENGINEERS Date : June 05, 1986

From : A. HARTONI File : F-003

Subject : STANDARD FLUID SYSTEM cc : TPT-FSM

USED FOR TOTALFINAELF BRI-LAB

E & P INDONESIE OPERATION :

WATER PAC FLUID, CACO3, HI-VSC. SOLUTION,

HI – VISC. SOLUTION (OIL)

1. WATER PAC FLUID 1000 GAL MIXING ORDER

H20 = 950 Gal 1

DO47 = 5 Gal 2

J285 = 250 Lbs. 3

J164 = 80-90 Lbs. 4

F78 = 5 Gal 7

W35 = 5 Gal for Handil field, 2 Gal

For Bekapai 5

M076/183 = 2 Gal 6

J218 = 2 Lbs. for handil, 0,5 Lb. For Bekapai 8

Viscosity result = 300 – 400 Cps.

2. CaC03 Solution per 1M(3) = SG ± 1.15 MIXING ORDER

H20 = ≤ 1 M(3) 1

DO47 = 0.5 Gal 2

J164 = 2 Lbs. 3

CaC03 = 250 Kg 4

3. HI-VISC SOLUTION PER 1000 GAL MIXING ORDER

H20 = 990 Gal 1

DO47 = 5 Gal 2

J164 = 85 Lbs. 3

CaC03 = 2–5 Gal 4

Viscosity ± 300-400 Cps

4. HI-VISC. SOLUTION (OIL) PER 1000 GAL MIXING ORDER

DIESEL OIL = 980 Gal 4

J292 (ex J421) = 10 Gal 3

J366 (ex J601) = 12 Lbs. 1

J353 (ex J602) = 10 Gal 2

K S/………. Visa : KS/………… Visa :

TotalFinaElf E& P WIRE LINE, SNUBBING, WORKSHOP

STANDING INSTRUCTIONS NO. 05 - 0121

PAGE 8/8

REVISION 0

Indonésie VISCOSIFIER FOR DIESEL OIL DATE 05/1989

Note :

- Lab test result, Fan – VG Reading after mixing :

300, 200, 100, 6, 3

110 90 85 49 45

J366 and J353 are to be mixed together, prior to adding them together with the J292 to the

diesel.

Regards,

A. HARTONI

AH/lr

K S/………. Visa : KS/………… Visa :

You might also like

- d601000258 Man 001Document24 pagesd601000258 Man 001Oswaldo VillarroelNo ratings yet

- Ohs-Pr-09-10-F20 (A) Fuel Driven Equipment InspectionDocument2 pagesOhs-Pr-09-10-F20 (A) Fuel Driven Equipment InspectionBalaNo ratings yet

- D-16005b-Petronas Carigali Ketapang II LTD - Condensate Assay Type B - Rev1Document16 pagesD-16005b-Petronas Carigali Ketapang II LTD - Condensate Assay Type B - Rev1aswarNo ratings yet

- P246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)Document10 pagesP246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)hafid CJSPNo ratings yet

- Not The Latest Sample: Mobile EquipmentDocument6 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- P246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)Document11 pagesP246101-E-BE-00-000-EL-EDS-005 (Diesel Generator)hafid CJSPNo ratings yet

- ZW Government Gazette Dated 2011-10-14 No 53Document22 pagesZW Government Gazette Dated 2011-10-14 No 53Serge KohemunNo ratings yet

- REV Description Date Approval: RevisionsDocument2 pagesREV Description Date Approval: RevisionsLONG Trương MinhNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDocument4 pagesVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNo ratings yet

- Indra: Firm Up No.3 Api Oil Separator Project (Civil & Building Work)Document9 pagesIndra: Firm Up No.3 Api Oil Separator Project (Civil & Building Work)sajay2010No ratings yet

- Production Released: Printing Color Grey Scala White Paper 52 GR/M - 70 GR/MDocument21 pagesProduction Released: Printing Color Grey Scala White Paper 52 GR/M - 70 GR/MJose Manuel Pereira LópezNo ratings yet

- A545-101-PA-MR-5001-1072-5099-FOA - 905139-LS - 02 - LUBRICATION SCHEDULE - Multiple TagsDocument3 pagesA545-101-PA-MR-5001-1072-5099-FOA - 905139-LS - 02 - LUBRICATION SCHEDULE - Multiple Tagsmahesh.easwaran3609No ratings yet

- TK-103-FGL-34 Holiday InspectionDocument1 pageTK-103-FGL-34 Holiday InspectionjoseNo ratings yet

- Raub Oil MillDocument7 pagesRaub Oil Millnaavin muthu krishnanNo ratings yet

- Aceite Royal Purple - Synfilm - 46Document2 pagesAceite Royal Purple - Synfilm - 46micmarley2012No ratings yet

- Not The Latest Sample: Mobile EquipmentDocument2 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- Engine Oil Test Results and Recommendations To Interkels - 07082019Document2 pagesEngine Oil Test Results and Recommendations To Interkels - 07082019Georgina SuleNo ratings yet

- Sample Oil April 2022 Manalagi AstaDocument9 pagesSample Oil April 2022 Manalagi Astacahyo putroNo ratings yet

- Omv Comp VDL S 100Document2 pagesOmv Comp VDL S 100Robert IsacNo ratings yet

- Joseph Field Ope 2021Document5 pagesJoseph Field Ope 2021Godwin GodwinNo ratings yet

- Mobil Delvac 1130 1140 and 1150 (API CC SD)Document2 pagesMobil Delvac 1130 1140 and 1150 (API CC SD)MichaelNo ratings yet

- Bill of Material Drg.Document1 pageBill of Material Drg.lalitendu jenaNo ratings yet

- Apporva Chandra Comm Report (ACC)Document23 pagesApporva Chandra Comm Report (ACC)ThangarajNo ratings yet

- AppNote 21-DOMINO Water Solubility AlgorithmsDocument4 pagesAppNote 21-DOMINO Water Solubility AlgorithmsMikeNo ratings yet

- Product Indy Hydrol Aw: Anti-Wear Hydraulic FluidDocument1 pageProduct Indy Hydrol Aw: Anti-Wear Hydraulic FluidThando ShongweNo ratings yet

- Corvus 4T 10W-40Document1 pageCorvus 4T 10W-40Cao Đức TrungNo ratings yet

- Ash Handling System Technical DatasheetDocument23 pagesAsh Handling System Technical DatasheetNutan PowerNo ratings yet

- TLB ServiceDocument5 pagesTLB ServiceHugh O'Brien GwazeNo ratings yet

- Bill of Material - 5Document1 pageBill of Material - 5lalitendu jenaNo ratings yet

- Industrial: Severity UrgentDocument2 pagesIndustrial: Severity UrgentNasser AyoubNo ratings yet

- 220 Synfilm GT PdsDocument3 pages220 Synfilm GT PdsSaul CarrilloNo ratings yet

- Fuels Winter Understanding CFPPDocument2 pagesFuels Winter Understanding CFPPNenad PopovicNo ratings yet

- Prueba de Dilucion de CombustibleDocument10 pagesPrueba de Dilucion de CombustibleGalo OrralaNo ratings yet

- Lubrication List: Client ConsultantDocument2 pagesLubrication List: Client Consultanthari prasadNo ratings yet

- 312 DatasheetDocument1 page312 DatasheetGregory Alan Francisco IINo ratings yet

- ZSK 9121 CB - 01Document23 pagesZSK 9121 CB - 01Joaquin Adolfo Chavez Quiroz100% (1)

- Pre-Inspection Report - DORC TransformersDocument9 pagesPre-Inspection Report - DORC Transformersmax MensNo ratings yet

- 1e15-Rev 6Document3 pages1e15-Rev 6sandyNo ratings yet

- SB 10054469 8890Document27 pagesSB 10054469 8890Youssef MoutaouadiNo ratings yet

- Data Sheet - 1600kVADocument2 pagesData Sheet - 1600kVAhammad1290% (1)

- Vdocuments - MX - Session 10 Technical Paul Davies Conocophillips PDFDocument38 pagesVdocuments - MX - Session 10 Technical Paul Davies Conocophillips PDFIrwan JanuarNo ratings yet

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDocument5 pages05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimNo ratings yet

- Not The Latest Sample: Mobile EquipmentDocument10 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 pagesChemical Manifest and Hazardous Chemical Substance List KathuVictorNo ratings yet

- 1hpomg 764012545Document3 pages1hpomg 764012545jean-pierre joubertNo ratings yet

- BFW Cooler Datasheet Rev 2Document3 pagesBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariNo ratings yet

- DOOSAN Generator PDFDocument355 pagesDOOSAN Generator PDFJesús Manuel Paz GonzálezNo ratings yet

- Aprilia Leonardo 125 KészDocument146 pagesAprilia Leonardo 125 Készpisti79No ratings yet

- Extended Life Coolant/Antifreeze: Product DescriptionDocument2 pagesExtended Life Coolant/Antifreeze: Product DescriptionDiegoNo ratings yet

- Lubriplate Syn Lube Synthetic Fluid Series: Description Typical Test Data - ApplicationsDocument2 pagesLubriplate Syn Lube Synthetic Fluid Series: Description Typical Test Data - ApplicationsDixo FernandezNo ratings yet

- TK-103-FGL-32 Tissue Visual and Thickness InspectionDocument1 pageTK-103-FGL-32 Tissue Visual and Thickness InspectionjoseNo ratings yet

- GES052 - Torque Spec - DS ES FSDocument99 pagesGES052 - Torque Spec - DS ES FSJavier PalaciosNo ratings yet

- Module 3Document35 pagesModule 3oneofoneNo ratings yet

- Anti FoamDocument20 pagesAnti FoamNduong NguyenNo ratings yet

- Total Quartz Ineo Ecob 5W-20: Key DataDocument2 pagesTotal Quartz Ineo Ecob 5W-20: Key DataVelibor KaranovicNo ratings yet

- ForewordDocument11 pagesForewordJuNo ratings yet

- Not The Latest Sample: Mobile EquipmentDocument12 pagesNot The Latest Sample: Mobile EquipmentBOANERGES IRUNGNo ratings yet

- Mobil Delvac 1600 Monogrades PDFDocument2 pagesMobil Delvac 1600 Monogrades PDFMichaelNo ratings yet

- Dayanan, Elland Br09112021Document6 pagesDayanan, Elland Br09112021Elland NanayadNo ratings yet

- The Role of Engine Oil Viscosity in Low Temperature Cranking and Starting: Prepared Under the Auspices of the SAE Fuels and Lubricants ActivityFrom EverandThe Role of Engine Oil Viscosity in Low Temperature Cranking and Starting: Prepared Under the Auspices of the SAE Fuels and Lubricants ActivityNo ratings yet

- SNB Unit Main FeaturesDocument8 pagesSNB Unit Main FeaturesMas SusiloNo ratings yet

- SNB TBG CuttingDocument18 pagesSNB TBG CuttingMas SusiloNo ratings yet

- SNB TBG Clean UpDocument4 pagesSNB TBG Clean UpMas SusiloNo ratings yet

- Material HWUDocument38 pagesMaterial HWUMas SusiloNo ratings yet

- PDN HwuDocument2 pagesPDN HwuMas SusiloNo ratings yet

- GENERAL5 Answer-1Document4 pagesGENERAL5 Answer-1JlkKumarNo ratings yet

- LevelingDocument4 pagesLevelingNikoli MajorNo ratings yet

- One Component Pu Foams - FormulationDocument10 pagesOne Component Pu Foams - FormulationgunelNo ratings yet

- 100 MZR Multi-PlexDocument8 pages100 MZR Multi-PlexHarry CortezNo ratings yet

- The Chemistry and Applications of Metal-Organic Frameworks: BackgroundDocument14 pagesThe Chemistry and Applications of Metal-Organic Frameworks: BackgroundGrad OanaNo ratings yet

- Fuel, Lubricants & Fluids SCANIA NTGDocument58 pagesFuel, Lubricants & Fluids SCANIA NTGcah ndeso channelNo ratings yet

- Production of Brick and BlocksDocument15 pagesProduction of Brick and BlocksDawit Awash100% (3)

- Acid Base and SaltDocument3 pagesAcid Base and SaltShark -TOHNo ratings yet

- AIGA 021 - 05 Oxygen Pipeline SystemsDocument74 pagesAIGA 021 - 05 Oxygen Pipeline SystemsRamesh RameshvdNo ratings yet

- Guru Nanak Dev Thermal Plant: BathindaDocument28 pagesGuru Nanak Dev Thermal Plant: BathindadeepzsohlNo ratings yet

- Astm B443 PDFDocument8 pagesAstm B443 PDFMohammad ShamimNo ratings yet

- Plastic Material Used in TrucksDocument22 pagesPlastic Material Used in TrucksnishantNo ratings yet

- Teflon Research PaperDocument11 pagesTeflon Research PaperluluazulNo ratings yet

- 218.amisol Trio - Brochure - WebDocument4 pages218.amisol Trio - Brochure - WebLiliana SierraNo ratings yet

- Specification of SaltDocument4 pagesSpecification of SaltAhmad DawamNo ratings yet

- Wang Et Al 2008Document14 pagesWang Et Al 2008Venkata KrishnaNo ratings yet

- 2.2 Bonding and Structure QPDocument42 pages2.2 Bonding and Structure QPabisolafaluyi5No ratings yet

- Which Statement(s) Is/are Generally True About The Melting Points of Substances? Different TopicDocument3 pagesWhich Statement(s) Is/are Generally True About The Melting Points of Substances? Different TopicDaNo ratings yet

- Intermolecular Forces,, And: LiquidsDocument72 pagesIntermolecular Forces,, And: LiquidsGlenn ClementeNo ratings yet

- AQA Chemistry Unit 1: S.L.O.P Shed Loads of Practice! Atomic Structure & The Periodic TableDocument11 pagesAQA Chemistry Unit 1: S.L.O.P Shed Loads of Practice! Atomic Structure & The Periodic TableImama FaisalNo ratings yet

- Alloy 59 - Alfa Laval Olmi Aprile 2018 PDFDocument12 pagesAlloy 59 - Alfa Laval Olmi Aprile 2018 PDFfabianoNo ratings yet

- Electrochemistry: OxidationDocument17 pagesElectrochemistry: OxidationVignesh RajendranNo ratings yet

- Chemical BondingDocument30 pagesChemical Bondingzikra azizah100% (2)

- CB&I Horton SpheresDocument6 pagesCB&I Horton Sphereskjpatel2No ratings yet

- Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocument4 pagesRepair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingskhuzafaNo ratings yet

- Lab Report5 ChemDocument3 pagesLab Report5 Chemkoko BunchNo ratings yet

- Chemistry Form 5 Module Organic CompoundDocument23 pagesChemistry Form 5 Module Organic CompoundMudzaffar Shah100% (3)

- Astmd1259non Volatile Contentpdf - CompressDocument6 pagesAstmd1259non Volatile Contentpdf - Compressubaid_nedianNo ratings yet

- Dao 2014-02 (Pco)Document47 pagesDao 2014-02 (Pco)Roselyn Antonio TabundaNo ratings yet

- Pub 122 Hicon Copper For Electrical EngineeringDocument32 pagesPub 122 Hicon Copper For Electrical EngineeringCounter RoverNo ratings yet